torque YAMAHA YZ426F 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZ426F, Model: YAMAHA YZ426F 2000Pages: 608, PDF Size: 45.52 MB

Page 261 of 608

4 - 13

ENG

CARBURATEUR

VERGASER

Choke-Schieber

1. Kontrollieren:

lKaltstarter-Tauchkolben 1

lHeißstarter-Tauchkolben (rot) 2

Verschleiß/Beschädigung ® Erneuern.

Beschleunigungspumpe

1. Kontrollieren:

lMembran (Beschleunigungspumpe) 1

lFeder 2

lDeckel 3

lO-Ring 4

Rißbildung (Membran)/Beschädigung ®

Erneuern.

Schmutz ® Säubern.

ZUSAMMENBAU UND MONTAGE

Vergaser

1. Montieren:

lHeißstarter-Tauchkolben (rot) 1

lKaltstarter-Tauchkolben 2

2. Montieren:

lHauptluftdüse 1

lLeerlaufluftdüse 2

lAnsaugstutzen 3

3. Montieren:

lChoke-Düse 1

lLeerlaufdüse 2

lDistanzstück 3

lNadeldüse 4

lHauptdüse 5 Plongeur de starter

1. Contrôler:

lPlongeur de démarrage à froid 1

lPlongeur de démarrage à chaud (rouge) 2

Usure/endommagement ® Remplacer.

Pompe d’accélérateur

1. Contrôler:

lDiaphragme (pompe d’accélérateur) 1

lRessort 2

lCouvercle 3

lJoint torque 4

Déchirure (diaphragme)/endommagement

® Remplacer.

Sale ® Nettoyer.

ASSEMBLAGE ET MONTAGE

Carburateur

1. Monter:

lPlongeur de démarrage à chaud (rouge) 1

lPlongeur de démarrage à froid 2

2. Monter:

lGicleur d’air principal 1

lGicleur d’air de ralenti 2

lRaccord d’admission 3

3. Monter:

lGicleur de starter 1

lGicleur de ralenti 2

lEntretoise 3

lPuits d’aiguille 4

lGicleur principal 5

Page 280 of 608

4 - 23

ENG

CAMSHAFTS

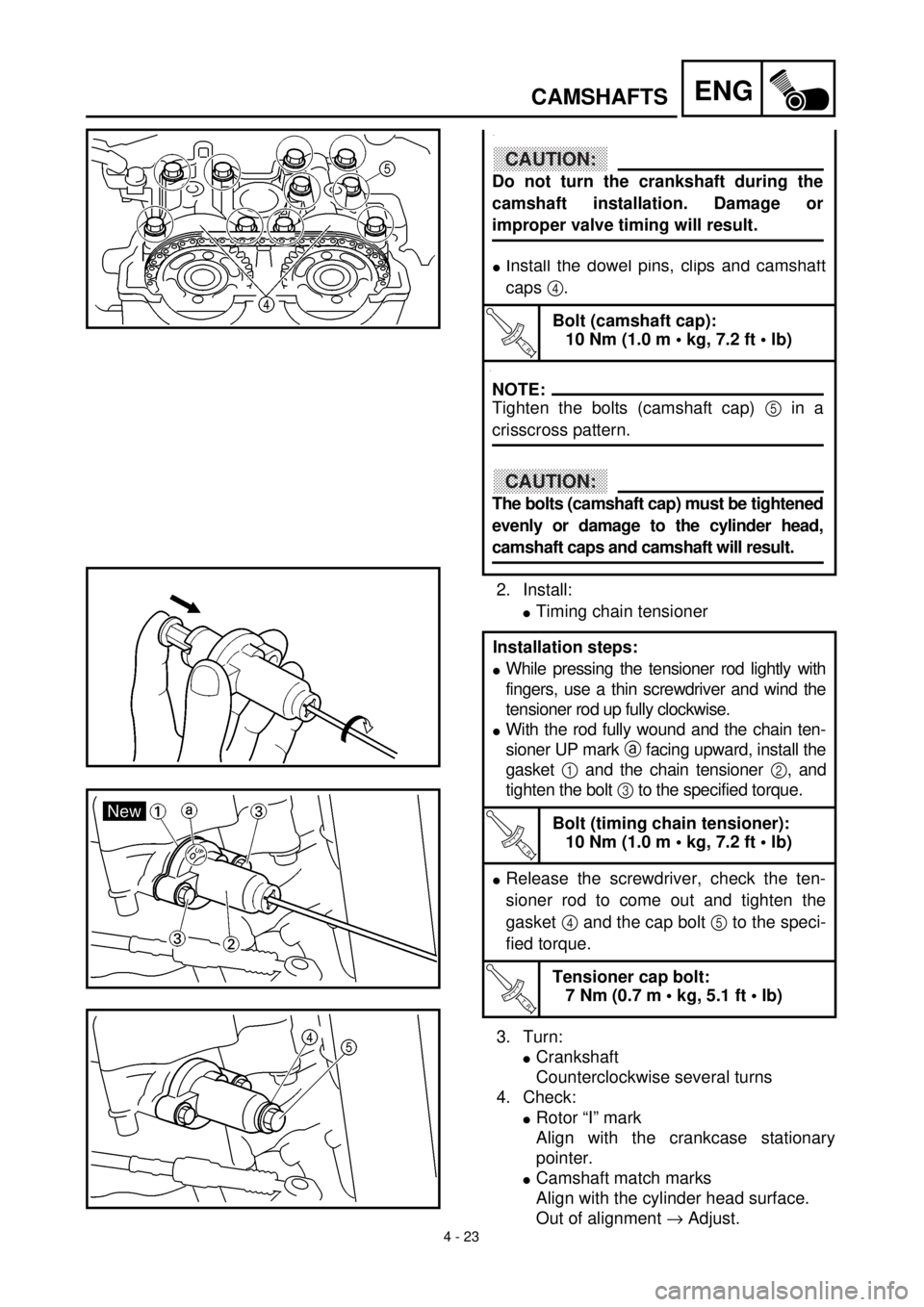

2. Install:

l

Timing chain tensioner

3. Turn:

l

Crankshaft

Counterclockwise several turns

4. Check:

l

Rotor “I” mark

Align with the crankcase stationary

pointer.

l

Camshaft match marks

Align with the cylinder head surface.

Out of alignment

®

Adjust.

.

l

Install the dowel pins, clips and camshaft

caps

4

.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

.

Installation steps:

l

While pressing the tensioner rod lightly with

fingers, use a thin screwdriver and wind the

tensioner rod up fully clockwise.

l

With the rod fully wound and the chain ten-

sioner UP mark

a

facing upward, install the

gasket

1

and the chain tensioner

2

, and

tighten the bolt

3

to the specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

l

Release the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket

4

and the cap bolt

5

to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

NOTE:

Tighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tightened

evenly or damage to the cylinder head,

camshaft caps and camshaft will result.

Page 488 of 608

5 - 38

CHASFRONT FORK

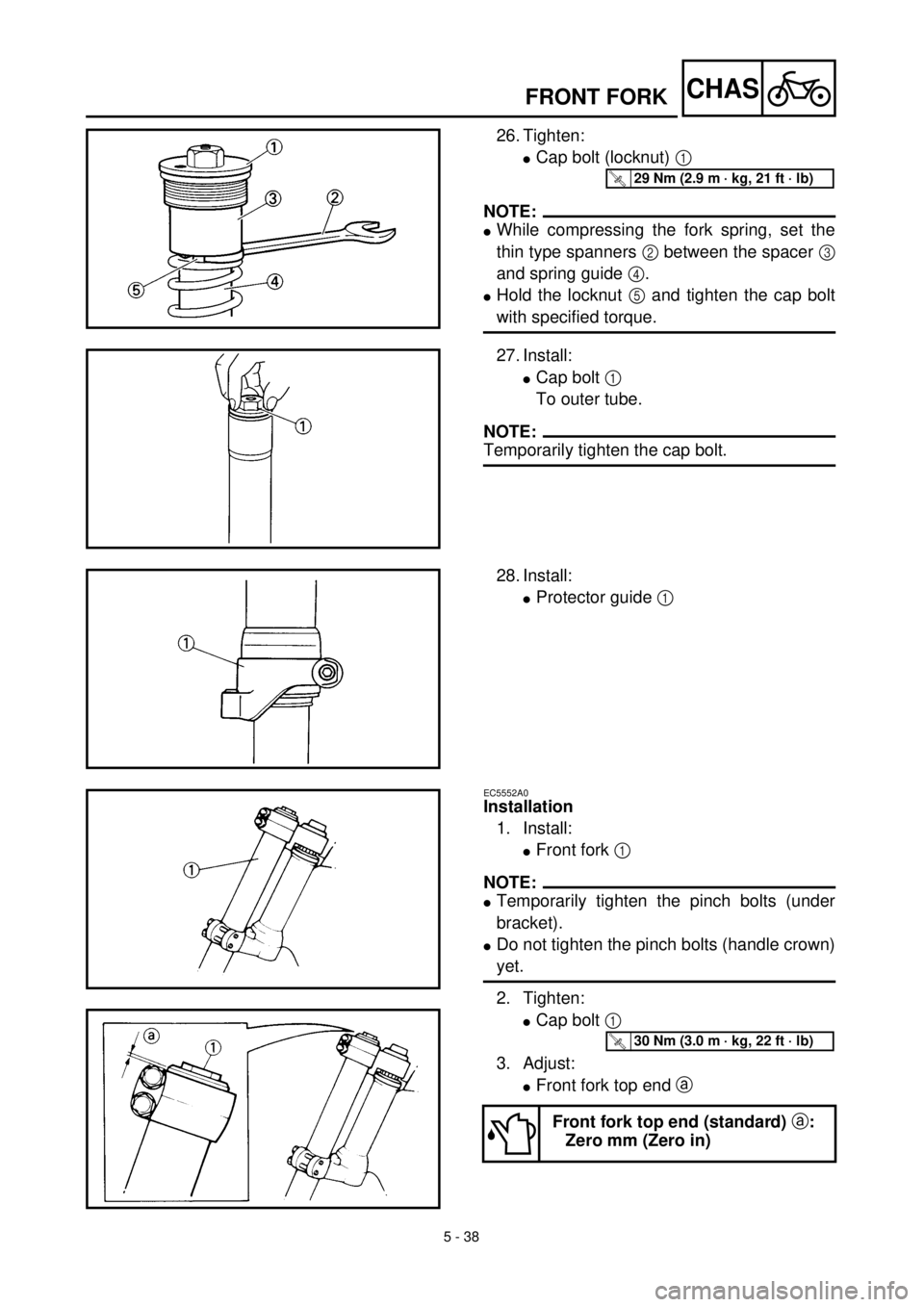

26. Tighten:

lCap bolt (locknut) 1

NOTE:

lWhile compressing the fork spring, set the

thin type spanners 2 between the spacer 3

and spring guide 4.

lHold the locknut 5 and tighten the cap bolt

with specified torque.

T R..29 Nm (2.9 m · kg, 21 ft · lb)

27. Install:

lCap bolt 1

To outer tube.

NOTE:

Temporarily tighten the cap bolt.

28. Install:

lProtector guide 1

EC5552A0

Installation

1. Install:

lFront fork 1

NOTE:

lTemporarily tighten the pinch bolts (under

bracket).

lDo not tighten the pinch bolts (handle crown)

yet.

2. Tighten:

lCap bolt 1

3. Adjust:

lFront fork top end a

Front fork top end (standard) a:

Zero mm (Zero in)

T R..30 Nm (3.0 m · kg, 22 ft · lb)

Page 490 of 608

5 - 39

CHASFRONT FORK

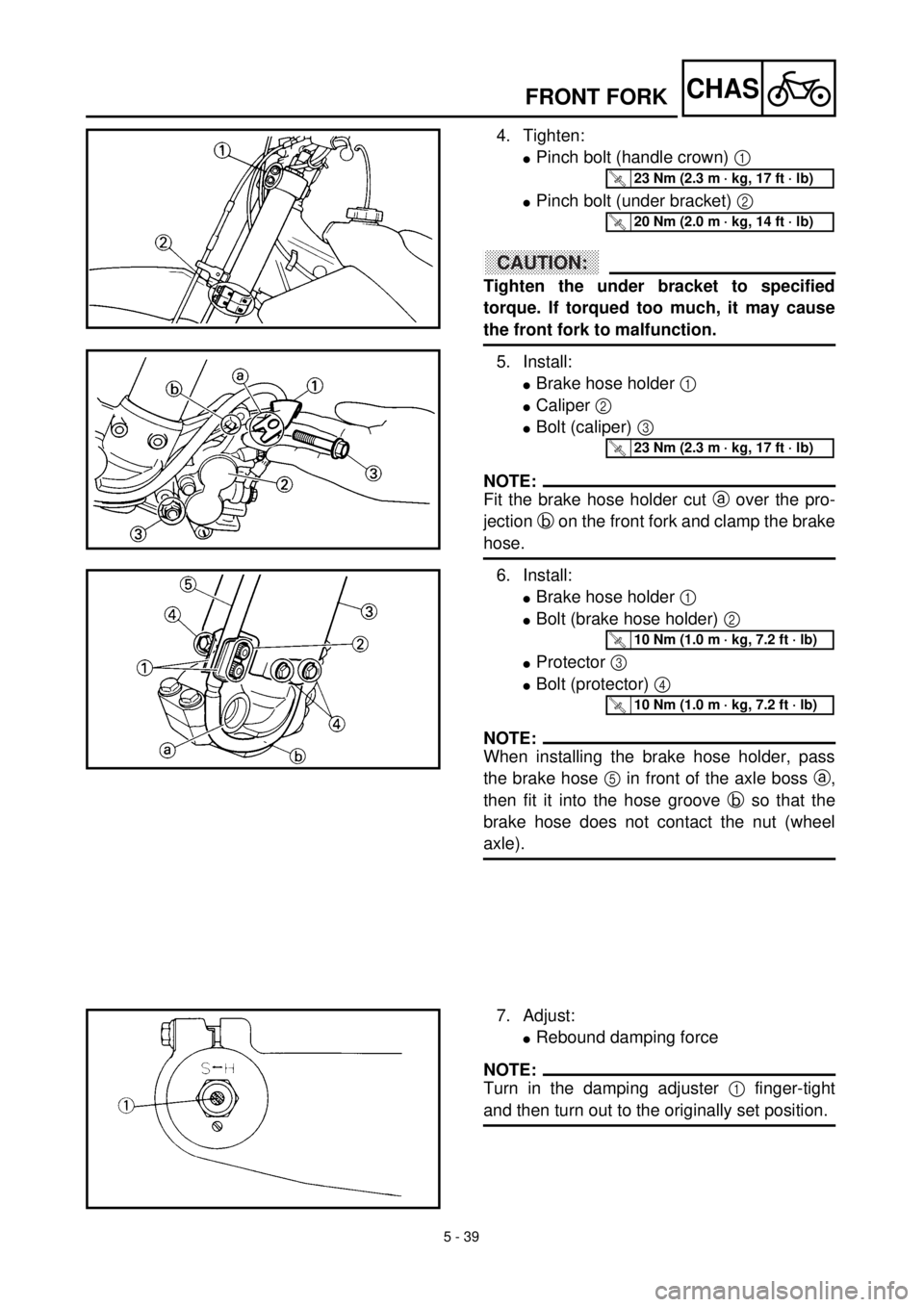

4. Tighten:

lPinch bolt (handle crown) 1

lPinch bolt (under bracket) 2

ACHTUNG:CAUTION:

Tighten the under bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:

lBrake hose holder 1

lCaliper 2

lBolt (caliper) 3

NOTE:

Fit the brake hose holder cut a over the pro-

jection b on the front fork and clamp the brake

hose.

6. Install:

lBrake hose holder 1

lBolt (brake hose holder) 2

lProtector 3

lBolt (protector) 4

NOTE:

When installing the brake hose holder, pass

the brake hose 5 in front of the axle boss a,

then fit it into the hose groove b so that the

brake hose does not contact the nut (wheel

axle).

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

7. Adjust:

lRebound damping force

NOTE:

Turn in the damping adjuster 1 finger-tight

and then turn out to the originally set position.

Page 510 of 608

5 - 49

CHASSTEERING

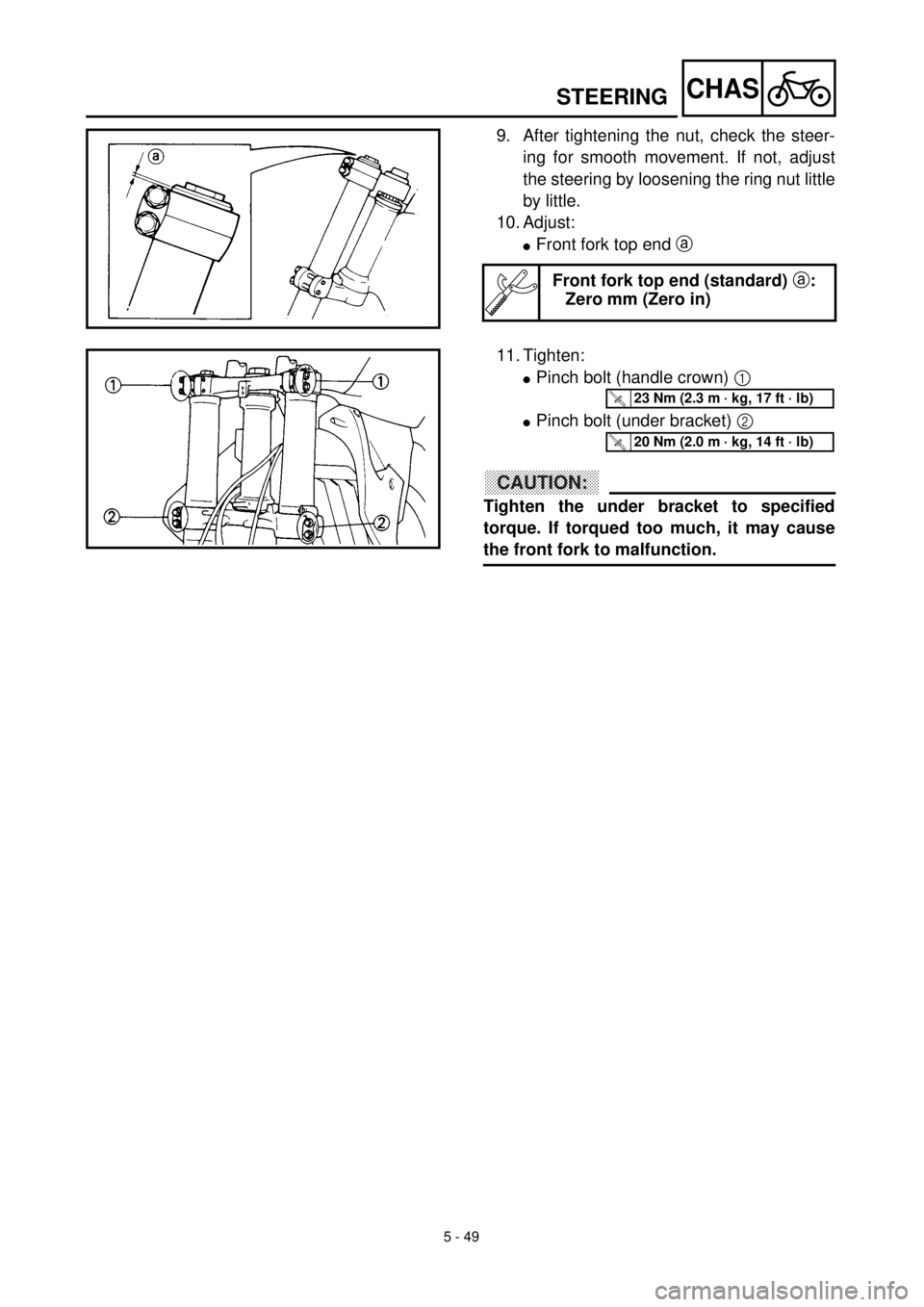

9. After tightening the nut, check the steer-

ing for smooth movement. If not, adjust

the steering by loosening the ring nut little

by little.

10. Adjust:

lFront fork top end a

Front fork top end (standard) a:

Zero mm (Zero in)

11. Tighten:

lPinch bolt (handle crown) 1

lPinch bolt (under bracket) 2

ACHTUNG:CAUTION:

Tighten the under bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 602 of 608

7 - 20

TUNSETTING

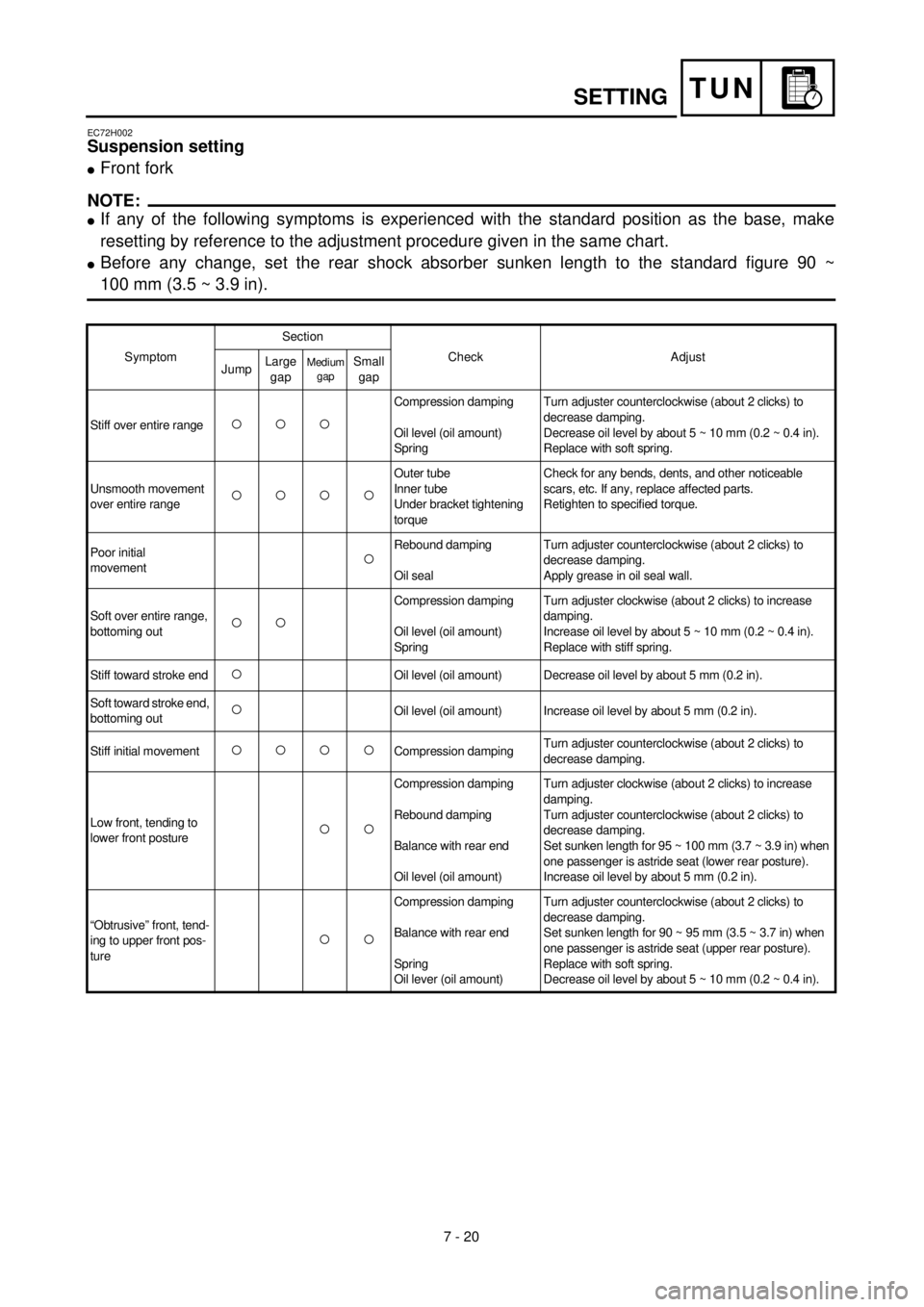

EC72H002

Suspension setting

lFront fork

NOTE:

lIf any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

lBefore any change, set the rear shock absorber sunken length to the standard figure 90 ~

100 mm (3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire range

CCC

Compression damping

Oil level (oil amount)

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with soft spring.

Unsmooth movement

over entire range

CCCC

Outer tube

Inner tube

Under bracket tightening

torqueCheck for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Retighten to specified torque.

Poor initial

movement

C

Rebound damping

Oil sealTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Apply grease in oil seal wall.

Soft over entire range,

bottoming out

CC

Compression damping

Oil level (oil amount)

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with stiff spring.

Stiff toward stroke end

COil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke end,

bottoming out

COil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement

CCCCCompression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture

CC

Compression damping

Rebound damping

Balance with rear end

Oil level (oil amount)Turn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat (lower rear posture).

Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front, tend-

ing to upper front pos-

ture

CC

Compression damping

Balance with rear end

Spring

Oil lever (oil amount)Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in) when

one passenger is astride seat (upper rear posture).

Replace with soft spring.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).