warning YAMAHA YZ426F 2000 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZ426F, Model: YAMAHA YZ426F 2000Pages: 608, PDF Size: 45.52 MB

Page 452 of 608

5 - 20

CHASFRONT BRAKE AND REAR BRAKE

EC5A5200

Master cylinder kit

1. Clean:

lMaster cylinder

lMaster cylinder kit

Clean them with brake fluid.

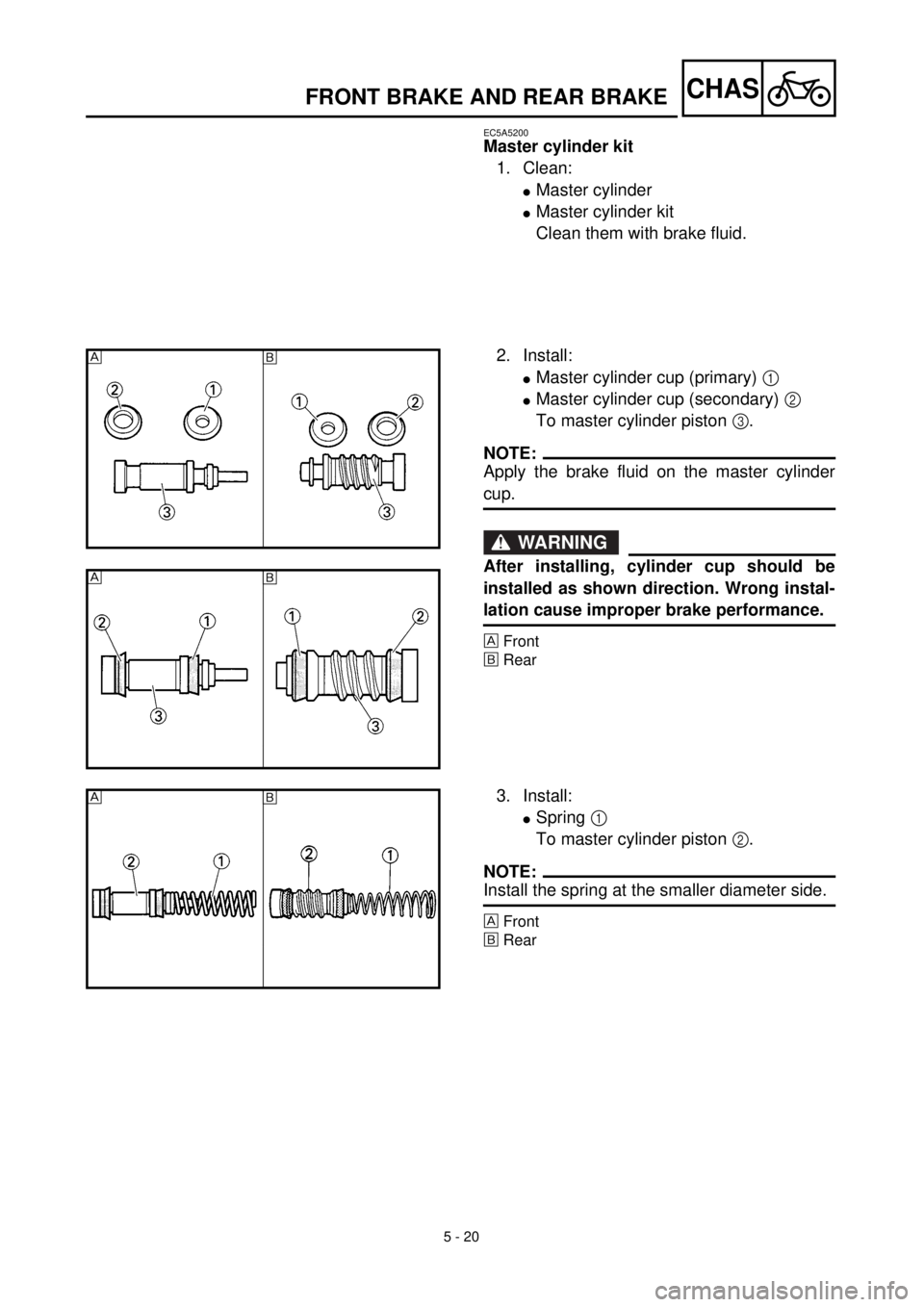

2. Install:

lMaster cylinder cup (primary) 1

lMaster cylinder cup (secondary) 2

To master cylinder piston 3.

NOTE:

Apply the brake fluid on the master cylinder

cup.

WARNING

After installing, cylinder cup should be

installed as shown direction. Wrong instal-

lation cause improper brake performance.

Front

õRear

õ

õ

3. Install:

lSpring 1

To master cylinder piston 2.

NOTE:

Install the spring at the smaller diameter side.

Front

õRear

õ

Page 454 of 608

![YAMAHA YZ426F 2000 Owners Guide

5 - 21

CHAS

FRONT BRAKE AND REAR BRAKE

4. Install:

[Front]

l

Master cylinder kit

1

l

Push rod

2

l

Plain washer

3

l

Circlip

4

l

Master cylinder boot

5

YAMAHA YZ426F 2000 Owners Guide

5 - 21

CHAS

FRONT BRAKE AND REAR BRAKE

4. Install:

[Front]

l

Master cylinder kit

1

l

Push rod

2

l

Plain washer

3

l

Circlip

4

l

Master cylinder boot

5](/img/51/53972/w960_53972-453.png)

5 - 21

CHAS

FRONT BRAKE AND REAR BRAKE

4. Install:

[Front]

l

Master cylinder kit

1

l

Push rod

2

l

Plain washer

3

l

Circlip

4

l

Master cylinder boot

5

l

Locknut

6

To master cylinder

7

.

[Rear]

l

Master cylinder kit

1

l

Push rod

2

l

Circlip

3

l

Master cylinder boot

4

l

Locknut

5

To master cylinder

6

.

NOTE:

l

Apply the brake fluid on the master cylinder

kit.

l

Apply the lithium soap base grease on the tip

of the push rod.

l

When installing the circlip, use a long nose

circlip pliers.

Front

õ

Rear

EC5A5300

Front master cylinder

1. Install:

l

Master cylinder

1

l

Master cylinder bracket

2

l

Bolt (master cylinder bracket)

3

NOTE:

l

Install the bracket so that the arrow mark

a

face upward.

l

First tighten the bolts on the upper side of the

master cylinder bracket, and then tighten the

bolts on the lower side.

WARNING

Install the master cylinder so that the gaps

b

and

c

between the bolt (grip cap)

4

and

push rod

5

are equal. If you make a mis-

take in the master cylinder installation

position, the brake lever may contact the

grip cap, resulting in poor brake perfor-

mance.

õ

T R..9 Nm (0.9 m · kg, 6.5 ft · lb)

Page 460 of 608

5 - 24

CHASFRONT BRAKE AND REAR BRAKE

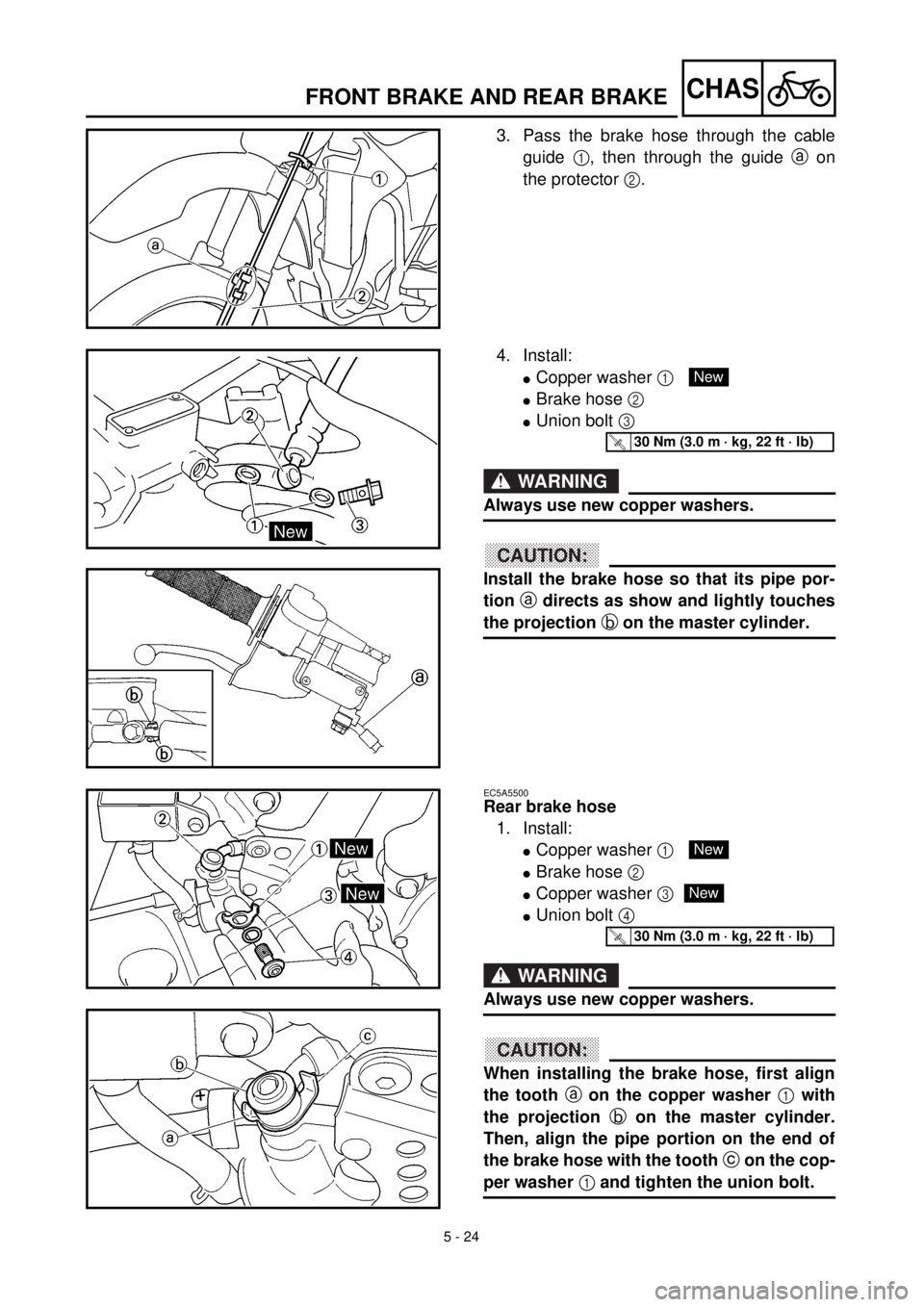

3. Pass the brake hose through the cable

guide 1, then through the guide a on

the protector 2.

4. Install:

lCopper washer 1

lBrake hose 2

lUnion bolt 3

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

Install the brake hose so that its pipe por-

tion a directs as show and lightly touches

the projection b on the master cylinder.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

EC5A5500

Rear brake hose

1. Install:

lCopper washer 1

lBrake hose 2

lCopper washer 3

lUnion bolt 4

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

When installing the brake hose, first align

the tooth a on the copper washer 1 with

the projection b on the master cylinder.

Then, align the pipe portion on the end of

the brake hose with the tooth c on the cop-

per washer 1 and tighten the union bolt.

New

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

Page 462 of 608

5 - 25

CHASFRONT BRAKE AND REAR BRAKE

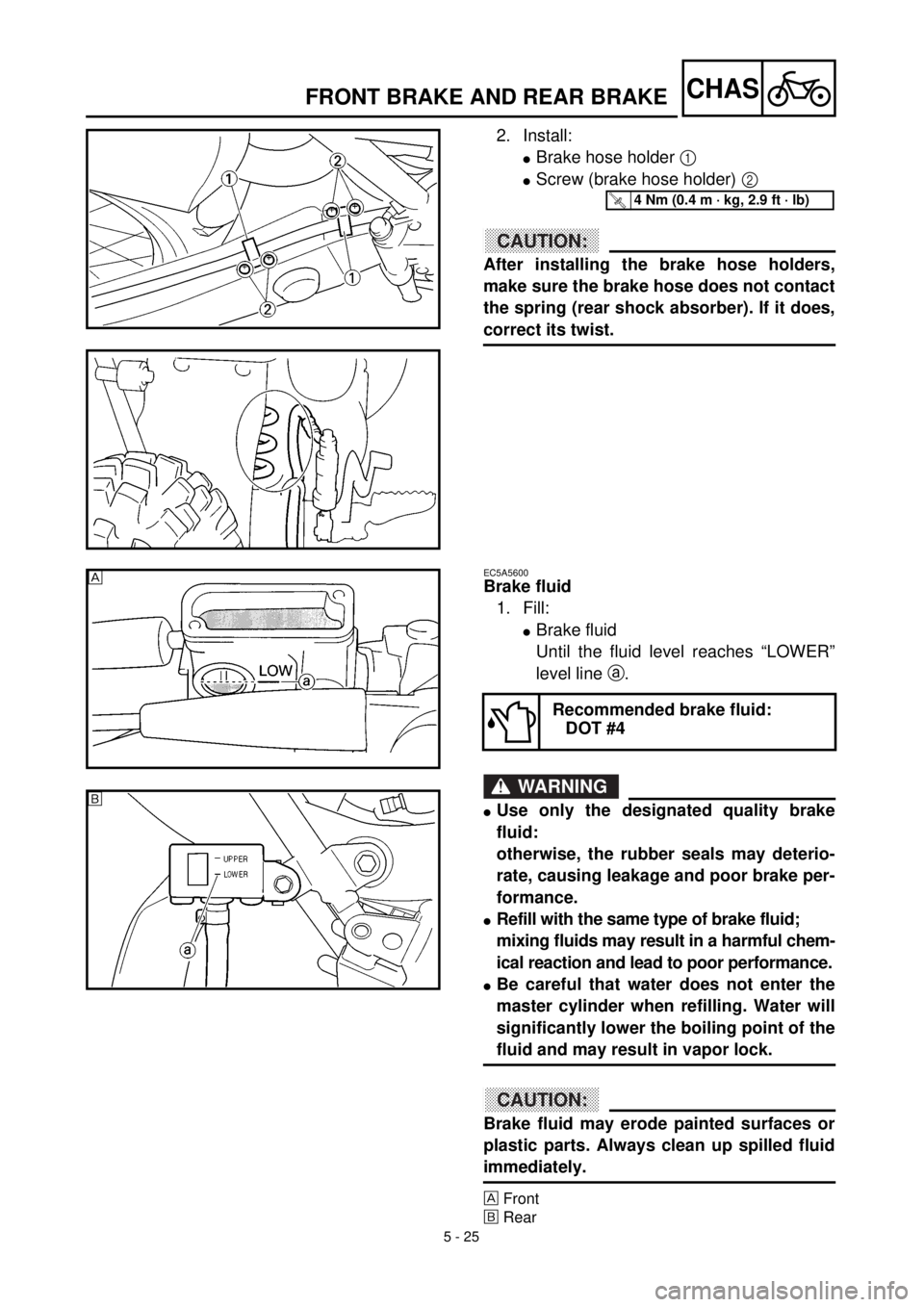

2. Install:

lBrake hose holder 1

lScrew (brake hose holder) 2

ACHTUNG:CAUTION:

After installing the brake hose holders,

make sure the brake hose does not contact

the spring (rear shock absorber). If it does,

correct its twist.

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

EC5A5600

Brake fluid

1. Fill:

lBrake fluid

Until the fluid level reaches “LOWER”

level line a.

WARNING

lUse only the designated quality brake

fluid:

otherwise, the rubber seals may deterio-

rate, causing leakage and poor brake per-

formance.

lRefill with the same type of brake fluid;

mixing fluids may result in a harmful chem-

ical reaction and lead to poor performance.

lBe careful that water does not enter the

master cylinder when refilling. Water will

significantly lower the boiling point of the

fluid and may result in vapor lock.

ACHTUNG:CAUTION:

Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

Front

õRear

Recommended brake fluid:

DOT #4

õ

Page 466 of 608

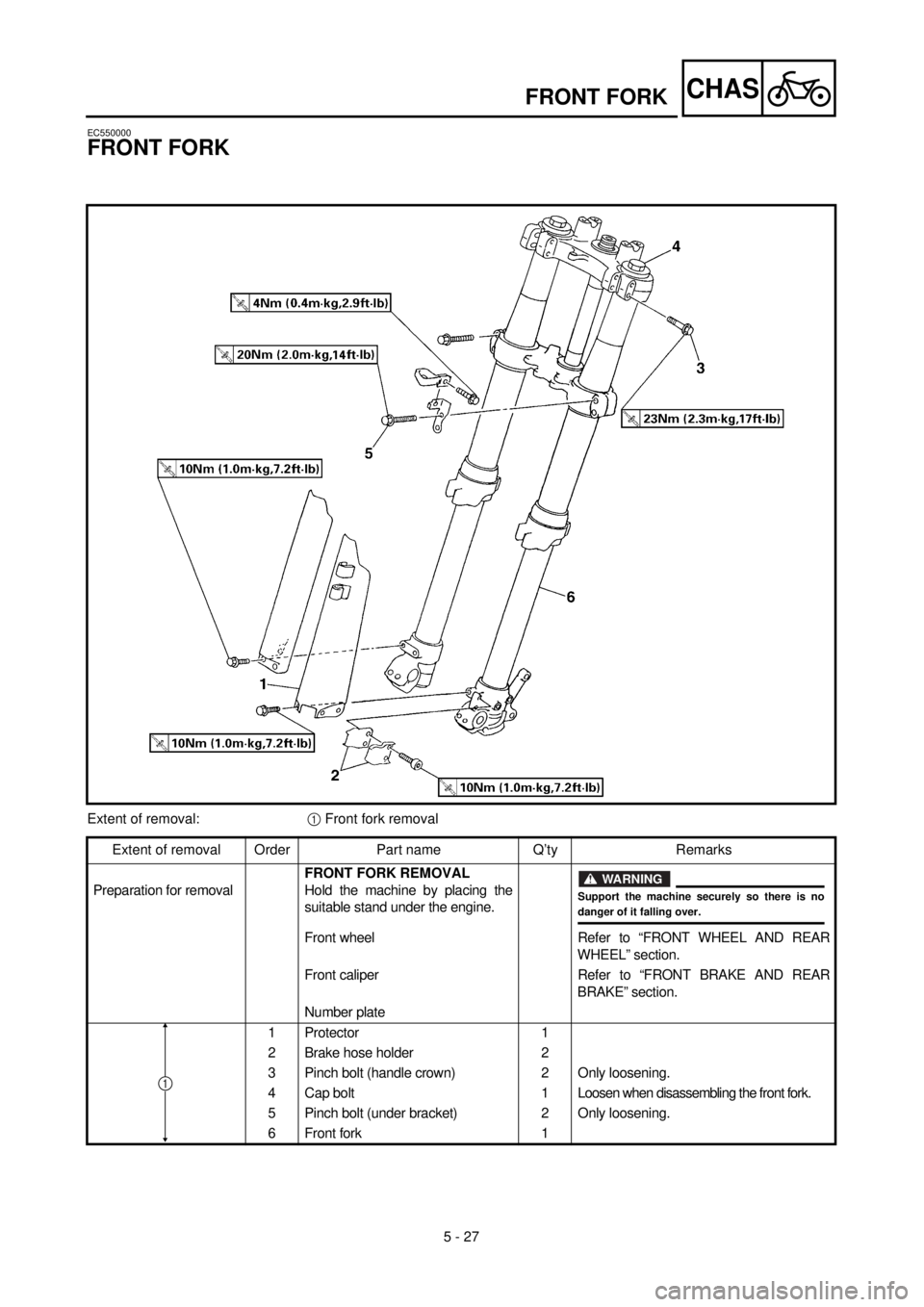

5 - 27

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT FORK REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Front caliper Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Number plate

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (handle crown) 2 Only loosening.

4 Cap bolt 1Loosen when disassembling the front fork.

5 Pinch bolt (under bracket) 2 Only loosening.

6 Front fork 1

WARNING

Support the machine securely so there is nodanger of it falling over.

1

Page 474 of 608

5 - 31

CHAS

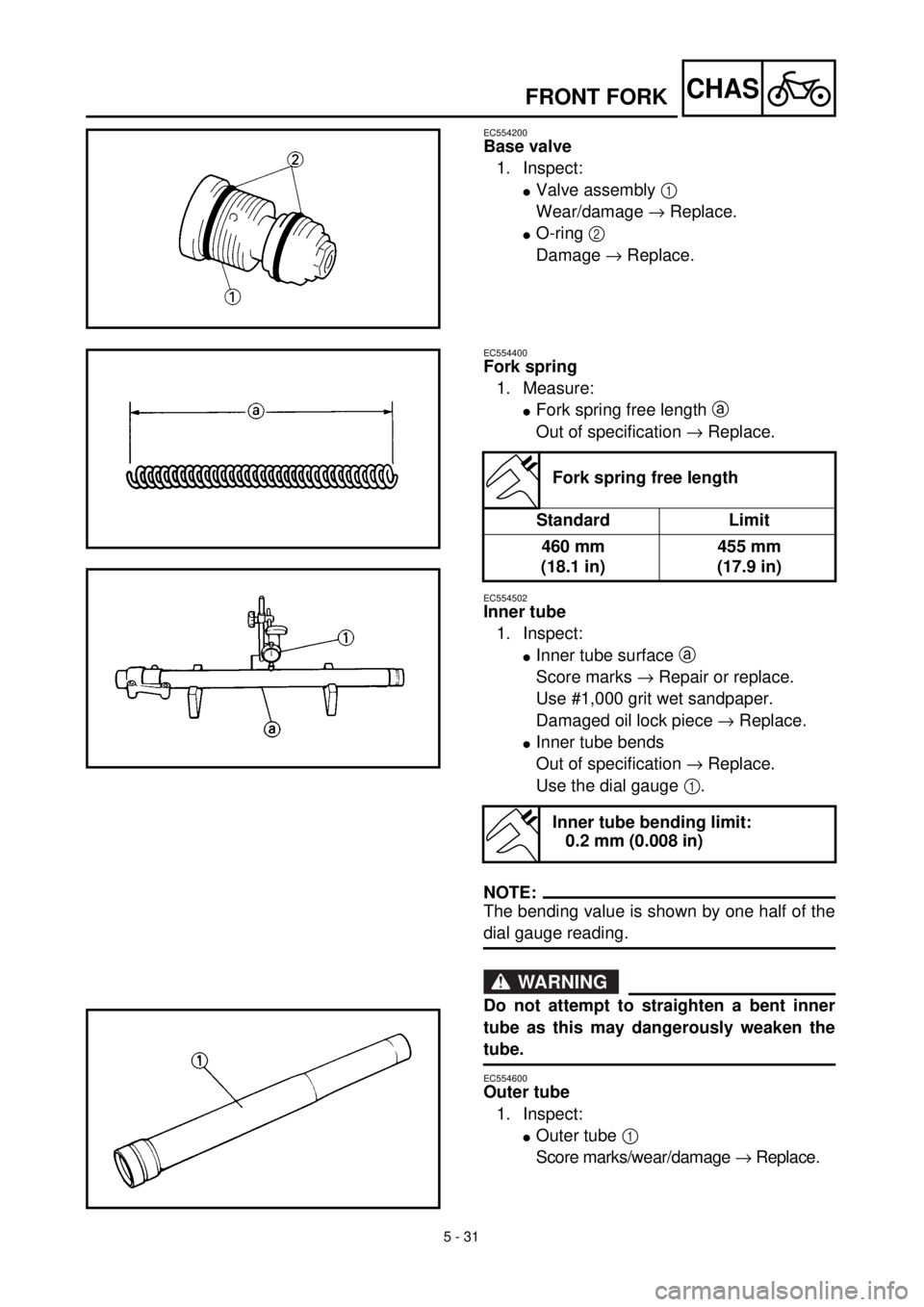

EC554200

Base valve

1. Inspect:

lValve assembly 1

Wear/damage ® Replace.

lO-ring 2

Damage ® Replace.

EC554400

Fork spring

1. Measure:

lFork spring free length a

Out of specification ® Replace.

EC554502

Inner tube

1. Inspect:

lInner tube surface a

Score marks ® Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece ® Replace.

lInner tube bends

Out of specification ® Replace.

Use the dial gauge 1.

NOTE:

The bending value is shown by one half of the

dial gauge reading.

WARNING

Do not attempt to straighten a bent inner

tube as this may dangerously weaken the

tube.

EC554600

Outer tube

1. Inspect:

lOuter tube 1

Score marks/wear/damage ® Replace.

Fork spring free length

Standard Limit

460 mm

(18.1 in)455 mm

(17.9 in)

Inner tube bending limit:

0.2 mm (0.008 in)

FRONT FORK

Page 484 of 608

5 - 36

CHASFRONT FORK

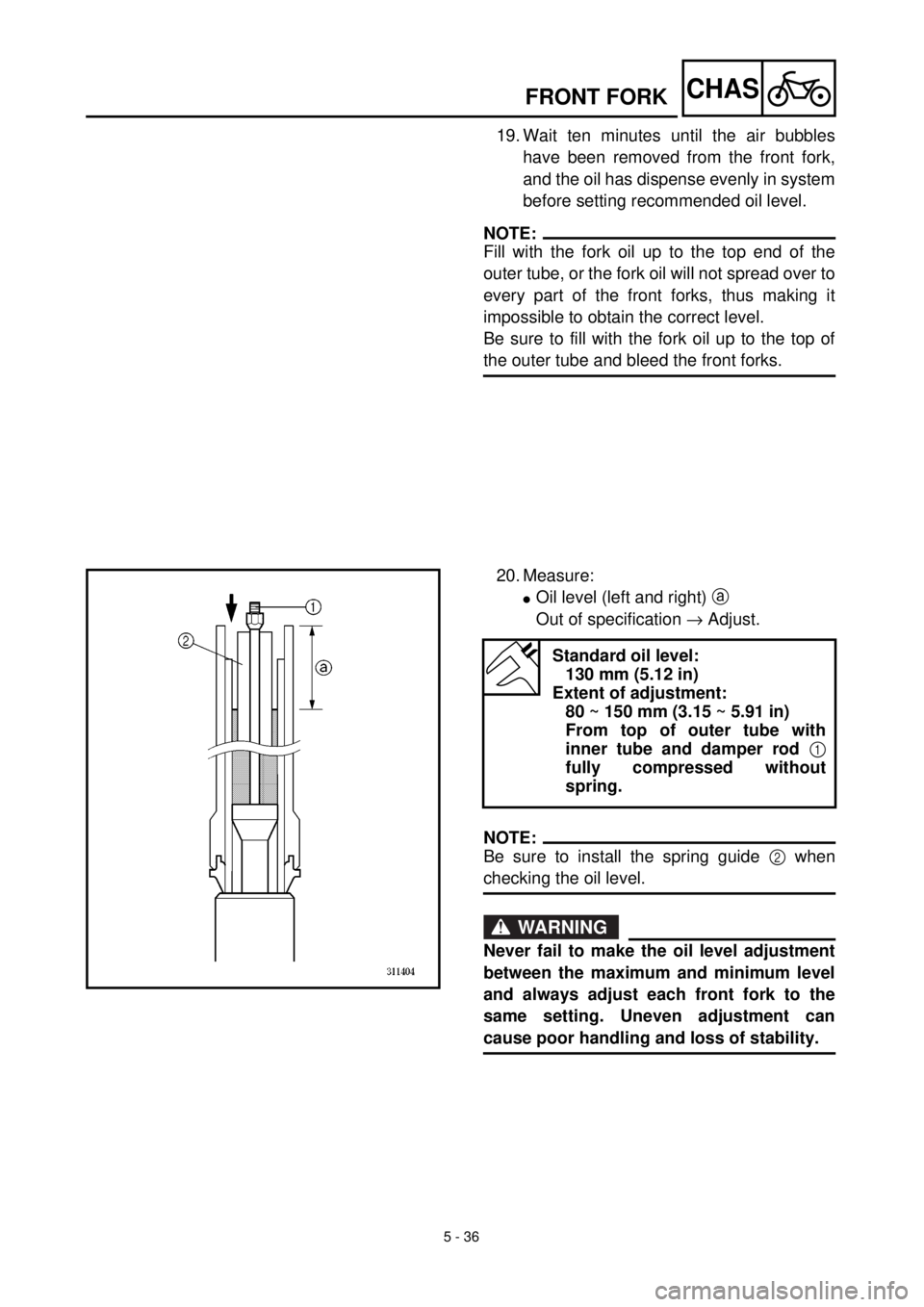

19. Wait ten minutes until the air bubbles

have been removed from the front fork,

and the oil has dispense evenly in system

before setting recommended oil level.

NOTE:

Fill with the fork oil up to the top end of the

outer tube, or the fork oil will not spread over to

every part of the front forks, thus making it

impossible to obtain the correct level.

Be sure to fill with the fork oil up to the top of

the outer tube and bleed the front forks.

20. Measure:

lOil level (left and right) a

Out of specification ® Adjust.

NOTE:

Be sure to install the spring guide 2 when

checking the oil level.

WARNING

Never fail to make the oil level adjustment

between the maximum and minimum level

and always adjust each front fork to the

same setting. Uneven adjustment can

cause poor handling and loss of stability.

Standard oil level:

130 mm (5.12 in)

Extent of adjustment:

80 ~ 150 mm (3.15 ~ 5.91 in)

From top of outer tube with

inner tube and damper rod 1

fully compressed without

spring.

Page 494 of 608

5 - 41

CHAS

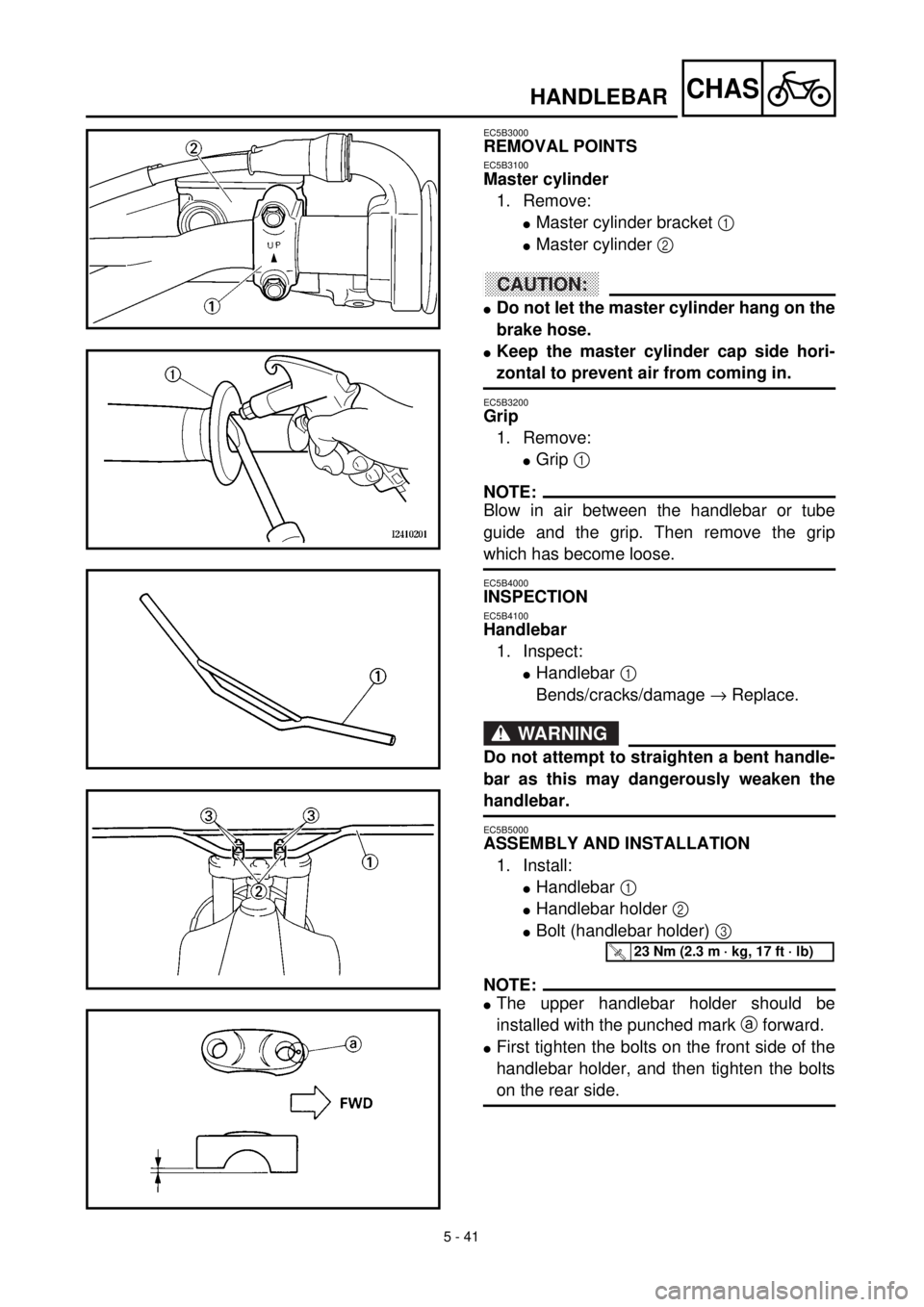

EC5B3000

REMOVAL POINTS

EC5B3100

Master cylinder

1. Remove:

l

Master cylinder bracket

1

l

Master cylinder

2

ACHTUNG:CAUTION:

l

Do not let the master cylinder hang on the

brake hose.

l

Keep the master cylinder cap side hori-

zontal to prevent air from coming in.

EC5B3200

Grip

1. Remove:

l

Grip

1

NOTE:

Blow in air between the handlebar or tube

guide and the grip. Then remove the grip

which has become loose.

EC5B4000

INSPECTION

EC5B4100

Handlebar

1. Inspect:

l

Handlebar

1

Bends/cracks/damage

®

Replace.

WARNING

Do not attempt to straighten a bent handle-

bar as this may dangerously weaken the

handlebar.

EC5B5000

ASSEMBLY AND INSTALLATION

1. Install:

l

Handlebar

1

l

Handlebar holder

2

l

Bolt (handlebar holder)

3

NOTE:

l

The upper handlebar holder should be

installed with the punched mark

a

forward.

l

First tighten the bolts on the front side of the

handlebar holder, and then tighten the bolts

on the rear side.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

HANDLEBAR

Page 498 of 608

5 - 43

CHAS

HANDLEBAR

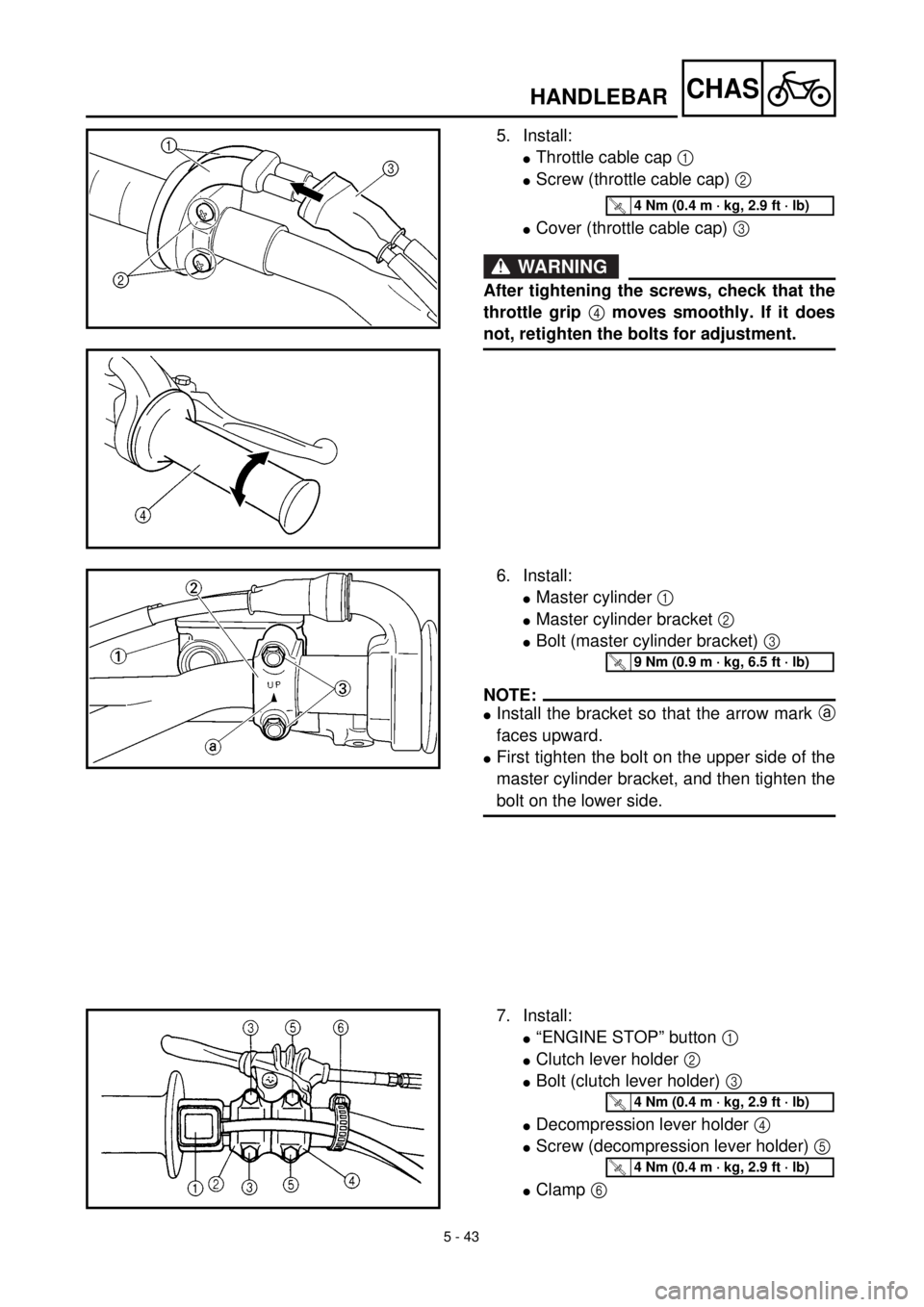

5. Install:

l

Throttle cable cap

1

l

Screw (throttle cable cap)

2

l

Cover (throttle cable cap)

3

WARNING

After tightening the screws, check that the

throttle grip

4

moves smoothly. If it does

not, retighten the bolts for adjustment.

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

6. Install:

l

Master cylinder

1

lMaster cylinder bracket 2

lBolt (master cylinder bracket) 3

NOTE:

lInstall the bracket so that the arrow mark a

faces upward.

lFirst tighten the bolt on the upper side of the

master cylinder bracket, and then tighten the

bolt on the lower side.

T R..9 Nm (0.9 m · kg, 6.5 ft · lb)

7. Install:

l“ENGINE STOP” button 1

lClutch lever holder 2

lBolt (clutch lever holder) 3

lDecompression lever holder 4

lScrew (decompression lever holder) 5

lClamp 6

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

Page 502 of 608

5 - 45

CHAS

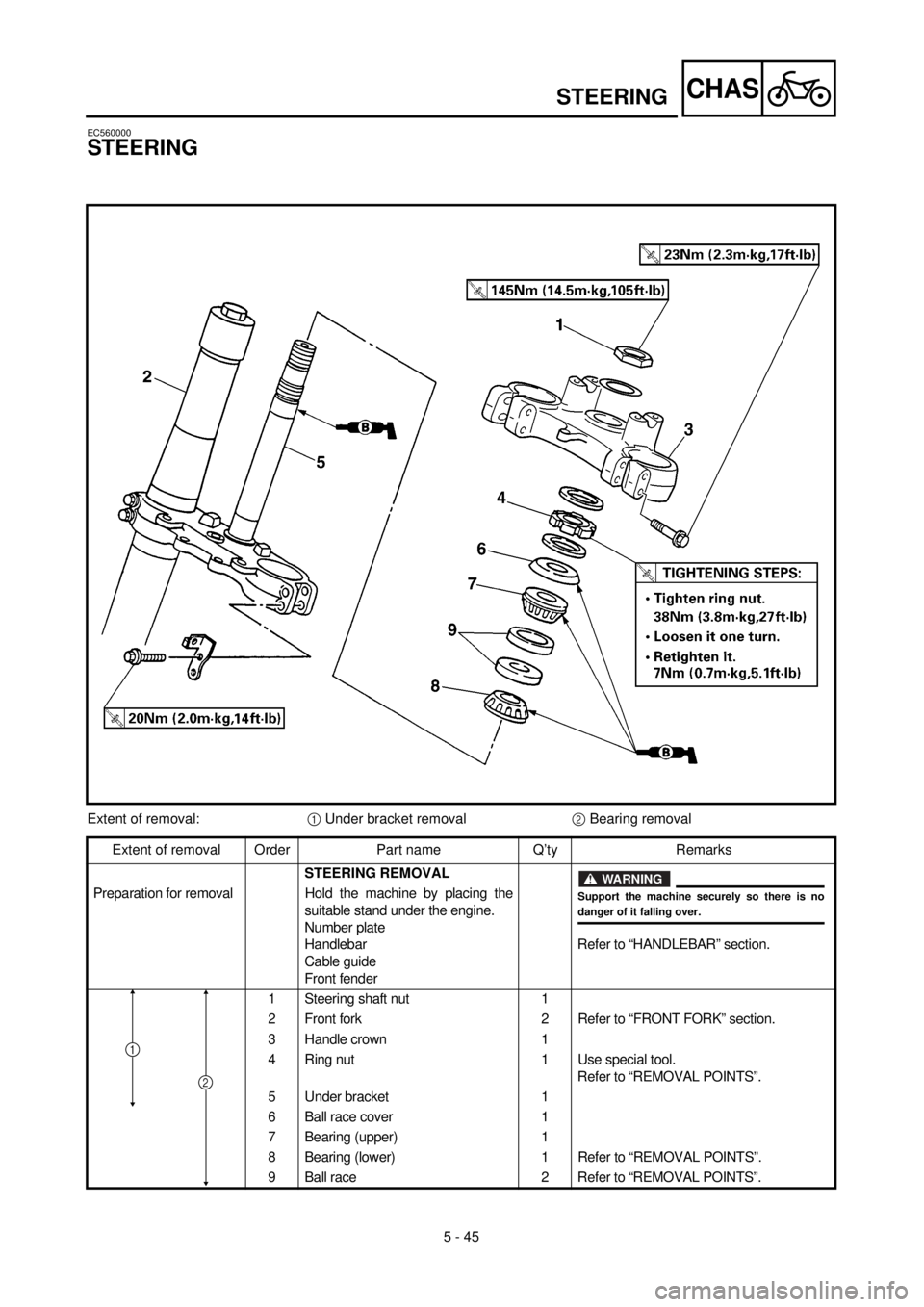

EC560000

STEERING

Extent of removal:1 Under bracket removal2 Bearing removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

Refer to “HANDLEBAR” section. Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Number plate

Handlebar

Cable guide

Front fender

1 Steering shaft nut 1

2 Front fork 2 Refer to “FRONT FORK” section.

3 Handle crown 1

4 Ring nut 1 Use special tool.

Refer to “REMOVAL POINTS”.

5 Under bracket 1

6 Ball race cover 1

7 Bearing (upper) 1

8 Bearing (lower) 1 Refer to “REMOVAL POINTS”.

9 Ball race 2 Refer to “REMOVAL POINTS”.

WARNING

Support the machine securely so there is nodanger of it falling over.

2

1

STEERING