width YAMAHA YZ450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ450F, Model: YAMAHA YZ450F 2008Pages: 188, PDF Size: 11.75 MB

Page 23 of 188

2-1

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name: YZ450FX (USA, CDN, AUS, NZ)

YZ450F (EUROPE, ZA)

Model code number: 2S2B (USA,CDN)

2S2C (EUROPE)

2S2E (AUS, NZ, ZA)

Dimensions: USA, CDN, AUS, NZ, ZA EUROPE

Overall length 2,194 mm (86.38 in) 2,195 mm (86.42 in)

Overall width 825 mm (32.48 in)

←

Overall height 1,306 mm (51.42 in)←

Seat height 990 mm (38.98 in) 1,001 mm (39.41 in)

Wheelbase 1,495 mm (58.86 in)

←

Minimum ground clearance 374 mm (14.72 in) 375 mm (14.76 in)

Dry weight:

Without oil and fuel 99.5 kg (219 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 449 cm

3 (15.8 Imp oz, 15.2 US oz)

Bore × stroke 95.0 × 63.4 mm (3.74 × 2.50 in)

Compression ratio 12.3 : 1

Starting system Kickstarter

Lubrication system: Dry sump

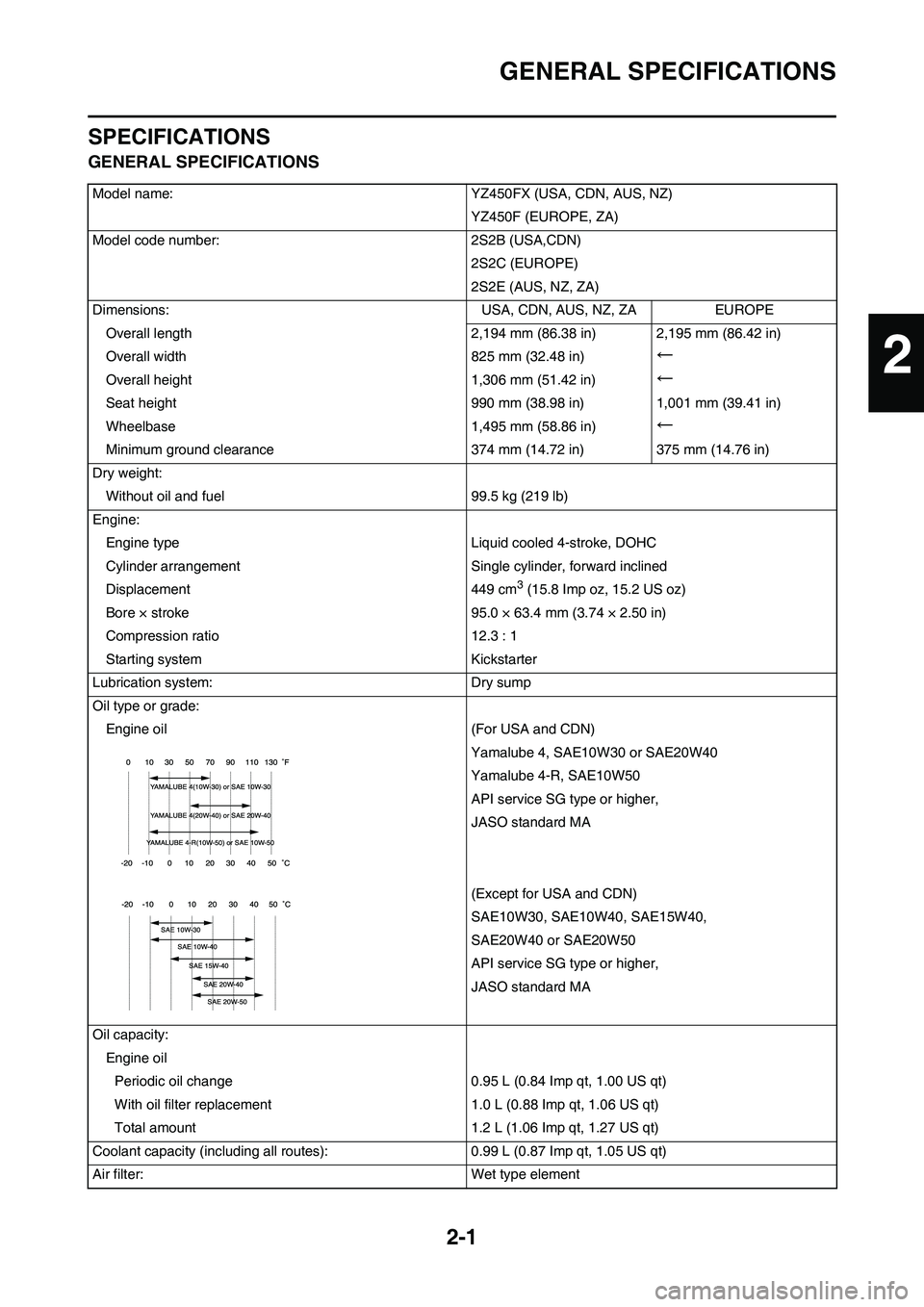

Oil type or grade:

Engine oil (For USA and CDN)

Yamalube 4, SAE10W30 or SAE20W40

Yamalube 4-R, SAE10W50

API service SG type or higher,

JASO standard MA

(Except for USA and CDN)

SAE10W30, SAE10W40, SAE15W40,

SAE20W40 or SAE20W50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 0.95 L (0.84 Imp qt, 1.00 US qt)

With oil filter replacement 1.0 L (0.88 Imp qt, 1.06 US qt)

Total amount 1.2 L (1.06 Imp qt, 1.27 US qt)

Coolant capacity (including all routes): 0.99 L (0.87 Imp qt, 1.05 US qt)

Air filter: Wet type element

2

Page 26 of 188

2-4

MAINTENANCE SPECIFICATIONS

Timing chain:

Timing chain type/No. of links 98XRH2010-118M/118 ----

Timing chain adjustment method Automatic ----

Valve, valve seat, valve guide:

Valve clearance (cold)

IN 0.10–0.15 mm (0.0039–0.0059 in) ----

EX 0.20–0.25 mm (0.0079–0.0098 in) ----

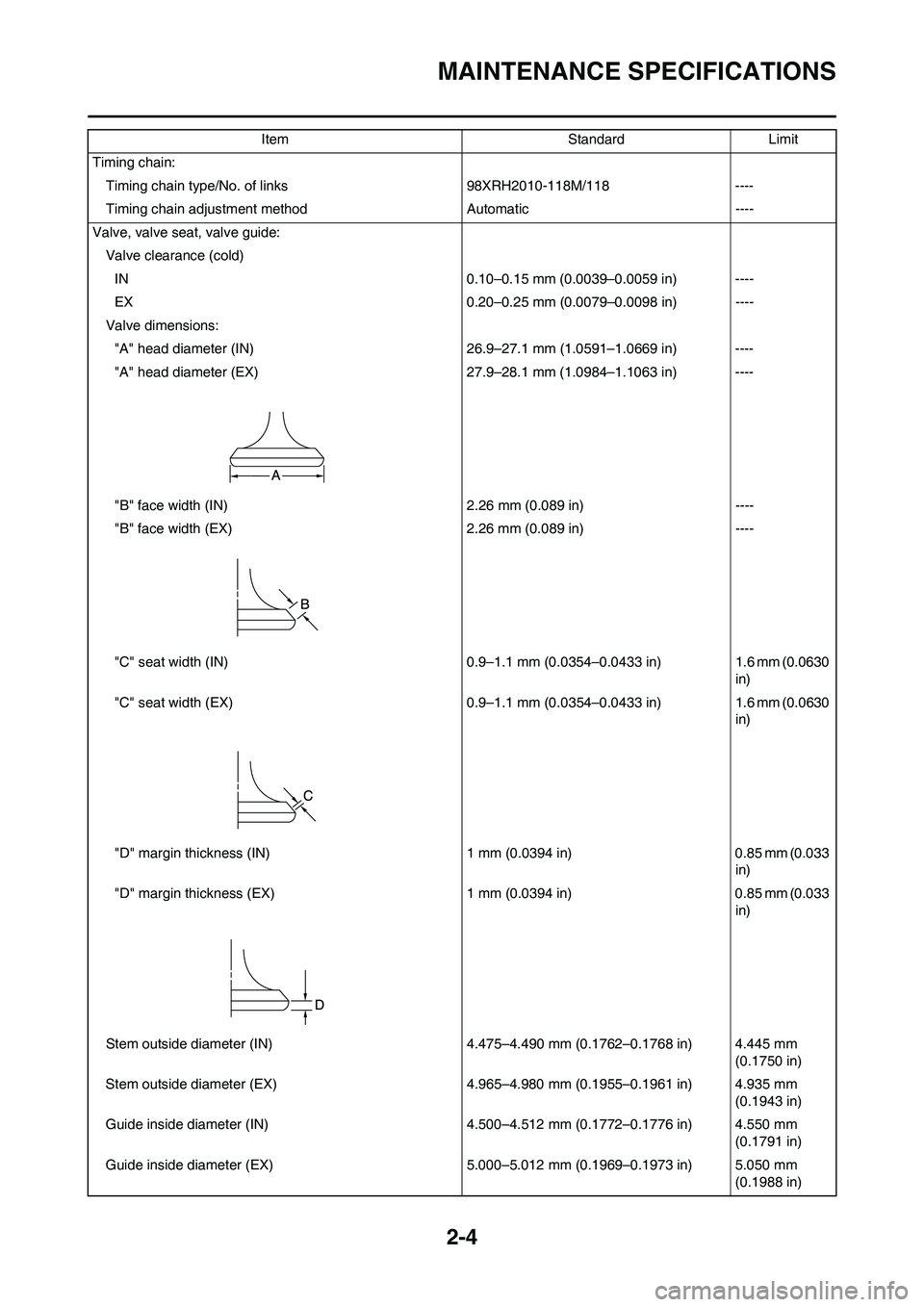

Valve dimensions:

"A" head diameter (IN) 26.9–27.1 mm (1.0591–1.0669 in) ----

"A" head diameter (EX) 27.9–28.1 mm (1.0984–1.1063 in) ----

"B" face width (IN) 2.26 mm (0.089 in) ----

"B" face width (EX) 2.26 mm (0.089 in) ----

"C" seat width (IN) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

"C" seat width (EX) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

"D" margin thickness (IN) 1 mm (0.0394 in) 0.85 mm (0.033

in)

"D" margin thickness (EX) 1 mm (0.0394 in) 0.85 mm (0.033

in)

Stem outside diameter (IN) 4.475–4.490 mm (0.1762–0.1768 in) 4.445 mm

(0.1750 in)

Stem outside diameter (EX) 4.965–4.980 mm (0.1955–0.1961 in) 4.935 mm

(0.1943 in)

Guide inside diameter (IN) 4.500–4.512 mm (0.1772–0.1776 in) 4.550 mm

(0.1791 in)

Guide inside diameter (EX) 5.000–5.012 mm (0.1969–0.1973 in) 5.050 mm

(0.1988 in) Item Standard Limit

Page 27 of 188

2-5

MAINTENANCE SPECIFICATIONS

Stem-to-guide clearance (IN) 0.010–0.037 mm (0.0004–0.0015 in) 0.08 mm (0.003

in)

Stem-to-guide clearance (EX) 0.020–0.047 mm (0.0008–0.0019 in) 0.10 mm (0.004

in)

Stem runout limit ---- 0.01 mm

(0.0004 in)

Valve seat width (IN) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

Valve seat width (EX) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0.0630

in)

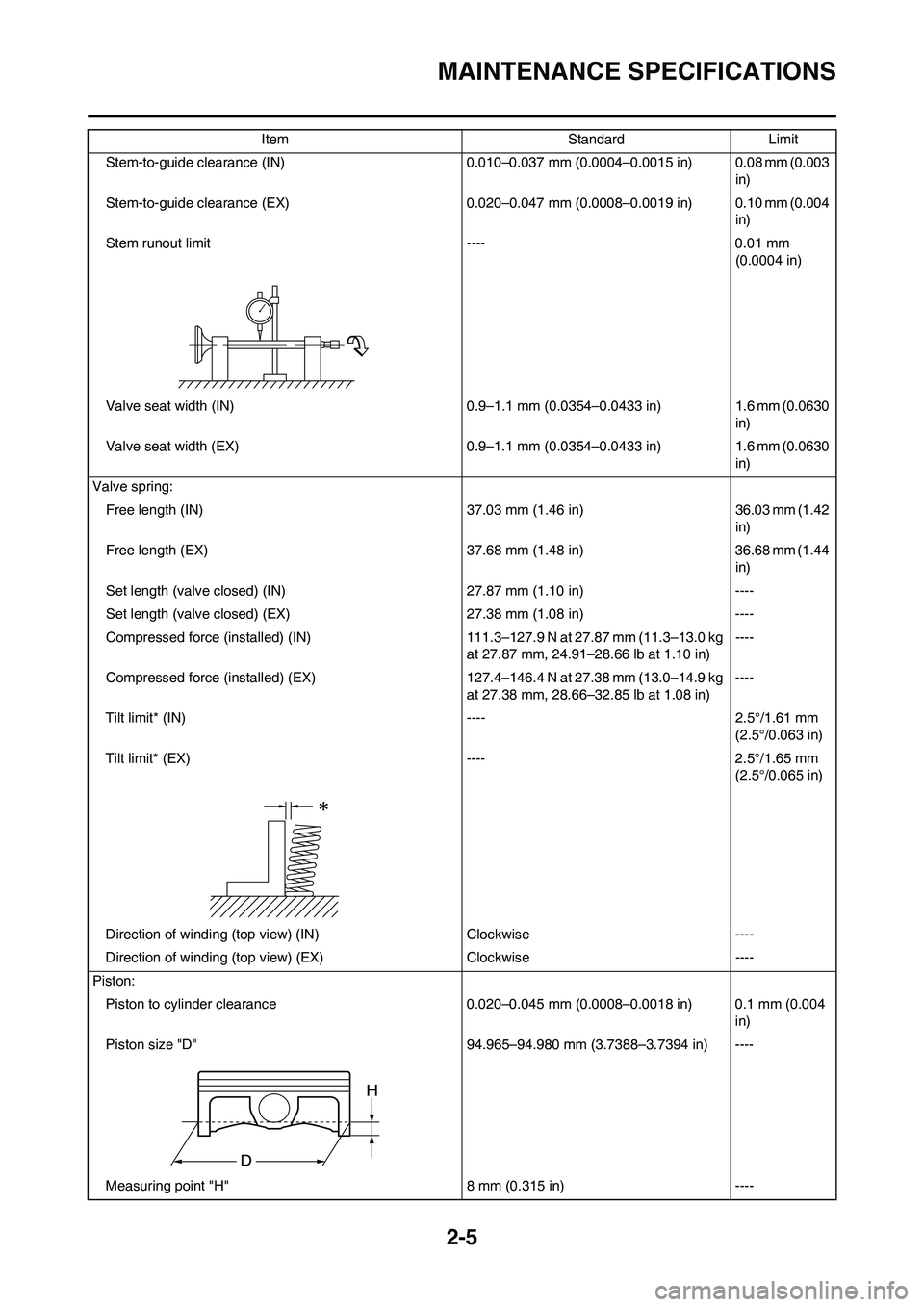

Valve spring:

Free length (IN) 37.03 mm (1.46 in) 36.03 mm (1.42

in)

Free length (EX) 37.68 mm (1.48 in) 36.68 mm (1.44

in)

Set length (valve closed) (IN) 27.87 mm (1.10 in) ----

Set length (valve closed) (EX) 27.38 mm (1.08 in) ----

Compressed force (installed) (IN) 111.3–127.9 N at 27.87 mm (11.3–13.0 kg

at 27.87 mm, 24.91–28.66 lb at 1.10 in)----

Compressed force (installed) (EX) 127.4–146.4 N at 27.38 mm (13.0–14.9 kg

at 27.38 mm, 28.66–32.85 lb at 1.08 in)----

Tilt limit* (IN) ---- 2.5°/1.61 mm

(2.5°/0.063 in)

Tilt limit* (EX) ---- 2.5°/1.65 mm

(2.5°/0.065 in)

Direction of winding (top view) (IN) Clockwise ----

Direction of winding (top view) (EX) Clockwise ----

Piston:

Piston to cylinder clearance 0.020–0.045 mm (0.0008–0.0018 in) 0.1 mm (0.004

in)

Piston size "D" 94.965–94.980 mm (3.7388–3.7394 in) ----

Measuring point "H" 8 mm (0.315 in) ---- Item Standard Limit

Page 28 of 188

2-6

MAINTENANCE SPECIFICATIONS

Piston off-set 1 mm (0.0394 in) ----

Piston pin bore inside diameter 18.004–18.015 mm (0.7088–0.7093 in) 18.045 mm

(0.7104 in)

Piston pin outside diameter 17.991–18.000 mm (0.7083–0.7087 in) 17.971 mm

(0.7075 in)

Piston rings:

Top ring:

Type Barrel ----

Dimensions (B × T) 1.2 × 3.5 mm (0.05 × 0.14 in) ----

End gap (installed) 0.20–0.30 mm (0.008–0.012 in) 0.55 mm (0.022

in)

Side clearance (installed) 0.030–0.065 mm (0.0012–0.0026 in) 0.12 mm (0.005

in)

2nd ring:

Type Taper ----

Dimensions (B × T) 1.00 × 3.35 mm (0.04 × 0.13 in) ----

End gap (installed) 0.35–0.50 mm (0.014–0.020 in) 0.85 mm (0.033

in)

Side clearance 0.020–0.055 mm (0.0008–0.0022 in) 0.12 mm (0.005

in)

Oil ring:

Dimensions (B × T) 2.0 × 2.9 mm (0.08 × 0.11 in) ----

End gap (installed) 0.2–0.5 mm (0.01–0.02 in) ----

Crankshaft:

Crank width "A" 61.95–62.00 mm (2.439–2.441 in) ----

Runout limit "C" 0.03 mm (0.0012 in) 0.05 mm (0.002

in)

Big end side clearance "D" 0.15–0.45 mm (0.0059–0.0177 in) 0.50 mm (0.02

in)

Small end free play "F" 0.4–1.0 mm (0.02–0.04 in) 2.0 mm (0.08

in)

Balancer:

Balancer drive method Gear ----Item Standard Limit

Page 30 of 188

2-8

MAINTENANCE SPECIFICATIONS

CHASSISSide clearance 0.09–0.17 mm (0.0035–0.0067 in) 0.24 mm (0.009

in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm (0.007

in)

Bypass valve setting pressure 40–80 kPa (0.4–0.8 kg/cm

2, 5.69–11.38

psi)----

Cooling:

Radiator core size

Width 120.2 mm (4.73 in) ----

Height 240 mm (9.45 in) ----

Thickness 22 mm (0.87 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi) ----

Radiator capacity (total) 0.56 L (0.49 Imp qt, 0.59 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Front suspension:

Front fork travel 300 mm (11.8 in) ----

Fork spring free length 454 mm (17.9 in) 449 mm (17.7

in)

Spring rate, STD K = 4.6 N/mm (0.469 kg/mm, 26.3 lb/in) ----

Optional spring Yes ----

Oil capacity 541 cm

3 (19.0 lmp oz, 18.3 US oz) ----

Oil grade Suspension oil "S1" ----

Inner tube outer diameter 48 mm (1.89 in) ----

Front fork top end 5 mm (0.20 in) ----

Rear suspension: USA, CDN, AUS, NZ,

ZAEUROPE

Shock absorber travel 131.5 mm (5.18 in)

←----

Spring free length Approx.275 mm (10.83

in)

←----

Fitting length

One I.D. mark 267 mm (10.51 in) 262 mm (10.31 in) ----

Two I.D. marks 273 mm (10.75 in) 268 mm (10.55 in) ----

Three I.D. marks 264.5 mm (10.41 in) 259.5 mm (10.22 in) ----

One I.D. mark 255.5–273.5 mm

(10.06–10.77 in)

←----

Two I.D. marks 261.5–279.5 mm

(10.30–11.00 in)

←----

Three I.D. marks 253.0–271.0 mm (9.96–

10.67 in)

←----

Spring rate, STD K = 54.0 N/mm (5.50 kg/

mm, 308.0 lb/in)

←----

Page 85 of 188

4-17

CAMSHAFTS

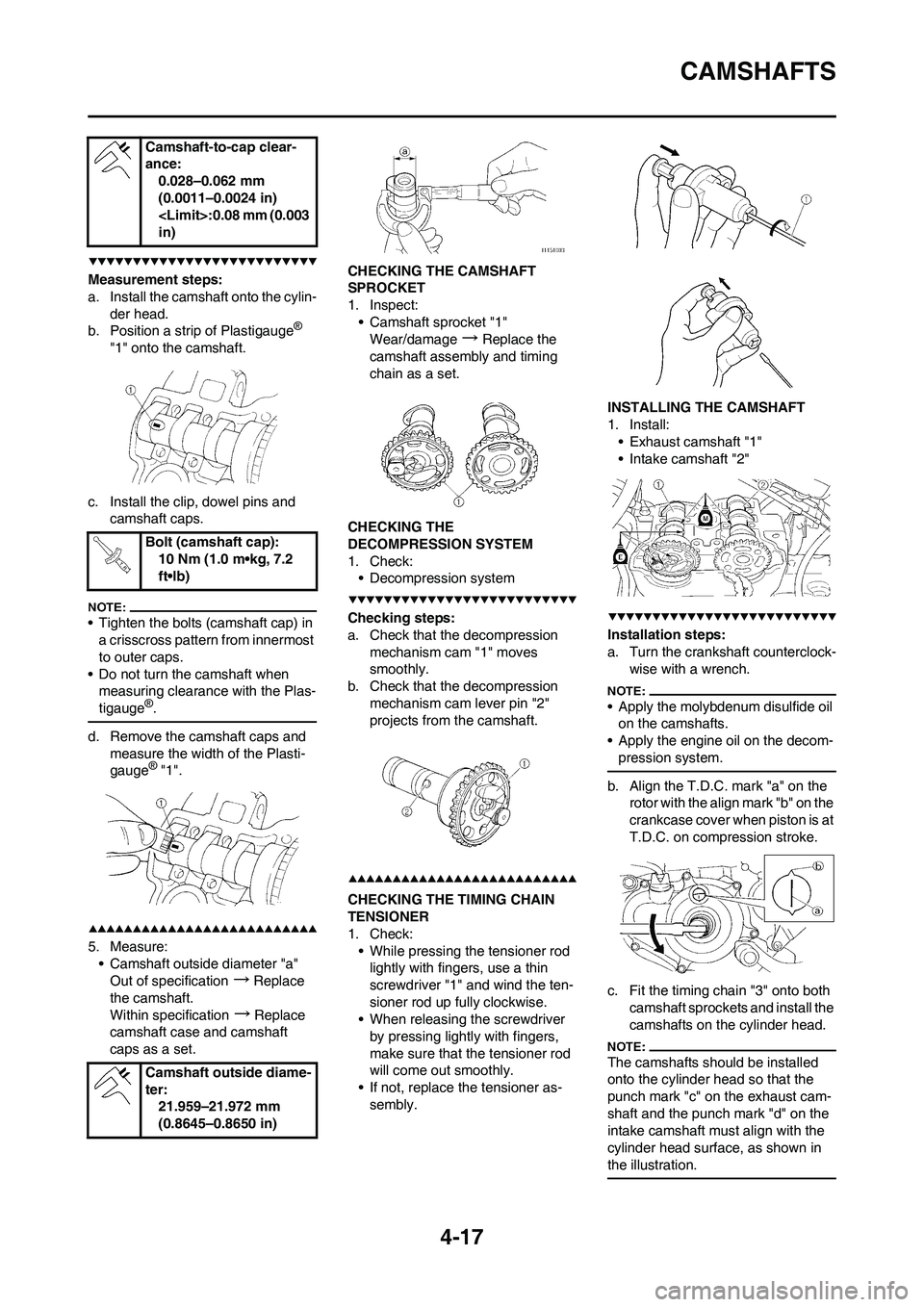

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the Plas-

tigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification

→Replace

the camshaft.

Within specification

→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage

→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2"

projects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head.

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 91 of 188

4-23

VALVES AND VALVE SPRINGS

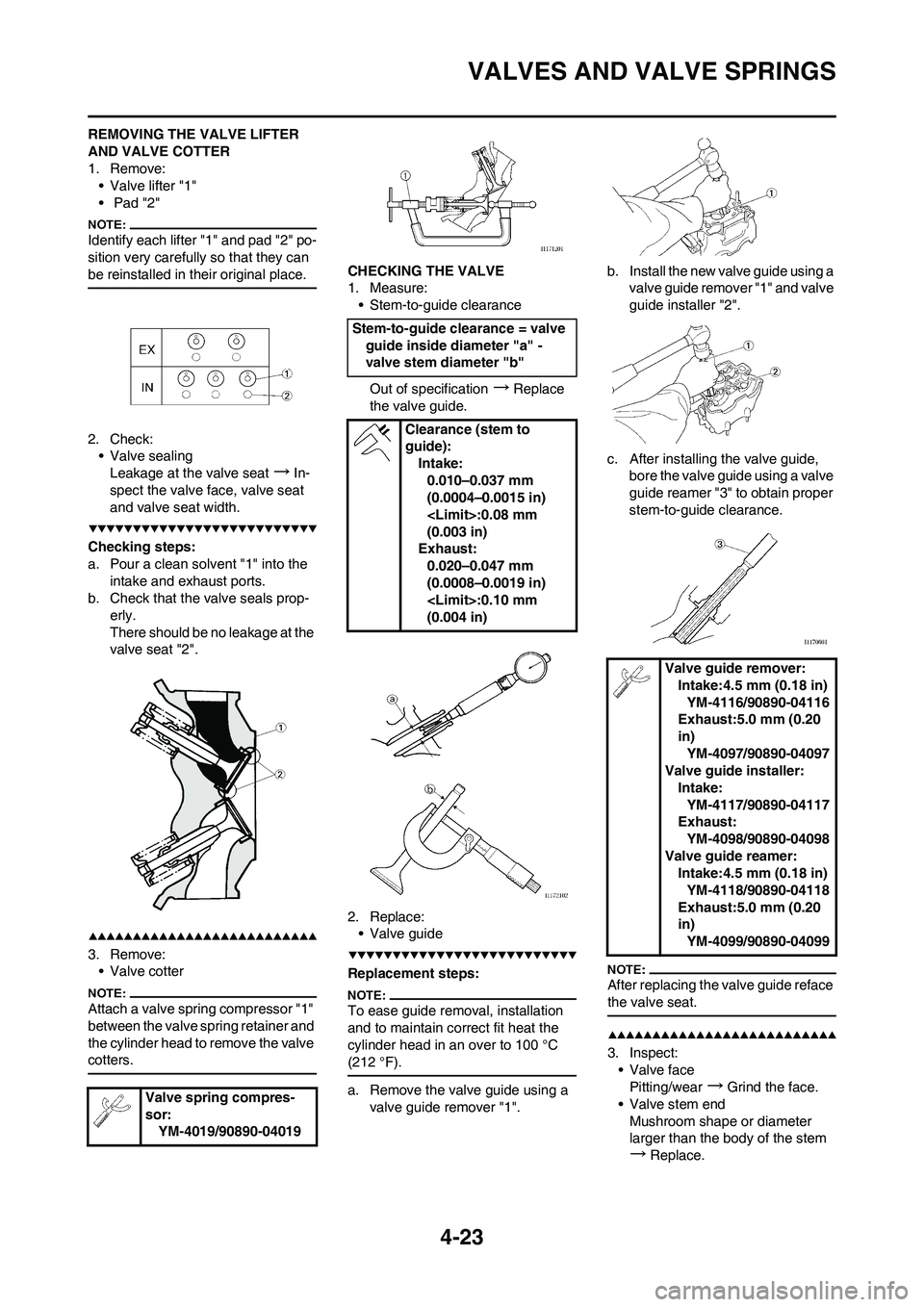

REMOVING THE VALVE LIFTER

AND VALVE COTTER

1. Remove:

• Valve lifter "1"

• Pad "2"

Identify each lifter "1" and pad "2" po-

sition very carefully so that they can

be reinstalled in their original place.

2. Check:

• Valve sealing

Leakage at the valve seat

→In-

spect the valve face, valve seat

and valve seat width.

Checking steps:

a. Pour a clean solvent "1" into the

intake and exhaust ports.

b. Check that the valve seals prop-

erly.

There should be no leakage at the

valve seat "2".

3. Remove:

• Valve cotter

Attach a valve spring compressor "1"

between the valve spring retainer and

the cylinder head to remove the valve

cotters.

CHECKING THE VALVE

1. Measure:

• Stem-to-guide clearance

Out of specification

→Replace

the valve guide.

2. Replace:

• Valve guide

Replacement steps:

To ease guide removal, installation

and to maintain correct fit heat the

cylinder head in an over to 100 °C

(212 °F).

a. Remove the valve guide using a

valve guide remover "1".b. Install the new valve guide using a

valve guide remover "1" and valve

guide installer "2".

c. After installing the valve guide,

bore the valve guide using a valve

guide reamer "3" to obtain proper

stem-to-guide clearance.

After replacing the valve guide reface

the valve seat.

3. Inspect:

• Valve face

Pitting/wear

→Grind the face.

• Valve stem end

Mushroom shape or diameter

larger than the body of the stem

→Replace. Valve spring compres-

sor:

YM-4019/90890-04019

Stem-to-guide clearance = valve

guide inside diameter "a" -

valve stem diameter "b"

Clearance (stem to

guide):

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

(0.003 in)

Exhaust:

0.020–0.047 mm

(0.0008–0.0019 in)

(0.004 in)

Valve guide remover:

Intake:4.5 mm (0.18 in)

YM-4116/90890-04116

Exhaust:5.0 mm (0.20

in)

YM-4097/90890-04097

Valve guide installer:

Intake:

YM-4117/90890-04117

Exhaust:

YM-4098/90890-04098

Valve guide reamer:

Intake:4.5 mm (0.18 in)

YM-4118/90890-04118

Exhaust:5.0 mm (0.20

in)

YM-4099/90890-04099

Page 92 of 188

4-24

VALVES AND VALVE SPRINGS

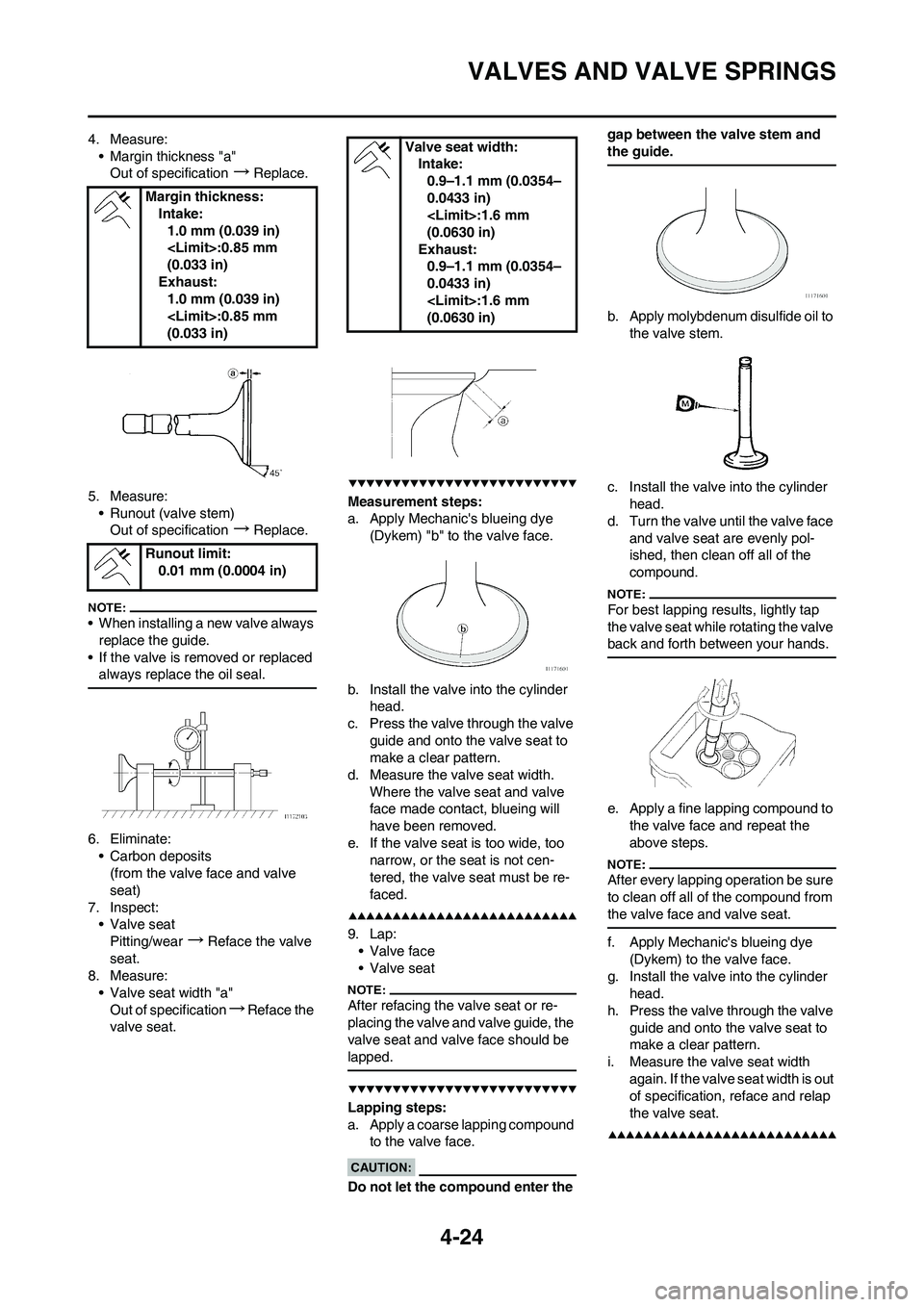

4. Measure:

• Margin thickness "a"

Out of specification

→Replace.

5. Measure:

• Runout (valve stem)

Out of specification

→Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

• Valve seat

Pitting/wear

→Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification

→Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be re-

faced.

9. Lap:

• Valve face

• Valve seat

After refacing the valve seat or re-

placing the valve and valve guide, the

valve seat and valve face should be

lapped.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.

c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

Margin thickness:

Intake:

1.0 mm (0.039 in)

(0.033 in)

Exhaust:

1.0 mm (0.039 in)

(0.033 in)

Runout limit:

0.01 mm (0.0004 in)

Valve seat width:

Intake:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Exhaust:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Page 103 of 188

4-35

OIL FILTER ELEMENT AND WATER PUMP

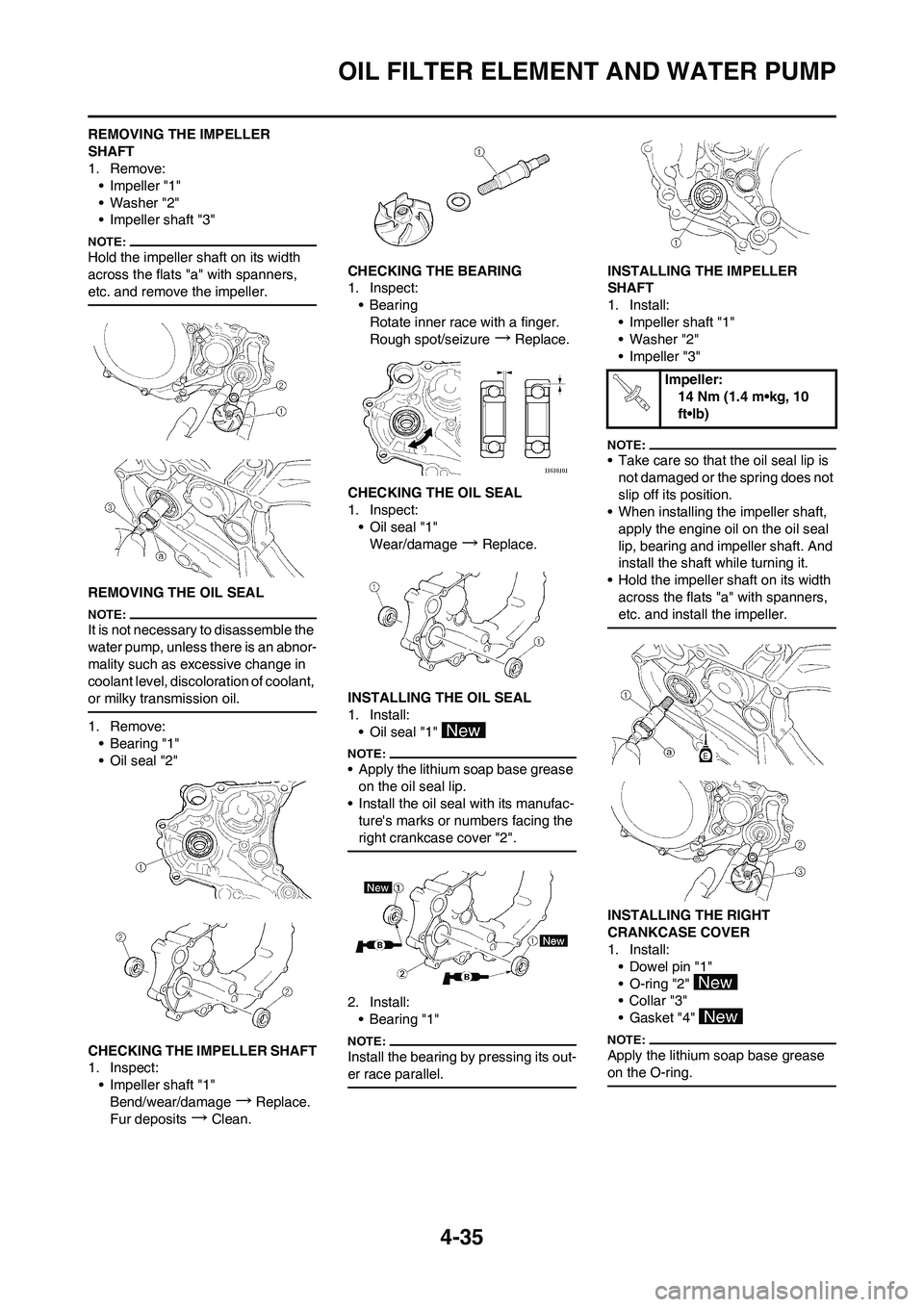

REMOVING THE IMPELLER

SHAFT

1. Remove:

• Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:

• Bearing "1"

• Oil seal "2"

CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"

Bend/wear/damage

→Replace.

Fur deposits

→Clean.CHECKING THE BEARING

1. Inspect:

•Bearing

Rotate inner race with a finger.

Rough spot/seizure

→Replace.

CHECKING THE OIL SEAL

1. Inspect:

• Oil seal "1"

Wear/damage

→Replace.

INSTALLING THE OIL SEAL

1. Install:

• Oil seal "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or numbers facing the

right crankcase cover "2".

2. Install:

•Bearing "1"

Install the bearing by pressing its out-

er race parallel.

INSTALLING THE IMPELLER

SHAFT

1. Install:

• Impeller shaft "1"

• Washer "2"

• Impeller "3"

• Take care so that the oil seal lip is

not damaged or the spring does not

slip off its position.

• When installing the impeller shaft,

apply the engine oil on the oil seal

lip, bearing and impeller shaft. And

install the shaft while turning it.

• Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and install the impeller.

INSTALLING THE RIGHT

CRANKCASE COVER

1. Install:

• Dowel pin "1"

• O-ring "2"

•Collar "3"

• Gasket "4"

Apply the lithium soap base grease

on the O-ring.

Impeller:

14 Nm (1.4 m•kg, 10

ft•lb)

Page 125 of 188

4-57

CRANKCASE AND CRANKSHAFT

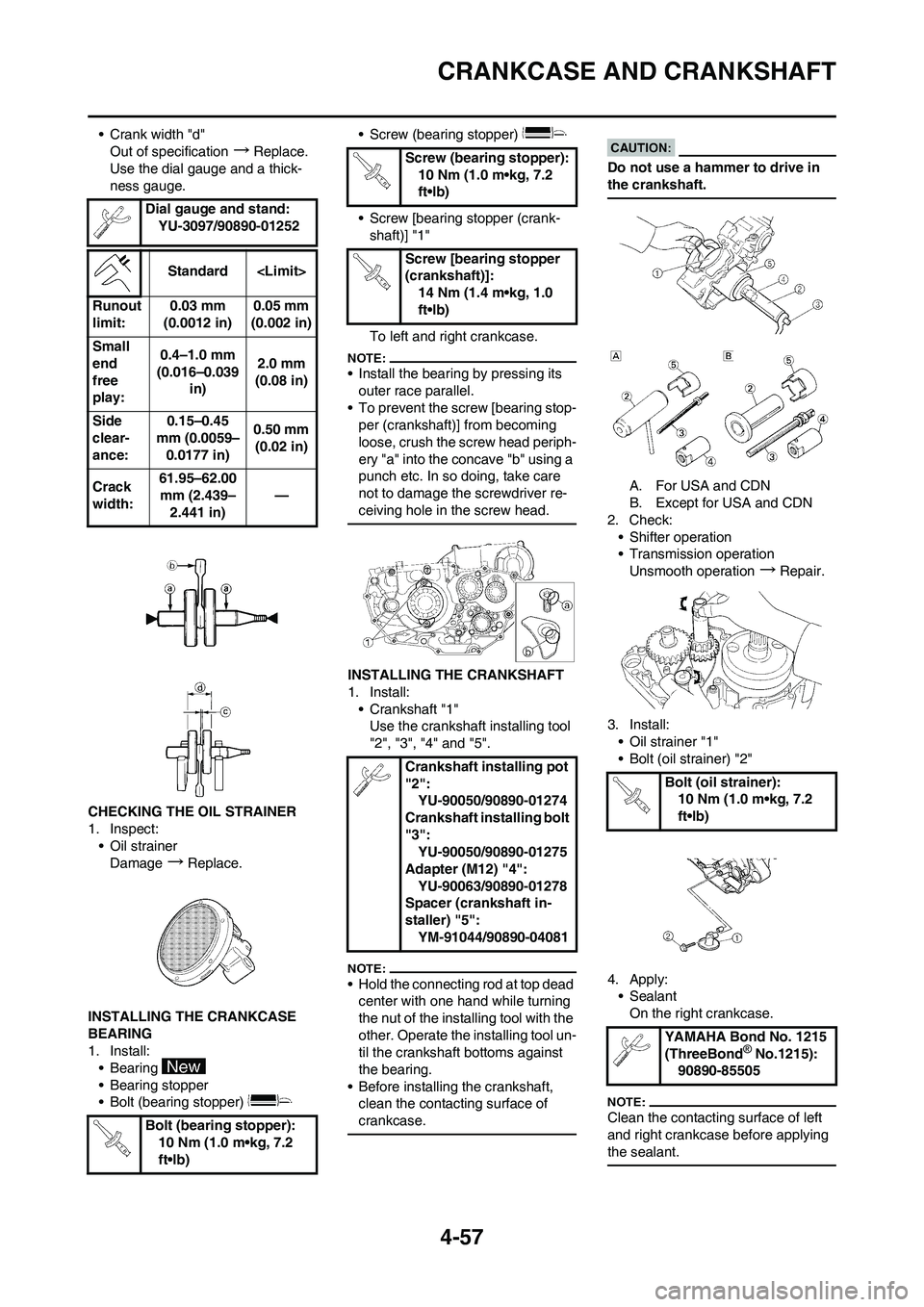

• Crank width "d"

Out of specification

→Replace.

Use the dial gauge and a thick-

ness gauge.

CHECKING THE OIL STRAINER

1. Inspect:

• Oil strainer

Damage

→Replace.

INSTALLING THE CRANKCASE

BEARING

1. Install:

• Bearing

• Bearing stopper

• Bolt (bearing stopper) • Screw (bearing stopper)

• Screw [bearing stopper (crank-

shaft)] "1"

To left and right crankcase.

• Install the bearing by pressing its

outer race parallel.

• To prevent the screw [bearing stop-

per (crankshaft)] from becoming

loose, crush the screw head periph-

ery "a" into the concave "b" using a

punch etc. In so doing, take care

not to damage the screwdriver re-

ceiving hole in the screw head.

INSTALLING THE CRANKSHAFT

1. Install:

• Crankshaft "1"

Use the crankshaft installing tool

"2", "3", "4" and "5".

• Hold the connecting rod at top dead

center with one hand while turning

the nut of the installing tool with the

other. Operate the installing tool un-

til the crankshaft bottoms against

the bearing.

• Before installing the crankshaft,

clean the contacting surface of

crankcase.

Do not use a hammer to drive in

the crankshaft.

A. For USA and CDN

B. Except for USA and CDN

2. Check:

• Shifter operation

• Transmission operation

Unsmooth operation

→Repair.

3. Install:

• Oil strainer "1"

• Bolt (oil strainer) "2"

4. Apply:

• Sealant

On the right crankcase.

Clean the contacting surface of left

and right crankcase before applying

the sealant.

Dial gauge and stand:

YU-3097/90890-01252

Standard

Runout

limit:0.03 mm

(0.0012 in)0.05 mm

(0.002 in)

Small

end

free

play:0.4–1.0 mm

(0.016–0.039

in)2.0 mm

(0.08 in)

Side

clear-

ance:0.15–0.45

mm (0.0059–

0.0177 in)0.50 mm

(0.02 in)

Crack

width:61.95–62.00

mm (2.439–

2.441 in)—

Bolt (bearing stopper):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Screw (bearing stopper):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Screw [bearing stopper

(crankshaft)]:

14 Nm (1.4 m•kg, 1.0

ft•lb)

Crankshaft installing pot

"2":

YU-90050/90890-01274

Crankshaft installing bolt

"3":

YU-90050/90890-01275

Adapter (M12) "4":

YU-90063/90890-01278

Spacer (crankshaft in-

staller) "5":

YM-91044/90890-04081

Bolt (oil strainer):

10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No.1215):

90890-85505