stop start YAMAHA YZ450F 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ450F, Model: YAMAHA YZ450F 2006Pages: 650, PDF Size: 20.71 MB

Page 83 of 650

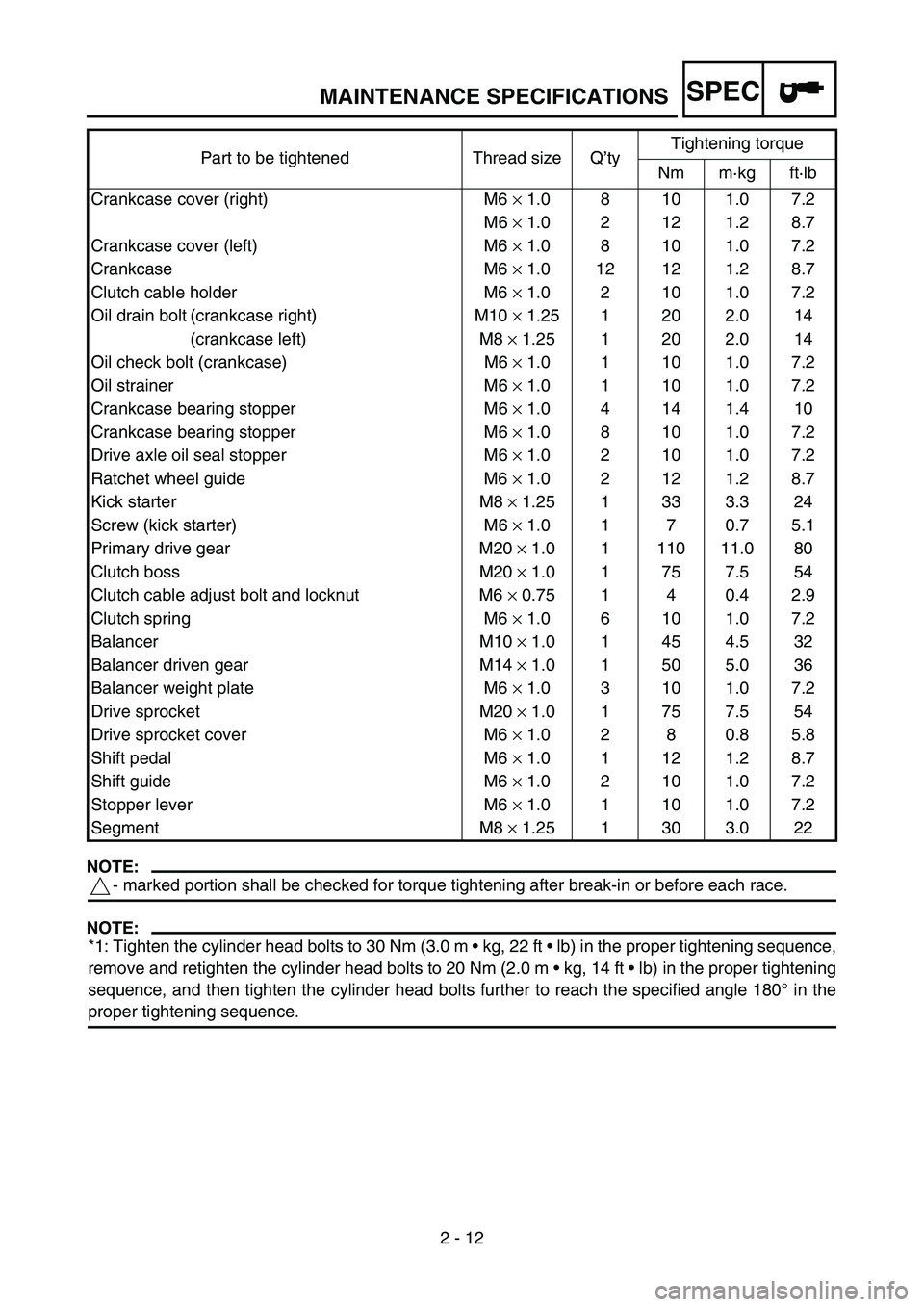

SPEC

2 - 12

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

NOTE:

*1: Tighten the cylinder head bolts to 30 Nm (3.0 m kg, 22 ft lb) in the proper tightening sequence,

remove and retighten the cylinder head bolts to 20 Nm (2.0 m kg, 14 ft lb) in the proper tightening

sequence, and then tighten the cylinder head bolts further to reach the specified angle 180° in the

proper tightening sequence.Crankcase cover (right) M6 × 1.0 8 10 1.0 7.2

M6 × 1.0 2 12 1.2 8.7

Crankcase cover (left) M6 × 1.0 8 10 1.0 7.2

Crankcase M6 × 1.0 12 12 1.2 8.7

Clutch cable holder M6 × 1.0 2 10 1.0 7.2

Oil drain bolt (crankcase right) M10 × 1.25 1 20 2.0 14

(crankcase left) M8 × 1.25 1 20 2.0 14

Oil check bolt (crankcase) M6 × 1.0 1 10 1.0 7.2

Oil strainer M6 × 1.0 1 10 1.0 7.2

Crankcase bearing stopper M6 × 1.0 4 14 1.4 10

Crankcase bearing stopper M6 × 1.0 8 10 1.0 7.2

Drive axle oil seal stopper M6 × 1.0 2 10 1.0 7.2

Ratchet wheel guide M6 × 1.0 2 12 1.2 8.7

Kick starter M8 × 1.25 1 33 3.3 24

Screw (kick starter) M6 × 1.0 1 7 0.7 5.1

Primary drive gear M20 × 1.0 1 110 11.0 80

Clutch boss M20 × 1.0 1 75 7.5 54

Clutch cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Clutch spring M6 × 1.0 6 10 1.0 7.2

Balancer M10 × 1.0 1 45 4.5 32

Balancer driven gear M14 × 1.0 1 50 5.0 36

Balancer weight plate M6 × 1.0 3 10 1.0 7.2

Drive sprocket M20 × 1.0 1 75 7.5 54

Drive sprocket cover M6 × 1.0 2 8 0.8 5.8

Shift pedal M6 × 1.0 1 12 1.2 8.7

Shift guide M6 × 1.0 2 10 1.0 7.2

Stopper lever M6 × 1.0 1 10 1.0 7.2

Segment M8 × 1.25 1 30 3.0 22 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

MAINTENANCE SPECIFICATIONS

Page 132 of 650

2 - 22

SPECCABLE ROUTING DIAGRAM

1Hot starter cable

2Clamp

3TPS (throttle position sensor)

lead

4Hump (frame)

5Neutral switch lead

6Engine bracket

7Engine skid plate stay

8CDI magneto lead

9Clutch cable

0Radiator breather hose

ARadiator hose 2

B“ENGINE STOP” button leadCSub wire harness

DGround lead

ECDI unit bracket

FCDI unit

GCable guide

HIgnition coil lead

IThrottle cable

ÈFasten the hot starter cable and

throttle cables onto the frame.

Locate the clamp ends under

the hot starter cable.ÉFasten the hot starter cable,

throttle cables, TPS lead and

ignition coil lead to the frame.

ÊFasten the TPS lead to the

frame behind its hump.

ËPass the TPS lead over the hot

starter cable.

ÌPass the neutral switch lead on

the inside of the engine bracket.

ÍPass the neutral switch lead

over the engine skid plate stay.

C-C

G-G

E

2

Õ

4 58E

É

D GGA

AB

D

5

ÌÍ Í

Í Î

F

E

D

2

2

2

Ï Ð Ò

Ñ Ó

1

G

2

3

4 2

0

8

5

9

8Ë Ê

0

0 8 5

CC

B

È 2

9

FF

Ô

Ô

B-B

A-A

I

H

3

1

C

B

A

0

0

8

5

D-D

3 F-F

6

7

2 5 0

Page 133 of 650

2 - 22

SPEC

1Warmstartzug

2Klemme

3Drosselklappensensor-Kabel

4Buckel (Rahmen)

5Leerlaufschalter-Kabel

6Motorhalterung

7Motorschutzhalterung

8Lichtmaschinen-Kabel

9Kupplungszug

0Kühler-Entlüftungsschlauch

AKühlerschlauch 2

BKabel des Motorstoppschalters “ENGINE STOP”

CNebenkabelbaum

DMassekabel

EZündbox-Halterung

FZündbox

GKabelführung

HZündspulenkabel

IGaszug

ÈDen Warmstartzug und die Gaszüge am Rah-

men befestigen. Die Klemmen-Enden müssen

sich unter dem Warmstartzug befinden.

ÉDen Warmstartzug, die Gaszüge, das Drossel-

klappensensor-Kabel und das Zündspulen-

Kabel am Rahmen befestigen.

ÊDas Drosselklappensensor-Kabel nach der Wöl-

bung am Rahmen befestigen.

ËDas Drosselklappensensor-Kabel über den

Warmstartzug führen.

ÌDas Leerlaufschalter-Kabel hinter die Motorhal-

terung führen.

ÍDas Leerlaufschalter-Kabel über die Motor-

schutzhalterung führen.

DIAGRAMME D’ACHEMINEMENT DES CABLES

KABELFÜHRUNGSDIAGRAMME

1Câble de starter à chaud

2Collier à pince

3Fil du capteur de position de papillon des gaz

4Bosse (cadre)

5Fil du contacteur de point mort

6Support de moteur

7Support de la plaque de protection du moteur

8Fil du volant magnétique C.D.I.

9Câble d’embrayage

0Durit de mise à l’air du radiateur

ADurit de radiateur 2

BFil du bouton “ENGINE STOP”

CFaisceau de fils secondaire

DFil de terre

ESupport de boîtier CDI

FBoîtier C.D.I.

GGuide-câble

HFil de la bobine d’allumage

ICâble des gaz

ÈFixer le câble de démarrage à chaud et les câbles des

gaz au cadre. Placer les extrémités du collier à pince

sous le câble de démarrage à chaud.

ÉAttacher le câble de starter à chaud, les câbles des

gaz, le fil du capteur de position de papillon des gaz

et le fil de la bobine d’allumage au cadre.

ÊFixer le câble du capteur de position de papillon des

gaz derrière la bosse du cadre.

ËAcheminer le câble du capteur de position de papillon

des gaz au-dessus du câble de starter à chaud.

ÌAcheminer le fil du contacteur de point mort à l’inté-

rieur du support de moteur.

ÍAcheminer le fil du contacteur de point mort au-des-

sus du support de la plaque de protection.

Page 140 of 650

2 - 26

SPECCABLE ROUTING DIAGRAM

1Throttle cable

2Clamp

3Hot starter cable

4Clutch cable

5“ENGINE STOP” button lead

6Cable guide

7Brake hose

8Hose guideÈFasten the “ENGINE STOP” button lead to the

handlebar.

ÉPass the clutch cable and hot starter cable

through the cable guide.

ÊPass the brake hose in front of the number plate.

ËPass the throttle cables through the cable guide.

ÌPass the clutch cable and hot starter cable

through the cable guide on the number plate.

A

B

C

A

B

C40˚± 10˚

40˚± 10˚

2

È3

2

5

4

2

3

5

6

Ë1

4

5

7

Ê

6

É

Ì

8

Page 141 of 650

2 - 26

SPEC

1Gaszug

2Klemme

3Warmstartzug

4Kupplungszug

5Kabel des Motorstoppschalters “ENGINE STOP”

6Kabelführung

7Bremsschlauch

8Schlauchführung

ÈDas Kabel des Motorstoppschalters “ENGINE

STOP” am Lenker befestigen.

ÉDen Kupplungszug und den Warmstartzug

durch die Kabelführung führen.

ÊDen Bremsschlauch an der Vorderseite des

Nummernschildes entlang führen.

ËDie Gaszüge durch die Führung leiten.

ÌDen Kupplungszug und den Warmstartzug

durch die Kabelführung am Nummernschild füh-

ren.

DIAGRAMME D’ACHEMINEMENT DES CABLES

KABELFÜHRUNGSDIAGRAMME

1Câble des gaz

2Collier à pince

3Câble de starter à chaud

4Câble d’embrayage

5Fil du bouton “ENGINE STOP”

6Guide-câble

7Durit de frein

8Guide de durit

ÈFixer le fil du bouton “ENGINE STOP” au guidon.

ÉAcheminer le câble d’embrayage et le câble de starter

à chaud dans le guide-câble.

ÊAcheminer la durit de frein devant la plaque d’identi-

fication.

ËAcheminer les câbles des gaz dans le guide-câble.

ÌAcheminer le câble d’embrayage et le câble de starter

à chaud dans le guide-câble sur la plaque d’identifica-

tion.

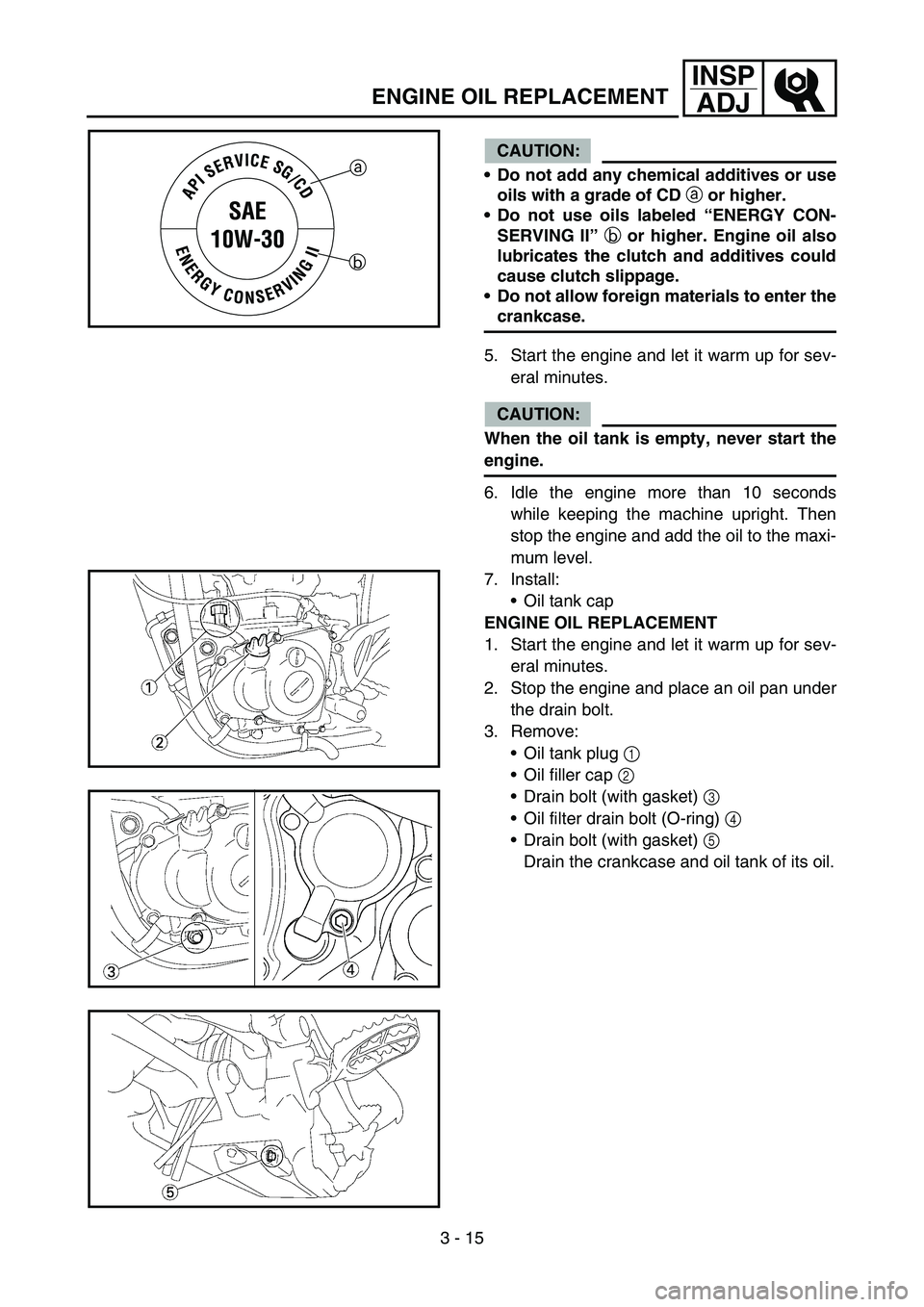

Page 174 of 650

3 - 15

INSP

ADJ

ENGINE OIL REPLACEMENT

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD

a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II”

b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

a

b

5. Start the engine and let it warm up for sev-

eral minutes.

CAUTION:

When the oil tank is empty, never start the

engine.

6. Idle the engine more than 10 seconds

while keeping the machine upright. Then

stop the engine and add the oil to the maxi-

mum level.

7. Install:

Oil tank cap

ENGINE OIL REPLACEMENT

1. Start the engine and let it warm up for sev-

eral minutes.

2. Stop the engine and place an oil pan under

the drain bolt.

3. Remove:

Oil tank plug 1

Oil filler cap 2

Drain bolt (with gasket) 3

Oil filter drain bolt (O-ring) 4

Drain bolt (with gasket) 5

Drain the crankcase and oil tank of its oil.

Page 180 of 650

3 - 18

INSP

ADJIDLE SPEED ADJUSTMENT/

VALVE CLEARANCE ADJUSTMENT

EC35M021

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

Idle speed

VALVE CLEARANCE ADJUSTMENT

NOTE:

The valve clearance should be adjusted

when the engine is cool to the touch.

The piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

Seat

Fuel tank

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

2. Remove:

Spark plug

Engine upper bracket

Hot starter plunger

Refer to “CARBURETOR” section in the

CHAPTER 4.

Cylinder head cover

Refer to “CAMSHAFTS” section in the

CHAPTER 4. Adjustment steps:

Adjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

Turn the throttle stop screw 1 until the

specified engine idling speed.

NOTE:

Using a digital engine tachometer for idle

speed adjustment, detect the engine idling

speed by bringing the sensing element c of

the engine tachometer close to the ignition

coil 2.

To increase idle speed

→

Turn the throttle stop screw

1 in

a.

To decrease idle speed

→

Turn the throttle stop screw

1 out

b.

Engine idling speed:

1,900 ~ 2,100 r/min

c2

Page 267 of 650

4 - 13

ENG

2. Kontrollieren:

Hauptdüse 1

Leerlaufdüse 2

Nadeldüse 3

Chokedüse 4

Leerlauf-Luftdüse 5

Ausströmdüse 6

Beschädigt → Erneuern.

Verunreinigt → Reinigen.

HINWEIS:

Zum Reinigen ein Lösungsmittel auf Petro-

leumbasis verwenden. Sämtliche Kanäle und

Düsen mit Druckluft ausblasen.

Niemals einen Draht verwenden.

Nadelventil

1. Kontrollieren:

Nadelventil 1

Ventilsitz 2

Riefig a → Erneuern.

Verstaubt b → Reinigen.

Filter c

Verstopft → Reinigen.

Drosselklappe

1. Kontrollieren:

Leichtgängigkeit

Fest → Instand setzen, ggf. erneuern.

HINWEIS:

Die Drosselklappe 1 in das Vergasergehäuse

einsetzen und deren Leichtgängigkeit kontrol-

lieren.

Düsennadel

1. Kontrollieren:

Düsennadel 1

Verbogen/verschlissen → Erneuern.

Clip-Nut

Spiel vorhanden/verschlissen → Erneu-

ern.

Clipposition

Standard-Clipposition:

4. Nut

CARBURATEUR

VERGASER

2. Contrôler:

Gicleur principal 1

Gicleur de ralenti 2

Gicleur d’aiguille 3

Gicleur de starter 4

Gicleur d’air de ralenti 5

Gicleur de fuite 6

Endommagement → Remplacer.

Encrassé → Nettoyer.

N.B.:

Nettoyer avec un solvant à base de pétrole. Net-

toyer tous les conduits et gicleurs à l’air com-

primé.

Ne jamais utiliser de fil métallique.

Pointeau

1. Contrôler:

Pointeau 1

Siège de pointeau 2

Usure en creux a → Remplacer.

Poussière b → Nettoyer.

Filtre c

Bouché → Nettoyer.

Papillon des gaz

1. Contrôler:

Mouvement

Coincement → Réparer ou remplacer.

N.B.:

Insérer le papillon des gaz 1 dans le corps du car-

burateur et contrôler qu’il coulisse librement.

Aiguille

1. Contrôler:

Aiguille 1

Déformation/usure → Remplacer.

Rainure du clip

Jeu/usure → Remplacer.

Position du clip

Position standard du clip:

Rainure n°4

Page 274 of 650

4 - 17

ENGCARBURETOR

8. Install:

Throttle shaft assembly 1

Plain washer (metal) 2

Plain washer (resin) 3

Valve lever 4

NOTE:

Apply the fluorochemical grease on the bear-

ings.

Fit the projection a on the throttle shaft

assembly into the slot b in the TPS (throttle

position sensor).

Make sure the stopper c of the spring fits

into the recess in the carburetor.

Turn the throttle shaft assembly left while

holding down the lever 1 5 and fit the throt-

tle stop screw tip d to the stopper e of the

throttle shaft assembly pulley.

1

23

4

b

a

c

e

d

5

9. Install:

Push rod 1

NOTE:

While holding down the lever 1 2, insert the

push rod farthest into the carburetor.12

10. Install:

Starter jet 1

Pilot jet 2

Spacer 3

Needle jet 4

Main jet 5

Page 524 of 650

5 - 43

CHAS

EC5B0000

HANDLEBAR

Extent of removal:

1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

HANDLEBAR REMOVAL

Preparation for removal Number plate Remove the band only.

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5“ENGINE STOP” button 1

6 Master cylinder 1 Refer to “REMOVAL POINTS”.

7 Throttle cable cap 1

8 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Grip (right) 1 Refer to “REMOVAL POINTS”.

11 Tube guide 1

12 Collar 1

13 Grip (left) 1 Refer to “REMOVAL POINTS”.

14 Handlebar holder (upper) 2

15 Handlebar 1

16 Handlebar holder (lower) 2

1

HANDLEBAR