YAMAHA YZ450F 2013 Owners Manual

Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ450F, Model: YAMAHA YZ450F 2013Pages: 228, PDF Size: 11.41 MB

Page 211 of 228

7-27

FUEL INJECTION SYSTEM

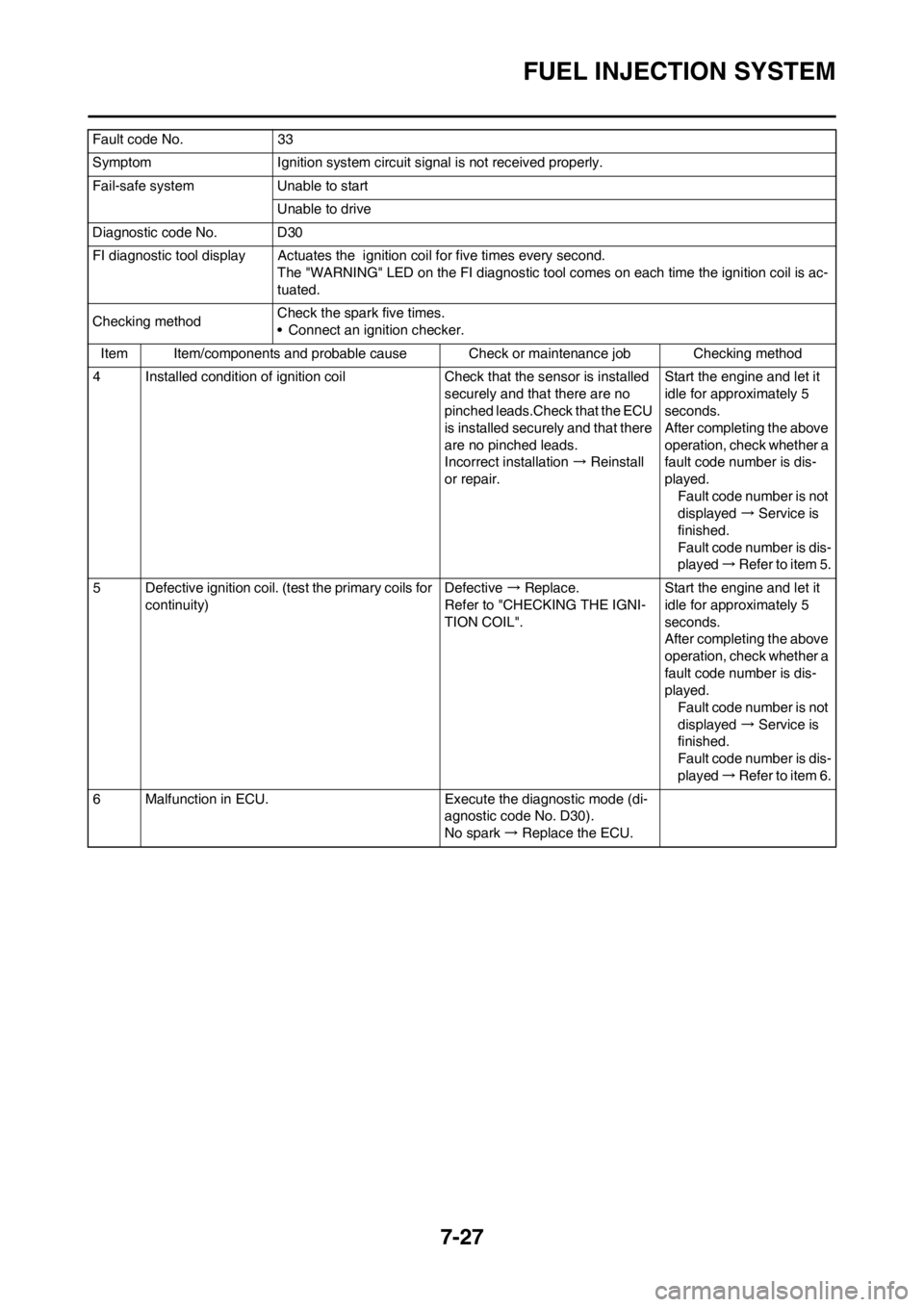

4 Installed condition of ignition coil Check that the sensor is installed

securely and that there are no

pinched leads.Check that the ECU

is installed securely and that there

are no pinched leads.

Incorrect installation → Reinstall

or repair.Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 5.

5 Defective ignition coil. (test the primary coils for

continuity)Defective → Replace.

Refer to "CHECKING THE IGNI-

TION COIL".Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 6.

6 Malfunction in ECU. Execute the diagnostic mode (di-

agnostic code No. D30).

No spark → Replace the ECU. Fault code No. 33

Symptom Ignition system circuit signal is not received properly.

Fail-safe system Unable to start

Unable to drive

Diagnostic code No. D30

FI diagnostic tool display Actuates the ignition coil for five times every second.

The "WARNING" LED on the FI diagnostic tool comes on each time the ignition coil is ac-

tuated.

Checking methodCheck the spark five times.

• Connect an ignition checker.

Item Item/components and probable cause Check or maintenance job Checking method

Page 212 of 228

7-28

FUEL INJECTION SYSTEM

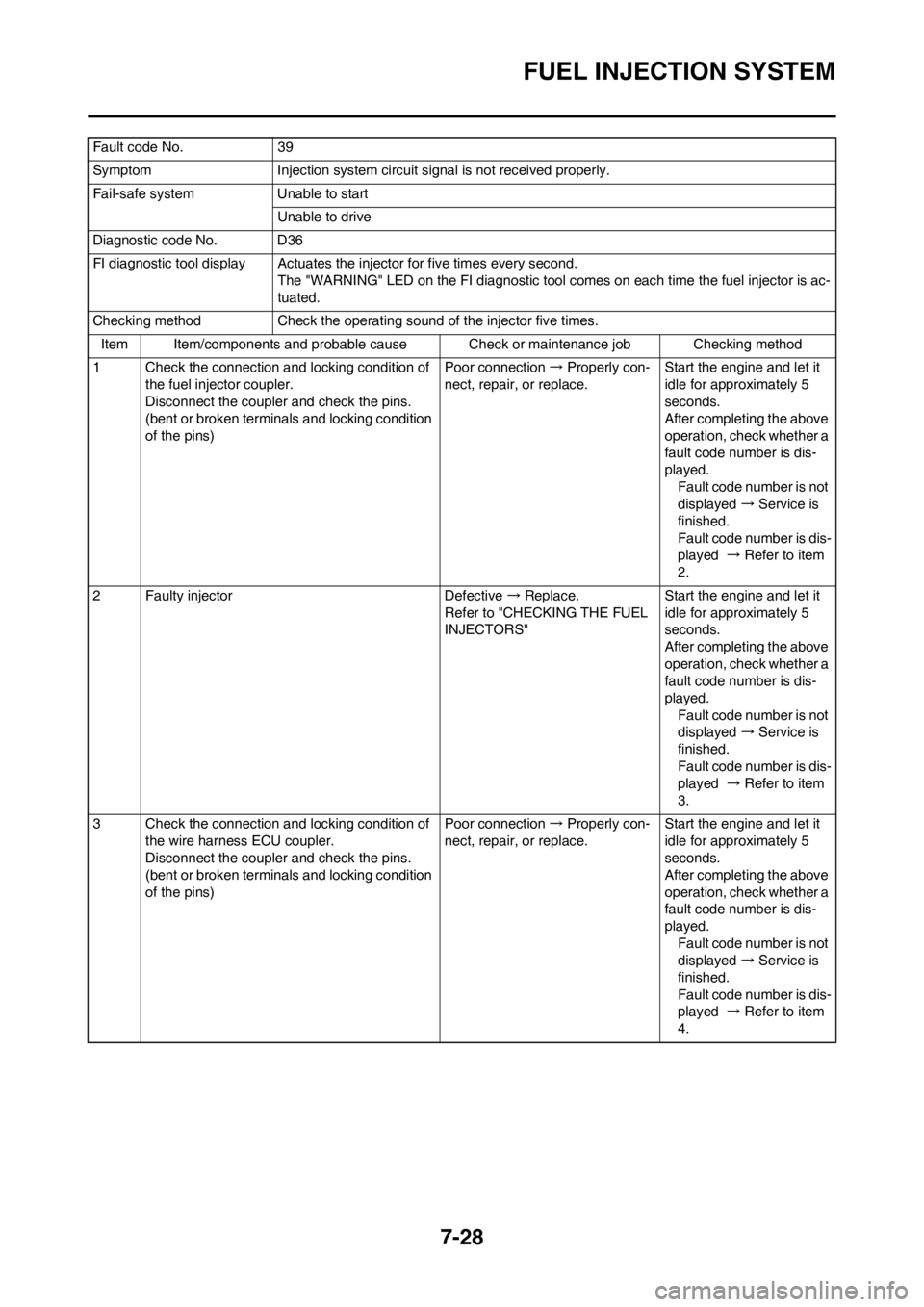

Fault code No. 39

Symptom Injection system circuit signal is not received properly.

Fail-safe system Unable to start

Unable to drive

Diagnostic code No. D36

FI diagnostic tool display Actuates the injector for five times every second.

The "WARNING" LED on the FI diagnostic tool comes on each time the fuel injector is ac-

tuated.

Checking method Check the operating sound of the injector five times.

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the fuel injector coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

2.

2 Faulty injector Defective → Replace.

Refer to "CHECKING THE FUEL

INJECTORS"Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

3.

3 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

4.

Page 213 of 228

7-29

FUEL INJECTION SYSTEM

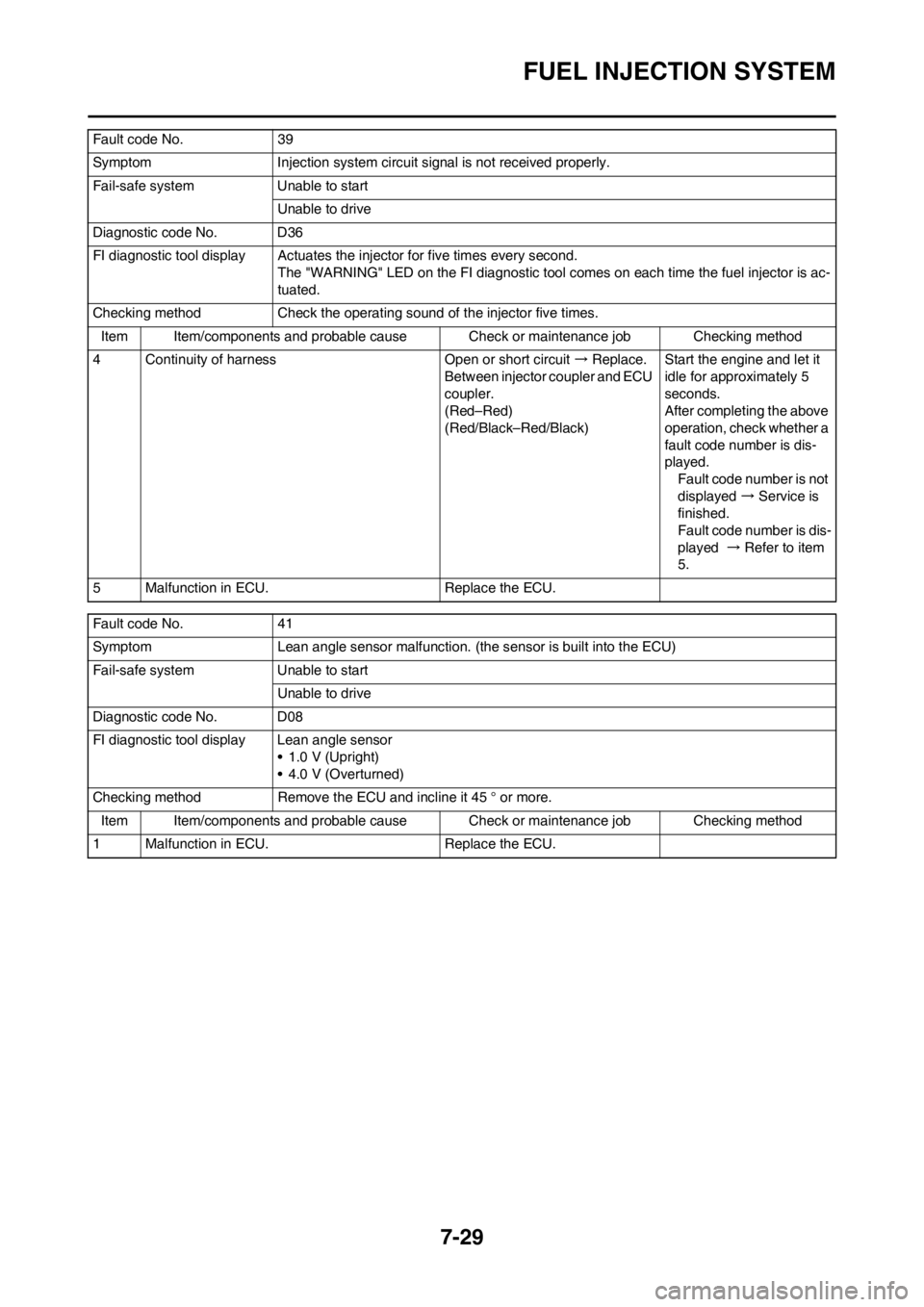

4 Continuity of harness Open or short circuit → Replace.

Between injector coupler and ECU

coupler.

(Red–Red)

(Red/Black–Red/Black)Start the engine and let it

idle for approximately 5

seconds.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item

5.

5 Malfunction in ECU. Replace the ECU.

Fault code No. 41

Symptom Lean angle sensor malfunction. (the sensor is built into the ECU)

Fail-safe system Unable to start

Unable to drive

Diagnostic code No. D08

FI diagnostic tool display Lean angle sensor

• 1.0 V (Upright)

• 4.0 V (Overturned)

Checking method Remove the ECU and incline it 45 ° or more.

Item Item/components and probable cause Check or maintenance job Checking method

1 Malfunction in ECU. Replace the ECU. Fault code No. 39

Symptom Injection system circuit signal is not received properly.

Fail-safe system Unable to start

Unable to drive

Diagnostic code No. D36

FI diagnostic tool display Actuates the injector for five times every second.

The "WARNING" LED on the FI diagnostic tool comes on each time the fuel injector is ac-

tuated.

Checking method Check the operating sound of the injector five times.

Item Item/components and probable cause Check or maintenance job Checking method

Page 214 of 228

7-30

FUEL INJECTION SYSTEM

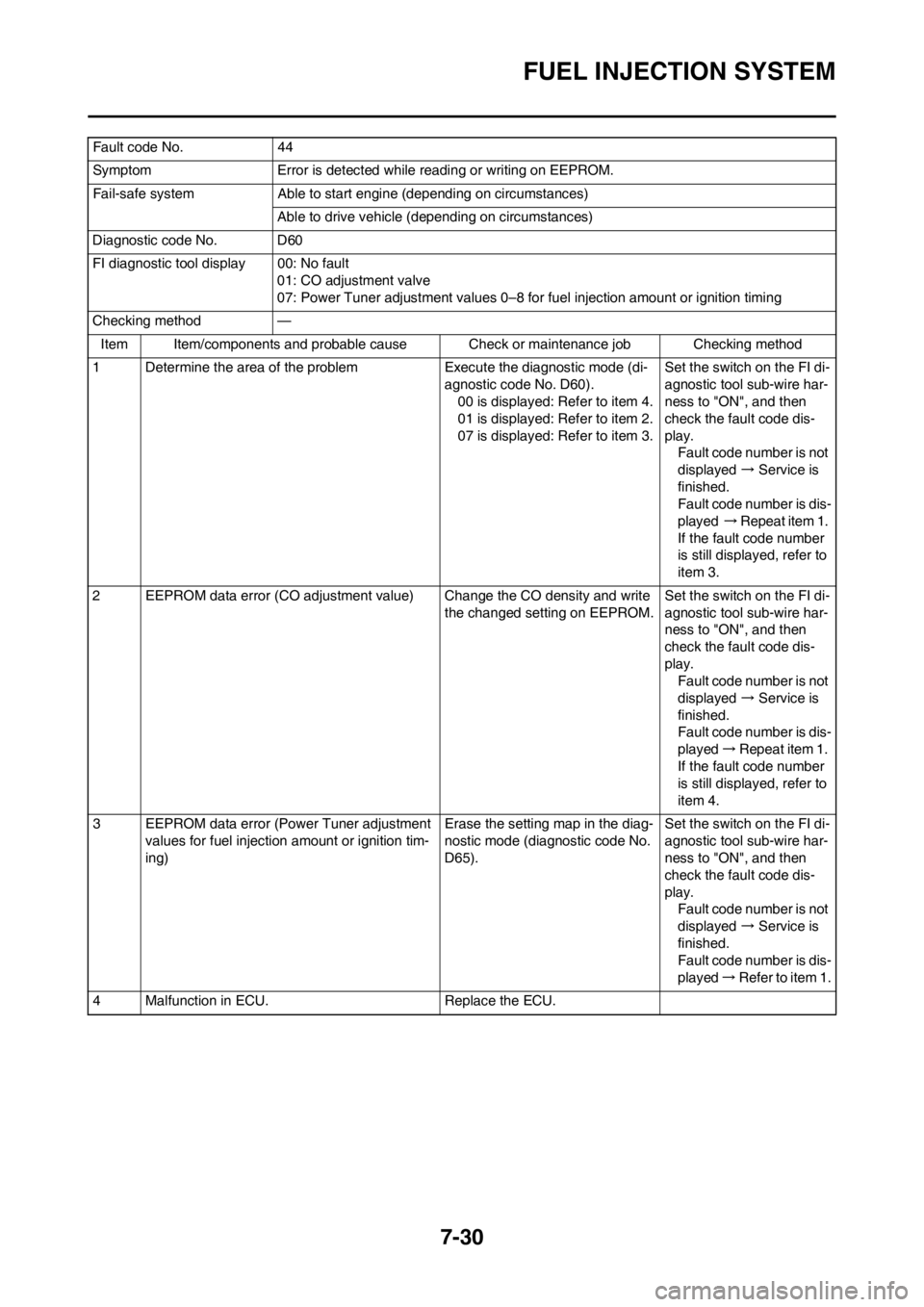

Fault code No. 44

Symptom Error is detected while reading or writing on EEPROM.

Fail-safe system Able to start engine (depending on circumstances)

Able to drive vehicle (depending on circumstances)

Diagnostic code No. D60

FI diagnostic tool display 00: No fault

01: CO adjustment valve

07: Power Tuner adjustment values 0–8 for fuel injection amount or ignition timing

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Determine the area of the problem Execute the diagnostic mode (di-

agnostic code No. D60).

00 is displayed: Refer to item 4.

01 is displayed: Refer to item 2.

07 is displayed: Refer to item 3.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Repeat item 1.

If the fault code number

is still displayed, refer to

item 3.

2 EEPROM data error (CO adjustment value) Change the CO density and write

the changed setting on EEPROM.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Repeat item 1.

If the fault code number

is still displayed, refer to

item 4.

3 EEPROM data error (Power Tuner adjustment

values for fuel injection amount or ignition tim-

ing)Erase the setting map in the diag-

nostic mode (diagnostic code No.

D65).Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 1.

4 Malfunction in ECU. Replace the ECU.

Page 215 of 228

7-31

FUEL INJECTION SYSTEM

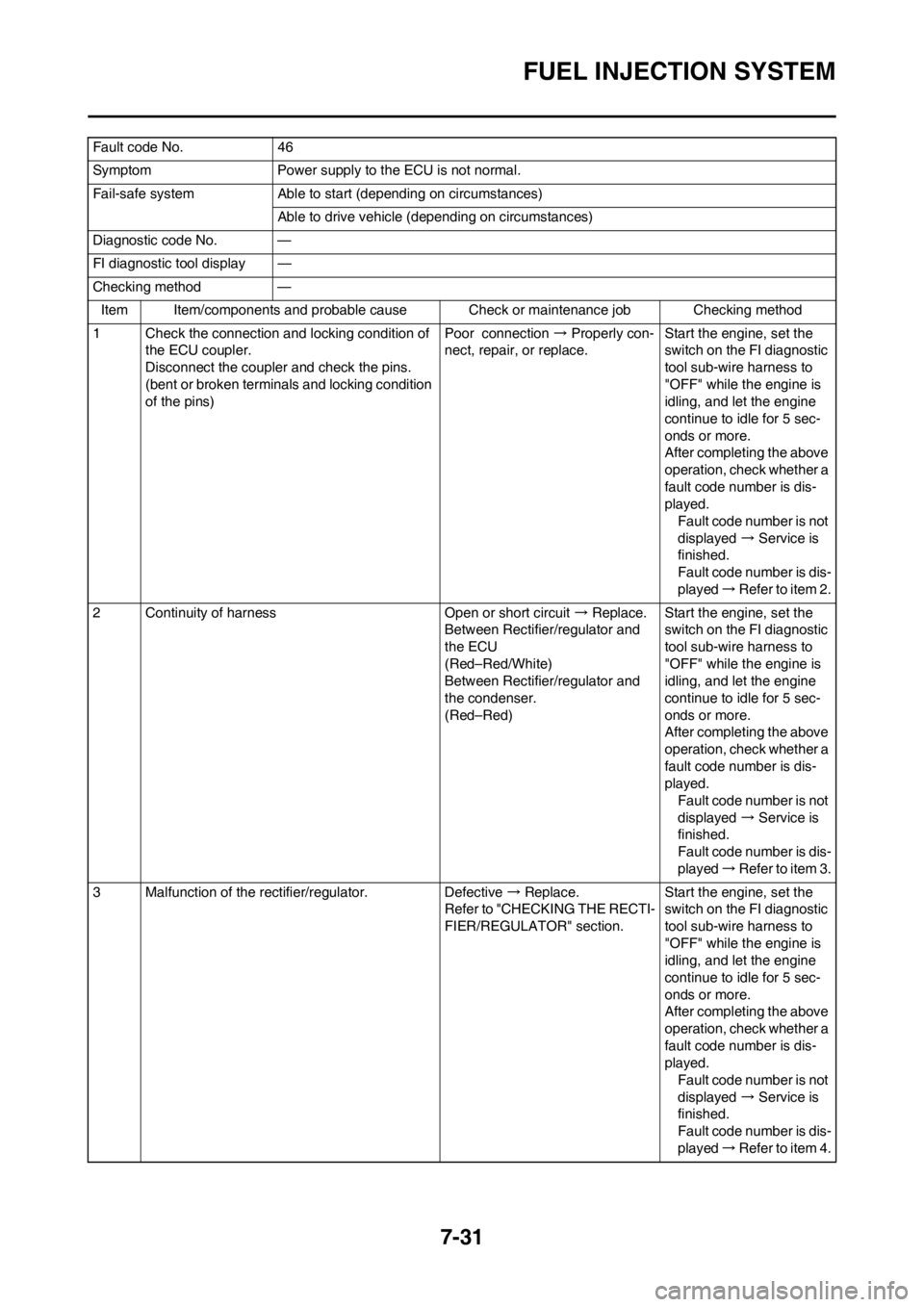

Fault code No. 46

Symptom Power supply to the ECU is not normal.

Fail-safe system Able to start (depending on circumstances)

Able to drive vehicle (depending on circumstances)

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Start the engine, set the

switch on the FI diagnostic

tool sub-wire harness to

"OFF" while the engine is

idling, and let the engine

continue to idle for 5 sec-

onds or more.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Continuity of harness Open or short circuit → Replace.

Between Rectifier/regulator and

the ECU

(Red–Red/White)

Between Rectifier/regulator and

the condenser.

(Red–Red)Start the engine, set the

switch on the FI diagnostic

tool sub-wire harness to

"OFF" while the engine is

idling, and let the engine

continue to idle for 5 sec-

onds or more.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Malfunction of the rectifier/regulator. Defective → Replace.

Refer to "CHECKING THE RECTI-

FIER/REGULATOR" section.Start the engine, set the

switch on the FI diagnostic

tool sub-wire harness to

"OFF" while the engine is

idling, and let the engine

continue to idle for 5 sec-

onds or more.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 4.

Page 216 of 228

7-32

FUEL INJECTION SYSTEM

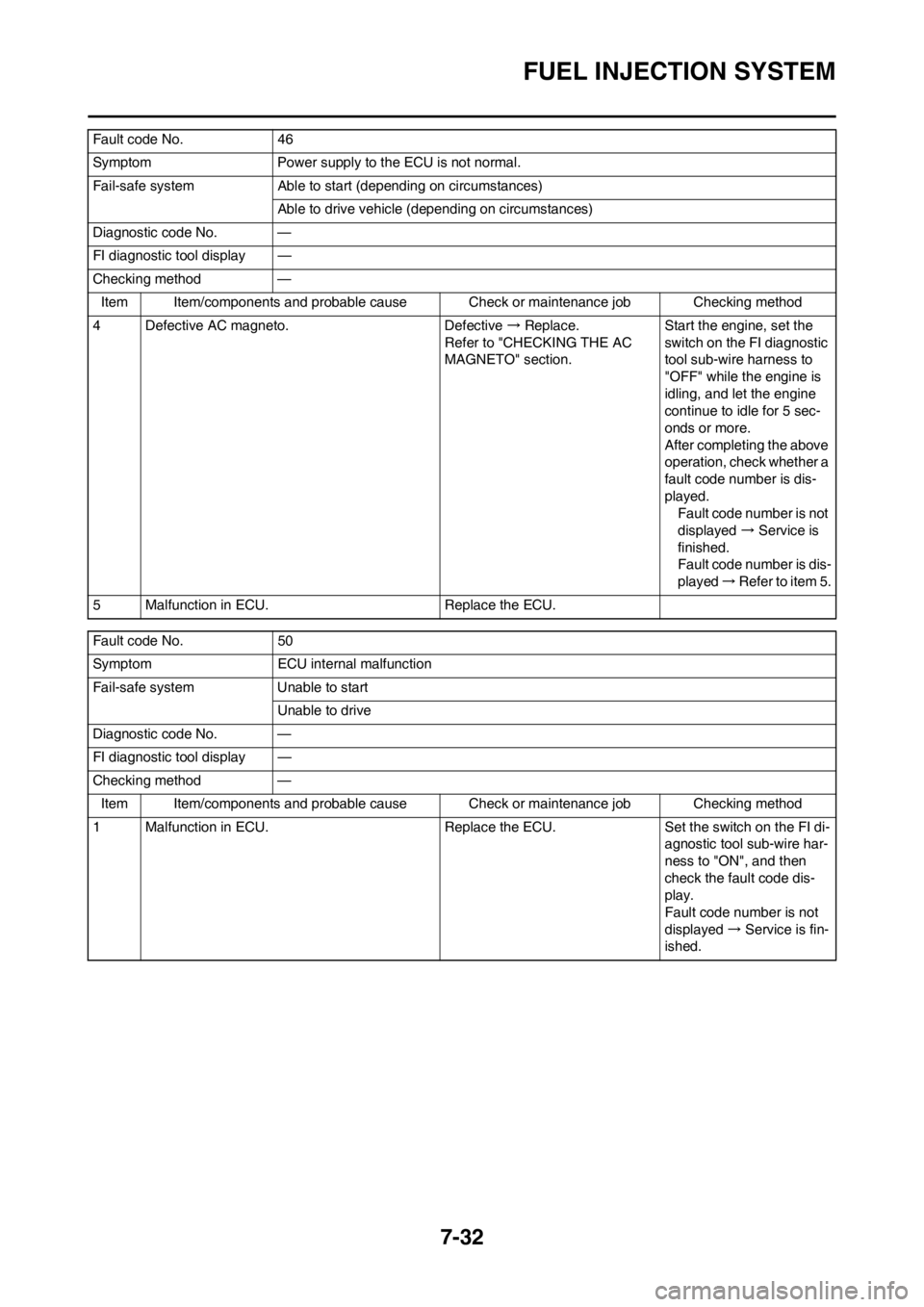

4 Defective AC magneto. Defective → Replace.

Refer to "CHECKING THE AC

MAGNETO" section.Start the engine, set the

switch on the FI diagnostic

tool sub-wire harness to

"OFF" while the engine is

idling, and let the engine

continue to idle for 5 sec-

onds or more.

After completing the above

operation, check whether a

fault code number is dis-

played.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 5.

5 Malfunction in ECU. Replace the ECU.

Fault code No. 50

Symptom ECU internal malfunction

Fail-safe system Unable to start

Unable to drive

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Malfunction in ECU. Replace the ECU. Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is fin-

ished. Fault code No. 46

Symptom Power supply to the ECU is not normal.

Fail-safe system Able to start (depending on circumstances)

Able to drive vehicle (depending on circumstances)

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

Page 217 of 228

7-33

FUEL INJECTION SYSTEM

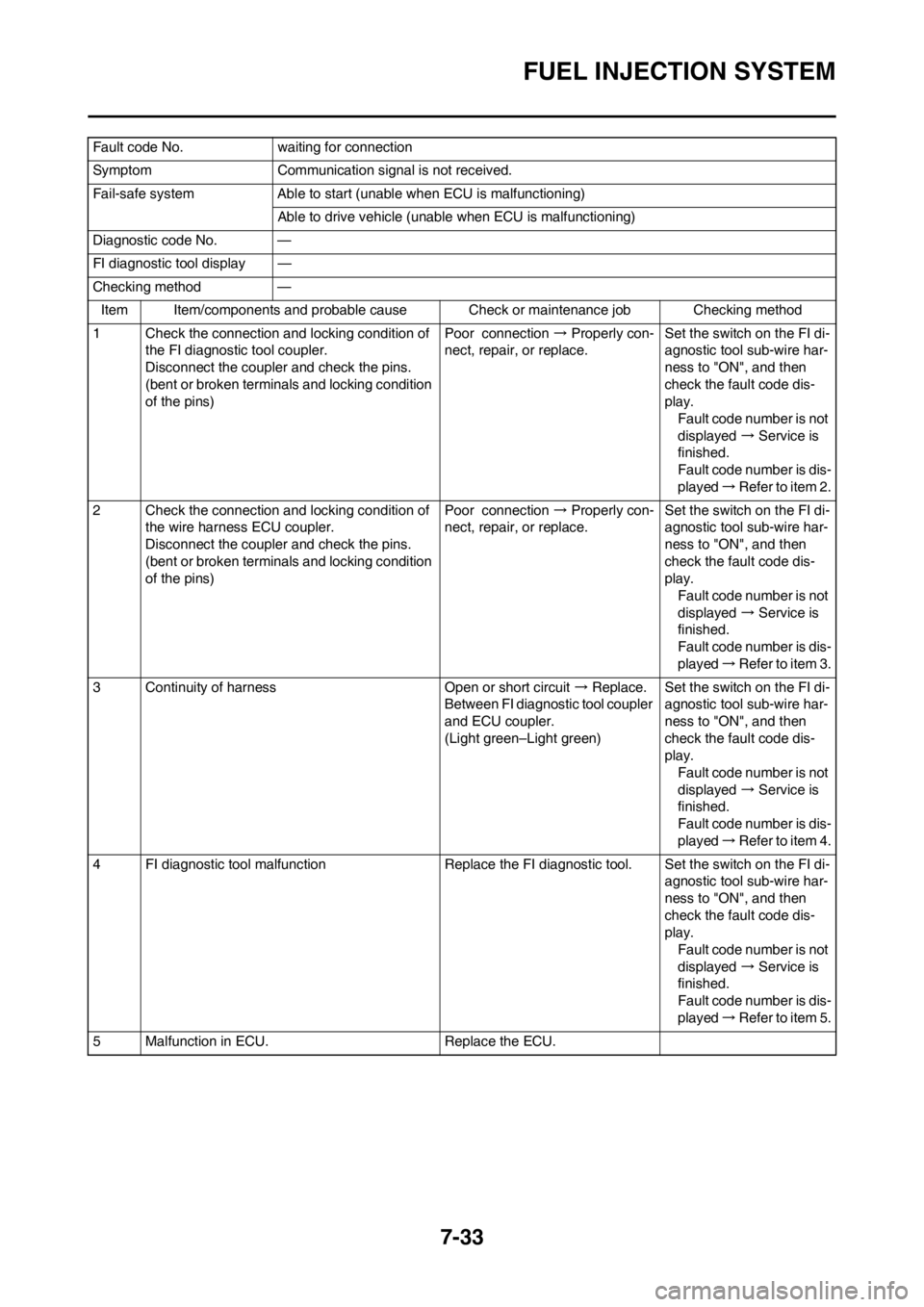

Fault code No. waiting for connection

Symptom Communication signal is not received.

Fail-safe system Able to start (unable when ECU is malfunctioning)

Able to drive vehicle (unable when ECU is malfunctioning)

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the FI diagnostic tool coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Continuity of harness Open or short circuit → Replace.

Between FI diagnostic tool coupler

and ECU coupler.

(Light green–Light green)Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 4.

4 FI diagnostic tool malfunction Replace the FI diagnostic tool. Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 5.

5 Malfunction in ECU. Replace the ECU.

Page 218 of 228

7-34

FUEL INJECTION SYSTEM

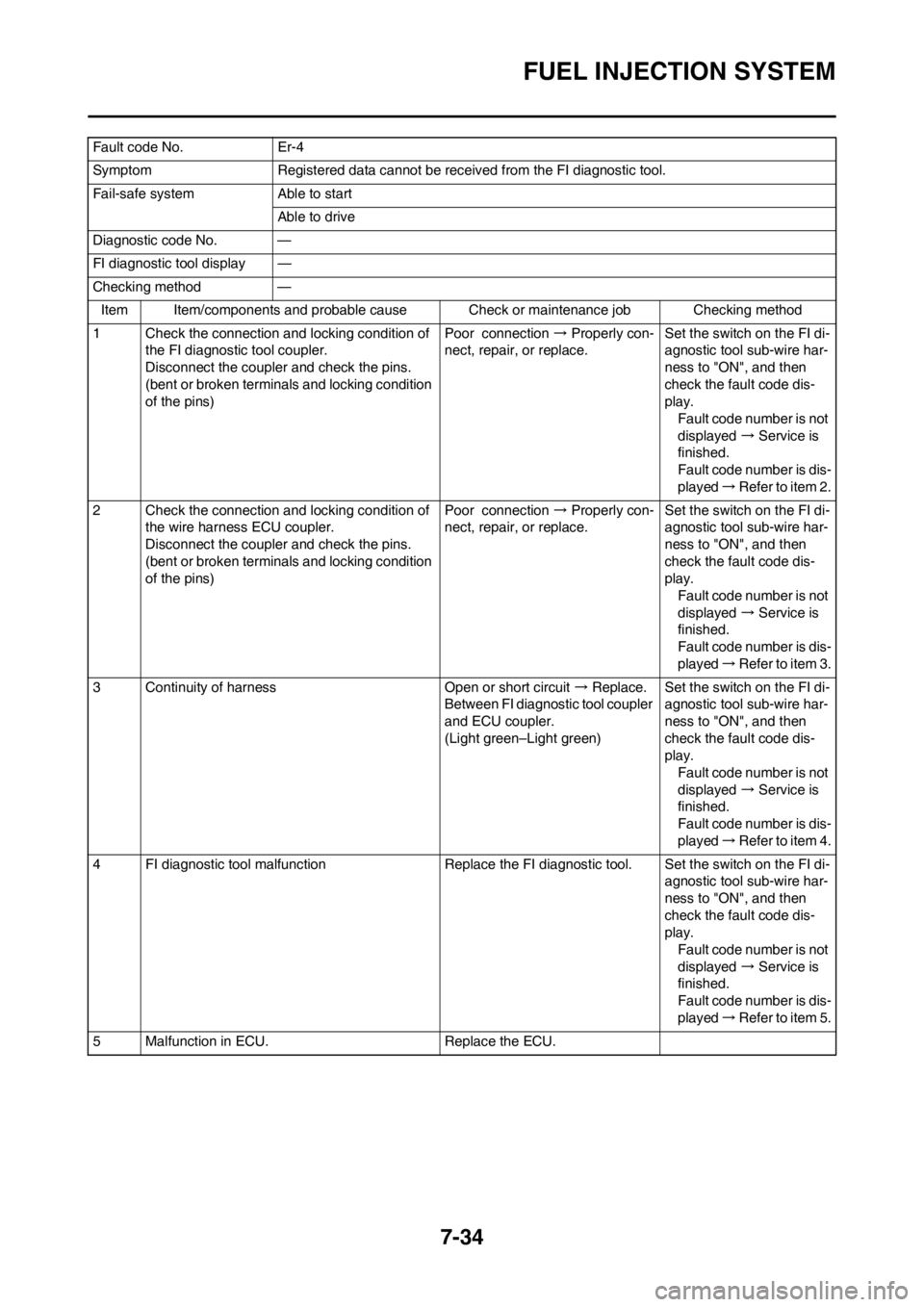

Fault code No. Er-4

Symptom Registered data cannot be received from the FI diagnostic tool.

Fail-safe system Able to start

Able to drive

Diagnostic code No. —

FI diagnostic tool display —

Checking method —

Item Item/components and probable cause Check or maintenance job Checking method

1 Check the connection and locking condition of

the FI diagnostic tool coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 2.

2 Check the connection and locking condition of

the wire harness ECU coupler.

Disconnect the coupler and check the pins.

(bent or broken terminals and locking condition

of the pins)Poor connection → Properly con-

nect, repair, or replace.Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 3.

3 Continuity of harness Open or short circuit → Replace.

Between FI diagnostic tool coupler

and ECU coupler.

(Light green–Light green)Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 4.

4 FI diagnostic tool malfunction Replace the FI diagnostic tool. Set the switch on the FI di-

agnostic tool sub-wire har-

ness to "ON", and then

check the fault code dis-

play.

Fault code number is not

displayed → Service is

finished.

Fault code number is dis-

played → Refer to item 5.

5 Malfunction in ECU. Replace the ECU.

Page 219 of 228

7-35

FUEL PUMP SYSTEM

FUEL PUMP SYSTEM

INSPECTION STEPS

If the fuel pump is not operating normally, perform the following procedures in the order given.

• Remove the following parts before inspection.

1. Seat

2. Side cover (right/left)

3. Fuel tank

• Use the following special tools in this inspection.

Check engine stop switch. No good→Replace.

OK ↓

Checking the couplers and leads connections No good→Repair or replace.

OK ↓

Check the fuel pump.(Checking the fuel pump

body)No good→

Replace the fuel pump assembly.

OK ↓

Replace the ECU.

Pocket tester:

YU-03112-C/90890-03112

Test harness S-pressure sensor (3P):

YU-03207/90890-03207

Page 220 of 228

7-36

ELECTRICAL COMPONENTS

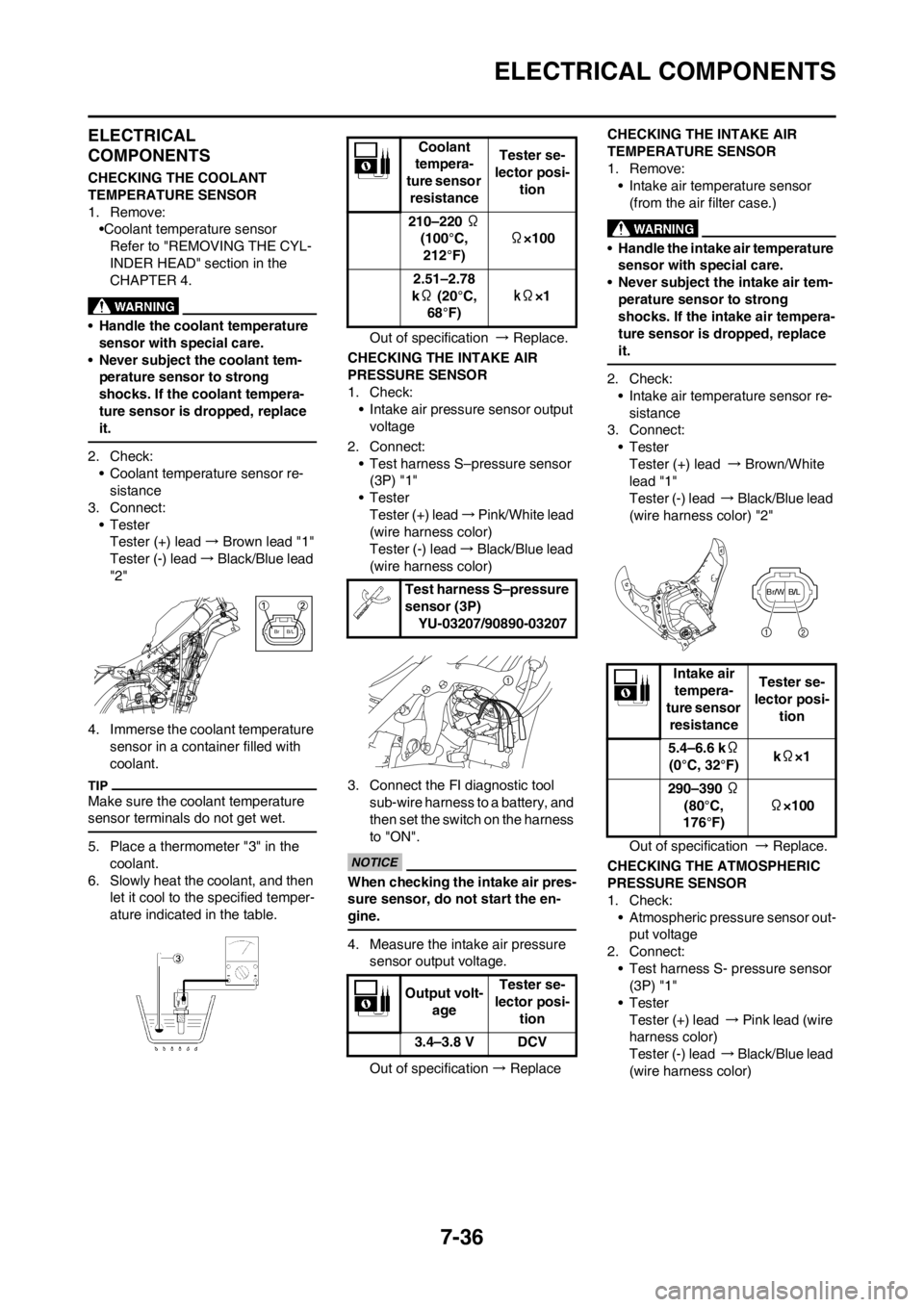

ELECTRICAL

COMPONENTS

CHECKING THE COOLANT

TEMPERATURE SENSOR

1. Remove:

•Coolant temperature sensor

Refer to "REMOVING THE CYL-

INDER HEAD" section in the

CHAPTER 4.

•Handle the coolant temperature

sensor with special care.

•Never subject the coolant tem-

perature sensor to strong

shocks. If the coolant tempera-

ture sensor is dropped, replace

it.

2. Check:

• Coolant temperature sensor re-

sistance

3. Connect:

•Tester

Tester (+) lead → Brown lead "1"

Tester (-) lead → Black/Blue lead

"2"

4. Immerse the coolant temperature

sensor in a container filled with

coolant.

Make sure the coolant temperature

sensor terminals do not get wet.

5. Place a thermometer "3" in the

coolant.

6. Slowly heat the coolant, and then

let it cool to the specified temper-

ature indicated in the table.Out of specification → Replace.

CHECKING THE INTAKE AIR

PRESSURE SENSOR

1. Check:

• Intake air pressure sensor output

voltage

2. Connect:

• Test harness S–pressure sensor

(3P) "1"

•Tester

Tester (+) lead → Pink/White lead

(wire harness color)

Tester (-) lead → Black/Blue lead

(wire harness color)

3. Connect the FI diagnostic tool

sub-wire harness to a battery, and

then set the switch on the harness

to "ON".

When checking the intake air pres-

sure sensor, do not start the en-

gine.

4. Measure the intake air pressure

sensor output voltage.

Out of specification → ReplaceCHECKING THE INTAKE AIR

TEMPERATURE SENSOR

1. Remove:

• Intake air temperature sensor

(from the air filter case.)

•Handle the intake air temperature

sensor with special care.

•Never subject the intake air tem-

perature sensor to strong

shocks. If the intake air tempera-

ture sensor is dropped, replace

it.

2. Check:

• Intake air temperature sensor re-

sistance

3. Connect:

•Tester

Tester (+) lead → Brown/White

lead "1"

Tester (-) lead →Black/Blue lead

(wire harness color) "2"

Out of specification → Replace.

CHECKING THE ATMOSPHERIC

PRESSURE SENSOR

1. Check:

• Atmospheric pressure sensor out-

put voltage

2. Connect:

• Test harness S- pressure sensor

(3P) "1"

•Tester

Tester (+) lead → Pink lead (wire

harness color)

Tester (-) lead → Black/Blue lead

(wire harness color)

B/L Br

Coolant

tempera-

ture sensor

resistanceTester se-

lector posi-

tion

210–220 Ω

(100°C,

212°F)Ω×100

2.51–2.78

kΩ (20°C,

68°F)kΩ×1

Test harness S–pressure

sensor (3P)

YU-03207/90890-03207

Output volt-

ageTester se-

lector posi-

tion

3.4–3.8 V DCV

Intake air

tempera-

ture sensor

resistanceTester se-

lector posi-

tion

5.4–6.6 kΩ

(0°C, 32°F)kΩ×1

290–390 Ω

(80°C,

176°F)Ω×100

Br/WB/L