relay YAMAHA YZ426F 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ426F, Model: YAMAHA YZ426F 2001Pages: 626, PDF Size: 47.57 MB

Page 87 of 626

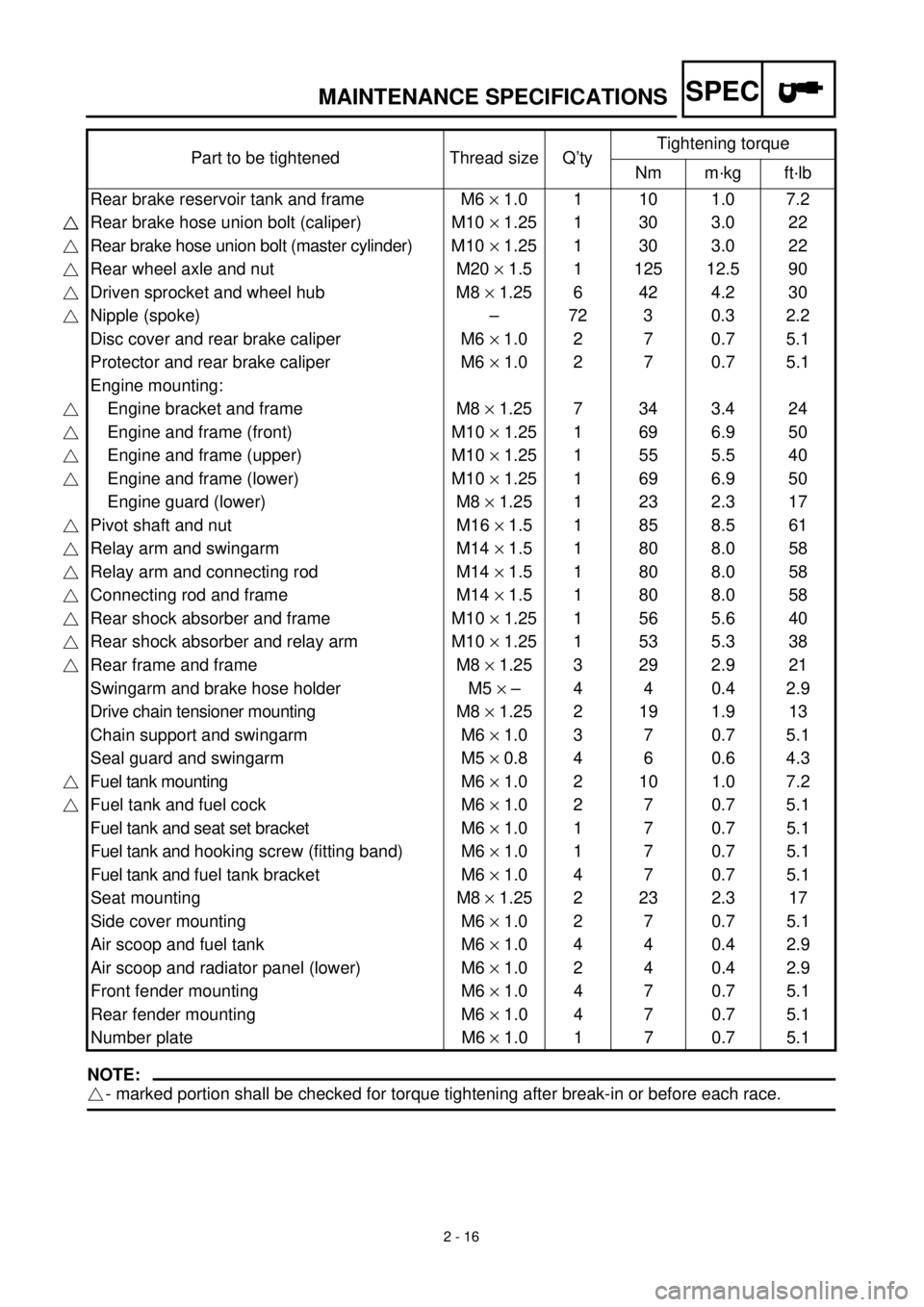

SPEC

2 - 16

MAINTENANCE SPECIFICATIONS

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear brake reservoir tank and frame M6 ´ 1.0 1 10 1.0 7.2

Rear brake hose union bolt (caliper) M10 ´ 1.25 1 30 3.0 22

Rear brake hose union bolt (master cylinder)M10 ´ 1.25 1 30 3.0 22

Rear wheel axle and nut M20 ´ 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 ´ 1.25 6 42 4.2 30

Nipple (spoke) – 72 3 0.3 2.2

Disc cover and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Engine mounting:

Engine bracket and frame M8 ´ 1.25 7 34 3.4 24

Engine and frame (front) M10 ´ 1.25 1 69 6.9 50

Engine and frame (upper) M10 ´ 1.25 1 55 5.5 40

Engine and frame (lower) M10 ´ 1.25 1 69 6.9 50

Engine guard (lower) M8 ´ 1.25 1 23 2.3 17

Pivot shaft and nut M16 ´ 1.5 1 85 8.5 61

Relay arm and swingarm M14 ´ 1.5 1 80 8.0 58

Relay arm and connecting rod M14 ´ 1.5 1 80 8.0 58

Connecting rod and frame M14 ´ 1.5 1 80 8.0 58

Rear shock absorber and frame M10 ´ 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 ´ 1.25 1 53 5.3 38

Rear frame and frame M8 ´ 1.25 3 29 2.9 21

Swingarm and brake hose holder M5 ´ – 4 4 0.4 2.9

Drive chain tensioner mounting M8 ´ 1.25 2 19 1.9 13

Chain support and swingarm M6 ´ 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 ´ 0.8 4 6 0.6 4.3

Fuel tank mounting M6 ´ 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 ´ 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 ´ 1.0 4 7 0.7 5.1

Seat mounting M8 ´ 1.25 2 23 2.3 17

Side cover mounting M6 ´ 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 ´ 1.0 4 4 0.4 2.9

Air scoop and radiator panel (lower) M6 ´ 1.0 2 4 0.4 2.9

Front fender mounting M6 ´ 1.0 4 7 0.7 5.1

Rear fender mounting M6 ´ 1.0 4 7 0.7 5.1

Number plate M6 ´ 1.0 1 7 0.7 5.1

Page 142 of 626

3 - 3

INSP

ADJ

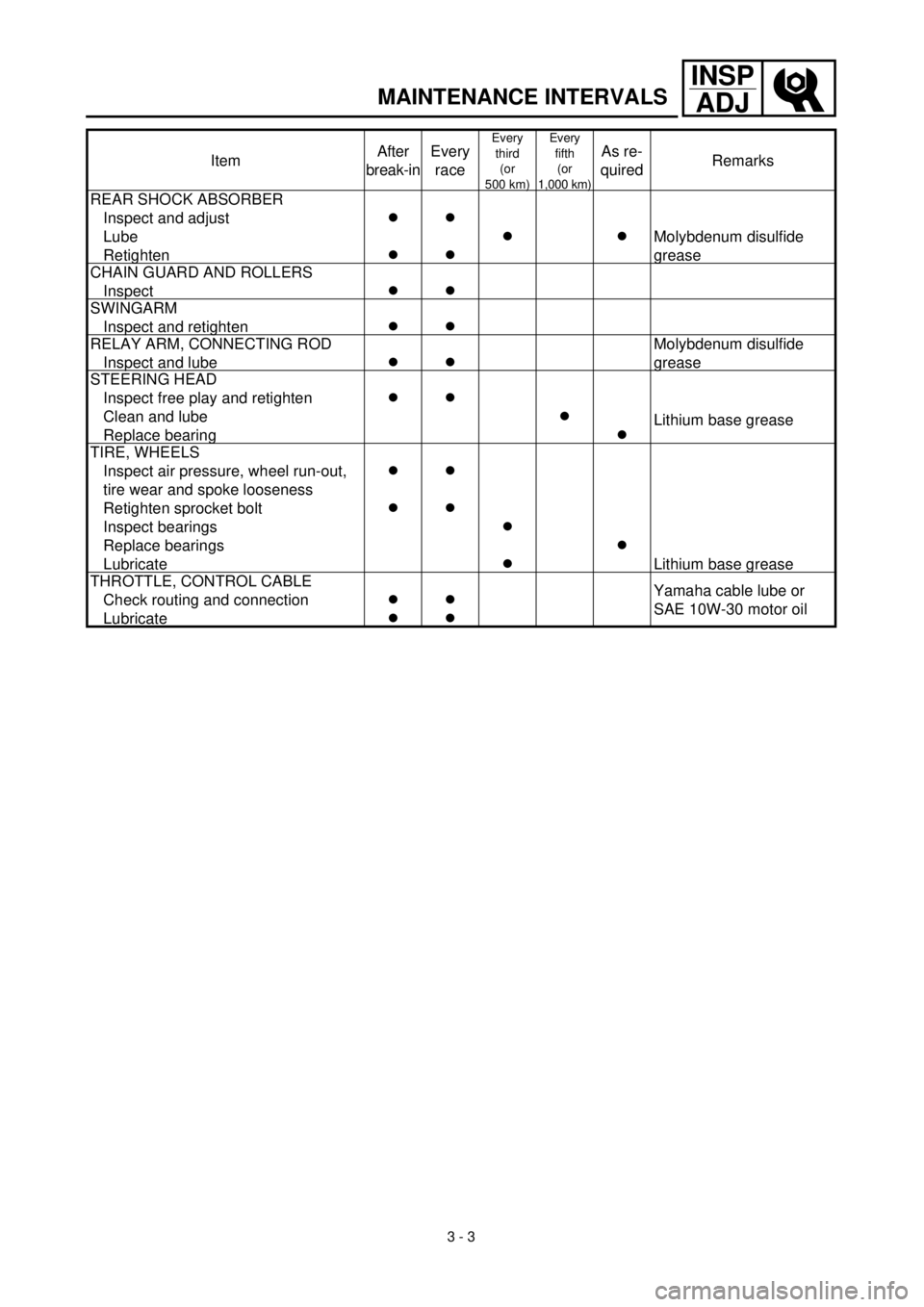

MAINTENANCE INTERVALS

REAR SHOCK ABSORBER

Inspect and adjust

Lube

Retighten

c

c

c

c

c

c Molybdenum disulfide

grease

CHAIN GUARD AND ROLLERS

Inspect

c c

SWINGARM

Inspect and retighten

c c

RELAY ARM, CONNECTING ROD

Inspect and lube

c c Molybdenum disulfide

grease

STEERING HEAD

Inspect free play and retighten

Clean and lube

Replace bearing

c c

c

c Lithium base grease

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate

c

c

c

c

c

c

c

Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection

Lubricate

c

c

c

c Yamaha cable lube or

SAE 10W-30 motor oil ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 526 of 626

5 - 50

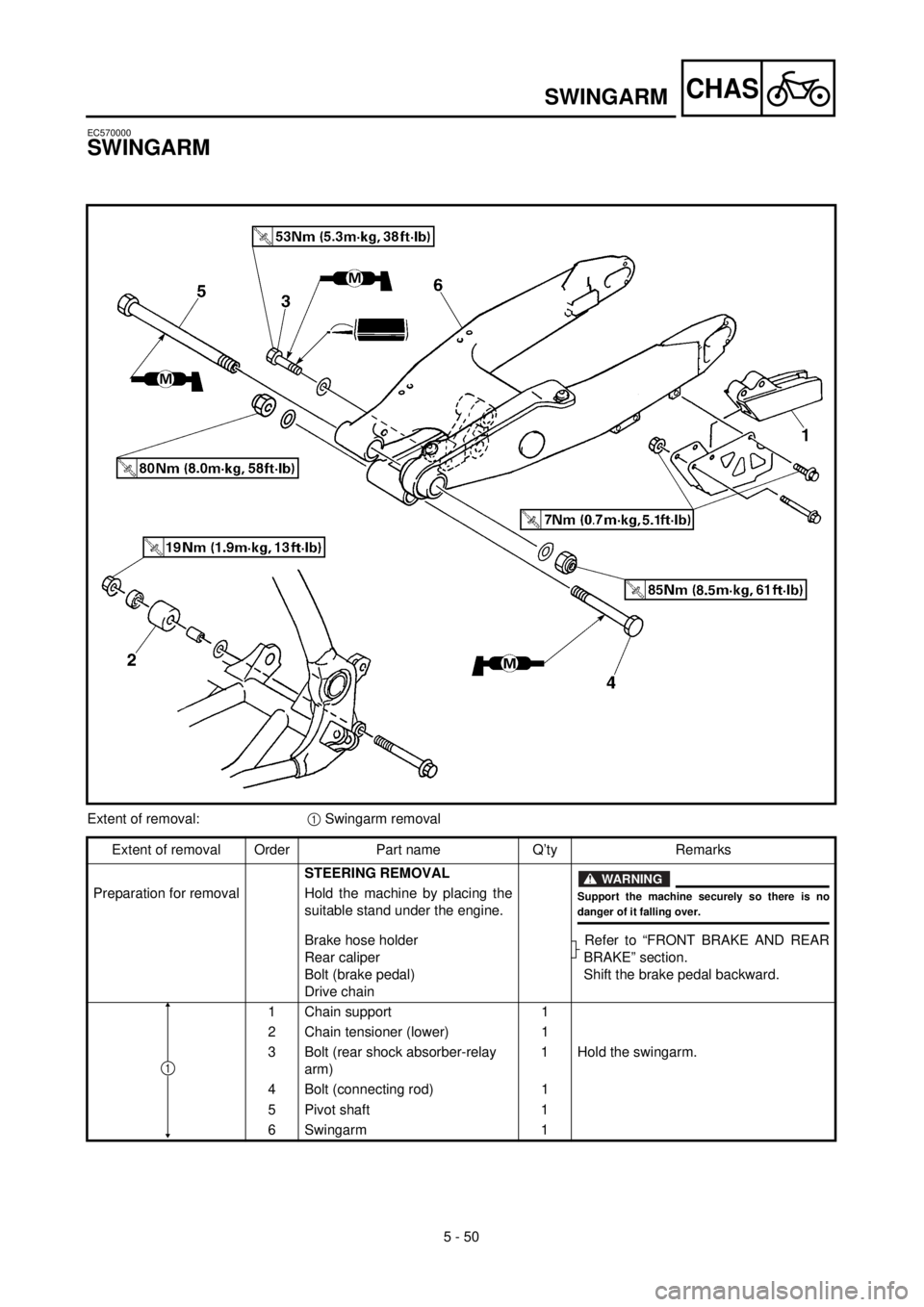

CHASSWINGARM

EC570000

SWINGARM

Extent of removal:1 Swingarm removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Brake hose holder

Rear caliper

Bolt (brake pedal)

Drive chainRefer to “FRONT BRAKE AND REAR

BRAKE” section.

Shift the brake pedal backward.

1 Chain support 1

2 Chain tensioner (lower) 1

3 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

4 Bolt (connecting rod) 1

5 Pivot shaft 1

6 Swingarm 1

1

Page 528 of 626

5 - 51

CHASSWINGARM

EC578000

SWINGARM DISASSEMBLY

Extent of removal:1 Swingarm disassembly2 Connecting rod removal and disassembly

3 Relay arm removal and disassembly

Extent of removal Order Part name Q’ty Remarks

SWINGARM DISASSEMBLY

1 Cap 2

2 Relay arm 1

3 Connecting rod 1

4 Collar 2

5 Oil seal 2

6 Thrust bearing 2

7 Bush 2

8 Oil seal 8

9 Bearing 8 Refer to “REMOVAL POINTS”.

1

2

32

3

Page 530 of 626

5 - 52

CHASSWINGARM

EC573000

REMOVAL POINTS

EC573200

Bearing

1. Remove:

lBearing 1

NOTE:

Install the bearing by pressing its outer race.

EC574010

INSPECTION

Wash the bearings, bushes, collars, and cov-

ers in a solvent.

EC574111

Swingarm

1. Inspect:

lBearing 1

lBush 2

Free play exists/unsmooth revolution/

rust ® Replace bearing and bush as a

set.

2. Inspect:

lOil seal 3

Damage ® Replace.

EC574210

Relay arm

1. Inspect:

lBearing 1

lCollar 2

Free play exists/unsmooth revolution/rust

® Replace bearing and collar as a set.

2. Inspect:

lOil seal 3

Damage ® Replace.

EC574310

Connecting rod

1. Inspect:

lBearing 1

lCollar 2

Free play exists/unsmooth revolution/rust

® Replace bearing and collar as a set.

2. Inspect:

lOil seal 3

Damage ® Replace.

Page 532 of 626

5 - 53

CHASSWINGARM

EC575000

ASSEMBLY AND INSTALLATION

EC575201

Bearing and oil seal

1. Install:

lBearing 1

lOil seal 2

To swingarm.

NOTE:

lApply the molybdenum disulfide grease on

the bearing when installing.

lInstall the bearing by pressing it on the side

having the manufacture’s marks or numbers.

lFirst install the outer and then the inner bear-

ings to a specified depth from inside.

Installed depth of bearings:

Outer a: Zero mm (Zero in)

Inner b: 8.5 mm (0.33 in)

2. Install:

lBearing 1

lOil seal 2

To relay arm.

NOTE:

lApply the molybdenum disulfide grease on

the bearing when installing.

lInstall the bearing by pressing it on the side

having the manufacture’s marks or numbers.

3. Install:

lBearing 1

lOil seal 2

To connecting rod.

NOTE:

lApply the molybdenum disulfide grease on

the bearing when installing.

lInstall the bearing by pressing it on the side

having the manufacture’s marks or numbers.

Installed depth of bearings a:

5 mm (0.20 in)

Installed depth of bearings a:

5 mm (0.20 in)

Page 534 of 626

5 - 54

CHASSWINGARM

EC5751B1

Swingarm

1. Install:

lBush 1

lThrust bearing 2

lOil seal 3

lCollar 4

To swingarm 5.

NOTE:

Apply the molybdenum disulfide grease on the

bushes, thrust bearings and oil seal lips.

2. Install:

lCollar 1

To relay arm 2.

NOTE:

Apply the molybdenum disulfide grease on the

collars, bearings and oil seal lips.

3. Install:

lCollar 1

To connecting rod 2.

NOTE:

Apply the molybdenum disulfide grease on the

collar, bearings and oil seal lips.

4. Install:

lConnecting rod 1

lBolt (connecting rod) 2

lPlain washer 3

lNut (connecting rod) 4

To relay arm 5.

NOTE:

Apply the molybdenum disulfide grease on the

bolt.

ACHTUNG:CAUTION:

Install the nut on the left side of the chas-

sis. If you make a mistake in its installation

position, the nut contacts the swingarm

when stroking the rear shock absorber.

T R..80 Nm (8.0 m · kg, 58 ft · lb)

Page 536 of 626

5 - 55

CHASSWINGARM

5. Install:

lRelay arm 1

lBolt (relay arm) 2

lPlain washer 3

lNut (relay arm) 4

To swingarm.

NOTE:

lApply the molybdenum disulfide grease on

the bolt.

lDo not tighten the nut yet.

6. Install:

lSwingarm 1

lPivot shaft 2

NOTE:

lApply the molybdenum disulfide grease on

the pivot shaft.

lInsert the pivot shaft from right side.

T R..85 Nm (8.5 m · kg, 61 ft · lb)

7. Check:

lSwingarm side play a

Free play exists ® Replace thrust bear-

ing.

lSwingarm up and down movement b

Unsmooth movement/binding/rough

spots ® Grease or replace bearings,

bushes and collars.

8. Install:

lBolt (connecting rod) 1

lPlain washer 2

lNut (connecting rod) 3

NOTE:

lApply the molybdenum disulfide grease on

the bolt.

lDo not tighten the nut yet.

9. Install:

lPlain washer 1

lBolt (rear shock absorber-relay arm) 2

NOTE:

lApply the molybdenum disulfide grease on

the bolt.

lInsert the bolt from right side.

T R..53 Nm (5.3 m · kg, 38 ft · lb)

Page 538 of 626

5 - 56

CHASSWINGARM

10. Tighten:

lNut (connecting rod) 1

T R..80 Nm (8.0 m · kg, 58 ft · lb)

11. Tighten:

lNut (relay arm) 1

T R..80 Nm (8.0 m · kg, 58 ft · lb)

12. Install:

lCap 1

NOTE:

Install the cap with its mark a facing forward.

13. Install:

lBolt [chain tensioner (lower)] 1

lPlain washer 2

lCollar 3

lChain tensioner 4

lNut [chain tensioner (lower)] 5

T R..19 Nm (1.9 m · kg, 13 ft · lb)

14. Install:

lChain support 1

lSupport cover 2

lBolt {chain support [r= 50 mm (1.97 in)]}

3

lNut (chain support) 4

lBolt {support cover [r= 10 mm (0.39 in)]}

5

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Page 540 of 626

5 - 57

CHASREAR SHOCK ABSORBER

EC580000

REAR SHOCK ABSORBER

Extent of removal:1 Rear shock absorber removal2 Rear shock absorber disassembly

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR SHOCK ABSORBER

REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

Seat and fitting band Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Silencer Refer to “EXHAUST PIPE AND

SILENCER” section in the CHAPTER 4.

1 Bolt (reservoir tank) 1

2 Clamp (air cleaner joint) 1 Only loosening.

3 Rear frame 1

4 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

5 Bolt (rear shock absorber-frame) 1

6 Rear shock absorber 1

7 Locknut 1 Only loosening.

8 Adjuster 1 Only loosening.

9 Spring guide (lower) 1

1

2