bolt pattern YAMAHA YZ450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ450F, Model: YAMAHA YZ450F 2008Pages: 188, PDF Size: 11.75 MB

Page 84 of 188

4-16

CAMSHAFTS

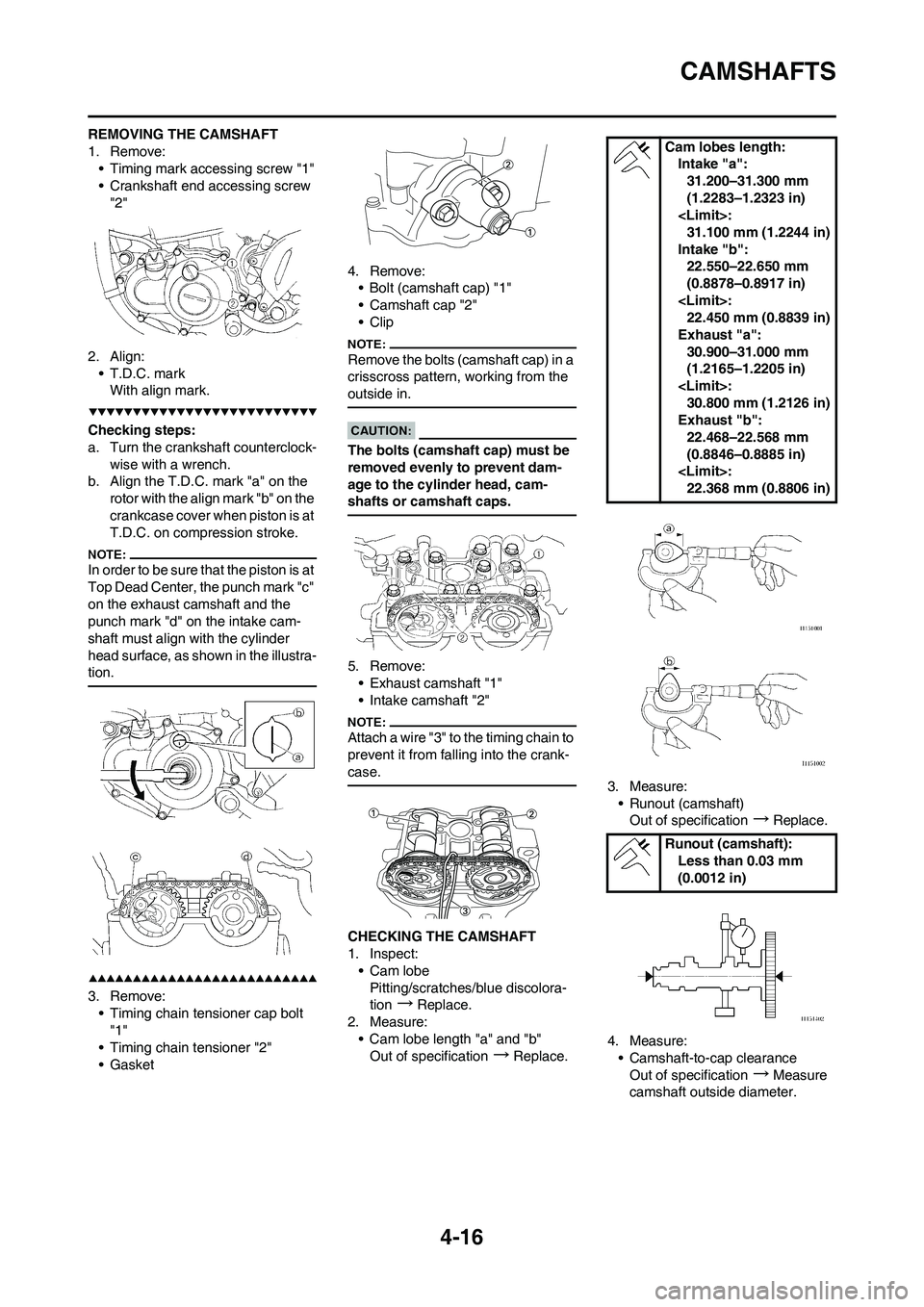

REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

2. Align:

• T.D.C. mark

With align mark.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

3. Remove:

• Timing chain tensioner cap bolt

"1"

• Timing chain tensioner "2"

• Gasket4. Remove:

• Bolt (camshaft cap) "1"

• Camshaft cap "2"

• Clip

Remove the bolts (camshaft cap) in a

crisscross pattern, working from the

outside in.

The bolts (camshaft cap) must be

removed evenly to prevent dam-

age to the cylinder head, cam-

shafts or camshaft caps.

5. Remove:

• Exhaust camshaft "1"

• Intake camshaft "2"

Attach a wire "3" to the timing chain to

prevent it from falling into the crank-

case.

CHECKING THE CAMSHAFT

1. Inspect:

• Cam lobe

Pitting/scratches/blue discolora-

tion

→Replace.

2. Measure:

• Cam lobe length "a" and "b"

Out of specification

→Replace.3. Measure:

• Runout (camshaft)

Out of specification

→Replace.

4. Measure:

• Camshaft-to-cap clearance

Out of specification

→Measure

camshaft outside diameter.

Cam lobes length:

Intake "a":

31.200–31.300 mm

(1.2283–1.2323 in)

31.100 mm (1.2244 in)

Intake "b":

22.550–22.650 mm

(0.8878–0.8917 in)

22.450 mm (0.8839 in)

Exhaust "a":

30.900–31.000 mm

(1.2165–1.2205 in)

30.800 mm (1.2126 in)

Exhaust "b":

22.468–22.568 mm

(0.8846–0.8885 in)

22.368 mm (0.8806 in)

Runout (camshaft):

Less than 0.03 mm

(0.0012 in)

Page 85 of 188

4-17

CAMSHAFTS

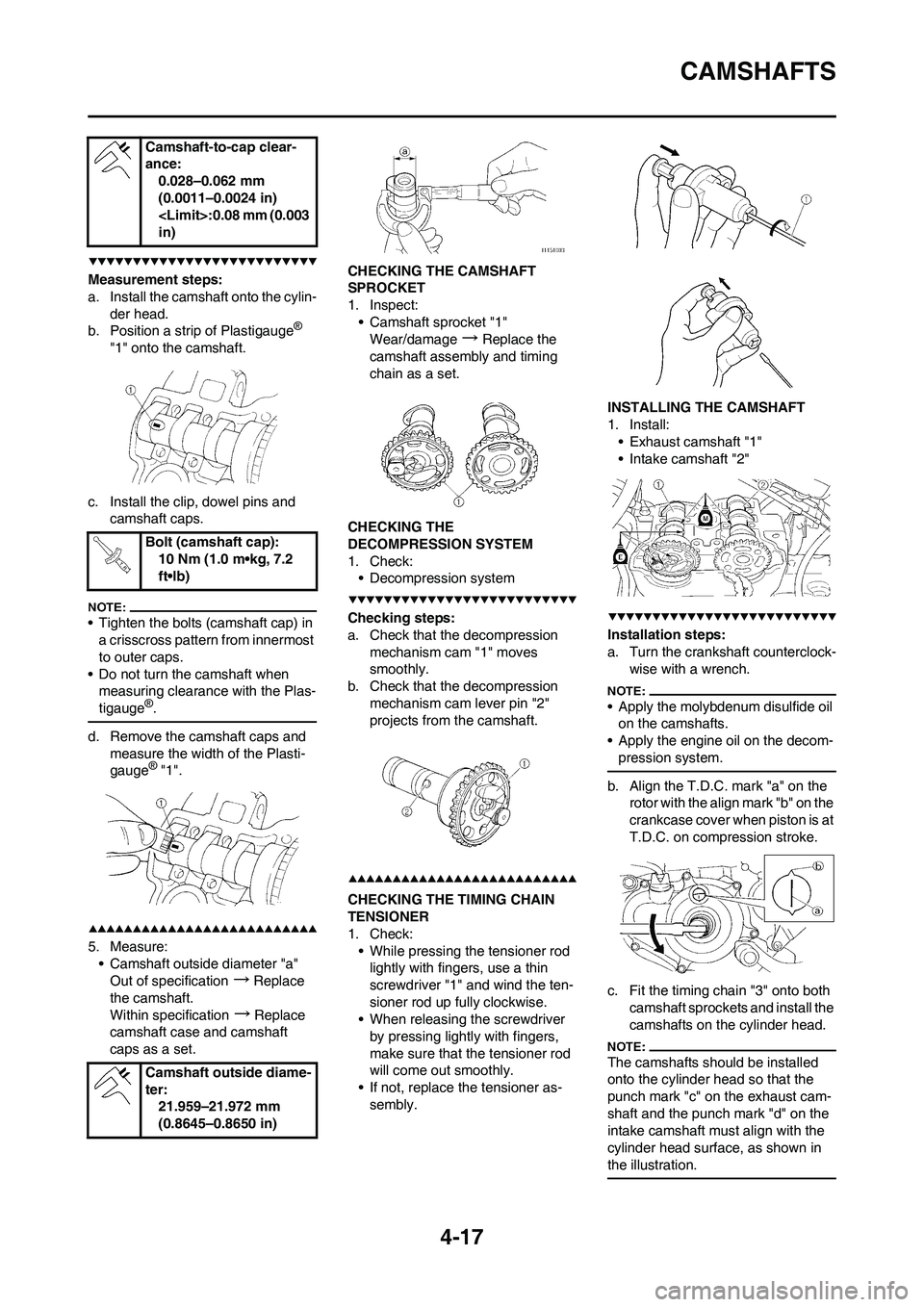

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the Plas-

tigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification

→Replace

the camshaft.

Within specification

→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage

→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2"

projects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head.

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 88 of 188

4-20

CYLINDER HEAD

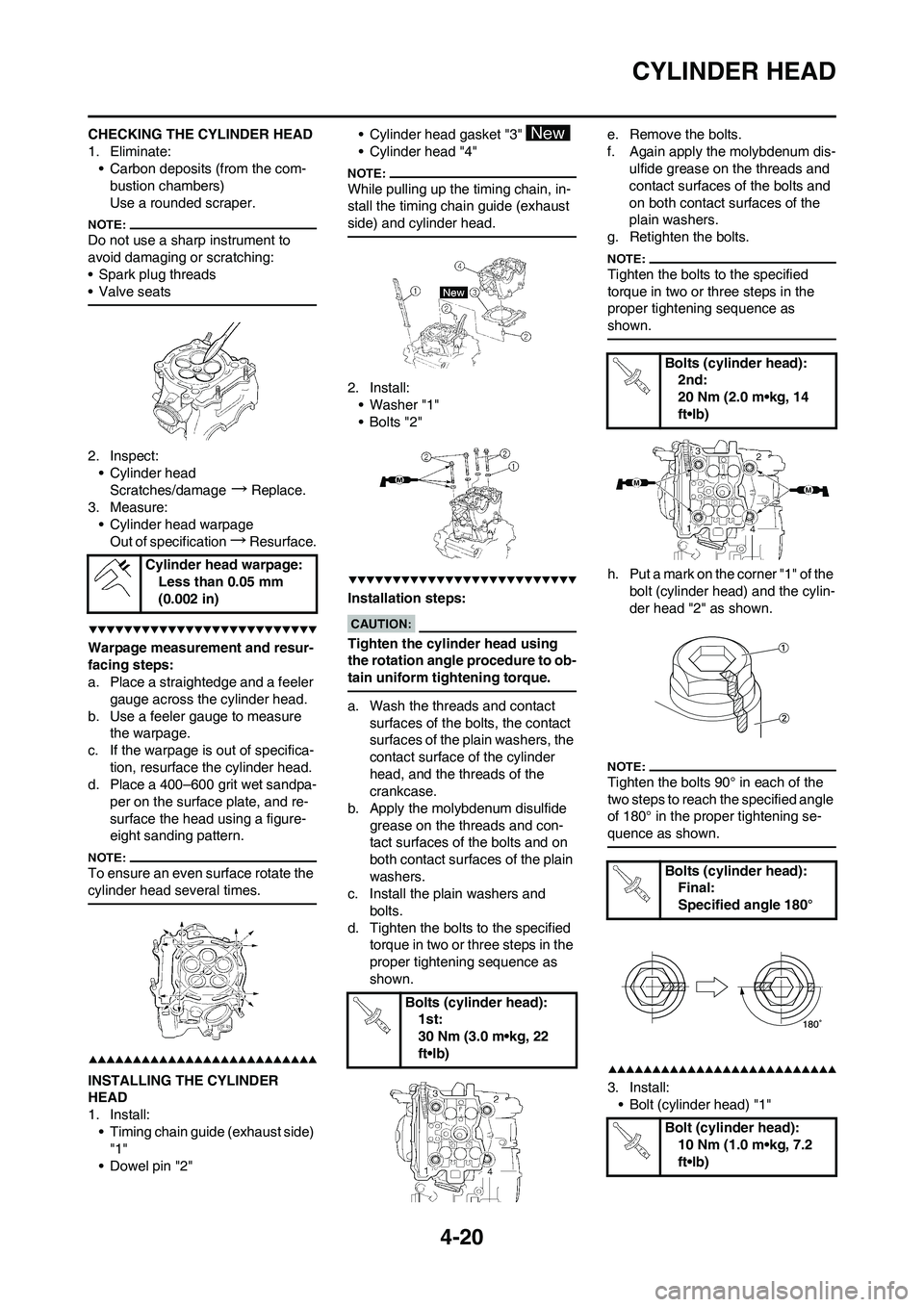

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

• Valve seats

2. Inspect:

• Cylinder head

Scratches/damage

→Replace.

3. Measure:

• Cylinder head warpage

Out of specification

→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Timing chain guide (exhaust side)

"1"

• Dowel pin "2"• Cylinder head gasket "3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

• Washer "1"

• Bolts "2"

Installation steps:

Tighten the cylinder head using

the rotation angle procedure to ob-

tain uniform tightening torque.

a. Wash the threads and contact

surfaces of the bolts, the contact

surfaces of the plain washers, the

contact surface of the cylinder

head, and the threads of the

crankcase.

b. Apply the molybdenum disulfide

grease on the threads and con-

tact surfaces of the bolts and on

both contact surfaces of the plain

washers.

c. Install the plain washers and

bolts.

d. Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.e. Remove the bolts.

f. Again apply the molybdenum dis-

ulfide grease on the threads and

contact surfaces of the bolts and

on both contact surfaces of the

plain washers.

g. Retighten the bolts.

Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.

h. Put a mark on the corner "1" of the

bolt (cylinder head) and the cylin-

der head "2" as shown.

Tighten the bolts 90° in each of the

two steps to reach the specified angle

of 180° in the proper tightening se-

quence as shown.

3. Install:

• Bolt (cylinder head) "1" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts (cylinder head):

1st:

30 Nm (3.0 m•kg, 22

ft•lb)

Bolts (cylinder head):

2nd:

20 Nm (2.0 m•kg, 14

ft•lb)

Bolts (cylinder head):

Final:

Specified angle 180°

Bolt (cylinder head):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 100 of 188

4-32

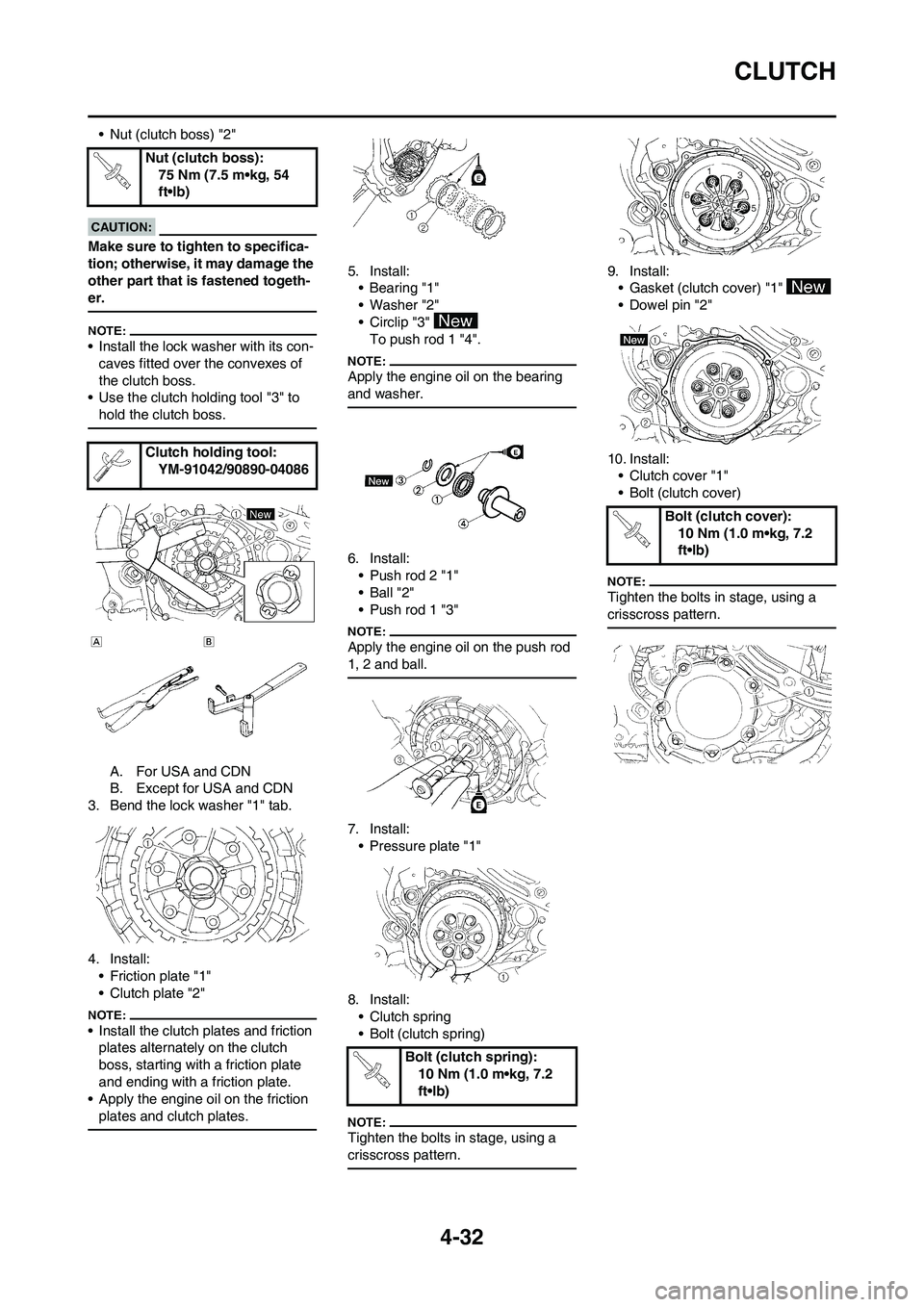

CLUTCH

• Nut (clutch boss) "2"

Make sure to tighten to specifica-

tion; otherwise, it may damage the

other part that is fastened togeth-

er.

• Install the lock washer with its con-

caves fitted over the convexes of

the clutch boss.

• Use the clutch holding tool "3" to

hold the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

3. Bend the lock washer "1" tab.

4. Install:

• Friction plate "1"

• Clutch plate "2"

• Install the clutch plates and friction

plates alternately on the clutch

boss, starting with a friction plate

and ending with a friction plate.

• Apply the engine oil on the friction

plates and clutch plates.

5. Install:

•Bearing "1"

• Washer "2"

• Circlip "3"

To push rod 1 "4".

Apply the engine oil on the bearing

and washer.

6. Install:

• Push rod 2 "1"

• Ball "2"

• Push rod 1 "3"

Apply the engine oil on the push rod

1, 2 and ball.

7. Install:

• Pressure plate "1"

8. Install:

• Clutch spring

• Bolt (clutch spring)

Tighten the bolts in stage, using a

crisscross pattern.

9. Install:

• Gasket (clutch cover) "1"

• Dowel pin "2"

10. Install:

• Clutch cover "1"

• Bolt (clutch cover)

Tighten the bolts in stage, using a

crisscross pattern.

Nut (clutch boss):

75 Nm (7.5 m•kg, 54

ft•lb)

Clutch holding tool:

YM-91042/90890-04086

Bolt (clutch spring):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (clutch cover):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 104 of 188

4-36

OIL FILTER ELEMENT AND WATER PUMP

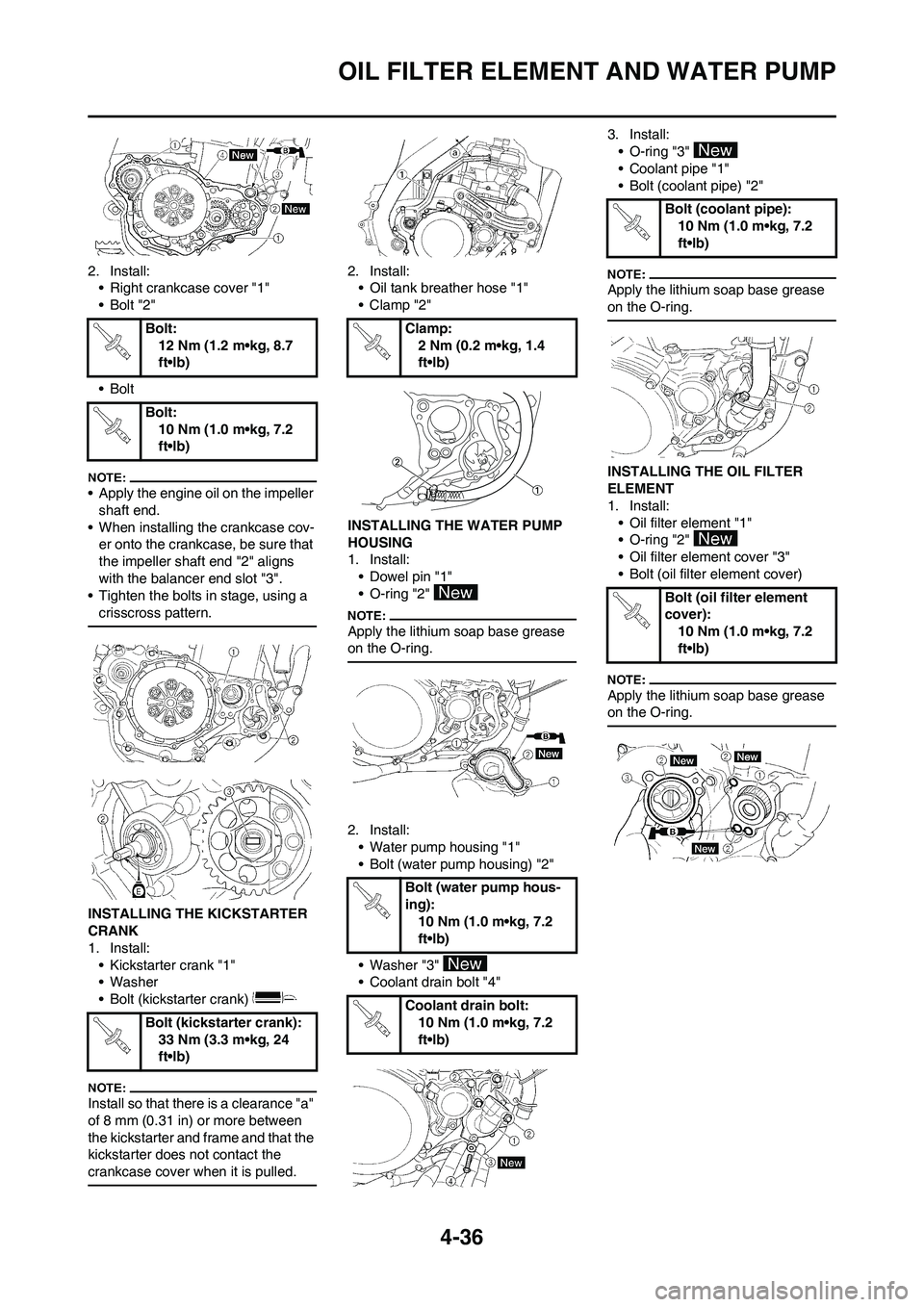

2. Install:

• Right crankcase cover "1"

•Bolt "2"

•Bolt

• Apply the engine oil on the impeller

shaft end.

• When installing the crankcase cov-

er onto the crankcase, be sure that

the impeller shaft end "2" aligns

with the balancer end slot "3".

• Tighten the bolts in stage, using a

crisscross pattern.

INSTALLING THE KICKSTARTER

CRANK

1. Install:

• Kickstarter crank "1"

• Washer

• Bolt (kickstarter crank)

Install so that there is a clearance "a"

of 8 mm (0.31 in) or more between

the kickstarter and frame and that the

kickstarter does not contact the

crankcase cover when it is pulled.

2. Install:

• Oil tank breather hose "1"

•Clamp "2"

INSTALLING THE WATER PUMP

HOUSING

1. Install:

• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Water pump housing "1"

• Bolt (water pump housing) "2"

• Washer "3"

• Coolant drain bolt "4"3. Install:

• O-ring "3"

• Coolant pipe "1"

• Bolt (coolant pipe) "2"

Apply the lithium soap base grease

on the O-ring.

INSTALLING THE OIL FILTER

ELEMENT

1. Install:

• Oil filter element "1"

• O-ring "2"

• Oil filter element cover "3"

• Bolt (oil filter element cover)

Apply the lithium soap base grease

on the O-ring.

Bolt:

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (kickstarter crank):

33 Nm (3.3 m•kg, 24

ft•lb)Clamp:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (water pump hous-

ing):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (coolant pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (oil filter element

cover):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 116 of 188

4-48

CDI MAGNETO

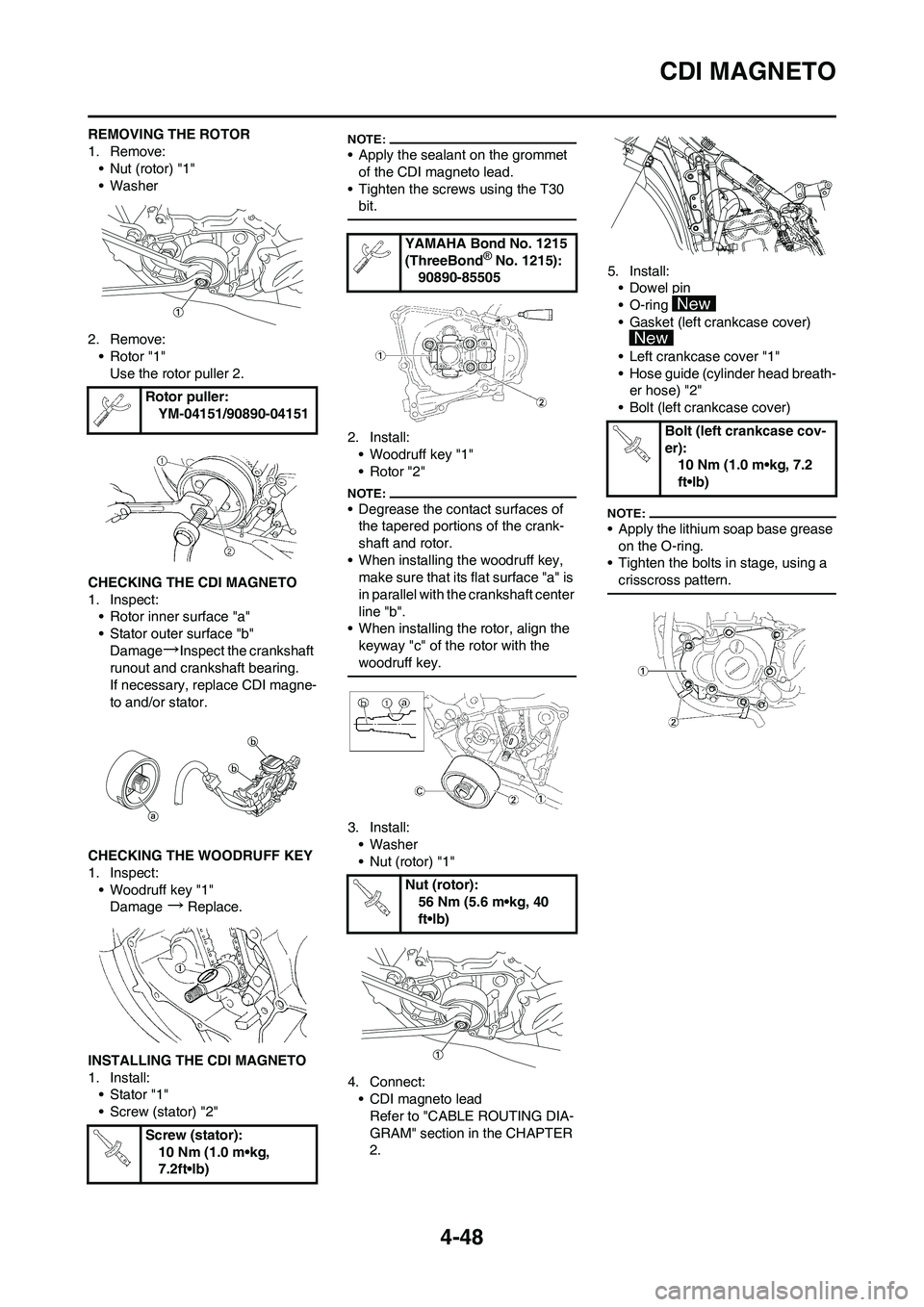

REMOVING THE ROTOR

1. Remove:

• Nut (rotor) "1"

• Washer

2. Remove:

• Rotor "1"

Use the rotor puller 2.

CHECKING THE CDI MAGNETO

1. Inspect:

• Rotor inner surface "a"

• Stator outer surface "b"

Damage

→Inspect the crankshaft

runout and crankshaft bearing.

If necessary, replace CDI magne-

to and/or stator.

CHECKING THE WOODRUFF KEY

1. Inspect:

• Woodruff key "1"

Damage

→Replace.

INSTALLING THE CDI MAGNETO

1. Install:

•Stator "1"

• Screw (stator) "2"

• Apply the sealant on the grommet

of the CDI magneto lead.

• Tighten the screws using the T30

bit.

2. Install:

• Woodruff key "1"

• Rotor "2"

• Degrease the contact surfaces of

the tapered portions of the crank-

shaft and rotor.

• When installing the woodruff key,

make sure that its flat surface "a" is

in parallel with the crankshaft center

line "b".

• When installing the rotor, align the

keyway "c" of the rotor with the

woodruff key.

3. Install:

• Washer

• Nut (rotor) "1"

4. Connect:

• CDI magneto lead

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.5. Install:

• Dowel pin

• O-ring

• Gasket (left crankcase cover)

• Left crankcase cover "1"

• Hose guide (cylinder head breath-

er hose) "2"

• Bolt (left crankcase cover)

• Apply the lithium soap base grease

on the O-ring.

• Tighten the bolts in stage, using a

crisscross pattern.

Rotor puller:

YM-04151/90890-04151

Screw (stator):

10 Nm (1.0 m•kg,

7.2ft•lb)

YAMAHA Bond No. 1215

(ThreeBond® No. 1215):

90890-85505

Nut (rotor):

56 Nm (5.6 m•kg, 40

ft•lb)

Bolt (left crankcase cov-

er):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 133 of 188

5-4

FRONT WHEEL AND REAR WHEEL

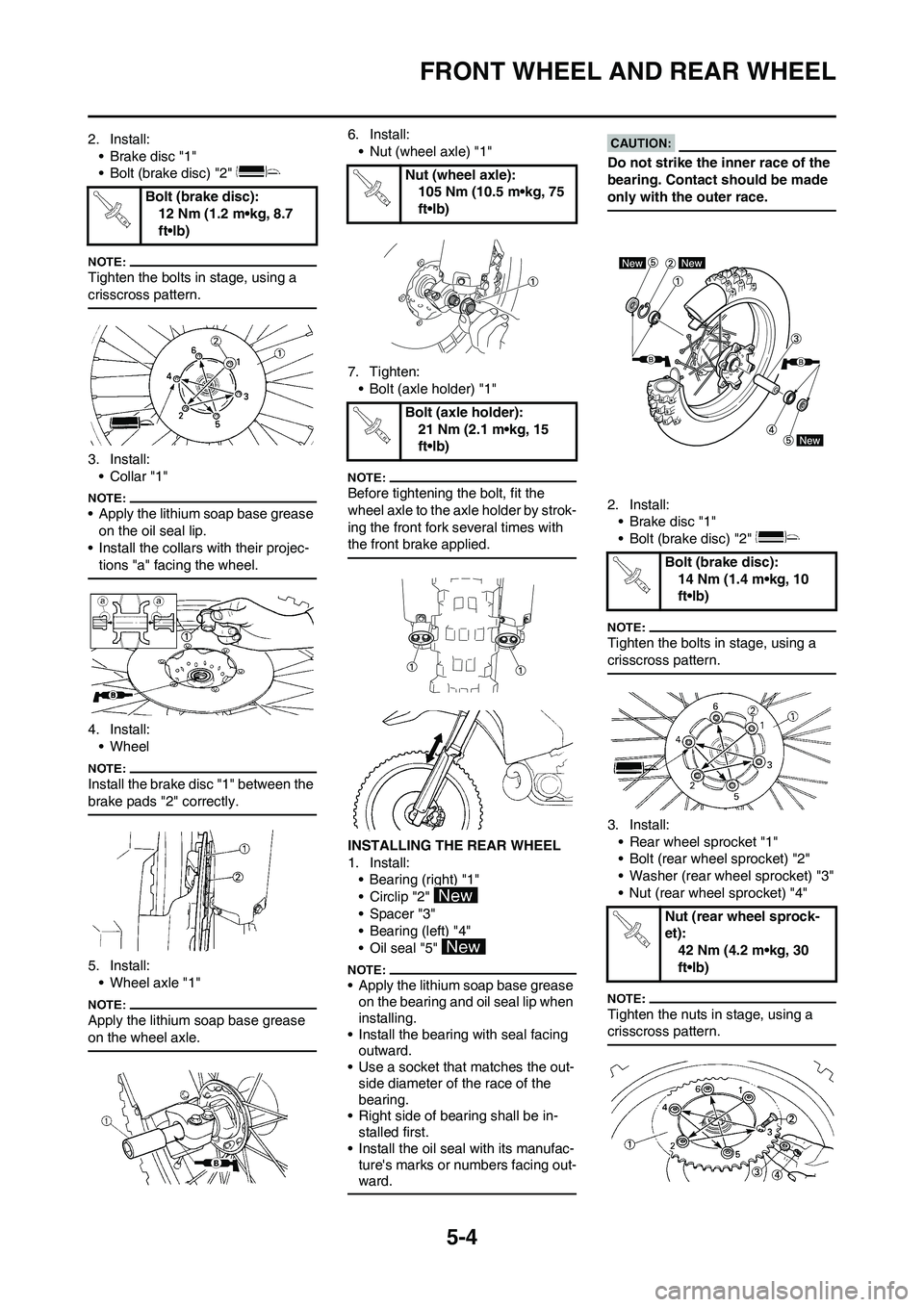

2. Install:

• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:

•Collar "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Install the collars with their projec-

tions "a" facing the wheel.

4. Install:

• Wheel

Install the brake disc "1" between the

brake pads "2" correctly.

5. Install:

• Wheel axle "1"

Apply the lithium soap base grease

on the wheel axle.

6. Install:

• Nut (wheel axle) "1"

7. Tighten:

• Bolt (axle holder) "1"

Before tightening the bolt, fit the

wheel axle to the axle holder by strok-

ing the front fork several times with

the front brake applied.

INSTALLING THE REAR WHEEL

1. Install:

• Bearing (right) "1"

• Circlip "2"

• Spacer "3"

• Bearing (left) "4"

• Oil seal "5"

• Apply the lithium soap base grease

on the bearing and oil seal lip when

installing.

• Install the bearing with seal facing

outward.

• Use a socket that matches the out-

side diameter of the race of the

bearing.

• Right side of bearing shall be in-

stalled first.

• Install the oil seal with its manufac-

ture's marks or numbers facing out-

ward.

Do not strike the inner race of the

bearing. Contact should be made

only with the outer race.

2. Install:

• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:

• Rear wheel sprocket "1"

• Bolt (rear wheel sprocket) "2"

• Washer (rear wheel sprocket) "3"

• Nut (rear wheel sprocket) "4"

Tighten the nuts in stage, using a

crisscross pattern.

Bolt (brake disc):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Nut (wheel axle):

105 Nm (10.5 m•kg, 75

ft•lb)

Bolt (axle holder):

21 Nm (2.1 m•kg, 15

ft•lb)

Bolt (brake disc):

14 Nm (1.4 m•kg, 10

ft•lb)

Nut (rear wheel sprock-

et):

42 Nm (4.2 m•kg, 30

ft•lb)