check engine YAMAHA YZ450F 2010 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ450F, Model: YAMAHA YZ450F 2010Pages: 230, PDF Size: 14.09 MB

Page 63 of 230

3-7

ENGINE

CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Apply water on the radiator cap seal.

3. Radiator cap

2. Apply the specified pressure.

3. Inspect:

• Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds →

Replace.

CHECKING THE COOLING

SYSTEM

1. Inspect:

• Coolant level

2. Attach:

• Radiator cap tester "1" and adapt-

er "2"3. Apply the specified pressure.

• Do not apply pressure more than

specified pressure.

• Radiator should be filled fully.

4. Inspect:

•Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds →

Repair.

• Radiator

• Radiator hose joint

Coolant leakage → Repair or re-

place.

• Radiator hose

Swelling → Replace.

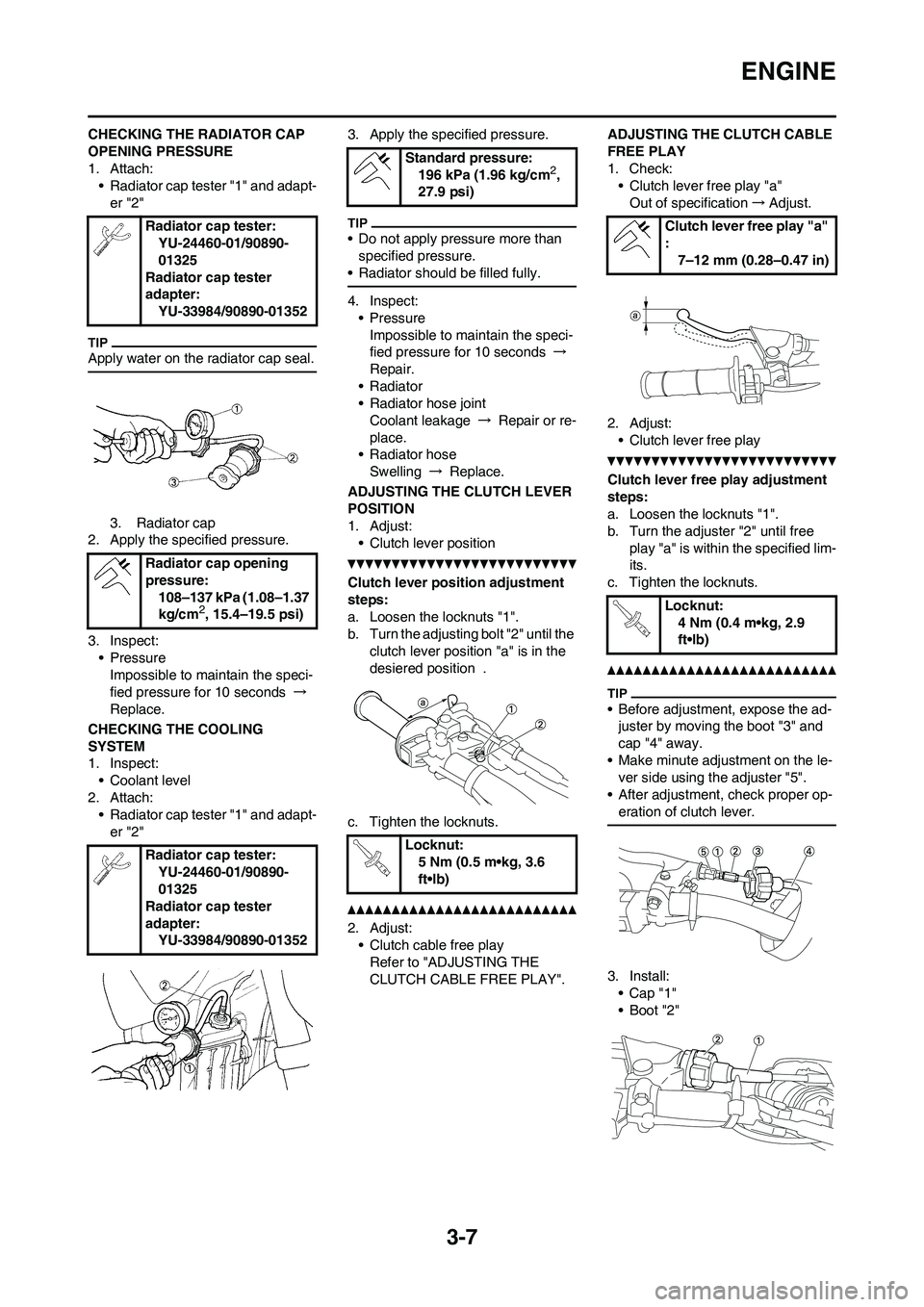

ADJUSTING THE CLUTCH LEVER

POSITION

1. Adjust:

• Clutch lever position

Clutch lever position adjustment

steps:

a. Loosen the locknuts "1".

b. Turn the adjusting bolt "2" until the

clutch lever position "a" is in the

desiered position .

c. Tighten the locknuts.

2. Adjust:

• Clutch cable free play

Refer to "ADJUSTING THE

CLUTCH CABLE FREE PLAY".ADJUSTING THE CLUTCH CABLE

FREE PLAY

1. Check:

• Clutch lever free play "a"

Out of specification→Adjust.

2. Adjust:

• Clutch lever free play

Clutch lever free play adjustment

steps:

a. Loosen the locknuts "1".

b. Turn the adjuster "2" until free

play "a" is within the specified lim-

its.

c. Tighten the locknuts.

• Before adjustment, expose the ad-

juster by moving the boot "3" and

cap "4" away.

• Make minute adjustment on the le-

ver side using the adjuster "5".

• After adjustment, check proper op-

eration of clutch lever.

3. Install:

•Cap "1"

• Boot "2" Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Radiator cap opening

pressure:

108–137 kPa (1.08–1.37

kg/cm

2, 15.4–19.5 psi)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Standard pressure:

196 kPa (1.96 kg/cm2,

27.9 psi)

Locknut:

5 Nm (0.5 m•kg, 3.6

ft•lb)

Clutch lever free play "a"

:

7–12 mm (0.28–0.47 in)

Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 64 of 230

3-8

ENGINE

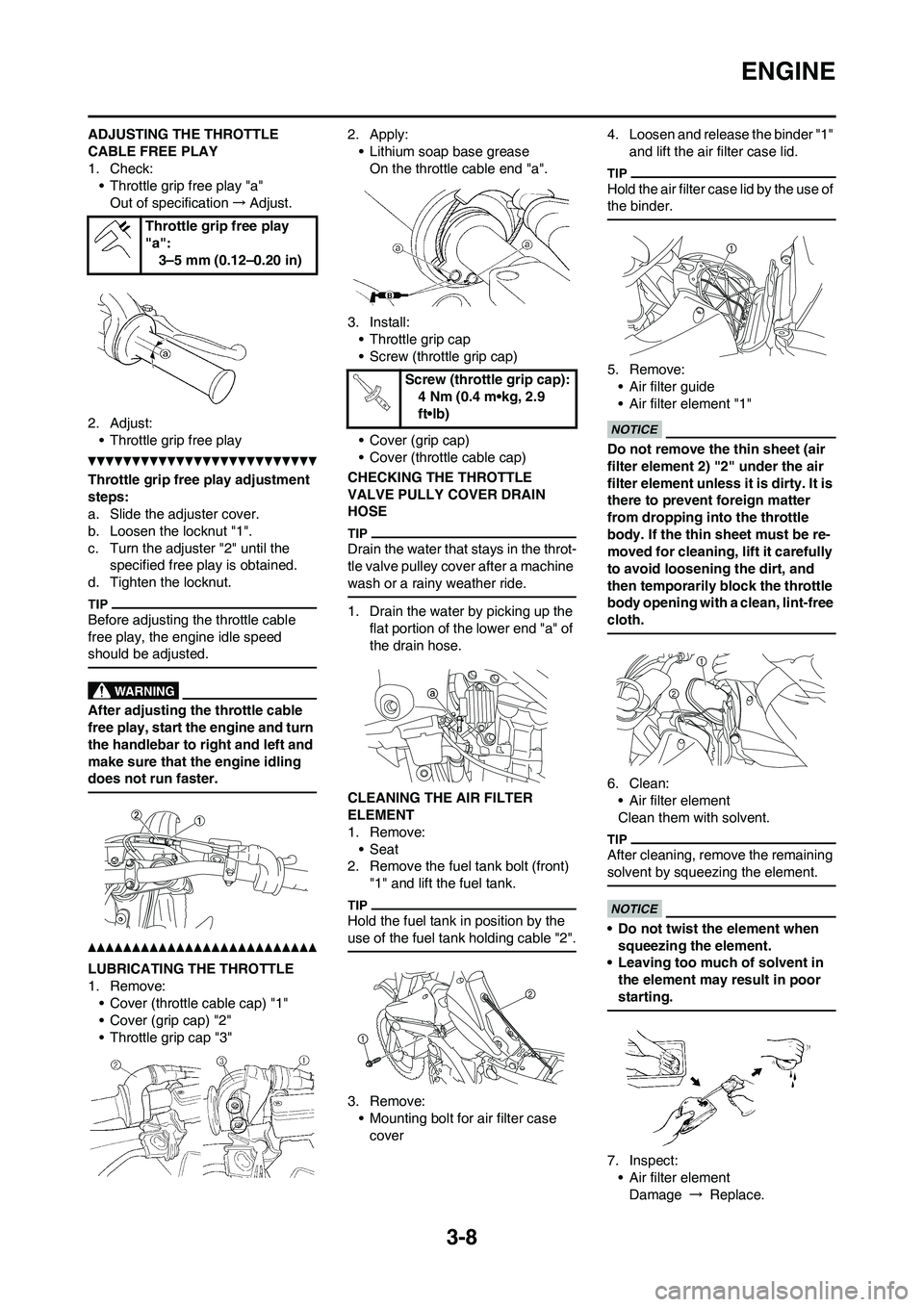

ADJUSTING THE THROTTLE

CABLE FREE PLAY

1. Check:• Throttle grip free play "a"

Out of specification →Adjust.

2. Adjust: • Throttle grip free play

Throttle grip free play adjustment

steps:

a. Slide the adjuster cover.

b. Loosen the locknut "1".

c. Turn the adjuster "2" until the specified free play is obtained.

d. Tighten the locknut.

Before adjusting the throttle cable

free play, the engine idle speed

should be adjusted.

After adjusting th e throttle cable

free play, start the engine and turn

the handlebar to right and left and

make sure that the engine idling

does not run faster.

LUBRICATING THE THROTTLE

1. Remove: • Cover (throttle cable cap) "1"

• Cover (grip cap) "2"

• Throttle grip cap "3" 2. Apply:

• Lithium soap base greaseOn the throttle cable end "a".

3. Install: • Throttle grip cap

• Screw (throttle grip cap)

• Cover (grip cap)

• Cover (throttle cable cap)

CHECKING THE THROTTLE

VALVE PULLY COVER DRAIN

HOSE

Drain the water that stays in the throt-

tle valve pulley cove r after a machine

wash or a rainy weather ride.

1. Drain the water by picking up the flat portion of the lower end "a" of

the drain hose.

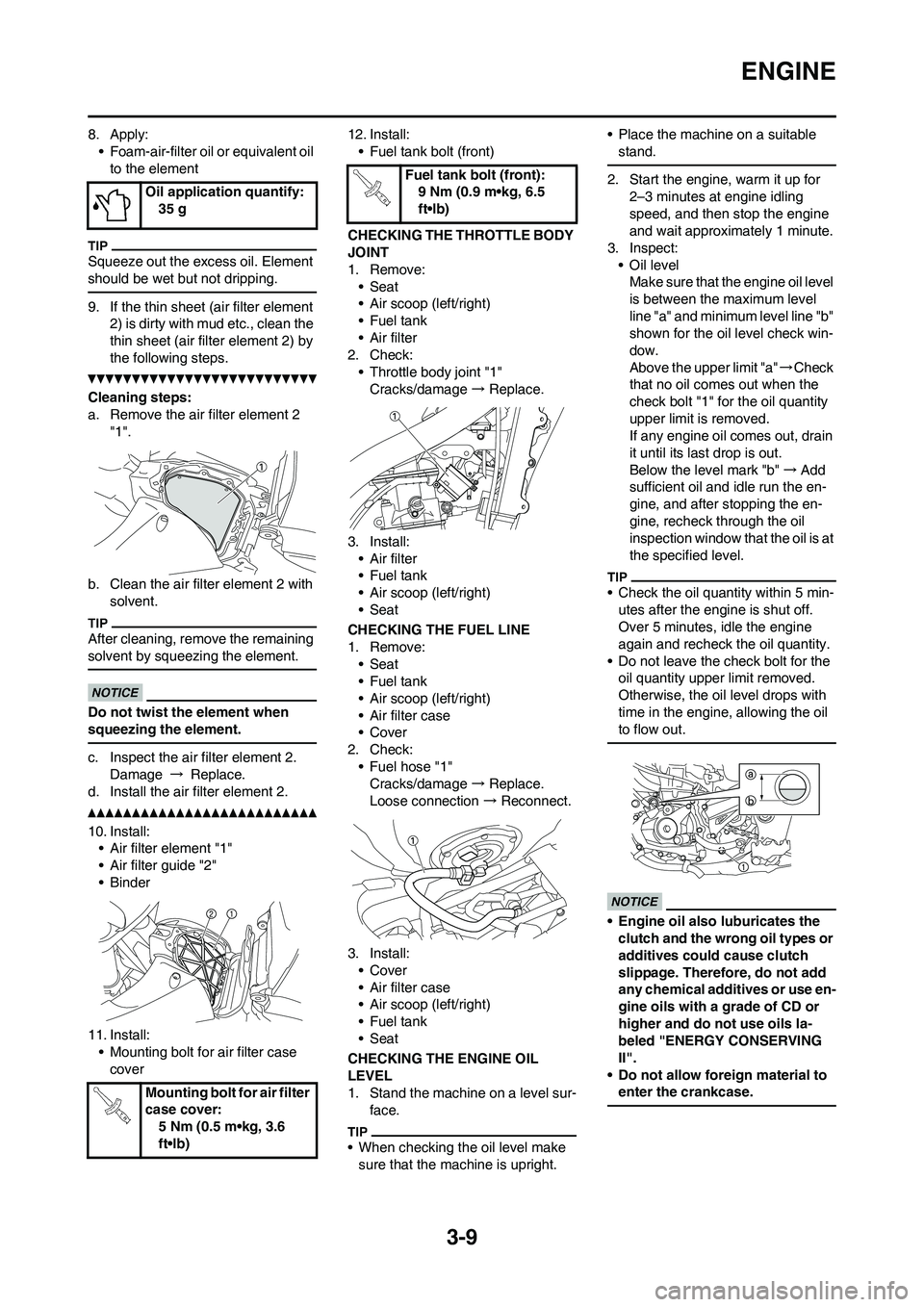

CLEANING THE AIR FILTER

ELEMENT

1. Remove: •Seat

2. Remove the fuel tank bolt (front) "1" and lift the fuel tank.

Hold the fuel tank in position by the

use of the fuel tank holding cable "2".

3. Remove:• Mounting bolt for air filter case

cover 4. Loosen and release the binder "1"

and lift the air filter case lid.

Hold the air filter case lid by the use of

the binder.

5. Remove:• Air filter guide

• Air filter element "1"

Do not remove the thin sheet (air

filter element 2) "2" under the air

filter element unless it is dirty. It is

there to prevent foreign matter

from dropping in to the throttle

body. If the thin sheet must be re-

moved for cleaning, lift it carefully

to avoid loosening the dirt, and

then temporarily block the throttle

body opening with a clean, lint-free

cloth.

6. Clean: • Air filter element

Clean them with solvent.

After cleaning, remo ve the remaining

solvent by squeezing the element.

• Do not twist the element when squeezing the element.

• Leaving too much of solvent in

the element may result in poor

starting.

7. Inspect:• Air filter elementDamage → Replace.

Throttle grip free play

"a":

3–5 mm (0.12–0.20 in)

Screw (throttle grip cap): 4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 65 of 230

3-9

ENGINE

8. Apply:• Foam-air-filter oil or equivalent oil to the element

Squeeze out the excess oil. Element

should be wet but not dripping.

9. If the thin sheet (air filter element 2) is dirty with mud etc., clean the

thin sheet (air filt er element 2) by

the following steps.

Cleaning steps:

a. Remove the air filter element 2 "1".

b. Clean the air filter element 2 with solvent.

After cleaning, remo ve the remaining

solvent by squeezing the element.

Do not twist the element when

squeezing the element.

c. Inspect the air filter element 2. Damage → Replace.

d. Install the air filter element 2.

10. Install: • Air filter element "1"

• Air filter guide "2"

•Binder

11. Install: • Mounting bolt for air filter case

cover 12. Install:

• Fuel tank bolt (front)

CHECKING THE THROTTLE BODY

JOINT

1. Remove: •Seat

• Air scoop (left/right)

•Fuel tank

• Air filter

2. Check: • Throttle body joint "1"

Cracks/damage → Replace.

3. Install: • Air filter

•Fuel tank

• Air scoop (left/right)

•Seat

CHECKING THE FUEL LINE

1. Remove: •Seat

•Fuel tank

• Air scoop (left/right)

• Air filter case

• Cover

2. Check:

• Fuel hose "1"Cracks/damage → Replace.

Loose connection → Reconnect.

3. Install: • Cover

• Air filter case

• Air scoop (left/right)

•Fuel tank

•Seat

CHECKING THE ENGINE OIL

LEVEL

1. Stand the machine on a level sur- face.

• When checking the oil level make sure that the machine is upright. • Place the machine on a suitable

stand.

2. Start the engine, warm it up for 2–3 minutes at engine idling

speed, and then stop the engine

and wait approximately 1 minute.

3. Inspect: • Oil levelMake sure that the engine oil level

is between the maximum level

line "a" and minimum level line "b"

shown for the oil level check win-

dow.

Above the upper limit "a" →Check

that no oil comes out when the

check bolt "1" for the oil quantity

upper limit is removed.

If any engine oil comes out, drain

it until its last drop is out.

Below the level mark "b" →Add

sufficient oil and idle run the en-

gine, and after stopping the en-

gine, recheck through the oil

inspection window that the oil is at

the specified level.

• Check the oil quantity within 5 min- utes after the engin e is shut off.

Over 5 minutes, idle the engine

again and recheck the oil quantity.

• Do not leave the check bolt for the oil quantity upper limit removed.

Otherwise, the oil level drops with

time in the engine, allowing the oil

to flow out.

• Engine oil also luburicates the clutch and the wrong oil types or

additives could cause clutch

slippage. Therefore, do not add

any chemical additives or use en-

gine oils with a grade of CD or

higher and do not use oils la-

beled "ENERGY CONSERVING

II".

• Do not allow fore ign material to

enter the crankcase.

Oil application quantify: 35 g

Mounting bolt for air filter

case cover: 5 Nm (0.5 m•kg, 3.6

ft•lb)

Fuel tank bolt (front):9 Nm (0.9 m•kg, 6.5

ft•lb)

Page 66 of 230

3-10

ENGINE

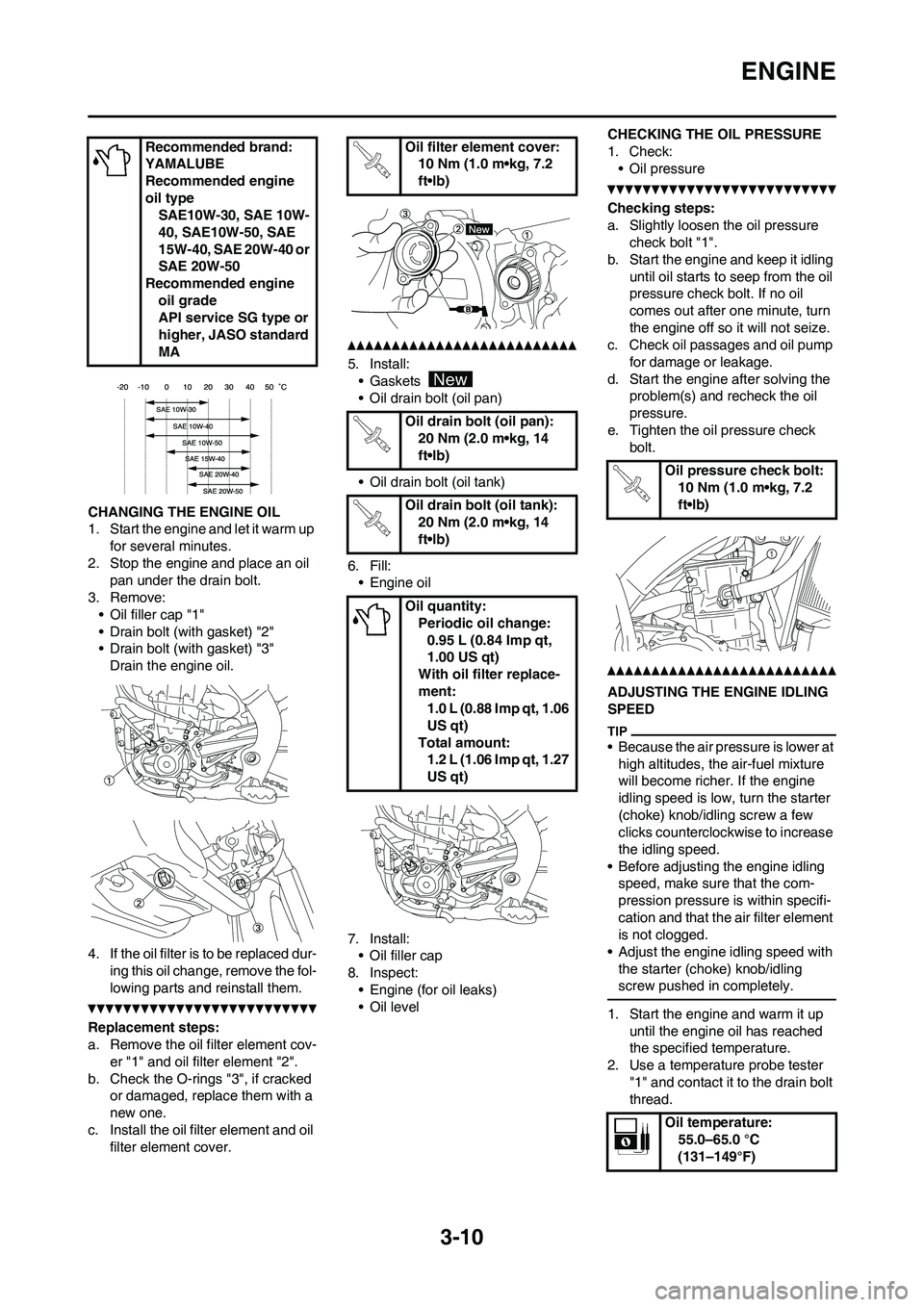

CHANGING THE ENGINE OIL

1. Start the engine and let it warm up for several minutes.

2. Stop the engine and place an oil pan under the drain bolt.

3. Remove: • Oil filler cap "1"

• Drain bolt (with gasket) "2"

• Drain bolt (with gasket) "3"Drain the engine oil.

4. If the oil filter is to be replaced dur- ing this oil change, remove the fol-

lowing parts and reinstall them.

Replacement steps:

a. Remove the oil filter element cov-er "1" and oil filter element "2".

b. Check the O-rings "3", if cracked or damaged, replace them with a

new one.

c. Install the oil filter element and oil filter element cover.

5. Install:• Gaskets

• Oil drain bolt (oil pan)

• Oil drain bolt (oil tank)

6. Fill: • Engine oil

7. Install: • Oil filler cap

8. Inspect:

• Engine (for oil leaks)

• Oil level CHECKING THE OIL PRESSURE

1. Check:

• Oil pressure

Checking steps:

a. Slightly loosen the oil pressure check bolt "1".

b. Start the engine and keep it idling until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump

for damage or leakage.

d. Start the engine after solving the problem(s) and recheck the oil

pressure.

e. Tighten the oil pressure check bolt.

ADJUSTING THE ENGINE IDLING

SPEED

• Because the air pressure is lower at

high altitudes, the air-fuel mixture

will become richer. If the engine

idling speed is low, turn the starter

(choke) knob/idling screw a few

clicks counterclockwise to increase

the idling speed.

• Before adjusting the engine idling speed, make sure that the com-

pression pressure is within specifi-

cation and that the air filter element

is not clogged.

• Adjust the engine idling speed with

the starter (choke) knob/idling

screw pushed in completely.

1. Start the engine and warm it up until the engine oil has reached

the specified temperature.

2. Use a temperature probe tester "1" and contact it to the drain bolt

thread.

Recommended brand:

YAMALUBE

Recommended engine

oil type

SAE10W-30, SAE 10W-

40, SAE10W-50, SAE

15W-40, SAE 20W-40 or

SAE 20W-50

Recommended engine

oil grade

API service SG type or

higher, JASO standard

MA

Oil filter element cover:10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil drain bolt (oil pan): 20 Nm (2.0 m•kg, 14

ft•lb)

Oil drain bolt (oil tank): 20 Nm (2.0 m•kg, 14

ft•lb)

Oil quantity: Periodic oil change:0.95 L (0.84 Imp qt,

1.00 US qt)

With oil filter replace-

ment: 1.0 L (0.88 Imp qt, 1.06

US qt)

Total amount: 1.2 L (1.06 Imp qt, 1.27

US qt)

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil temperature: 55.0–65.0 °C

(131–149°F)

Page 67 of 230

3-11

ENGINE

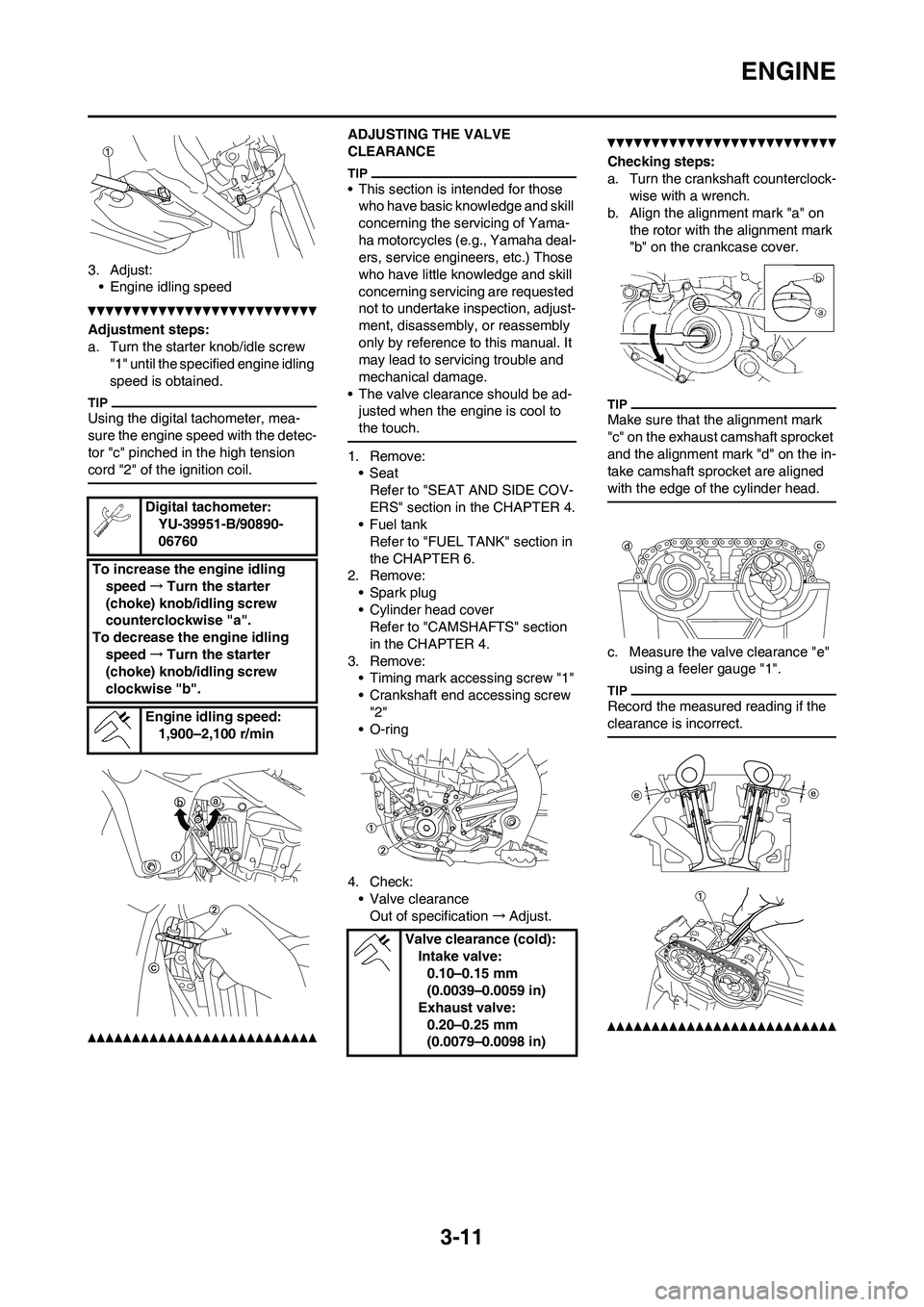

3. Adjust:• Engine idling speed

Adjustment steps:

a. Turn the starter knob/idle screw "1" until the specified engine idling

speed is obtained.

Using the digital tachometer, mea-

sure the engine speed with the detec-

tor "c" pinched in the high tension

cord "2" of the ignition coil.

ADJUSTING THE VALVE

CLEARANCE

• This section is intended for those who have basic knowledge and skill

concerning the servicing of Yama-

ha motorcycles (e.g., Yamaha deal-

ers, service engineers, etc.) Those

who have little knowledge and skill

concerning servicing are requested

not to undertake in spection, adjust-

ment, disassembly, or reassembly

only by reference to this manual. It

may lead to servicing trouble and

mechanical damage.

• The valve clearance should be ad- justed when the engine is cool to

the touch.

1. Remove:•Seat

Refer to "SEAT AND SIDE COV-

ERS" section in the CHAPTER 4.

•Fuel tank

Refer to "FUEL TANK" section in

the CHAPTER 6.

2. Remove:

• Spark plug

• Cylinder head coverRefer to "CAMSHAFTS" section

in the CHAPTER 4.

3. Remove: • Timing mark accessing screw "1"

• Crankshaft end accessing screw "2"

• O-ring

4. Check: • Valve clearanceOut of specification →Adjust.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the alignment mark "a" on the rotor with the alignment mark

"b" on the crankcase cover.

Make sure that the alignment mark

"c" on the exhaust camshaft sprocket

and the alignment mark "d" on the in-

take camshaft sprocket are aligned

with the edge of the cylinder head.

c. Measure the valve clearance "e" using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

Digital tachometer:

YU-39951-B/90890-

06760

To increase the engine idling speed →Turn the starter

(choke) knob/idling screw

counterclockwise "a".

To decrease the engine idling

speed →Turn the starter

(choke) knob/idling screw

clockwise "b".

Engine idling speed:1,900–2,100 r/min

Valve clearance (cold):Intake valve:0.10–0.15 mm

(0.0039–0.0059 in)

Exhaust valve: 0.20–0.25 mm

(0.0079–0.0098 in)

Page 74 of 230

3-18

CHASSIS

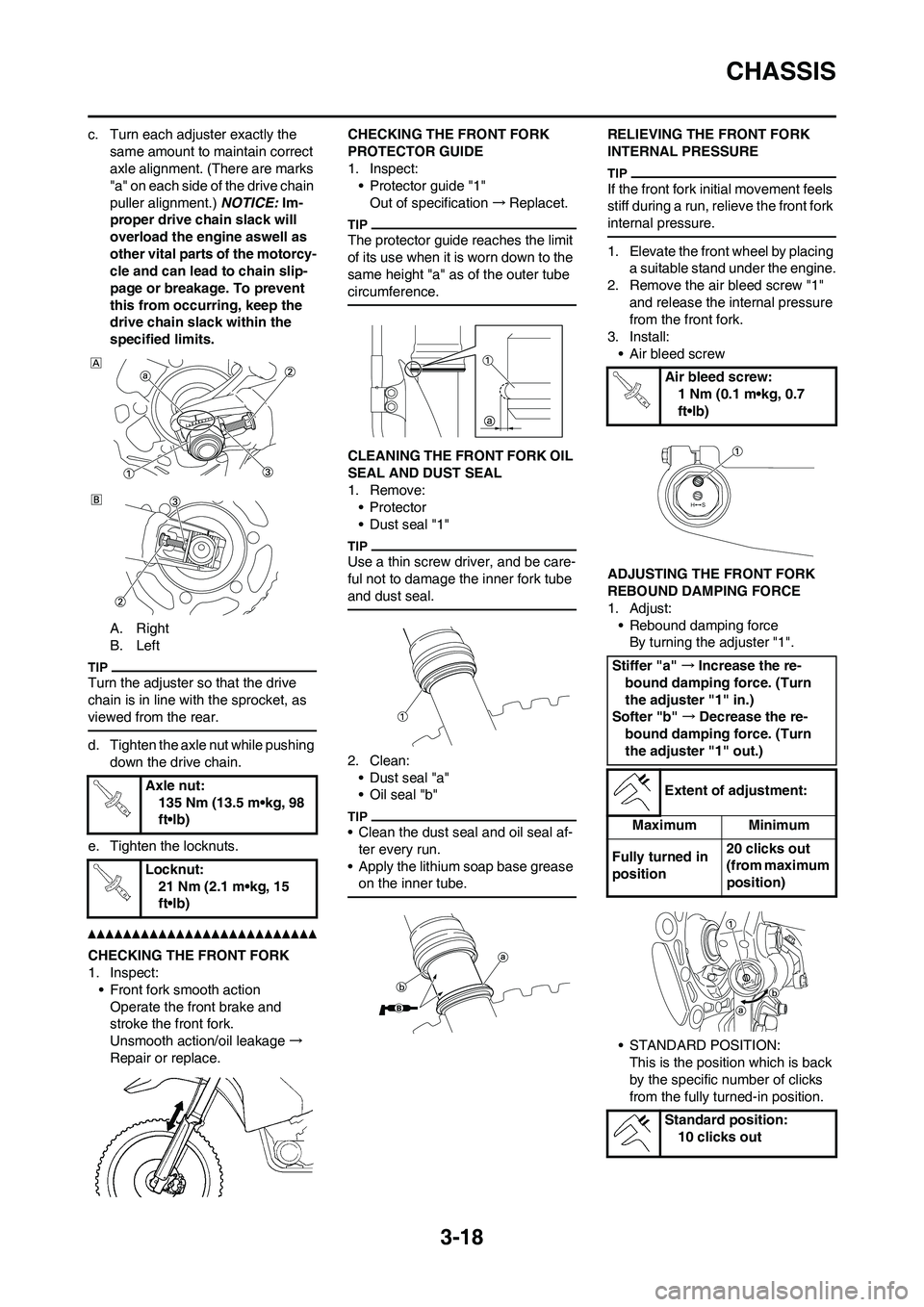

c. Turn each adjuster exactly the

same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.) NOTICE: Im-

proper drive chain slack will

overload the engine aswell as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. To prevent

this from occurring, keep the

drive chain slack within the

specified limits.

A. Right

B. Left

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

d. Tighten the axle nut while pushing

down the drive chain.

e. Tighten the locknuts.

CHECKING THE FRONT FORK

1. Inspect:

• Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage→

Repair or replace.CHECKING THE FRONT FORK

PROTECTOR GUIDE

1. Inspect:

• Protector guide "1"

Out of specification→Replacet.

The protector guide reaches the limit

of its use when it is worn down to the

same height "a" as of the outer tube

circumference.

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:

•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:

• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease

on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing

a suitable stand under the engine.

2. Remove the air bleed screw "1"

and release the internal pressure

from the front fork.

3. Install:

• Air bleed screw

ADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position. Axle nut:

135 Nm (13.5 m•kg, 98

ft•lb)

Locknut:

21 Nm (2.1 m•kg, 15

ft•lb)

Air bleed screw:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

10 clicks out

Page 77 of 230

3-21

CHASSIS

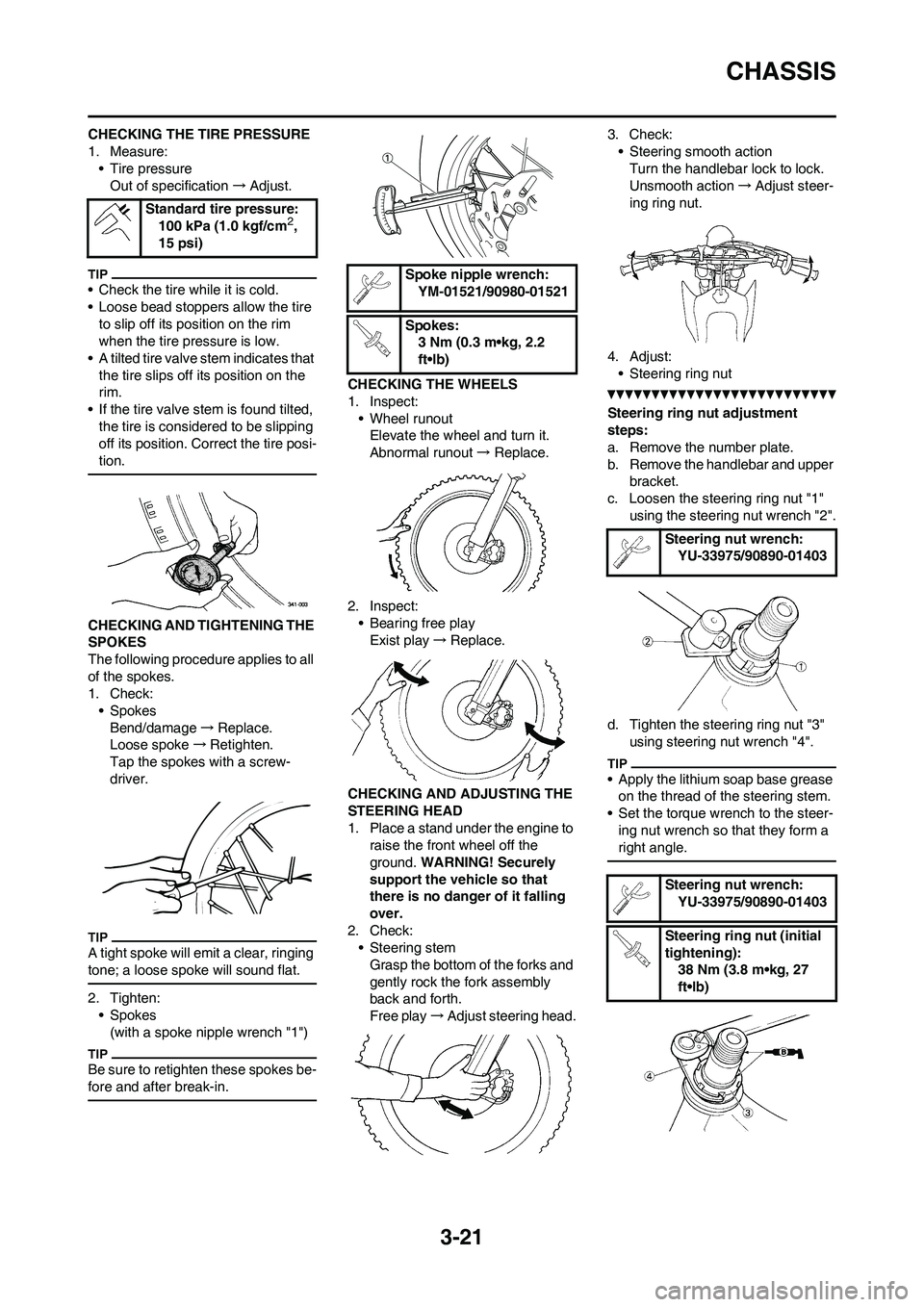

CHECKING THE TIRE PRESSURE

1. Measure:

• Tire pressure

Out of specification→Adjust.

• Check the tire while it is cold.

• Loose bead stoppers allow the tire

to slip off its position on the rim

when the tire pressure is low.

• A tilted tire valve stem indicates that

the tire slips off its position on the

rim.

• If the tire valve stem is found tilted,

the tire is considered to be slipping

off its position. Correct the tire posi-

tion.

CHECKING AND TIGHTENING THE

SPOKES

The following procedure applies to all

of the spokes.

1. Check:

• Spokes

Bend/damage→Replace.

Loose spoke→Retighten.

Tap the spokes with a screw-

driver.

A tight spoke will emit a clear, ringing

tone; a loose spoke will sound flat.

2. Tighten:

• Spokes

(with a spoke nipple wrench "1")

Be sure to retighten these spokes be-

fore and after break-in.

CHECKING THE WHEELS

1. Inspect:

• Wheel runout

Elevate the wheel and turn it.

Abnormal runout→ Replace.

2. Inspect:

• Bearing free play

Exist play→Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Place a stand under the engine to

raise the front wheel off the

ground. WARNING! Securely

support the vehicle so that

there is no danger of it falling

over.

2. Check:

• Steering stem

Grasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play→Adjust steering head.3. Check:

• Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action→Adjust steer-

ing ring nut.

4. Adjust:

• Steering ring nut

Steering ring nut adjustment

steps:

a. Remove the number plate.

b. Remove the handlebar and upper

bracket.

c. Loosen the steering ring nut "1"

using the steering nut wrench "2".

d. Tighten the steering ring nut "3"

using steering nut wrench "4".

• Apply the lithium soap base grease

on the thread of the steering stem.

• Set the torque wrench to the steer-

ing nut wrench so that they form a

right angle.

Standard tire pressure:

100 kPa (1.0 kgf/cm2,

15 psi)

Spoke nipple wrench:

YM-01521/90980-01521

Spokes:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Steering nut wrench:

YU-33975/90890-01403

Steering nut wrench:

YU-33975/90890-01403

Steering ring nut (initial

tightening):

38 Nm (3.8 m•kg, 27

ft•lb)

Page 80 of 230

3-24

ELECTRICAL

ELECTRICAL

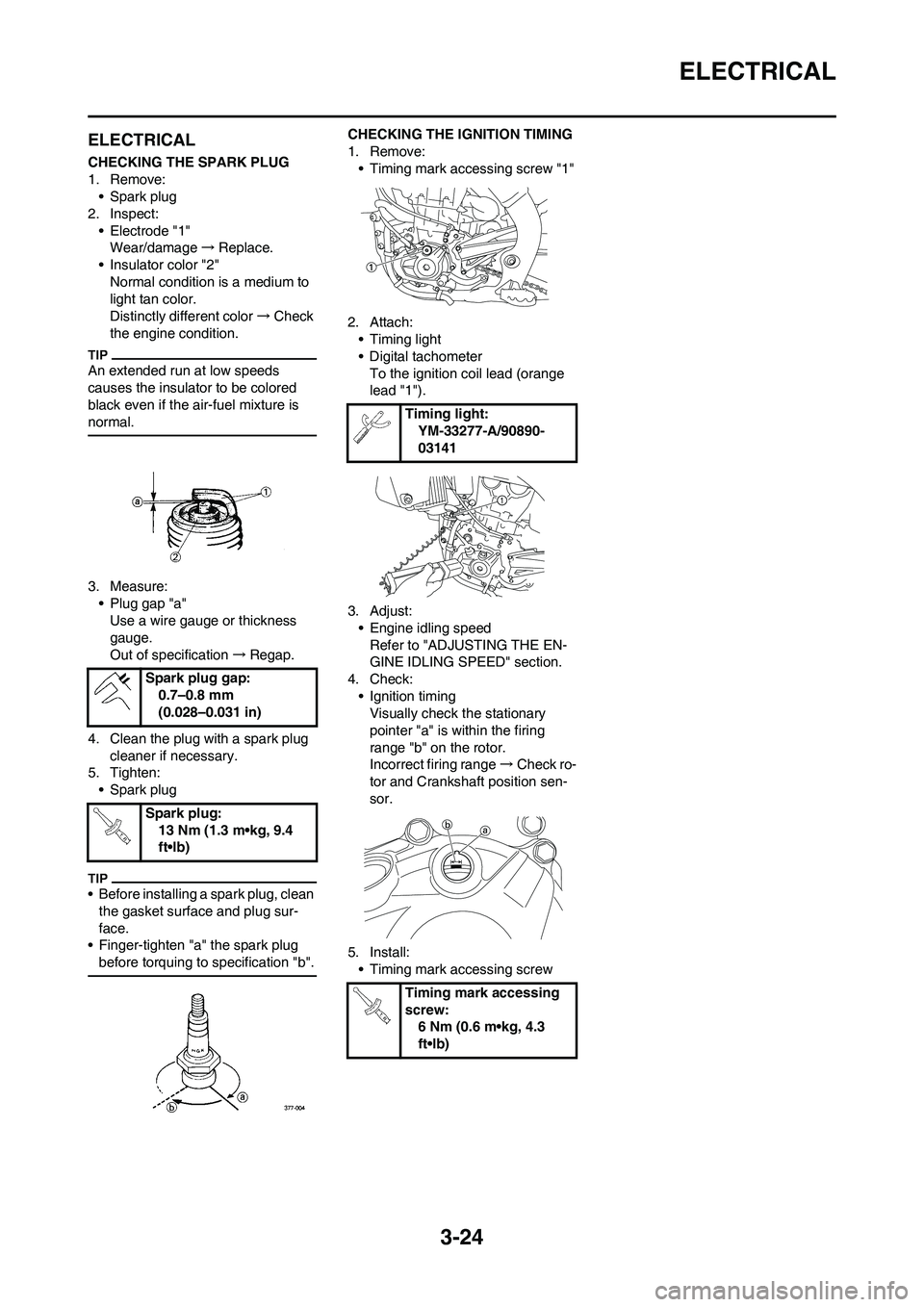

CHECKING THE SPARK PLUG

1. Remove:

• Spark plug

2. Inspect:

• Electrode "1"

Wear/damage→Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color→Check

the engine condition.

An extended run at low speeds

causes the insulator to be colored

black even if the air-fuel mixture is

normal.

3. Measure:

• Plug gap "a"

Use a wire gauge or thickness

gauge.

Out of specification→Regap.

4. Clean the plug with a spark plug

cleaner if necessary.

5. Tighten:

• Spark plug

• Before installing a spark plug, clean

the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug

before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw "1"

2. Attach:

• Timing light

• Digital tachometer

To the ignition coil lead (orange

lead "1").

3. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check:

• Ignition timing

Visually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range→Check ro-

tor and Crankshaft position sen-

sor.

5. Install:

• Timing mark accessing screw Spark plug gap:

0.7–0.8 mm

(0.028–0.031 in)

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Timing mark accessing

screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Page 81 of 230

3-25

ELECTRICAL

TROUBLESHOOTING

The following guide for troubleshooting does not cover all the possible causes of problems. If the following problems occur,

perform the specified checks or maintenance jobs. If a problem occurs that is not listed in this manual or if the problem

cannot be corrected by the procedures provided in this manual, contact your Yamaha dealer.

Engine starting problems, engine idling speed problems, and medium and high-speed performance problems

• Engine does not start even though the kickstarter is pushed.

• Engine starts, but soon stops.

Engine idling speed problems

• Engine idling speed fluctuates.

• Engine idling speed is high.

• Engine idling speed is low.

Medium and high-speed performance problems

• Engine speed does not increase.

• Engine knocks.

• Engine speed increases suddenly.

• Loss of engine power.

INSPECTION STEPS

If the aforementioned problems have occurred, perform the following inspection steps in the order given.

Check that the fuel tank is filled with fresh gaso-

line.No good→

Fill the fuel tank.

OK↓

Check that the fuel tank breather hose is not

clogged. (Refer to "INCLUDED PARTS" section

in the CHAPTER 1.)No good→

Repair or replace.

OK↓

Adjusting the engine idling speed(Refer to "AD-

JUSTING THE ENGINE IDLLING SPEED" sec-

tion in the CHAPTER 3.)No good→

Adjust.

OK↓

Check that the fuel hose is connected properly

and is not kinked or pinched.No good→

Repair.

OK↓

Check the spark plug for dirt, the spark plug gap,

and the spark plug cap. (Refer to "CHECKING

THE SPARK PLUG" section in the CHAPTER 3.)No good→

Clean or adjust.

OK↓

Check that the air filter element is installed cor-

rectly and is not clogged. (Refer to "CLEANING

THE AIR FILTER" section in the CHAPTER 3.)No good→

Clean or repair.

OK↓

Checking the sensors, injector and ignition coil

connection.No good→

Repair or replace.

OK↓

Installed condition of ECU (Refer to "CHECKING

THE ECU" section in the CHAPTER 7.)No good→

Repair.

OK↓

Check the assembled condition of the throttle

body, and check the throttle valve and its sur-

rounding parts for dirt.No good→

Repair or clean.

OK↓

Consult a Yamaha dealer.

Page 90 of 230

4-9

RADIATOR

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

CHECKING THE RADIATOR

1. Inspect:

• Radiator core "1"

Obstruction→Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin→Repair/replace.

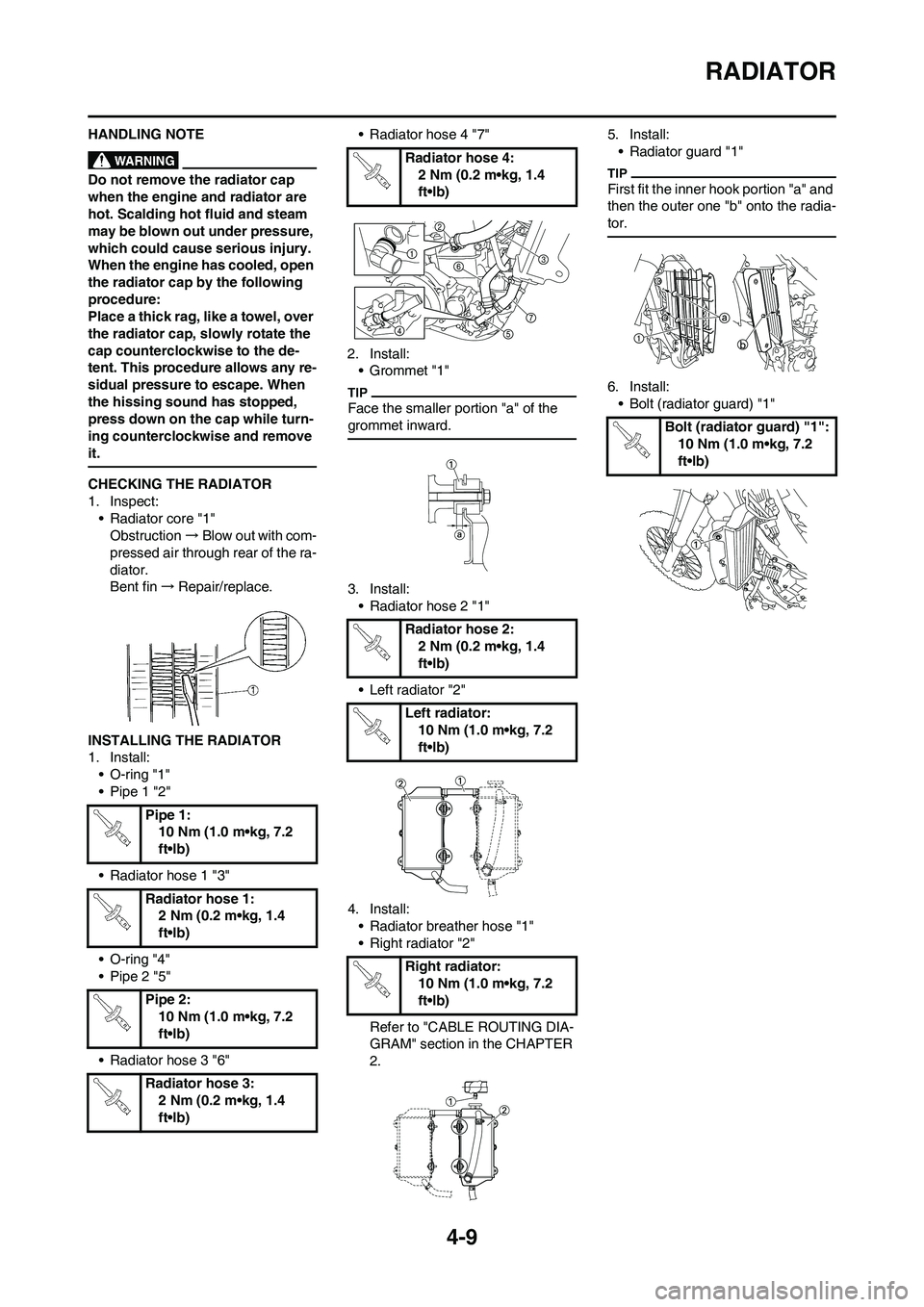

INSTALLING THE RADIATOR

1. Install:

• O-ring "1"

• Pipe 1 "2"

• Radiator hose 1 "3"

• O-ring "4"

• Pipe 2 "5"

• Radiator hose 3 "6"• Radiator hose 4 "7"

2. Install:

• Grommet "1"

Face the smaller portion "a" of the

grommet inward.

3. Install:

• Radiator hose 2 "1"

• Left radiator "2"

4. Install:

• Radiator breather hose "1"

• Right radiator "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.5. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

6. Install:

• Bolt (radiator guard) "1"

Pipe 1:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Pipe 2:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 3:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 4:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose 2:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Left radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Right radiator:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (radiator guard) "1":

10 Nm (1.0 m•kg, 7.2

ft•lb)