light YAMAHA YZ426F 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZ426F, Model: YAMAHA YZ426F 2000Pages: 608, PDF Size: 45.52 MB

Page 234 of 608

3 - 46

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming plug 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer

YU-8036-1

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming plug

Page 262 of 608

4 - 14

ENGCARBURETOR

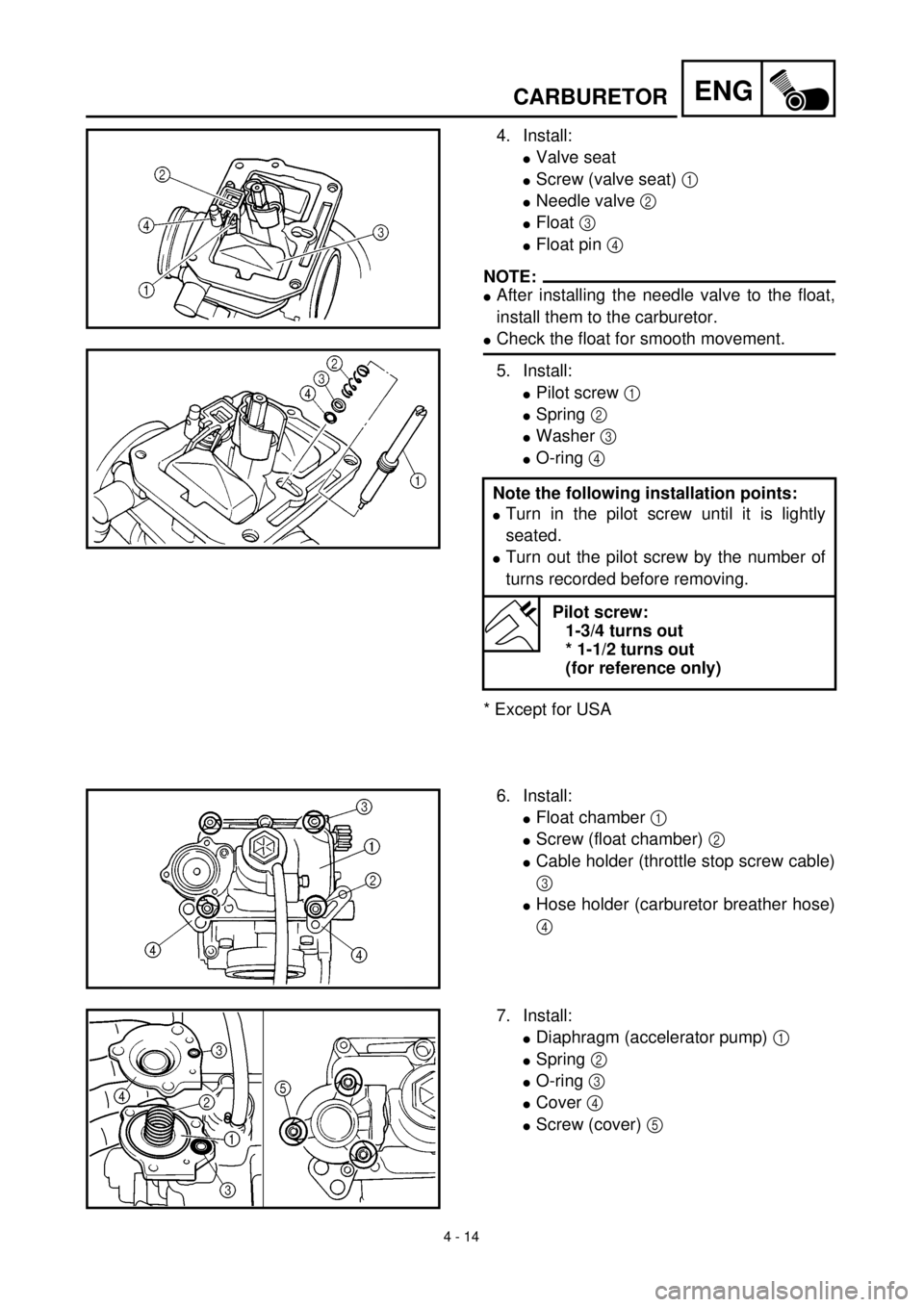

4. Install:

lValve seat

lScrew (valve seat) 1

lNeedle valve 2

lFloat 3

lFloat pin 4

NOTE:

lAfter installing the needle valve to the float,

install them to the carburetor.

lCheck the float for smooth movement.

5. Install:

lPilot screw 1

lSpring 2

lWasher 3

lO-ring 4

* Except for USANote the following installation points:

lTurn in the pilot screw until it is lightly

seated.

lTurn out the pilot screw by the number of

turns recorded before removing.

Pilot screw:

1-3/4 turns out

* 1-1/2 turns out

(for reference only)

6. Install:

lFloat chamber 1

lScrew (float chamber) 2

lCable holder (throttle stop screw cable)

3

lHose holder (carburetor breather hose)

4

7. Install:

lDiaphragm (accelerator pump) 1

lSpring 2

lO-ring 3

lCover 4

lScrew (cover) 5

Page 278 of 608

4 - 22

ENG

CAMSHAFTS

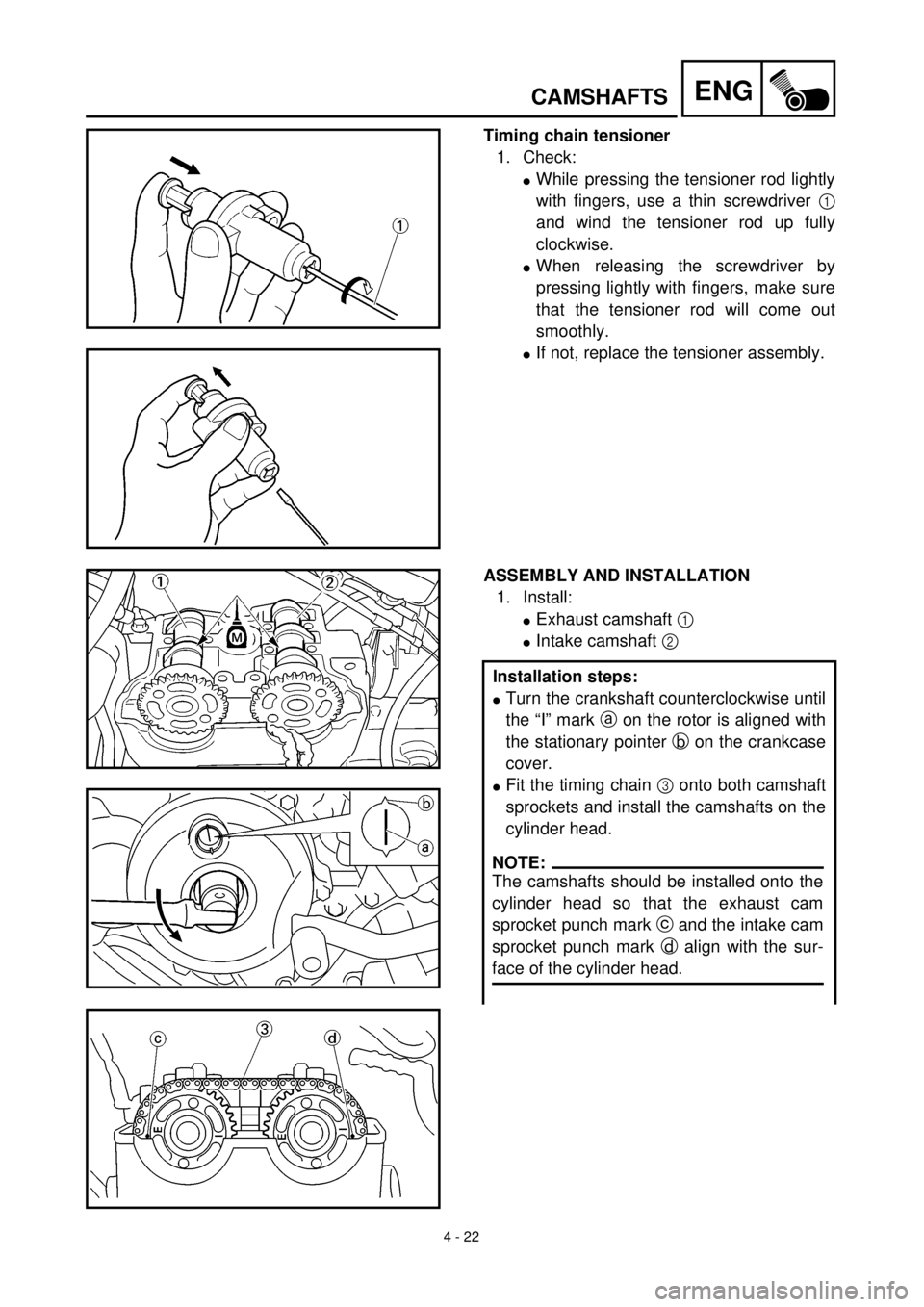

Timing chain tensioner

1. Check:

l

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver

1

and wind the tensioner rod up fully

clockwise.

l

When releasing the screwdriver by

pressing lightly with fingers, make sure

that the tensioner rod will come out

smoothly.

l

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

1. Install:

l

Exhaust camshaft

1

l

Intake camshaft

2

Installation steps:

l

Turn the crankshaft counterclockwise until

the “I” mark

a

on the rotor is aligned with

the stationary pointer

b

on the crankcase

cover.

l

Fit the timing chain

3

onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

Page 280 of 608

4 - 23

ENG

CAMSHAFTS

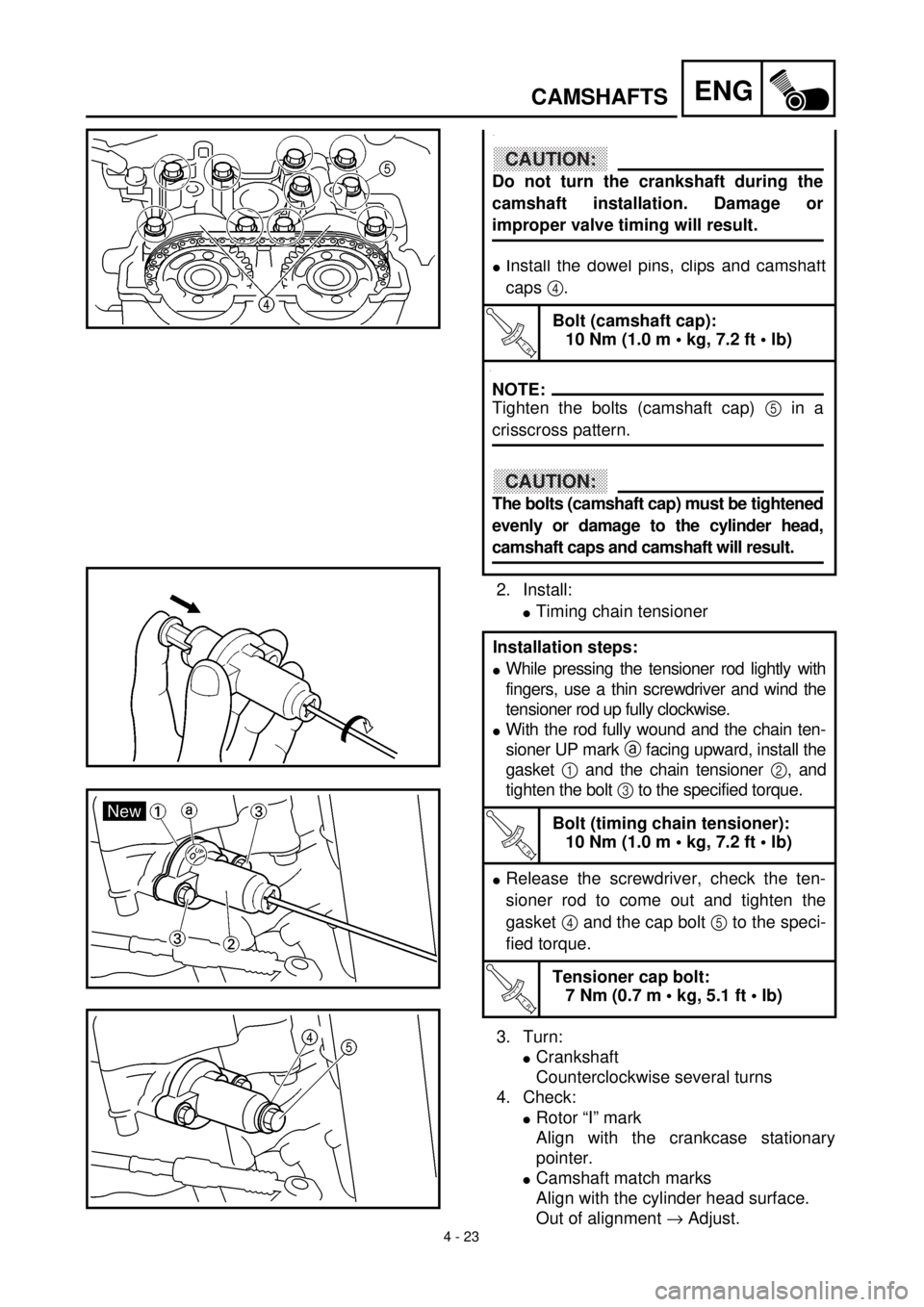

2. Install:

l

Timing chain tensioner

3. Turn:

l

Crankshaft

Counterclockwise several turns

4. Check:

l

Rotor “I” mark

Align with the crankcase stationary

pointer.

l

Camshaft match marks

Align with the cylinder head surface.

Out of alignment

®

Adjust.

.

l

Install the dowel pins, clips and camshaft

caps

4

.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

.

Installation steps:

l

While pressing the tensioner rod lightly with

fingers, use a thin screwdriver and wind the

tensioner rod up fully clockwise.

l

With the rod fully wound and the chain ten-

sioner UP mark

a

facing upward, install the

gasket

1

and the chain tensioner

2

, and

tighten the bolt

3

to the specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

l

Release the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket

4

and the cap bolt

5

to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

NOTE:

Tighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tightened

evenly or damage to the cylinder head,

camshaft caps and camshaft will result.

Page 296 of 608

4 - 31

ENGVALVES AND VALVE SPRINGS

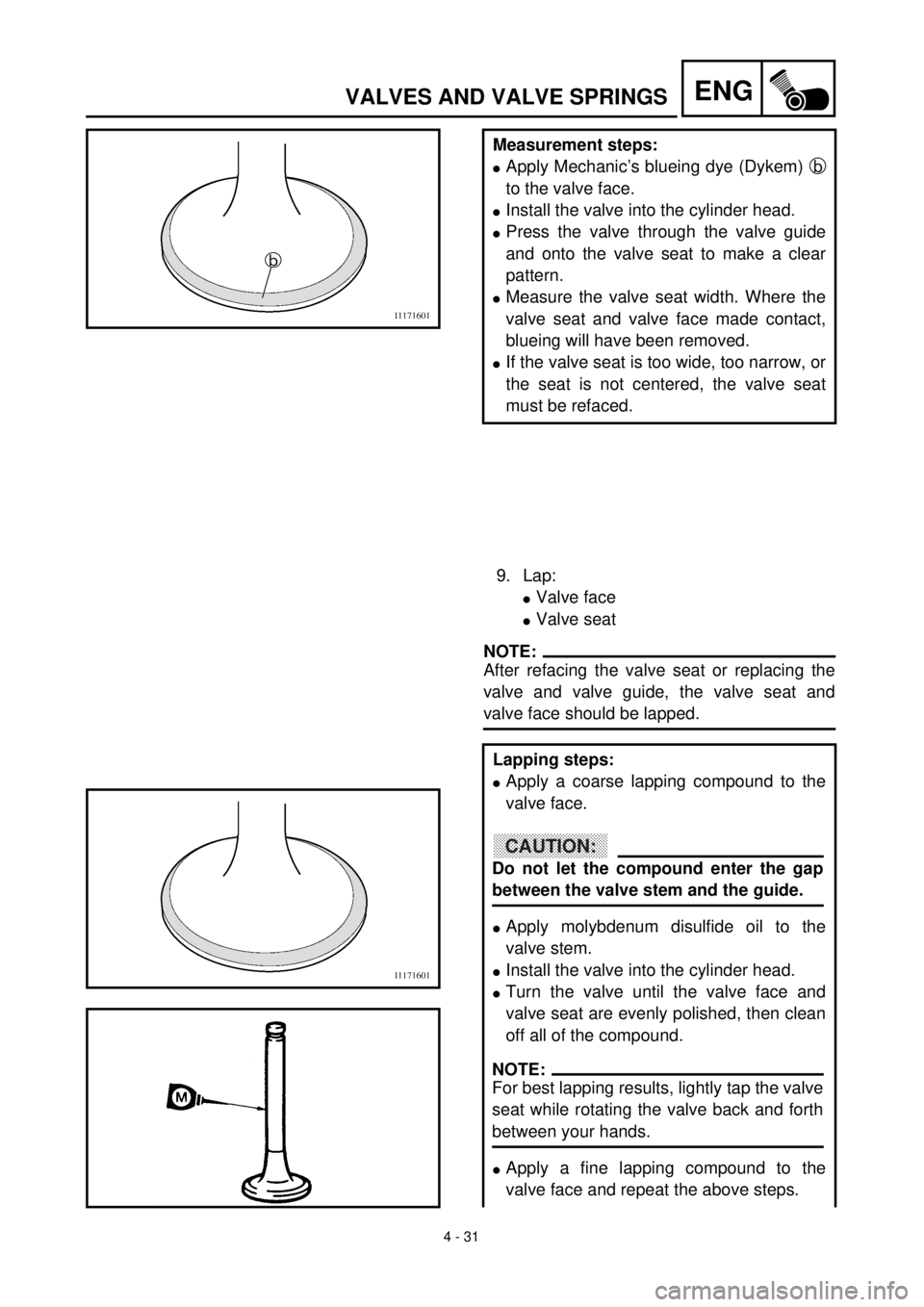

Measurement steps:

lApply Mechanic’s blueing dye (Dykem) b

to the valve face.

lInstall the valve into the cylinder head.

lPress the valve through the valve guide

and onto the valve seat to make a clear

pattern.

lMeasure the valve seat width. Where the

valve seat and valve face made contact,

blueing will have been removed.

lIf the valve seat is too wide, too narrow, or

the seat is not centered, the valve seat

must be refaced.

9. Lap:

lValve face

lValve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

lApply a coarse lapping compound to the

valve face.

lApply molybdenum disulfide oil to the

valve stem.

lInstall the valve into the cylinder head.

lTurn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

lApply a fine lapping compound to the

valve face and repeat the above steps.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the guide.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

Page 302 of 608

4 - 34

ENGVALVES AND VALVE SPRINGS

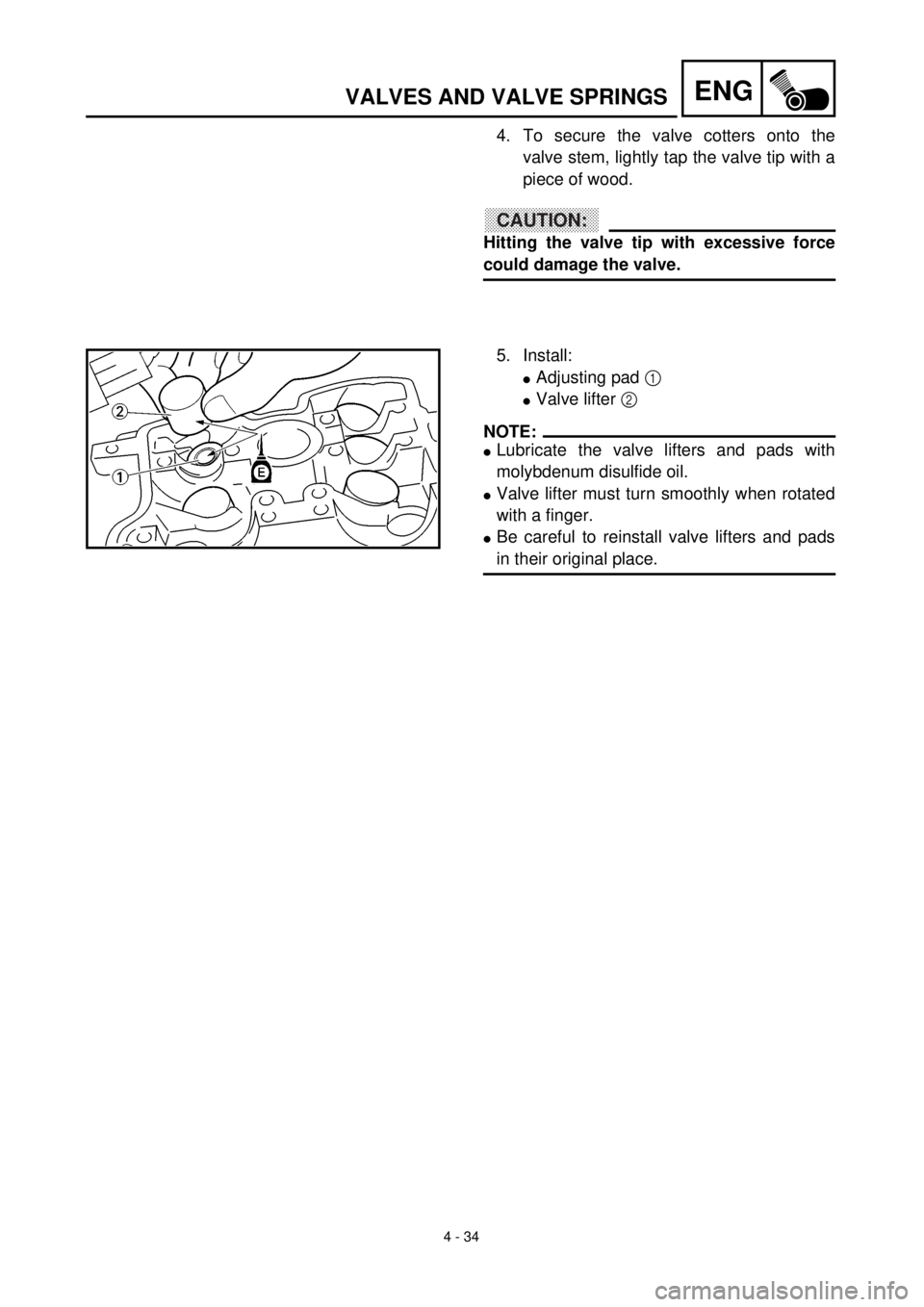

4. To secure the valve cotters onto the

valve stem, lightly tap the valve tip with a

piece of wood.

CAUTION:

Hitting the valve tip with excessive force

could damage the valve.

5. Install:

lAdjusting pad 1

lValve lifter 2

NOTE:

lLubricate the valve lifters and pads with

molybdenum disulfide oil.

lValve lifter must turn smoothly when rotated

with a finger.

lBe careful to reinstall valve lifters and pads

in their original place.

Page 402 of 608

4 - 84

ENG

CRANKCASE AND CRANKSHAFT

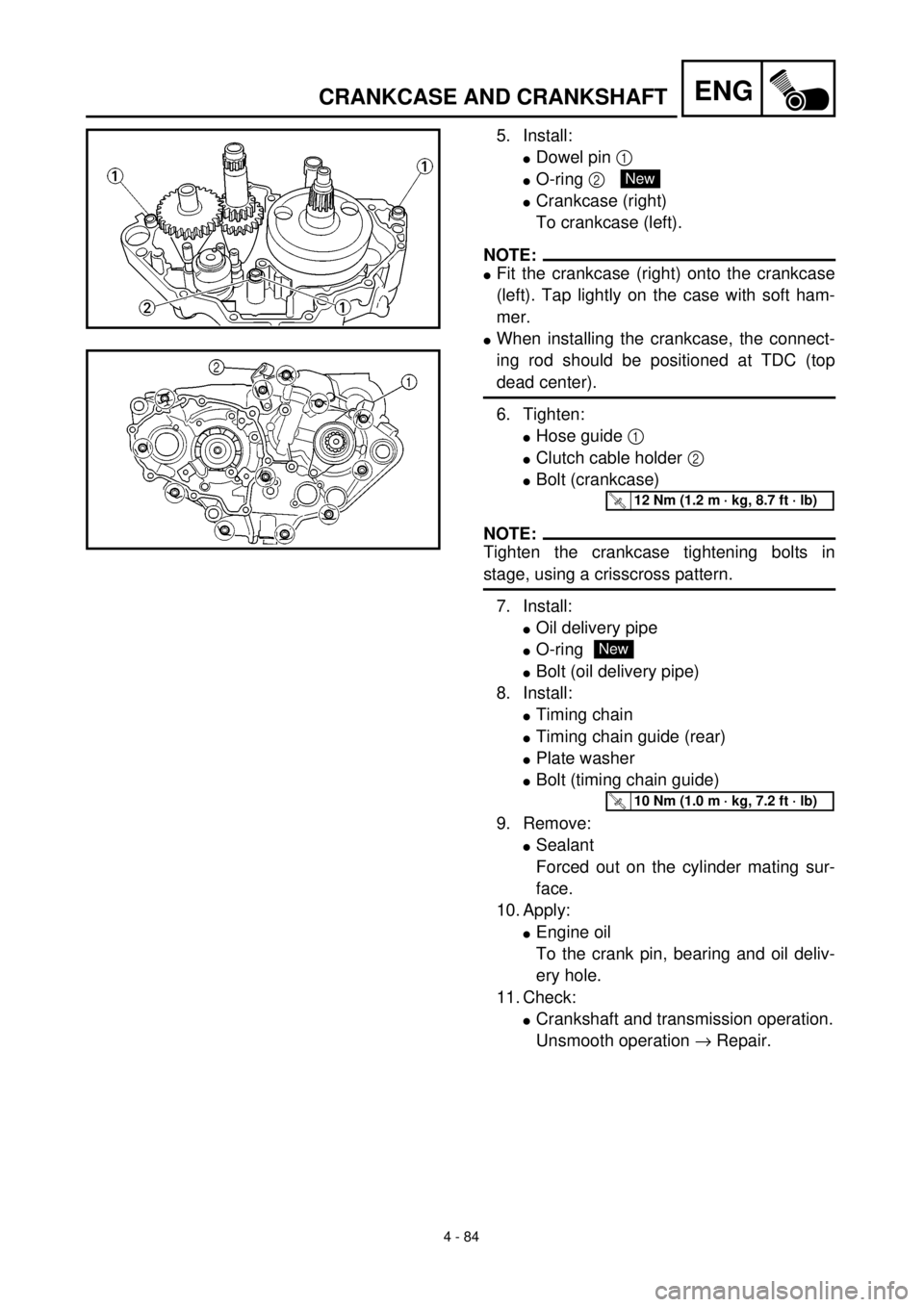

5. Install:

l

Dowel pin

1

lO-ring 2

lCrankcase (right)

To crankcase (left).

NOTE:

lFit the crankcase (right) onto the crankcase

(left). Tap lightly on the case with soft ham-

mer.

lWhen installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

6. Tighten:

lHose guide 1

lClutch cable holder 2

lBolt (crankcase)

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

7. Install:

lOil delivery pipe

lO-ring

lBolt (oil delivery pipe)

8. Install:

lTiming chain

lTiming chain guide (rear)

lPlate washer

lBolt (timing chain guide)

9. Remove:

lSealant

Forced out on the cylinder mating sur-

face.

10. Apply:

lEngine oil

To the crank pin, bearing and oil deliv-

ery hole.

11. Check:

lCrankshaft and transmission operation.

Unsmooth operation ® Repair.

New

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 406 of 608

4 - 86

ENGTRANSMISSION, SHIFT CAM, SHIFT FORK

EC4H3000

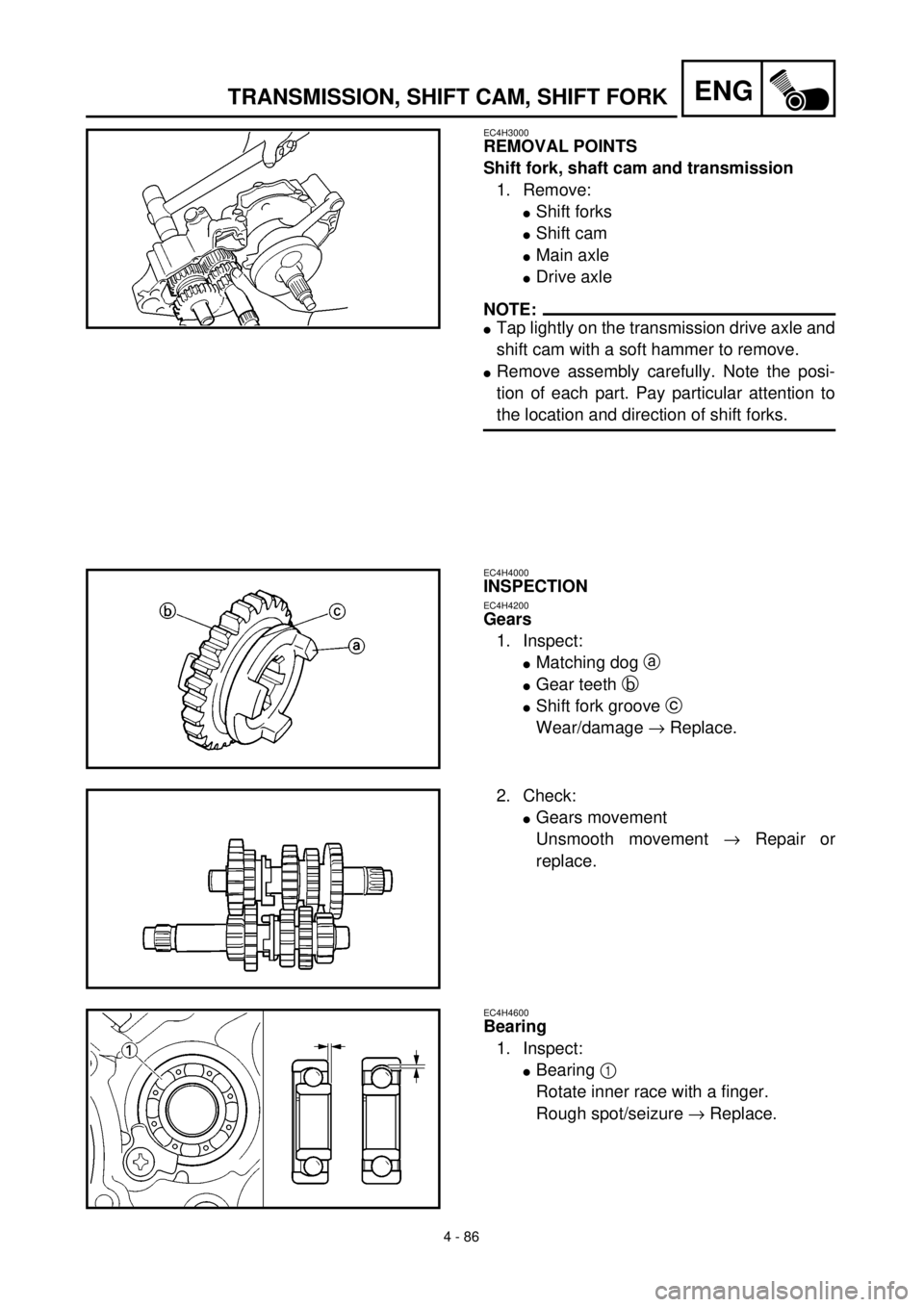

REMOVAL POINTS

Shift fork, shaft cam and transmission

1. Remove:

lShift forks

lShift cam

lMain axle

lDrive axle

NOTE:

lTap lightly on the transmission drive axle and

shift cam with a soft hammer to remove.

lRemove assembly carefully. Note the posi-

tion of each part. Pay particular attention to

the location and direction of shift forks.

EC4H4000

INSPECTION

EC4H4200

Gears

1. Inspect:

lMatching dog a

lGear teeth b

lShift fork groove c

Wear/damage ® Replace.

2. Check:

lGears movement

Unsmooth movement ® Repair or

replace.

EC4H4600

Bearing

1. Inspect:

lBearing 1

Rotate inner race with a finger.

Rough spot/seizure ® Replace.

Page 448 of 608

5 - 18

CHASFRONT BRAKE AND REAR BRAKE

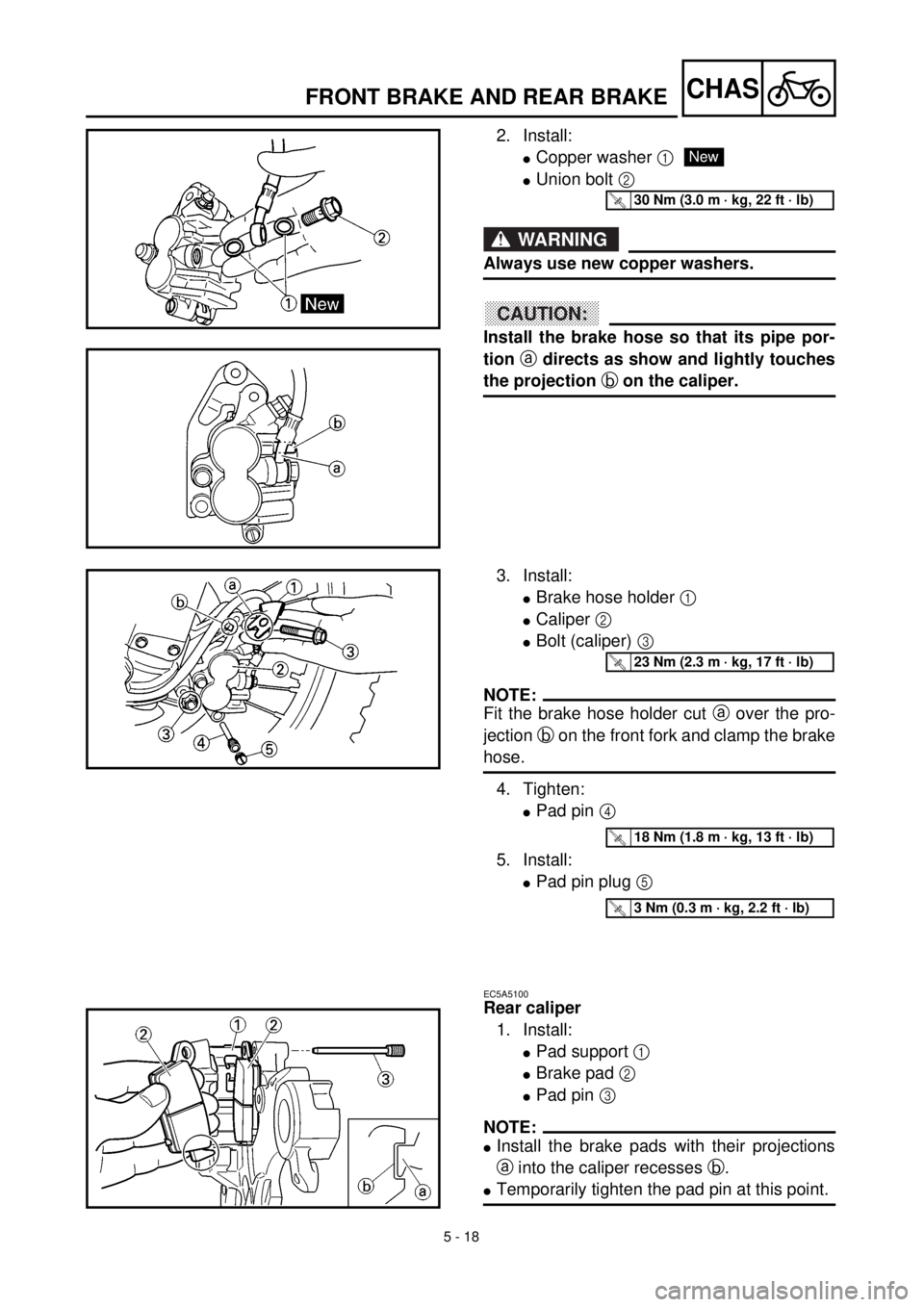

2. Install:

lCopper washer 1

lUnion bolt 2

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

Install the brake hose so that its pipe por-

tion a directs as show and lightly touches

the projection b on the caliper.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

3. Install:

lBrake hose holder 1

lCaliper 2

lBolt (caliper) 3

NOTE:

Fit the brake hose holder cut a over the pro-

jection b on the front fork and clamp the brake

hose.

4. Tighten:

lPad pin 4

5. Install:

lPad pin plug 5

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..18 Nm (1.8 m · kg, 13 ft · lb)

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

EC5A5100

Rear caliper

1. Install:

lPad support 1

lBrake pad 2

lPad pin 3

NOTE:

lInstall the brake pads with their projections

a into the caliper recesses b.

lTemporarily tighten the pad pin at this point.

Page 460 of 608

5 - 24

CHASFRONT BRAKE AND REAR BRAKE

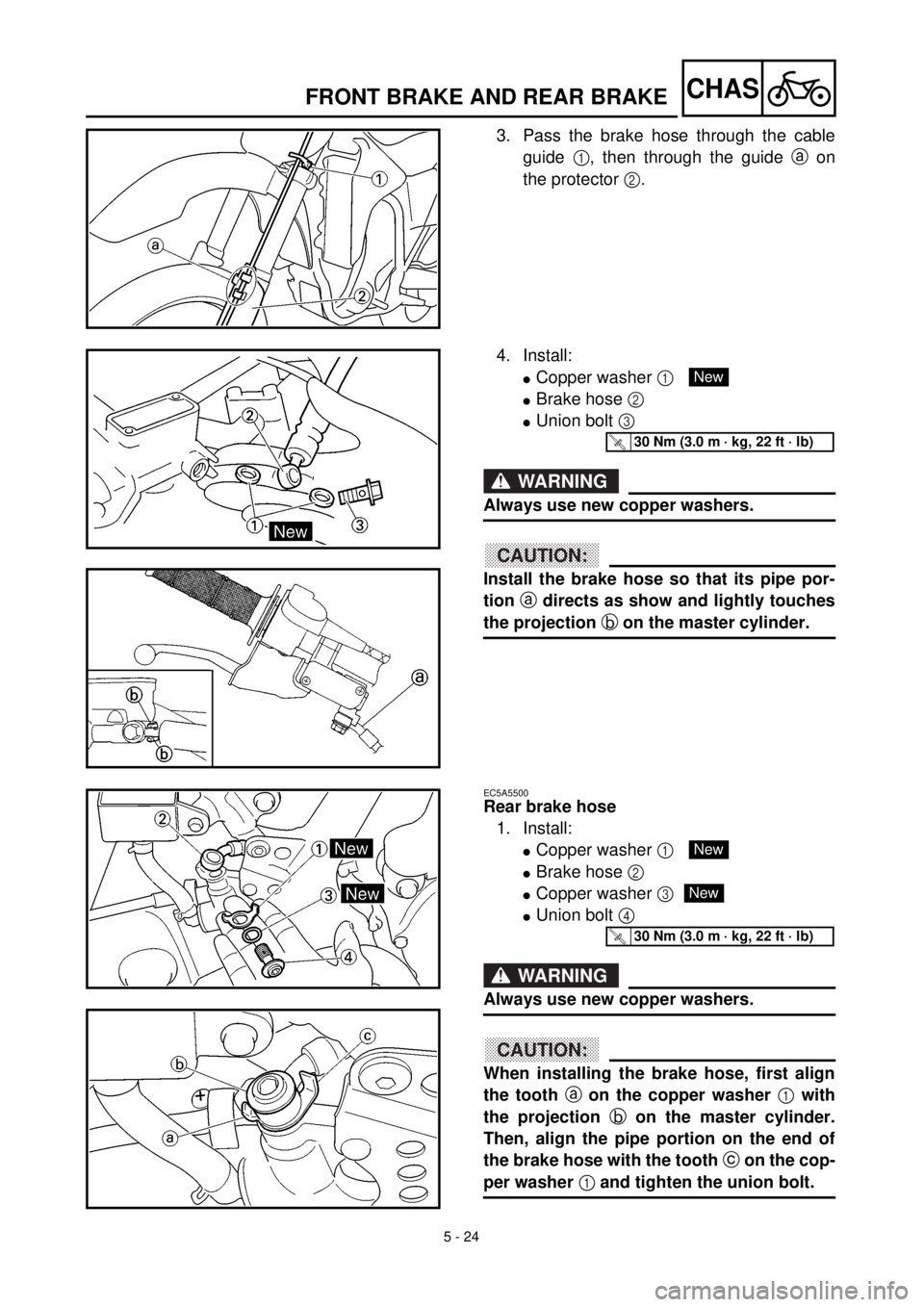

3. Pass the brake hose through the cable

guide 1, then through the guide a on

the protector 2.

4. Install:

lCopper washer 1

lBrake hose 2

lUnion bolt 3

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

Install the brake hose so that its pipe por-

tion a directs as show and lightly touches

the projection b on the master cylinder.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

EC5A5500

Rear brake hose

1. Install:

lCopper washer 1

lBrake hose 2

lCopper washer 3

lUnion bolt 4

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

When installing the brake hose, first align

the tooth a on the copper washer 1 with

the projection b on the master cylinder.

Then, align the pipe portion on the end of

the brake hose with the tooth c on the cop-

per washer 1 and tighten the union bolt.

New

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)