water pump YAMAHA YZ450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ450F, Model: YAMAHA YZ450F 2008Pages: 188, PDF Size: 11.75 MB

Page 10 of 188

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

DESCRIPTION ................. 1-1

MACHINE

IDENTIFICATION ............ 1-2

INCLUDED PARTS .......... 1-2

IMPORTANT

INFORMATION................. 1-2

CHECKING OF CONNEC-

TION ................................. 1-3

SPECIAL TOOLS ............. 1-4

CONTROL FUNCTIONS .. 1-8

STARTING AND

BREAK-IN ........................ 1-8

TORQUE-CHECK

POINTS........................... 1-11

CLEANING AND

STORAGE ...................... 1-12

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICA-

TIONS ............................... 2-1

MAINTENANCE SPECIFICA-

TIONS ............................... 2-3

TIGHTENING

TORQUES ...................... 2-10

LUBRICATION

DIAGRAMS .................... 2-16

CABLE ROUTING

DIAGRAM ....................... 2-18

CHAPTER 3

REGULAR INSPEC-

TION AND AD-

JUSTMENTS

MAINTENANCE

INTERVALS...................... 3-1PRE-OPERATION

INSPECTION AND MAINTE-

NANCE ............................. 3-4

ENGINE ............................ 3-5

CHASSIS ........................ 3-13

ELECTRICAL ................. 3-22

CHAPTER 4

ENGINE

SEAT, FUEL TANK AND

SIDE COVERS.................. 4-1

EXHAUST PIPE AND

SILENCER ........................ 4-3

RADIATOR ....................... 4-5

CARBURETOR................. 4-7

CAMSHAFTS.................. 4-14

CYLINDER HEAD........... 4-19

VALVES AND VALVE

SPRINGS ........................ 4-22

CYLINDER AND

PISTON ........................... 4-26

CLUTCH ......................... 4-29

OIL FILTER ELEMENT

AND WATER PUMP ....... 4-33

BALANCER .................... 4-37

OIL PUMP ....................... 4-39

KICK SHAFT AND SHIFT

SHAFT ............................ 4-42

CDI MAGNETO............... 4-47

ENGINE REMOVAL ....... 4-49

CRANKCASE AND CRANK-

SHAFT ............................ 4-53

TRANSMISSION, SHIFT

CAM AND SHIFT FORK. 4-59

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR

WHEEL ............................. 5-1

FRONT BRAKE AND REAR

BRAKE ............................. 5-6

FRONT FORK................. 5-16

HANDLEBAR ................. 5-24STEERING ......................5-28

SWINGARM ....................5-32

REAR SHOCK

ABSORBER ....................5-37

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING DIA-

GRAM ...............................6-1

IGNITION SYSTEM...........6-2

THROTTLE POSITION SEN-

SOR SYSTEM ...................6-5

CHAPTER 7

TUNING

ENGINE.............................7-1

CHASSIS ..........................7-6

Page 12 of 188

1-2

MACHINE IDENTIFICATION

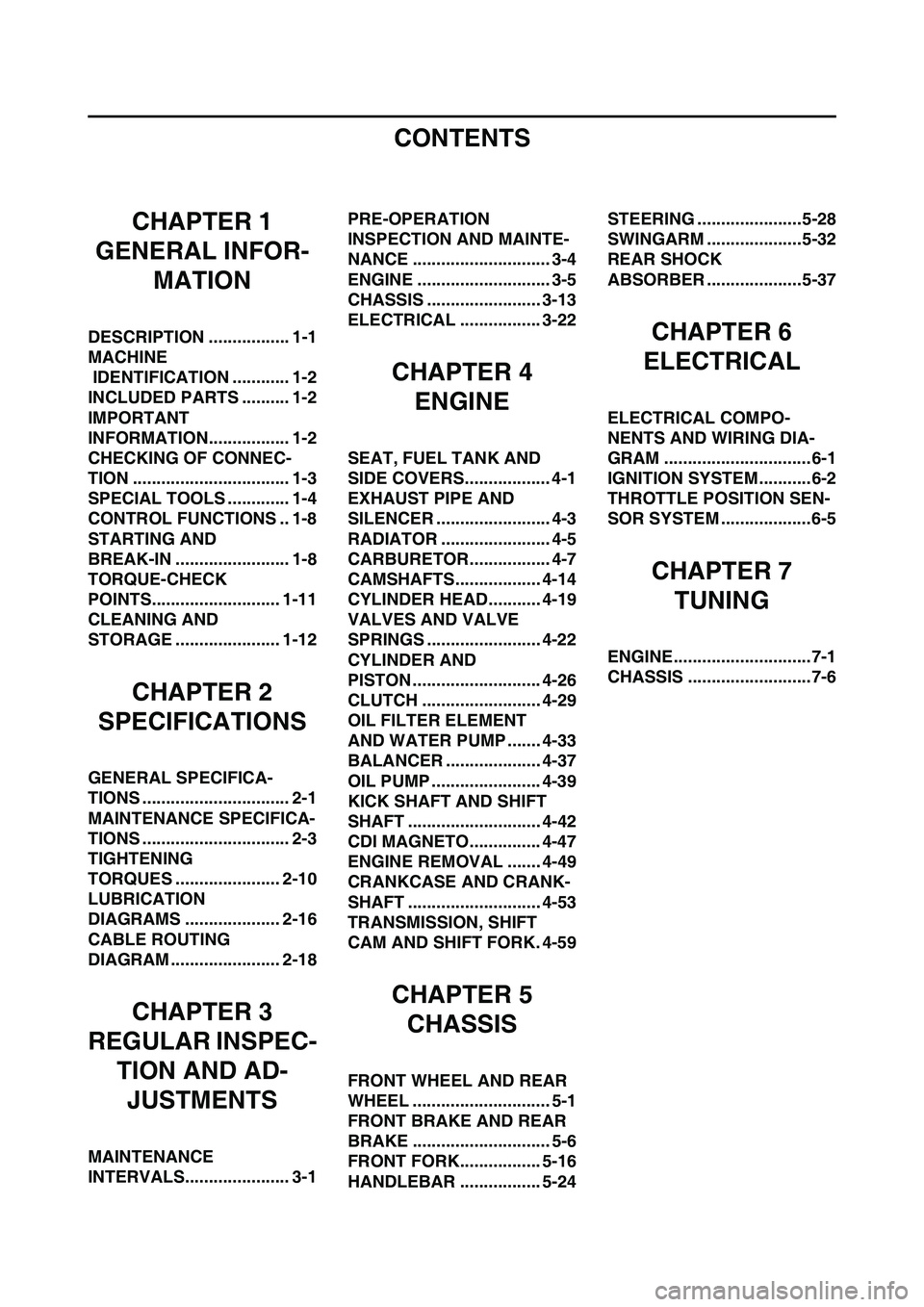

MACHINE IDENTIFICATION

There are two significant reasons for

knowing the serial number of your

machine:

1. When ordering parts, you can

give the number to your Yamaha

dealer for positive identification of

the model you own.

2. If your machine is stolen, the au-

thorities will need the number to

search for and identify your ma-

chine.

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number "1"

is stamped on the right of the steering

head pipe.

ENGINE SERIAL NUMBER

The engine serial number "1" is

stamped into the elevated part of the

right-side of the engine.

MODEL LABEL

The model label "1" is affixed to the

frame under the rider's seat. This in-

formation will be needed to order

spare parts.

INCLUDED PARTS

DETACHABLE SIDESTAND

This sidestand "1" is used to support

only the machine when standing or

transporting it.

• Never apply additional force to

the sidestand.

• Remove this sidestand before

starting out.

VALVE JOINT

This valve joint "1" prevents fuel from

flowing out and is installed to the fuel

tank breather hose.

In this installation, make sure the

arrow faces the fuel tank and also

downward.

SPARK PLUG WRENCH

This spark plug wrench "1" is used to

remove and install the spark plug.

NIPPLE WRENCH

This nipple wrench "1" is used to

tighten the spoke.

JET NEEDLE PULL-UP TOOL

The jet needle pull-up tool "1" is used

to pull the jet needle out of the carbu-

retor.

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

1. Remove all dirt, mud, dust, and

foreign material before removal

and disassembly.

• When washing the machine with

high pressured water, cover the

parts follows.

Silencer exhaust port

Side cover air intake port

Water pump housing hole at the

bottom

Drain hole on the cylinder head

(right side)

2. Use proper tools and cleaning

equipment. Refer to "SPECIAL

TOOLS" section.

3. When disassembling the ma-

chine, keep mated parts together.

They include gears, cylinders,

pistons, and other mated parts

that have been "mated" through

normal wear. Mated parts must

be reused as an assembly or re-

placed.

4. During the machine disassembly,

clean all parts and place them in

trays in the order of disassembly.

This will speed up assembly time

Page 30 of 188

2-8

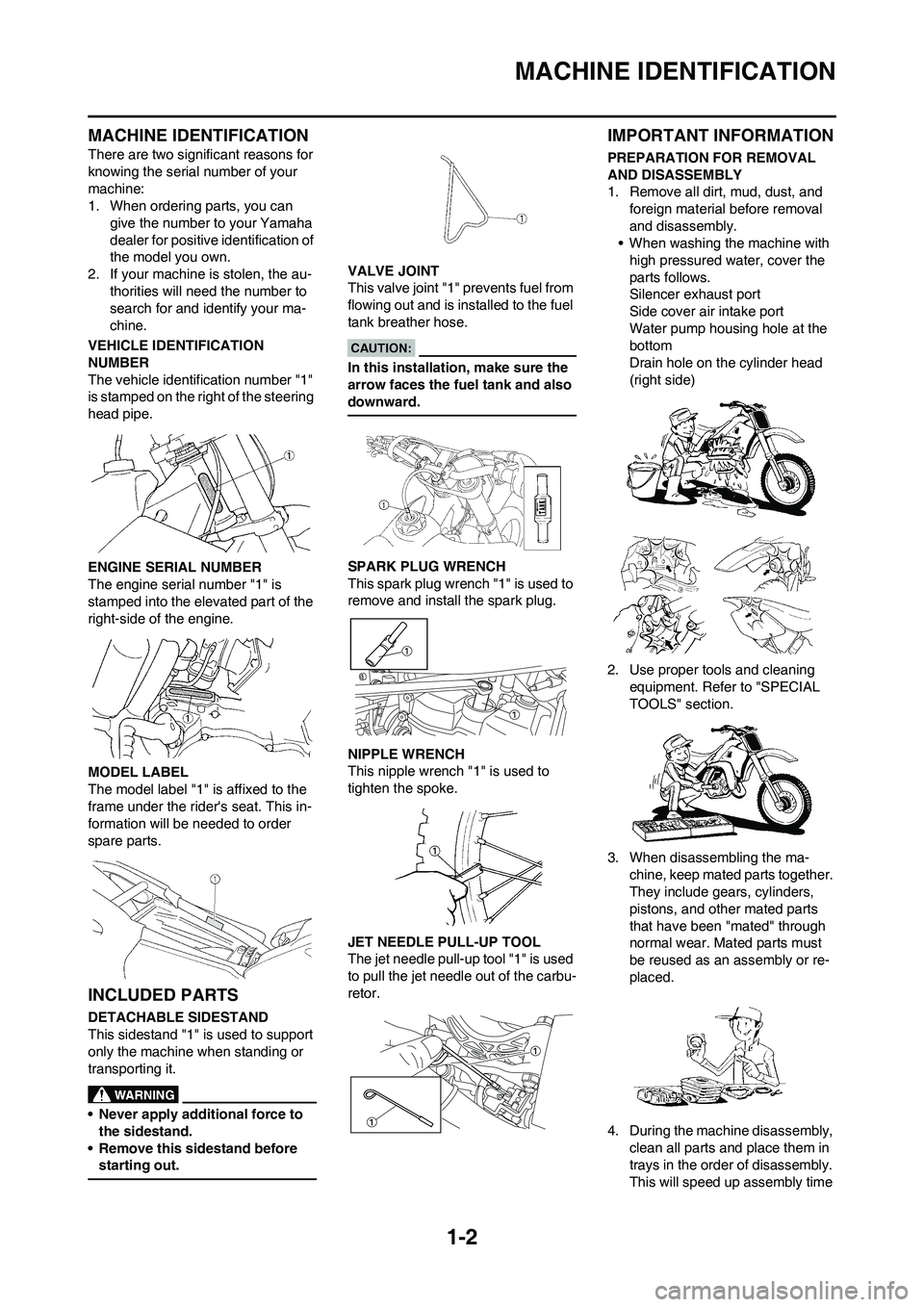

MAINTENANCE SPECIFICATIONS

CHASSISSide clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm (0.007

in)

Bypass valve setting pressure 40–80 kPa (0.4–0.8 kg/cm

2, 5.69–11.38

psi)----

Cooling:

Radiator core size

Width 120.2 mm (4.73 in) ----

Height 240 mm (9.45 in) ----

Thickness 22 mm (0.87 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi) ----

Radiator capacity (total) 0.56 L (0.49 Imp qt, 0.59 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Front suspension:

Front fork travel 300 mm (11.8 in) ----

Fork spring free length 454 mm (17.9 in) 449 mm (17.7

in)

Spring rate, STD K = 4.6 N/mm (0.469 kg/mm, 26.3 lb/in) ----

Optional spring Yes ----

Oil capacity 541 cm

3 (19.0 lmp oz, 18.3 US oz) ----

Oil grade Suspension oil "S1" ----

Inner tube outer diameter 48 mm (1.89 in) ----

Front fork top end 5 mm (0.20 in) ----

Rear suspension: USA, CDN, AUS, NZ,

ZAEUROPE

Shock absorber travel 131.5 mm (5.18 in)

←----

Spring free length Approx.275 mm (10.83

in)

←----

Fitting length

One I.D. mark 267 mm (10.51 in) 262 mm (10.31 in) ----

Two I.D. marks 273 mm (10.75 in) 268 mm (10.55 in) ----

Three I.D. marks 264.5 mm (10.41 in) 259.5 mm (10.22 in) ----

One I.D. mark 255.5–273.5 mm

(10.06–10.77 in)

←----

Two I.D. marks 261.5–279.5 mm

(10.30–11.00 in)

←----

Three I.D. marks 253.0–271.0 mm (9.96–

10.67 in)

←----

Spring rate, STD K = 54.0 N/mm (5.50 kg/

mm, 308.0 lb/in)

←----

Page 33 of 188

2-11

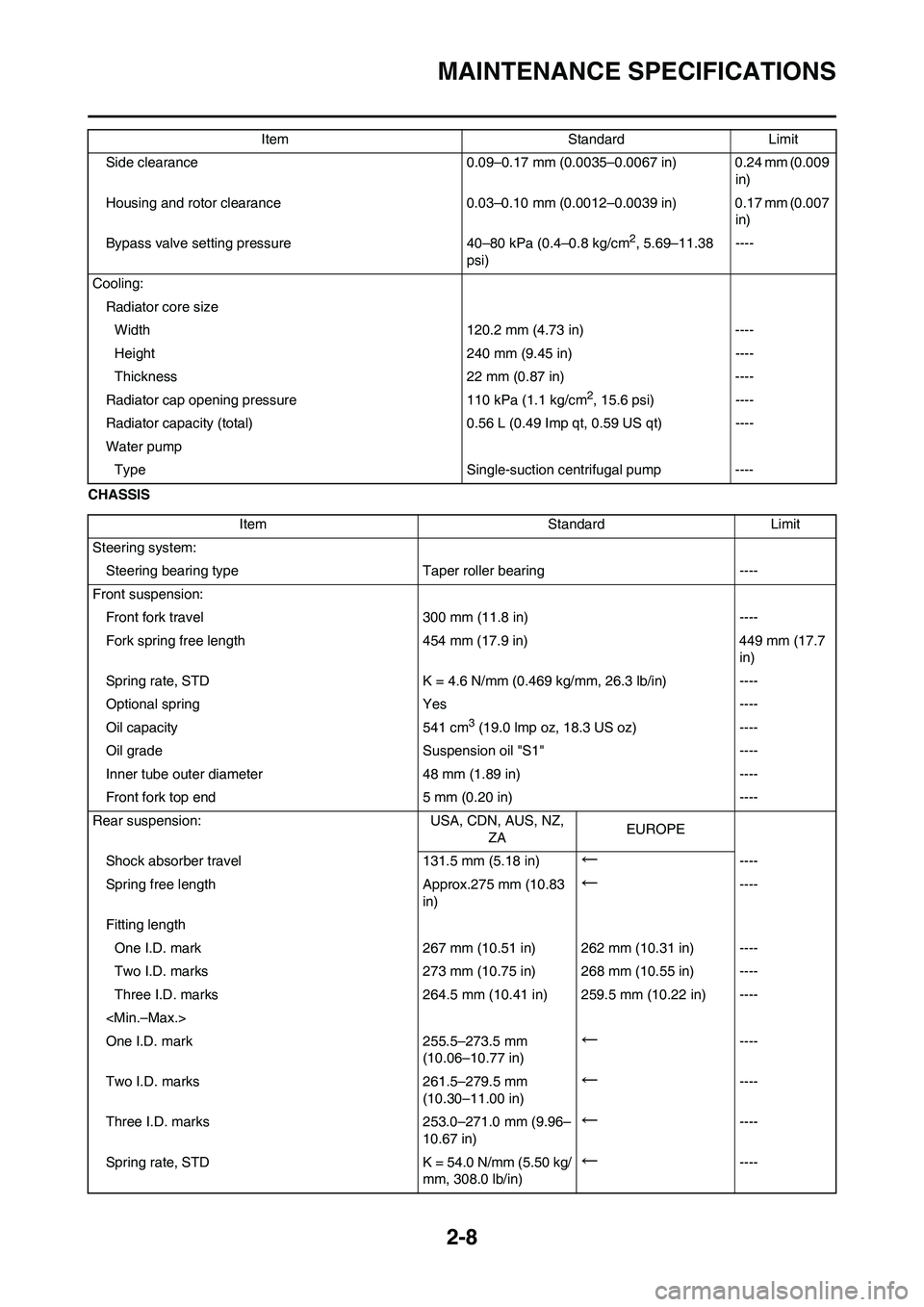

TIGHTENING TORQUES

Throttle cable (return) M12 × 1.0 1 11 1.1 8.0

Throttle cable cover M5 × 0.8 2 4 0.4 2.9

Hot starter plunger M12 × 1.0 1 2 0.2 1.4

Hot starter cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Air filter element M6 × 1.0 1 2 0.2 1.4

Radiator stay M6 × 1.0 6 7 0.7 5.1

Radiator M6 × 1.0 4 10 1.0 7.2

Radiator hose clamp M6 × 1.0 8 2 0.2 1.4

Radiator pipe 1, 2 M6 × 1.0 2 10 1.0 7.2

Impeller M8 × 1.25 1 14 1.4 10

Water pump housing cover M6 × 1.0 3 10 1.0 7.2

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 2 0.2 1.4

Oil pump M6 × 1.0 2 10 1.0 7.2

Oil pump drive gear shaft M6 × 1.0 1 10 1.0 7.2

Oil filter element drain bolt M6 × 1.0 1 10 1.0 7.2

Oil filter element cover M6 × 1.0 2 10 1.0 7.2

Oil pressure check bolt M6 × 1.0 1 10 1.0 7.2

△Oil hose clamp — 2 2 0.2 1.4

Crankshaft end accessing screw M27 × 1.5 1 10 1.0 7.2

Timing mark accessing screw M14 × 1.5 1 6 0.6 4.3

Clutch cover M6 × 1.0 7 10 1.0 7.2

Right crankcase cover M6 × 1.0 8 10 1.0 7.2

Right crankcase cover M6 × 1.0 2 12 1.2 8.7

Left crankcase cover M6 × 1.0 8 10 1.0 7.2

Crankcase M6 × 1.0 12 12 1.2 8.7

Clutch cable holder M6 × 1.0 2 10 1.0 7.2

Oil drain bolt (right crankcase) M10 × 1.25 1 20 2.0 14

Oil drain bolt (left crankcase) M8 × 1.25 1 20 2.0 14

Oil check bolt (crankcase) M6 × 1.0 1 10 1.0 7.2

Oil strainer M6 × 1.0 1 10 1.0 7.2

Crankcase bearing stopper M6 × 1.0 8 10 1.0 7.2

Crankcase bearing stopper (crankshaft) M6 × 1.0 4 14 1.4 10

Drive axle oil seal stopper M6 × 1.0 2 10 1.0 7.2

Kick shaft ratchet wheel guide M6 × 1.0 2 12 1.2 8.7

Kickstarter crank M8 × 1.25 1 33 3.3 24

Screw (kickstarter crank) M6 × 1.0 1 7 0.7 5.1

Primary drive gear M20 × 1.0 1 110 11.0 80

Clutch boss M20 × 1.0 1 75 7.5 54

Clutch cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Clutch spring M6 × 1.0 6 10 1.0 7.2

Balancer M10 × 1.0 1 45 4.5 32

Balancer shaft driven gear M14 × 1.0 1 50 5.0 36

Balancer weight M6 × 1.0 3 10 1.0 7.2Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 101 of 188

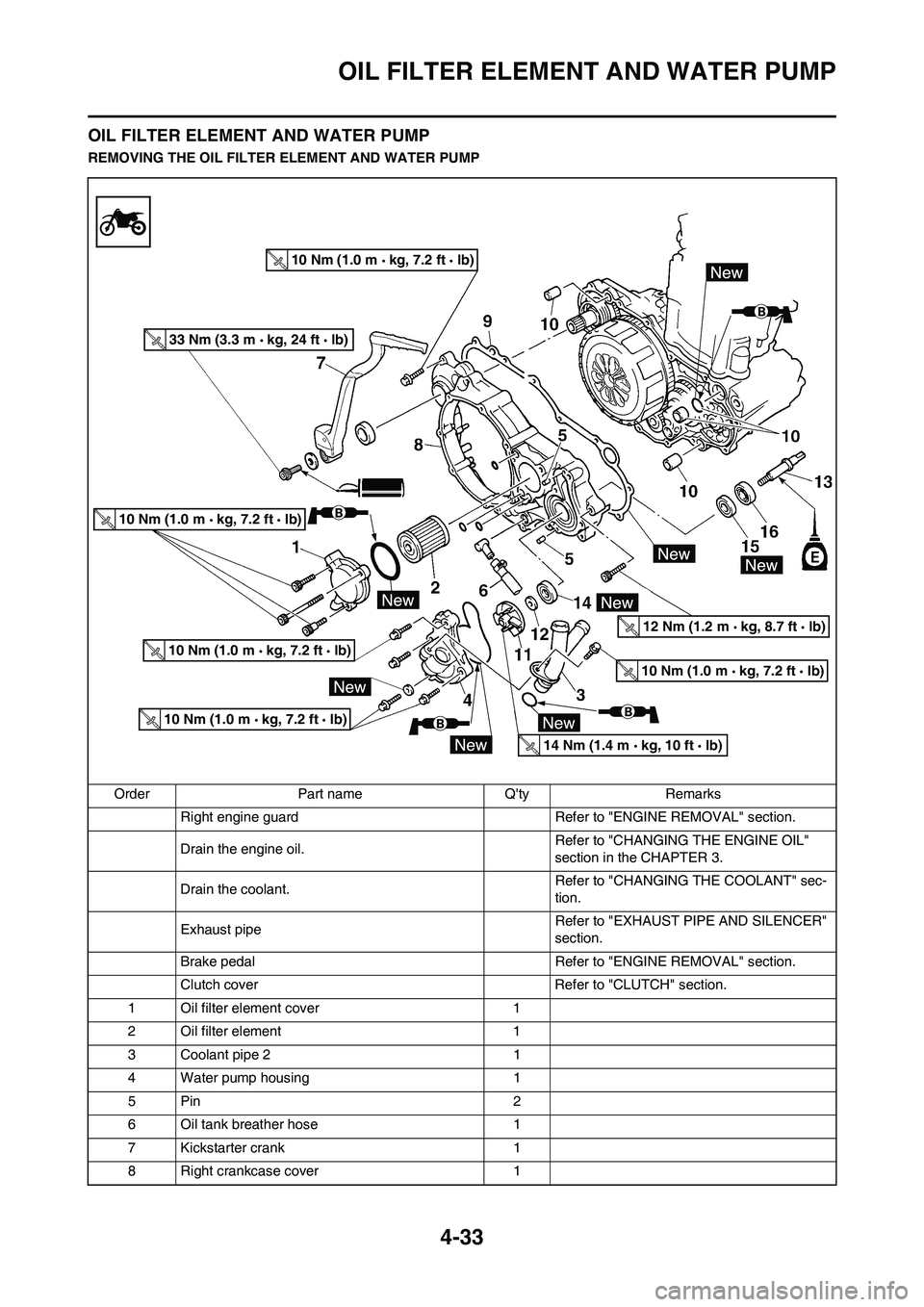

4-33

OIL FILTER ELEMENT AND WATER PUMP

OIL FILTER ELEMENT AND WATER PUMP

REMOVING THE OIL FILTER ELEMENT AND WATER PUMP

Order Part name Q'ty Remarks

Right engine guard Refer to "ENGINE REMOVAL" section.

Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Drain the coolant. Refer to "CHANGING THE COOLANT" sec-

tion.

Exhaust pipe Refer to "EXHAUST PIPE AND SILENCER"

section.

Brake pedal Refer to "ENGINE REMOVAL" section.

Clutch cover Refer to "CLUTCH" section.

1 Oil filter element cover 1

2 Oil filter element 1

3 Coolant pipe 2 1

4 Water pump housing 1

5Pin 2

6 Oil tank breather hose 1

7 Kickstarter crank 1

8 Right crankcase cover 1

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

33 Nm (3.3 m kg, 24 ft lb)

14 Nm (1.4 m kg, 10 ft lb)

12 Nm (1.2 m kg, 8.7 ft lb)

Page 102 of 188

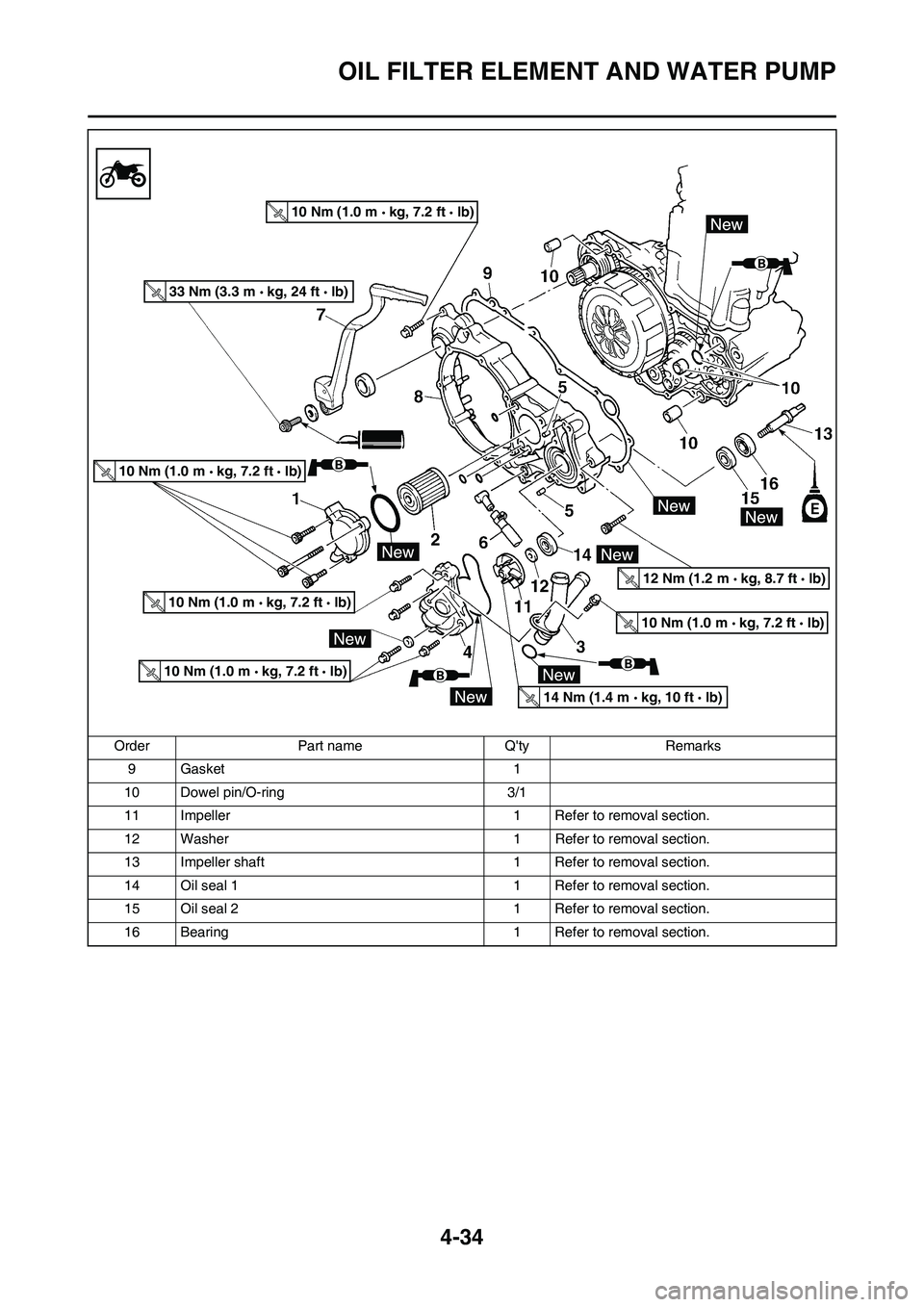

4-34

OIL FILTER ELEMENT AND WATER PUMP

9 Gasket 1

10 Dowel pin/O-ring 3/1

11 Impeller 1 Refer to removal section.

12 Washer 1 Refer to removal section.

13 Impeller shaft 1 Refer to removal section.

14 Oil seal 1 1 Refer to removal section.

15 Oil seal 2 1 Refer to removal section.

16 Bearing 1 Refer to removal section. Order Part name Q'ty Remarks

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

33 Nm (3.3 m kg, 24 ft lb)

14 Nm (1.4 m kg, 10 ft lb)

12 Nm (1.2 m kg, 8.7 ft lb)

Page 103 of 188

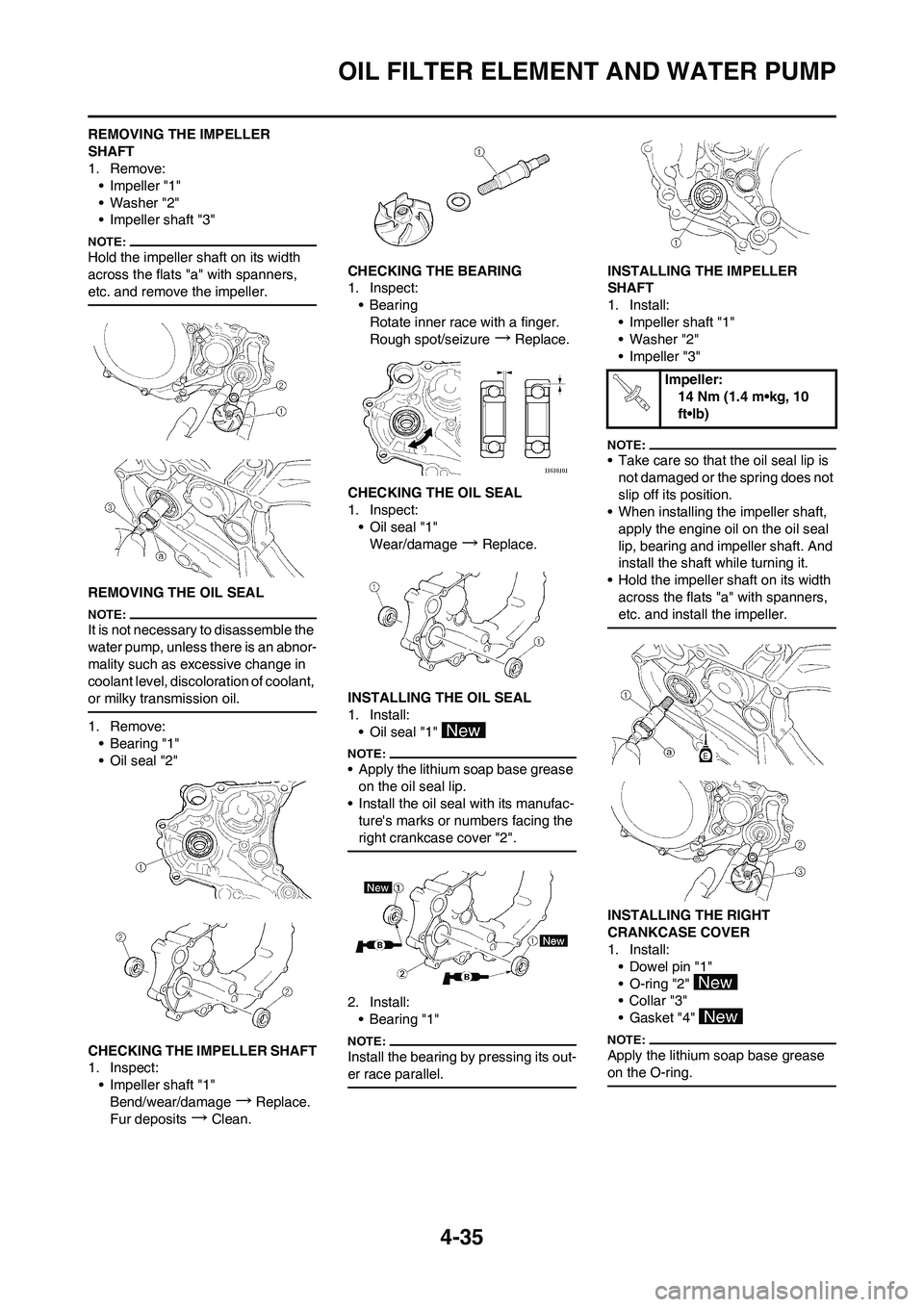

4-35

OIL FILTER ELEMENT AND WATER PUMP

REMOVING THE IMPELLER

SHAFT

1. Remove:

• Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:

• Bearing "1"

• Oil seal "2"

CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"

Bend/wear/damage

→Replace.

Fur deposits

→Clean.CHECKING THE BEARING

1. Inspect:

•Bearing

Rotate inner race with a finger.

Rough spot/seizure

→Replace.

CHECKING THE OIL SEAL

1. Inspect:

• Oil seal "1"

Wear/damage

→Replace.

INSTALLING THE OIL SEAL

1. Install:

• Oil seal "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or numbers facing the

right crankcase cover "2".

2. Install:

•Bearing "1"

Install the bearing by pressing its out-

er race parallel.

INSTALLING THE IMPELLER

SHAFT

1. Install:

• Impeller shaft "1"

• Washer "2"

• Impeller "3"

• Take care so that the oil seal lip is

not damaged or the spring does not

slip off its position.

• When installing the impeller shaft,

apply the engine oil on the oil seal

lip, bearing and impeller shaft. And

install the shaft while turning it.

• Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and install the impeller.

INSTALLING THE RIGHT

CRANKCASE COVER

1. Install:

• Dowel pin "1"

• O-ring "2"

•Collar "3"

• Gasket "4"

Apply the lithium soap base grease

on the O-ring.

Impeller:

14 Nm (1.4 m•kg, 10

ft•lb)

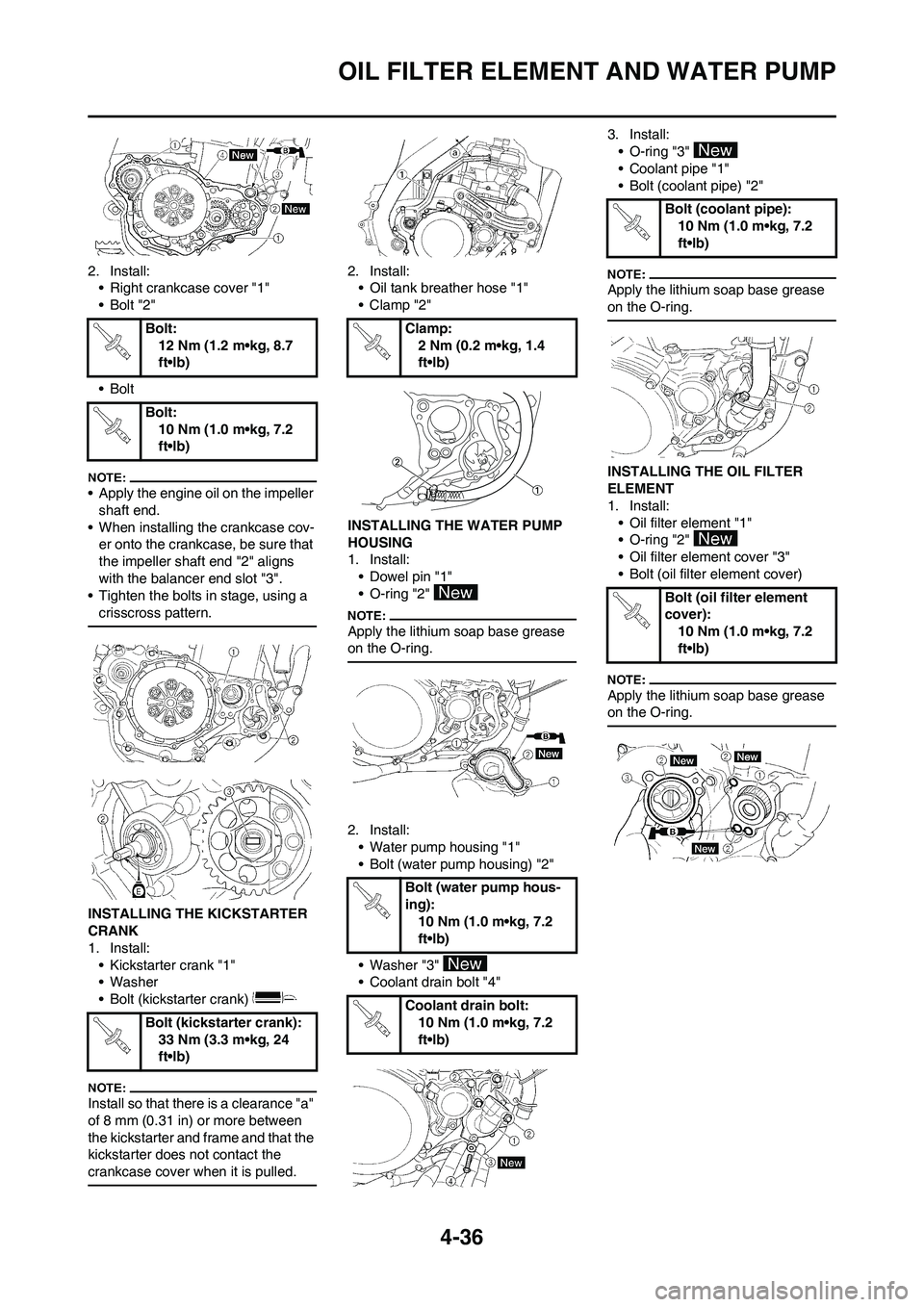

Page 104 of 188

4-36

OIL FILTER ELEMENT AND WATER PUMP

2. Install:

• Right crankcase cover "1"

•Bolt "2"

•Bolt

• Apply the engine oil on the impeller

shaft end.

• When installing the crankcase cov-

er onto the crankcase, be sure that

the impeller shaft end "2" aligns

with the balancer end slot "3".

• Tighten the bolts in stage, using a

crisscross pattern.

INSTALLING THE KICKSTARTER

CRANK

1. Install:

• Kickstarter crank "1"

• Washer

• Bolt (kickstarter crank)

Install so that there is a clearance "a"

of 8 mm (0.31 in) or more between

the kickstarter and frame and that the

kickstarter does not contact the

crankcase cover when it is pulled.

2. Install:

• Oil tank breather hose "1"

•Clamp "2"

INSTALLING THE WATER PUMP

HOUSING

1. Install:

• Dowel pin "1"

• O-ring "2"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Water pump housing "1"

• Bolt (water pump housing) "2"

• Washer "3"

• Coolant drain bolt "4"3. Install:

• O-ring "3"

• Coolant pipe "1"

• Bolt (coolant pipe) "2"

Apply the lithium soap base grease

on the O-ring.

INSTALLING THE OIL FILTER

ELEMENT

1. Install:

• Oil filter element "1"

• O-ring "2"

• Oil filter element cover "3"

• Bolt (oil filter element cover)

Apply the lithium soap base grease

on the O-ring.

Bolt:

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (kickstarter crank):

33 Nm (3.3 m•kg, 24

ft•lb)Clamp:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (water pump hous-

ing):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (coolant pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (oil filter element

cover):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 178 of 188

7-1

ENGINE

TUNING

ENGINE

CARBURETOR SETTING

• The air/fuel mixture will vary de-

pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop-

er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the

fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in-

take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-

sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor

and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or

when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well.

• After installing the carburetor,

check that the throttle operates correctly and opens and closes

smoothly.

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air

with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a

high altitude) reduces the density of

the air.

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot screw/pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jetCONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

The FLATCR carburetor is manufac-

tured with a pilot screw. The pilot

screw adjustment ranges from fully

closed throttle to 1/4 open throttle.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

6. Pilot screw

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #162

2. #158 Air

tem

p.Hu-

midi-

tyAir

pres-

sure

(alti-

tude)Mix-

tureSet-

ting

High HighLow

(high)Rich-

erLean-

er

Low LowHigh

(low)Lean-

erRich-

er

Standard main jet #160