light YAMAHA YZ450F 2005 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 16 of 646

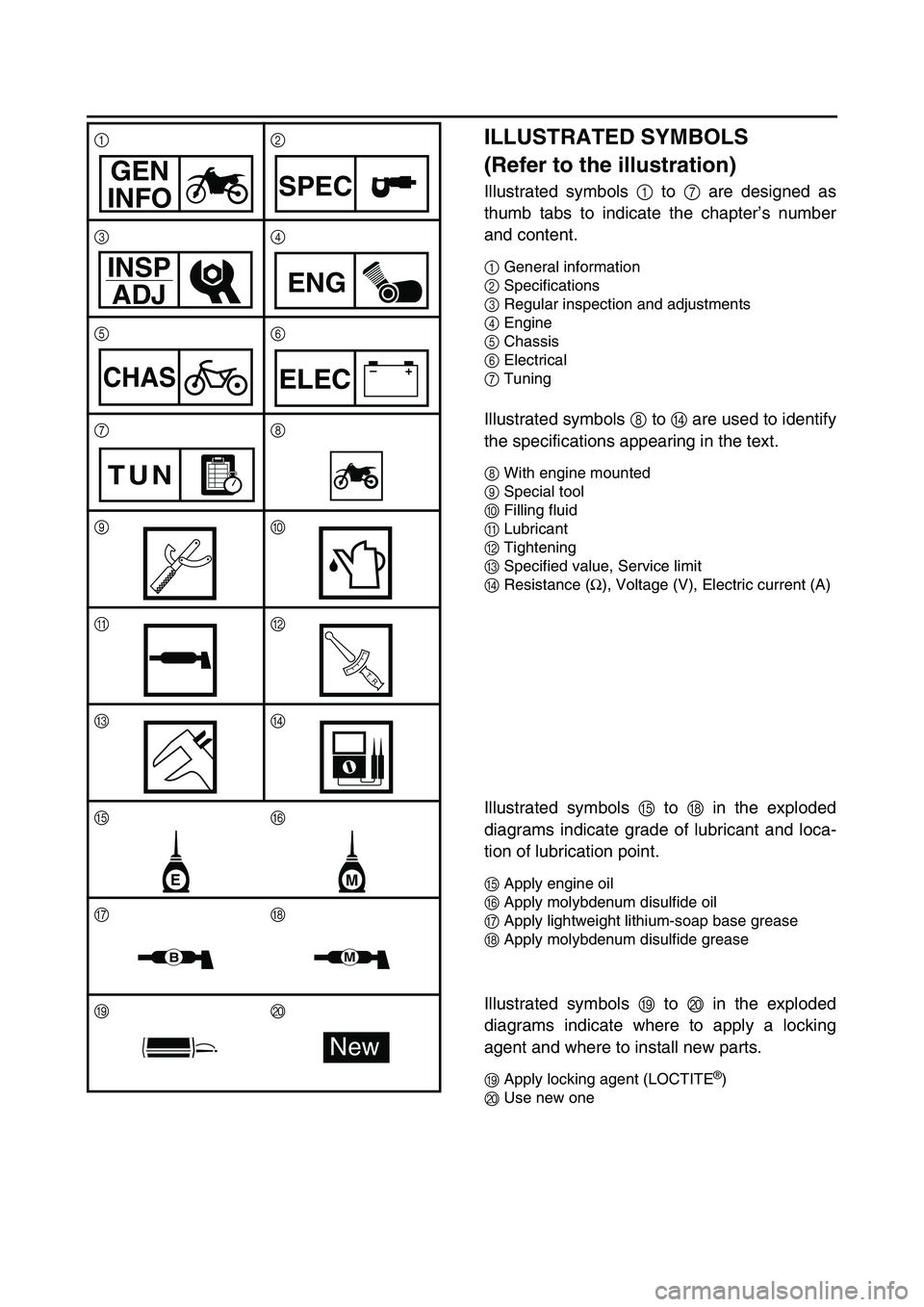

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 7 are designed as

thumb tabs to indicate the chapter’s number

and content.

1General information

2Specifications

3Regular inspection and adjustments

4Engine

5Chassis

6Electrical

7Tuning

Illustrated symbols 8 to D are used to identify

the specifications appearing in the text.

8With engine mounted

9Special tool

0Filling fluid

ALubricant

BTightening

CSpecified value, Service limit

DResistance (

Ω), Voltage (V), Electric current (A)

Illustrated symbols E to H in the exploded

diagrams indicate grade of lubricant and loca-

tion of lubrication point.

EApply engine oil

FApply molybdenum disulfide oil

GApply lightweight lithium-soap base grease

HApply molybdenum disulfide grease

Illustrated symbols I to J in the exploded

diagrams indicate where to apply a locking

agent and where to install new parts.

IApply locking agent (LOCTITE®)

JUse new one 12

34

56

78

90

AB

CD

EF

GH

IJ

GEN

INFOSPEC

INSP

ADJ

ENG

CHAS–+ELEC

TUN

T R..

EM

BM

New

Page 26 of 646

GEN

INFO

1 - 1

DESCRIPTION

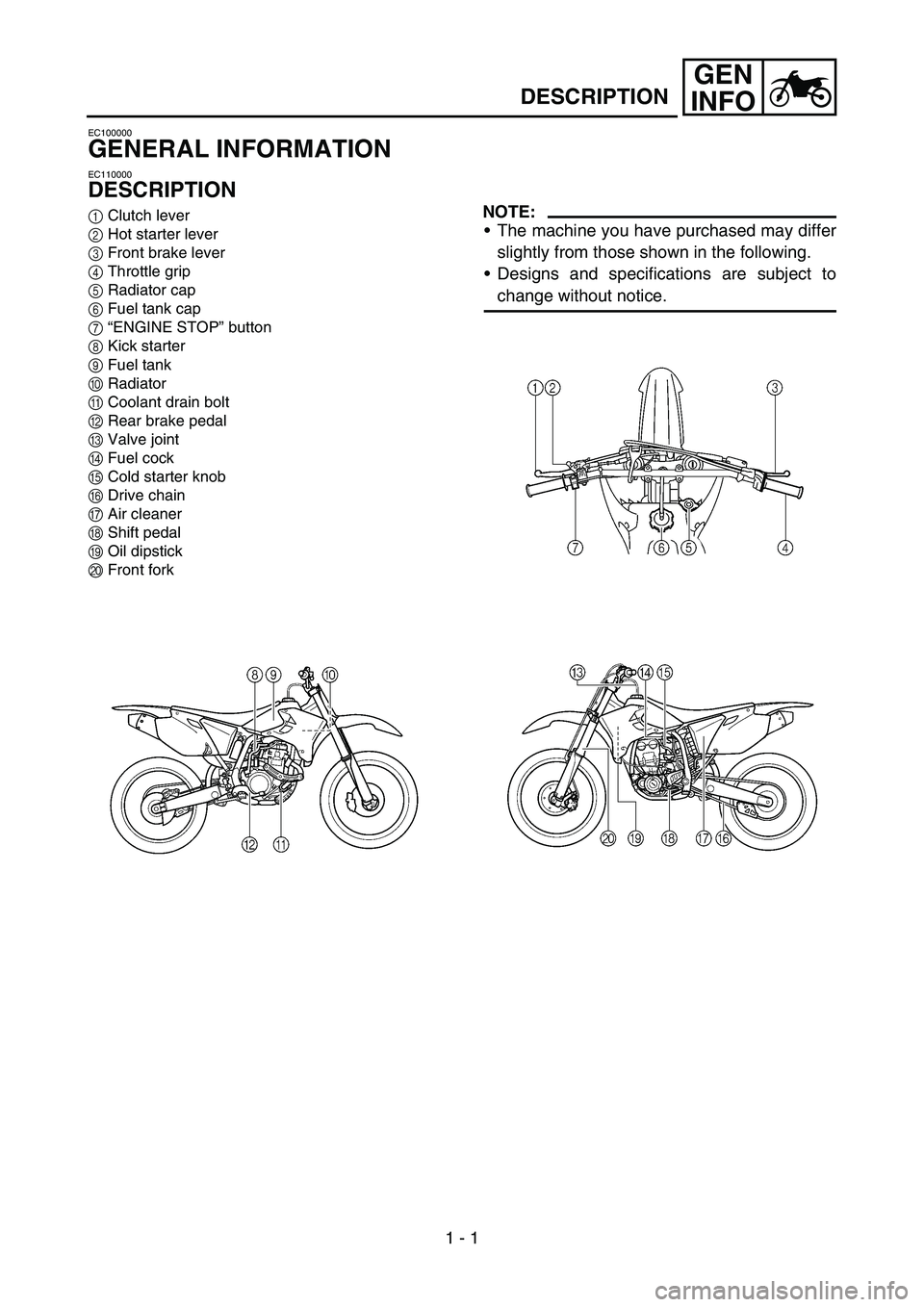

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1Clutch lever

2Hot starter lever

3Front brake lever

4Throttle grip

5Radiator cap

6Fuel tank cap

7“ENGINE STOP” button

8Kick starter

9Fuel tank

0Radiator

ACoolant drain bolt

BRear brake pedal

CValve joint

DFuel cock

ECold starter knob

FDrive chain

GAir cleaner

HShift pedal

IOil dipstick

JFront forkNOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

Page 32 of 646

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is overhauled.

All gasket surfaces, oil seal lips, and O-

rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

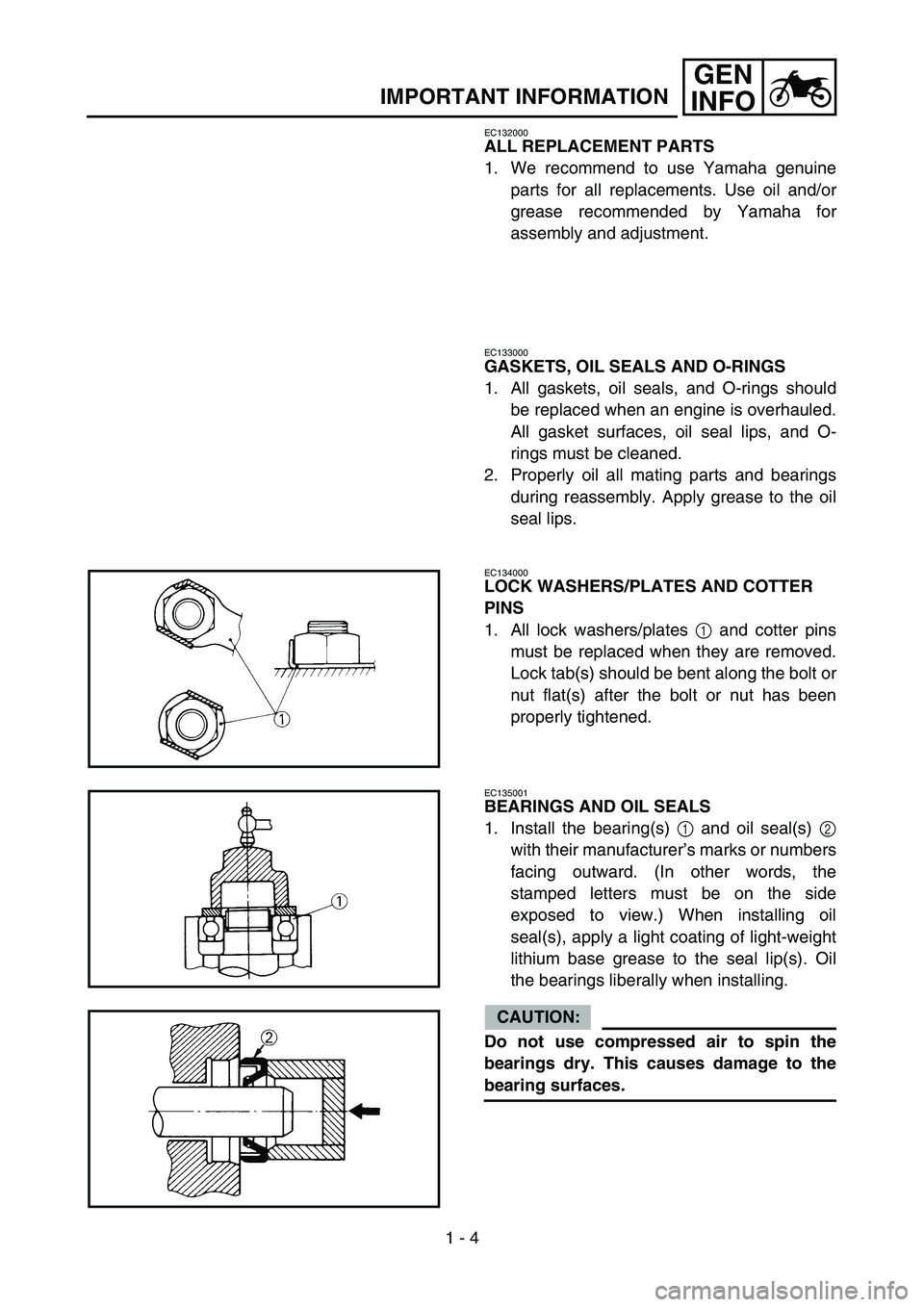

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

Page 39 of 646

GEN

INFO

1 - 8

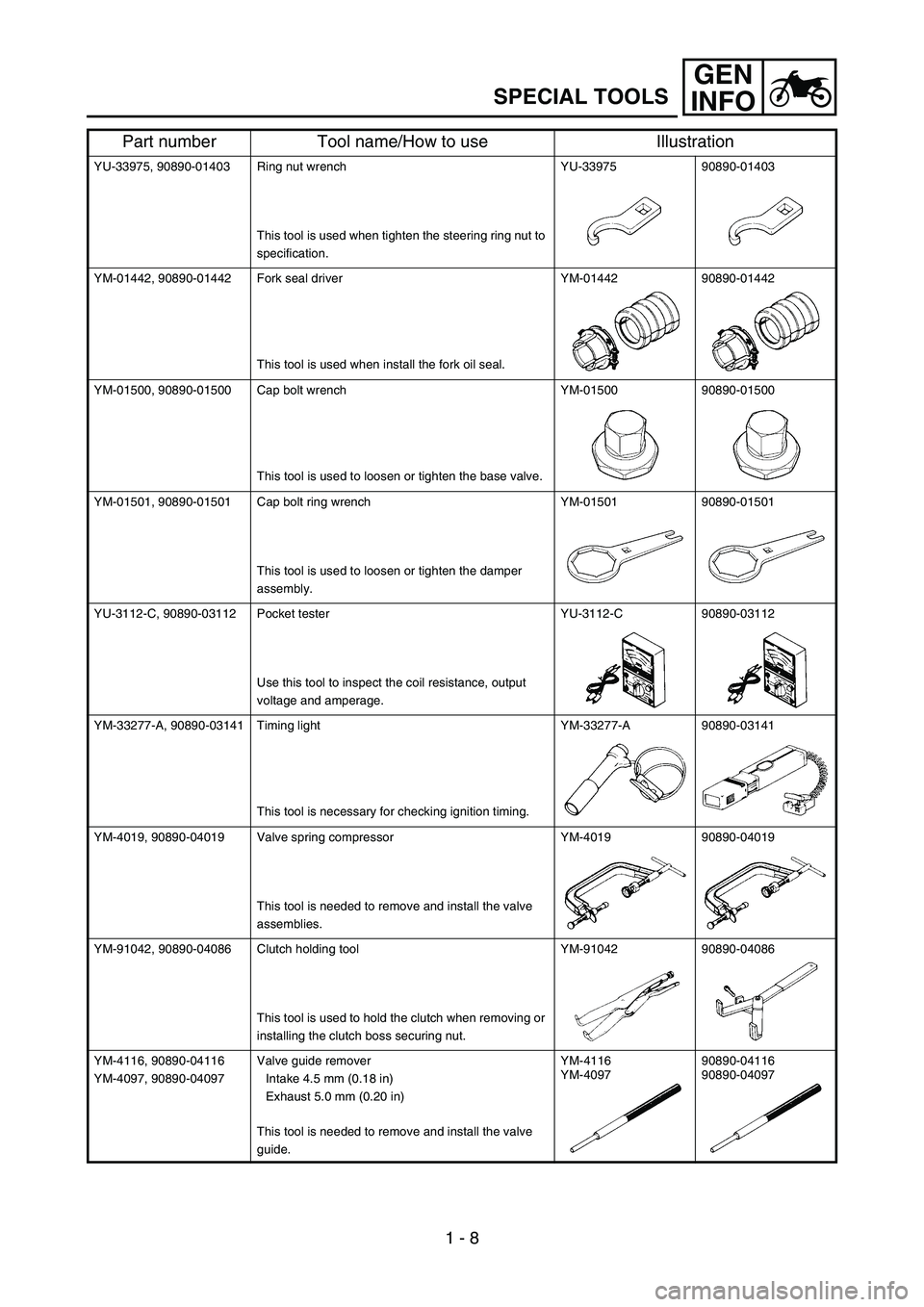

SPECIAL TOOLS

YU-33975, 90890-01403 Ring nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.YM-01442 90890-01442

YM-01500, 90890-01500 Cap bolt wrench

This tool is used to loosen or tighten the base valve.YM-01500 90890-01500

YM-01501, 90890-01501 Cap bolt ring wrench

This tool is used to loosen or tighten the damper

assembly.YM-01501 90890-01501

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-4019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-4019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4116, 90890-04116

YM-4097, 90890-04097Valve guide remover

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to remove and install the valve

guide.YM-4116

YM-409790890-04116

90890-04097

Part number Tool name/How to use Illustration

Page 48 of 646

1 - 10

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

EC151000

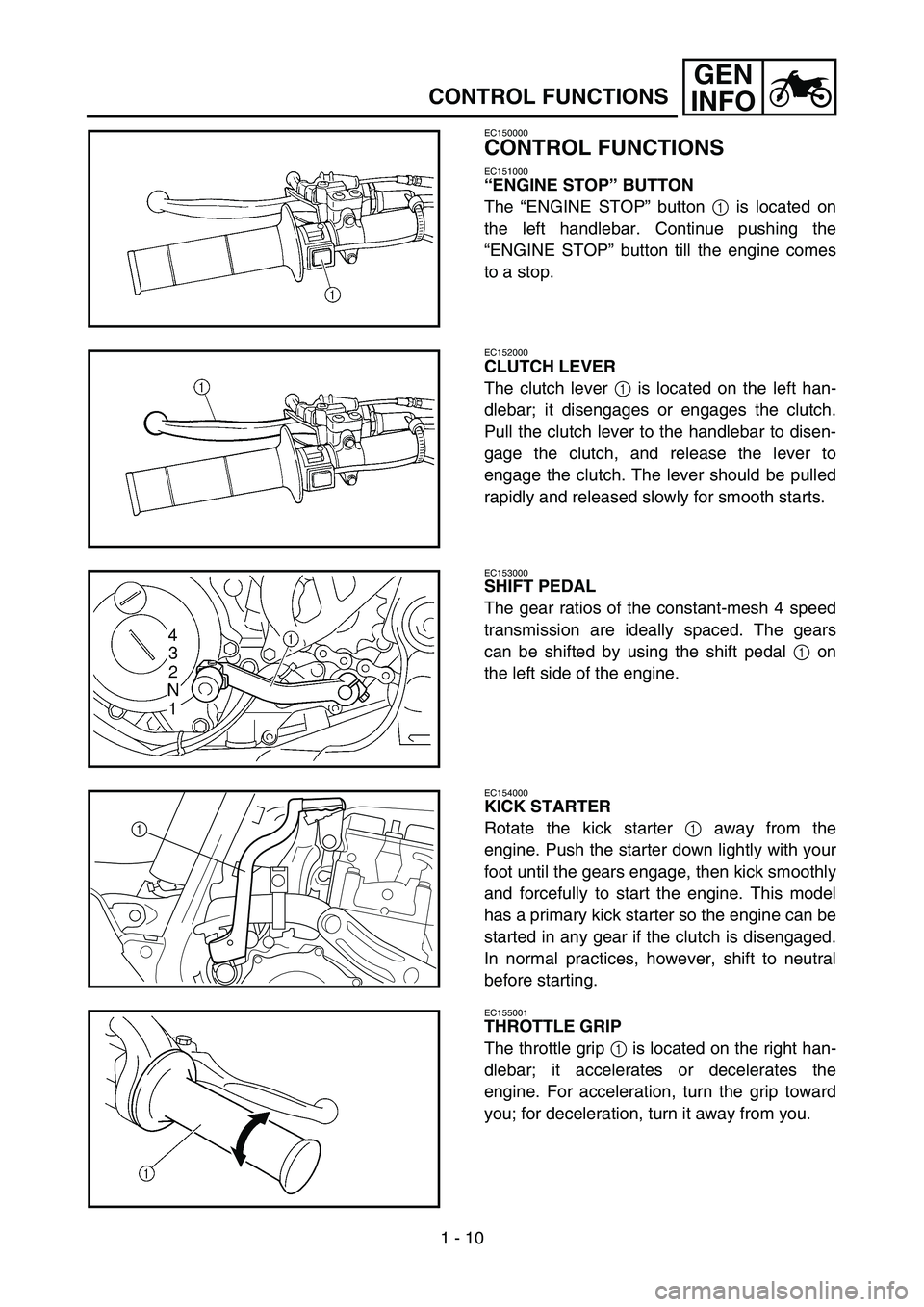

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disen-

gage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 4 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC154000

KICK STARTER

Rotate the kick starter 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kick starter so the engine can be

started in any gear if the clutch is disengaged.

In normal practices, however, shift to neutral

before starting.

1

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

Page 70 of 646

1 - 20

GEN

INFO

CLEANING AND STORAGE

8. Automotive wax may be applied to all

painted or chromed surfaces. Avoid combi-

nation cleaner-waxes, as they may contain

abrasives.

9. After completing the above, start the

engine and allow it to idle for several min-

utes.

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 138 of 646

2 - 25

SPECCABLE ROUTING DIAGRAM

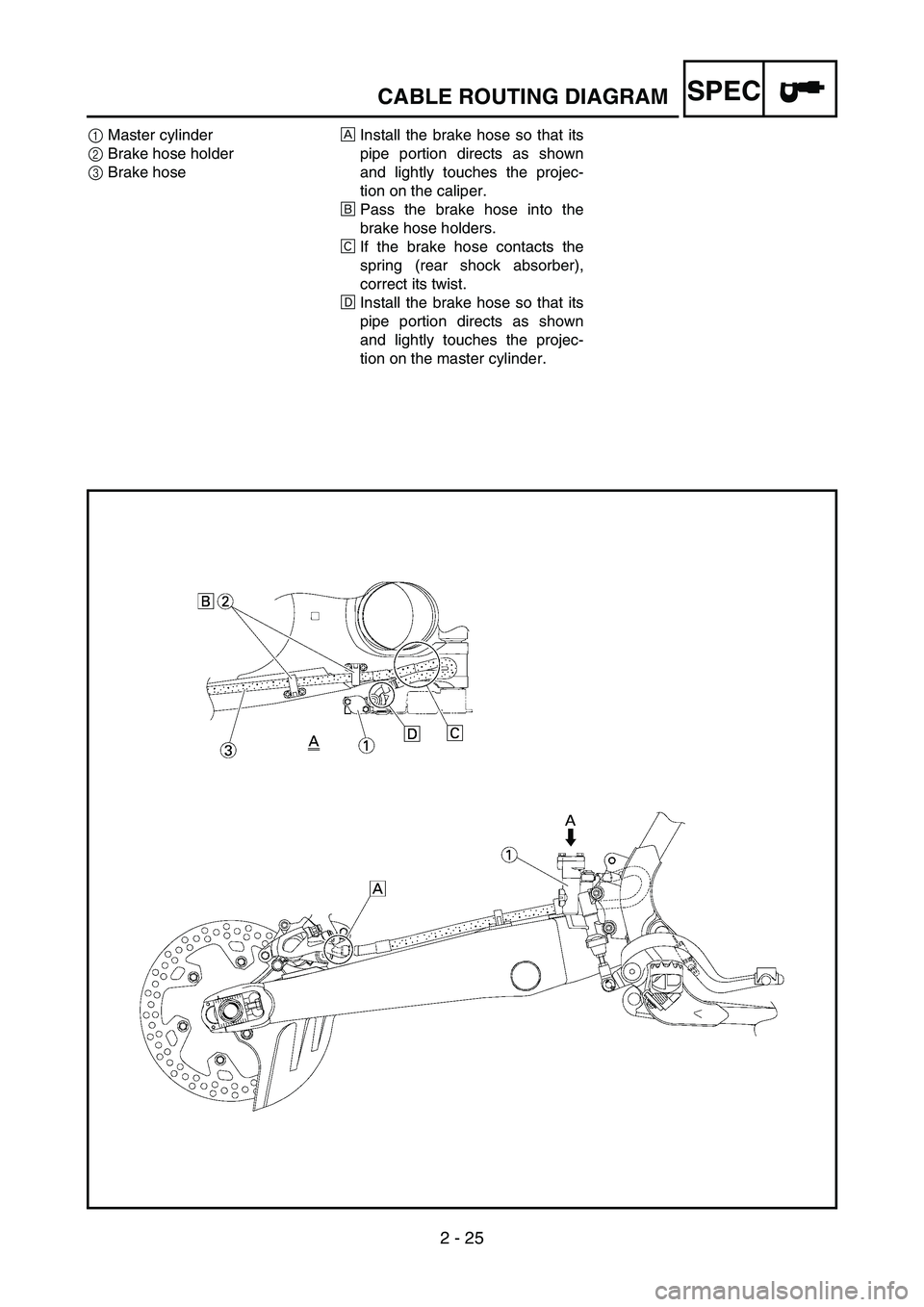

1Master cylinder

2Brake hose holder

3Brake hoseÈInstall the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the caliper.

ÉPass the brake hose into the

brake hose holders.

ÊIf the brake hose contacts the

spring (rear shock absorber),

correct its twist.

ËInstall the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the master cylinder.

Page 172 of 646

3 - 14

INSP

ADJ

ENGINE OIL LEVEL INSPECTION

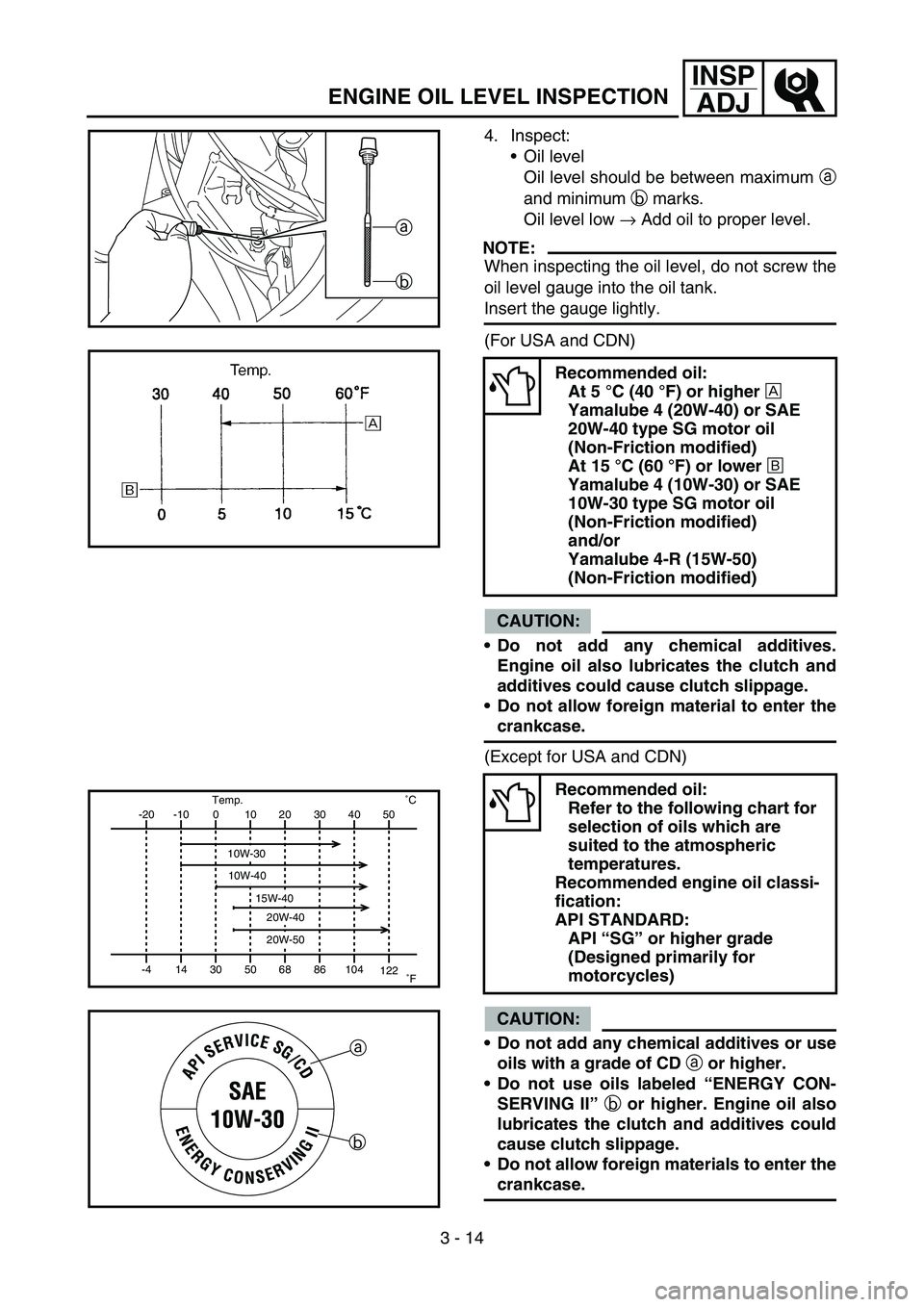

4. Inspect:

Oil level

Oil level should be between maximum a

and minimum b marks.

Oil level low → Add oil to proper level.

NOTE:

When inspecting the oil level, do not screw the

oil level gauge into the oil tank.

Insert the gauge lightly.

(For USA and CDN)

CAUTION:

Do not add any chemical additives.

Engine oil also lubricates the clutch and

additives could cause clutch slippage.

Do not allow foreign material to enter the

crankcase.

(Except for USA and CDN)

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD

a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II”

b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

Recommended oil:

At 5 °C (40 °F) or higher

È

Yamalube 4 (20W-40) or SAE

20W-40 type SG motor oil

(Non-Friction modified)

At 15 °C (60 °F) or lower

É

Yamalube 4 (10W-30) or SAE

10W-30 type SG motor oil

(Non-Friction modified)

and/or

Yamalube 4-R (15W-50)

(Non-Friction modified)

Recommended oil:

Refer to the following chart for

selection of oils which are

suited to the atmospheric

temperatures.

Recommended engine oil classi-

fication:

API STANDARD:

API “SG” or higher grade

(Designed primarily for

motorcycles)

a

b

-20

-4-10

140

3010

5020

6830

8640 50

104

122 ˚CTemp.

˚F

10W-30

10W-40

20W-40

20W-50

15W-40

a

b

Page 178 of 646

3 - 17

INSP

ADJ

PILOT SCREW ADJUSTMENT

10. Install:

Oil filler plug

11. Inspect:

Engine (for oil leaks)

Oil level

Refer to “ENGINE OIL LEVEL INSPEC-

TION”.

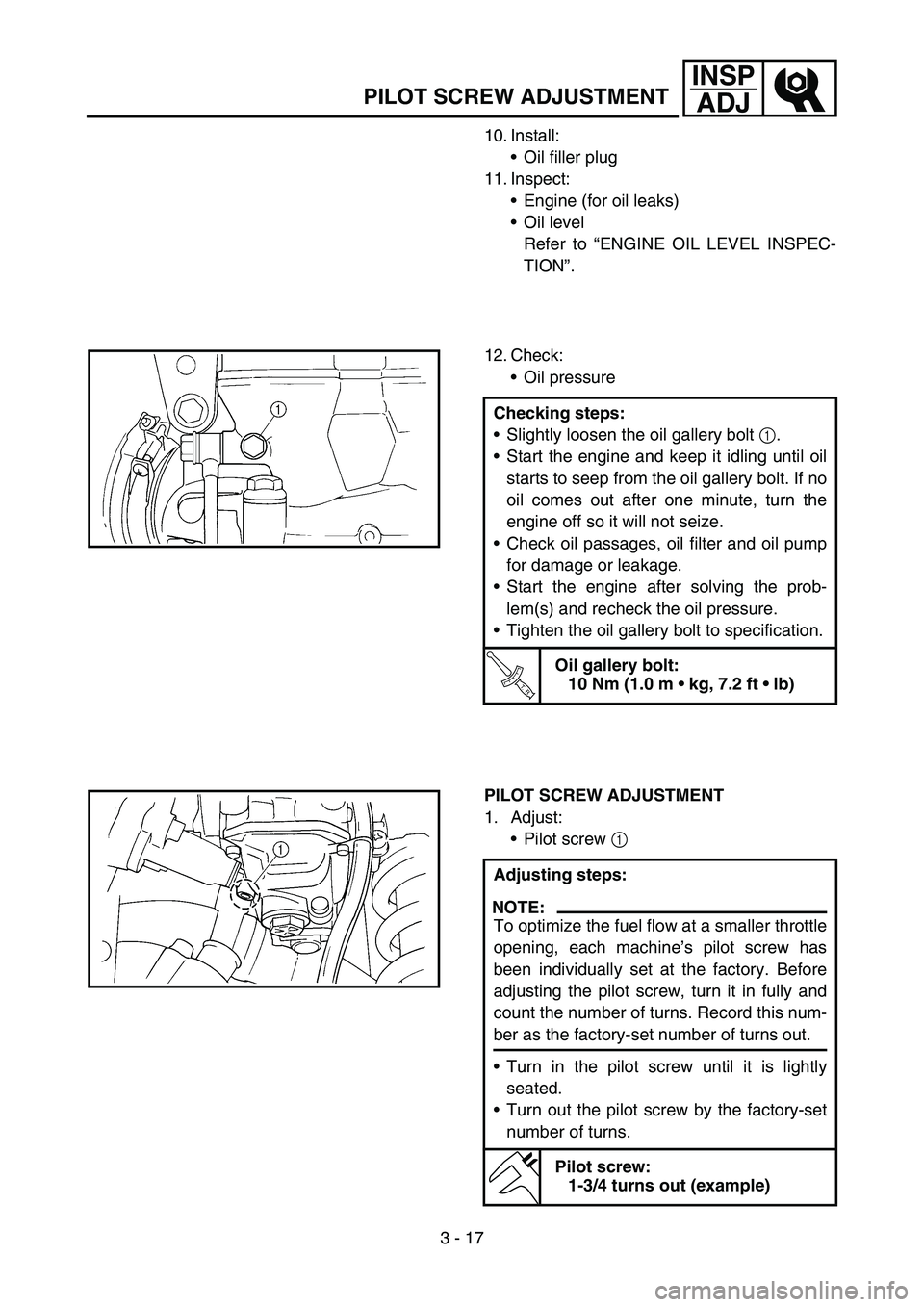

12. Check:

Oil pressure

Checking steps:

Slightly loosen the oil gallery bolt 1.

Start the engine and keep it idling until oil

starts to seep from the oil gallery bolt. If no

oil comes out after one minute, turn the

engine off so it will not seize.

Check oil passages, oil filter and oil pump

for damage or leakage.

Start the engine after solving the prob-

lem(s) and recheck the oil pressure.

Tighten the oil gallery bolt to specification.

T R..

Oil gallery bolt:

10 Nm (1.0 m kg, 7.2 ft lb)

PILOT SCREW ADJUSTMENT

1. Adjust:

Pilot screw 1

Adjusting steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this num-

ber as the factory-set number of turns out.

Turn in the pilot screw until it is lightly

seated.

Turn out the pilot screw by the factory-set

number of turns.

Pilot screw:

1-3/4 turns out (example)

Page 236 of 646

3 - 45

INSP

ADJ

LUBRICATION

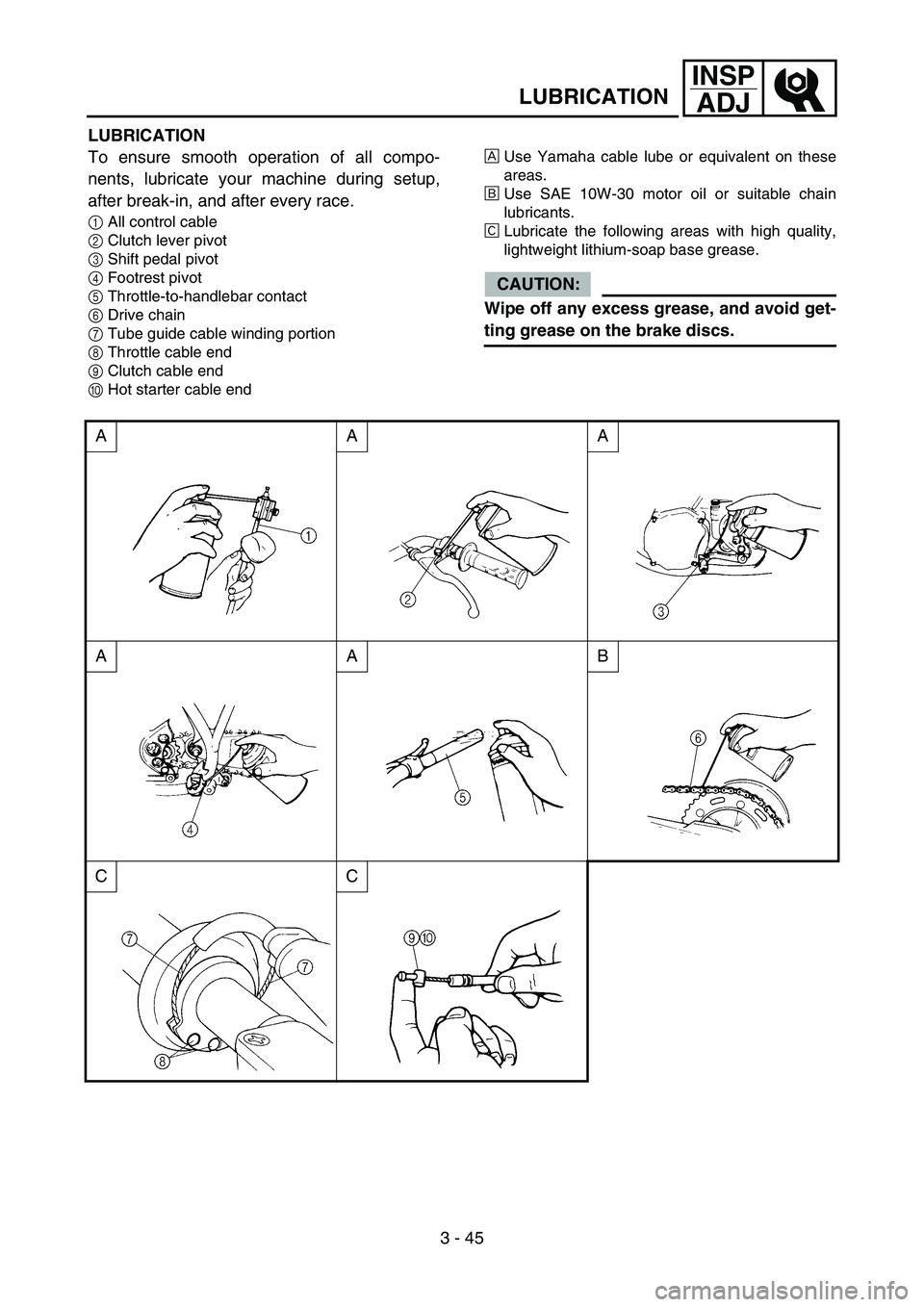

LUBRICATION

To ensure smooth operation of all compo-

nents, lubricate your machine during setup,

after break-in, and after every race.

1All control cable

2Clutch lever pivot

3Shift pedal pivot

4Footrest pivot

5Throttle-to-handlebar contact

6Drive chain

7Tube guide cable winding portion

8Throttle cable end

9Clutch cable end

0Hot starter cable endÈUse Yamaha cable lube or equivalent on these

areas.

ÉUse SAE 10W-30 motor oil or suitable chain

lubricants.

ÊLubricate the following areas with high quality,

lightweight lithium-soap base grease.

CAUTION:

Wipe off any excess grease, and avoid get-

ting grease on the brake discs.

AAA

AAB

CC