ABS YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 118 of 360

CHASSIS

3-30

CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm smooth action

• Swingarm free play

Refer to “SWINGARM” on page 4-60.

EAS1SL1105CHECKING THE REAR SUSPENSION

1. Stand the vehicle upright on a level surface.EWA@

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Rear shock absorber assembly

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-53.

3. Check:

• Rear shock absorber assembly smooth ac-

tion

• Rear suspension link smooth action

Sit astride the seat and shake your body up

and down several times to check whether

the rear shock absorber assembly operates

smoothly.

Unsmooth operation Correct or replace.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-53.

EAS1SL1106ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBLY

Use a suitable stand to raise the rear wheel off

the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

Spring preloadECA13590

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Remove:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-53.

2. Adjust:

• Spring preload

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

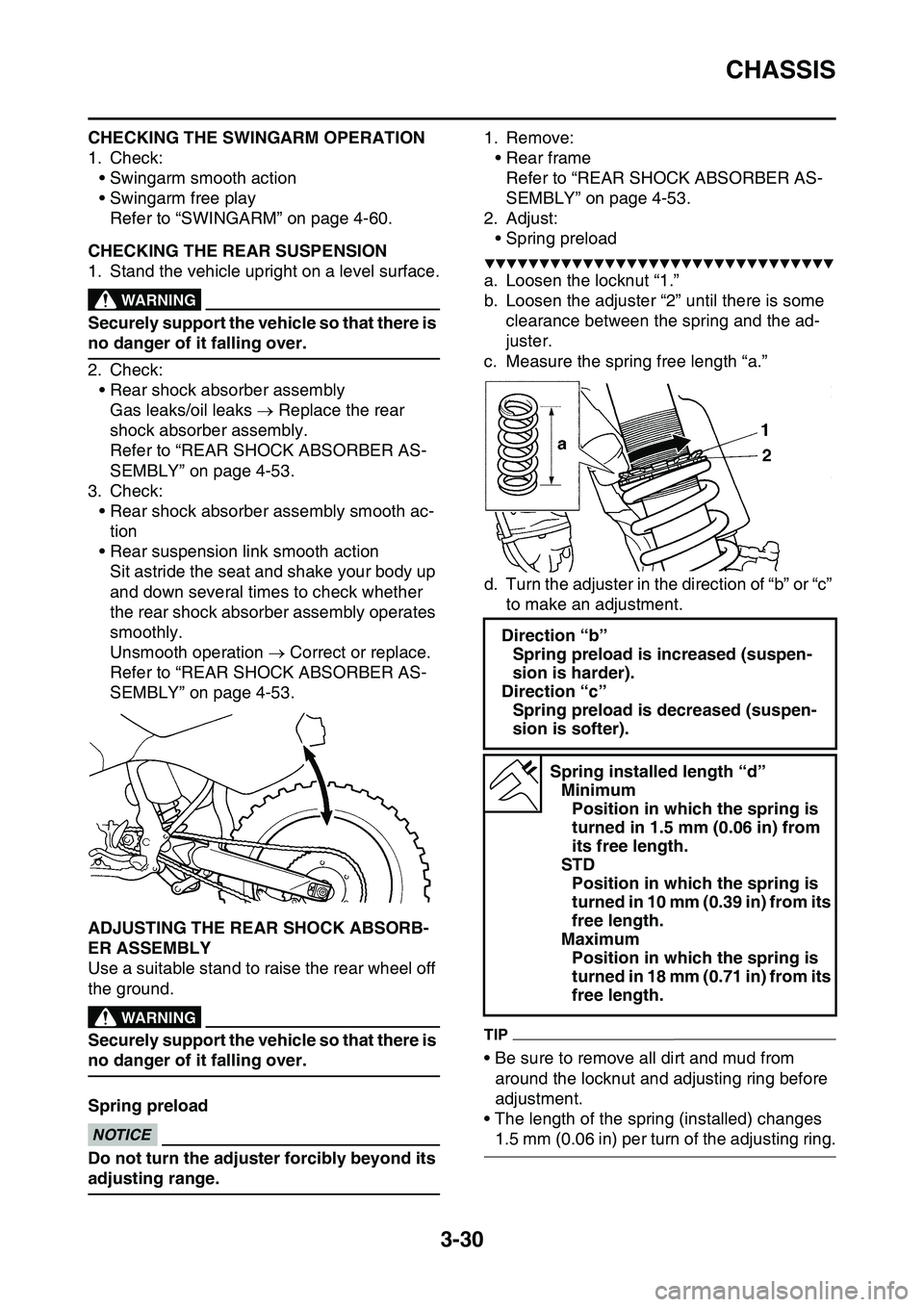

a. Loosen the locknut “1.”

b. Loosen the adjuster “2” until there is some

clearance between the spring and the ad

-

juster.

c. Measure the spring free length “a.”

d. Turn the adjuster in the direction of “b” or “c”

to make an adjustment.

TIP

• Be sure to remove all dirt and mud from

around the locknut and adjusting ring before

adjustment.

• The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjusting ring.

Direction “b”

Spring preload is increased (suspen-

sion is harder).

Direction “c”

Spring preload is decreased (suspen-

sion is softer).

Spring installed length “d”

Minimum

Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

STD

Position in which the spring is

turned in 10 mm (0.39 in) from its

free length.

Maximum

Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 119 of 360

CHASSIS

3-31

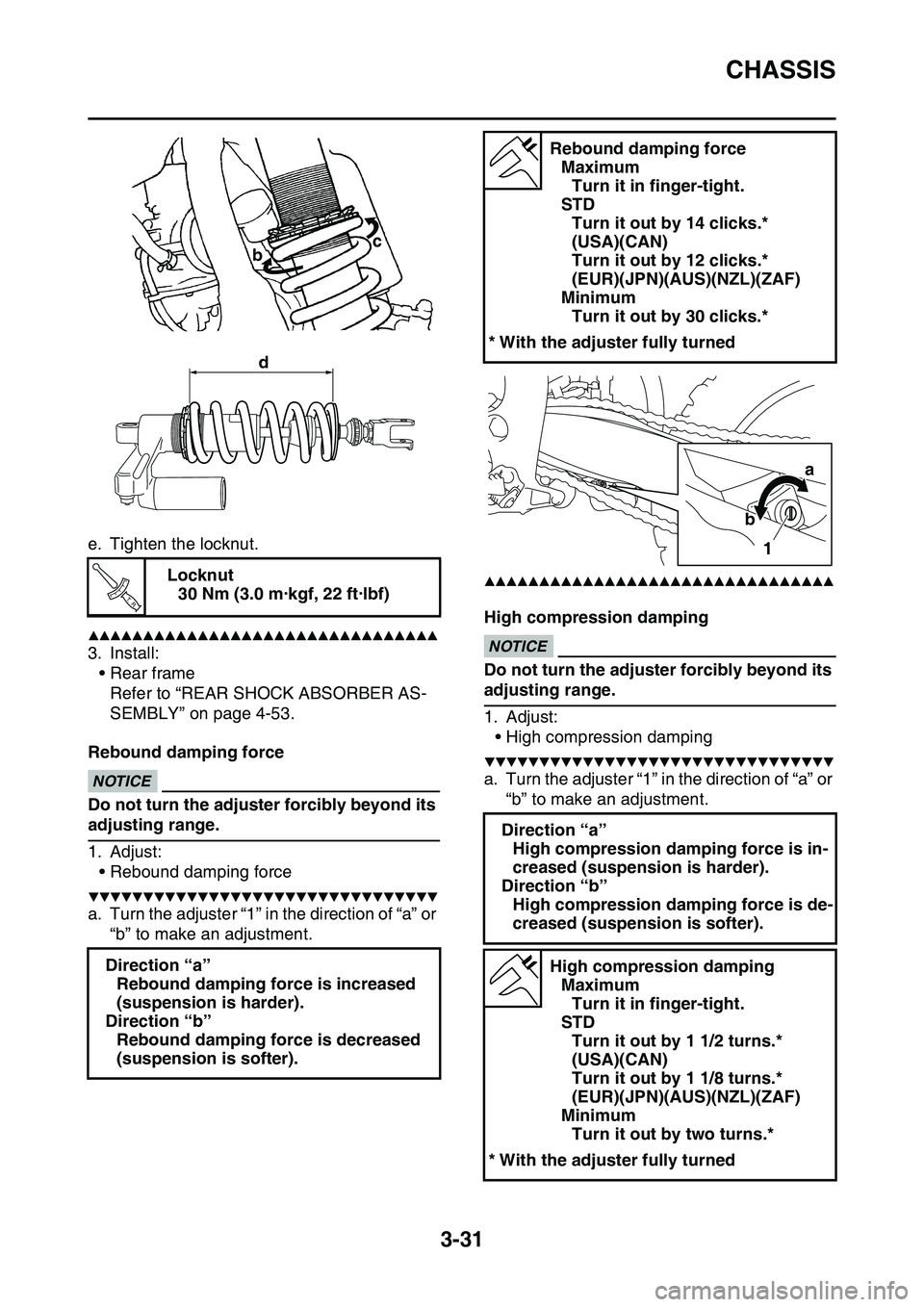

e. Tighten the locknut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-53.

Rebound damping forceECA13590

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Rebound damping force

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

High compression dampingECA13590

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• High compression damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

Locknut

30 Nm (3.0 m·kgf, 22 ft·lbf)

Direction “a”

Rebound damping force is increased

(suspension is harder).

Direction “b”

Rebound damping force is decreased

(suspension is softer).

c

b

d

T R..

Rebound damping force

Maximum

Turn it in finger-tight.

STD

Turn it out by 14 clicks.*

(USA)(CAN)

Turn it out by 12 clicks.*

(EUR)(JPN)(AUS)(NZL)(ZAF)

Minimum

Turn it out by 30 clicks.*

* With the adjuster fully turned

Direction “a”

High compression damping force is in-

creased (suspension is harder).

Direction “b”

High compression damping force is de-

creased (suspension is softer).

High compression damping

Maximum

Turn it in finger-tight.

STD

Turn it out by 1 1/2 turns.*

(USA)(CAN)

Turn it out by 1 1/8 turns.*

(EUR)(JPN)(AUS)(NZL)(ZAF)

Minimum

Turn it out by two turns.*

* With the adjuster fully turned

a

b

1

Page 126 of 360

HANDLEBAR................................................................................................. 4-31

REMOVING THE HANDLEBAR............................................................... 4-33

CHECKING THE HANDLEBAR ............................................................... 4-33

INSTALLING THE HANDLEBAR ............................................................. 4-33

FRONT FORK................................................................................................. 4-37

REMOVING THE FRONT FORK LEGS ................................................... 4-39

DISASSEMBLING THE FRONT FORK LEGS ......................................... 4-39

CHECKING THE FRONT FORK LEGS ................................................... 4-40

ASSEMBLING THE FRONT FORK LEGS ............................................... 4-41

INSTALLING THE FRONT FORK LEGS ................................................. 4-47

STEERING HEAD........................................................................................... 4-49

REMOVING THE LOWER BRACKET...................................................... 4-50

CHECKING THE STEERING HEAD ........................................................ 4-50

INSTALLING THE STEERING HEAD ...................................................... 4-50

REAR SHOCK ABSORBER ASSEMBLY..................................................... 4-53

HANDLING THE REAR SHOCK ABSORBER ......................................... 4-56

DISPOSING OF A REAR SHOCK ABSORBER ...................................... 4-56

REMOVING THE REAR SHOCK ABSORBER ASSEMBLY.................... 4-56

REMOVING THE BEARING..................................................................... 4-56

CHECKING THE REAR SHOCK ABSORBER ASSEMBLY .................... 4-57

CHECKING THE CONNECTING ARM AND RELAY ARM ...................... 4-57

INSTALLING THE RELAY ARM............................................................... 4-57

INSTALLING THE REAR SHOCK ABSORBER ASSEMBLY .................. 4-58

SWINGARM.................................................................................................... 4-60

REMOVING THE SWINGARM................................................................. 4-61

REMOVING THE BEARING..................................................................... 4-61

CHECKING THE SWINGARM ................................................................. 4-61

INSTALLING THE SWINGARM ............................................................... 4-62

CHAIN DRIVE................................................................................................. 4-63

REMOVING THE DRIVE CHAIN.............................................................. 4-64

CHECKING THE DRIVE CHAIN .............................................................. 4-64

CHECKING THE DRIVE SPROCKET...................................................... 4-65

CHECKING THE REAR WHEEL SPROCKET ......................................... 4-65

INSTALLING THE DRIVE CHAIN ............................................................ 4-65

Page 141 of 360

FRONT BRAKE

4-15

EAS1SL1136INTRODUCTIONEWA14100

WARNING

If you need to disassemble the disc brake

components, observe the following precau

-

tions.

• Never disassemble the brake components

unless absolutely necessary.

• If there is any problem with connections

on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing brake

components.

• Use new brake fluid for cleaning the brake

components.

• Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to

let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING

THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

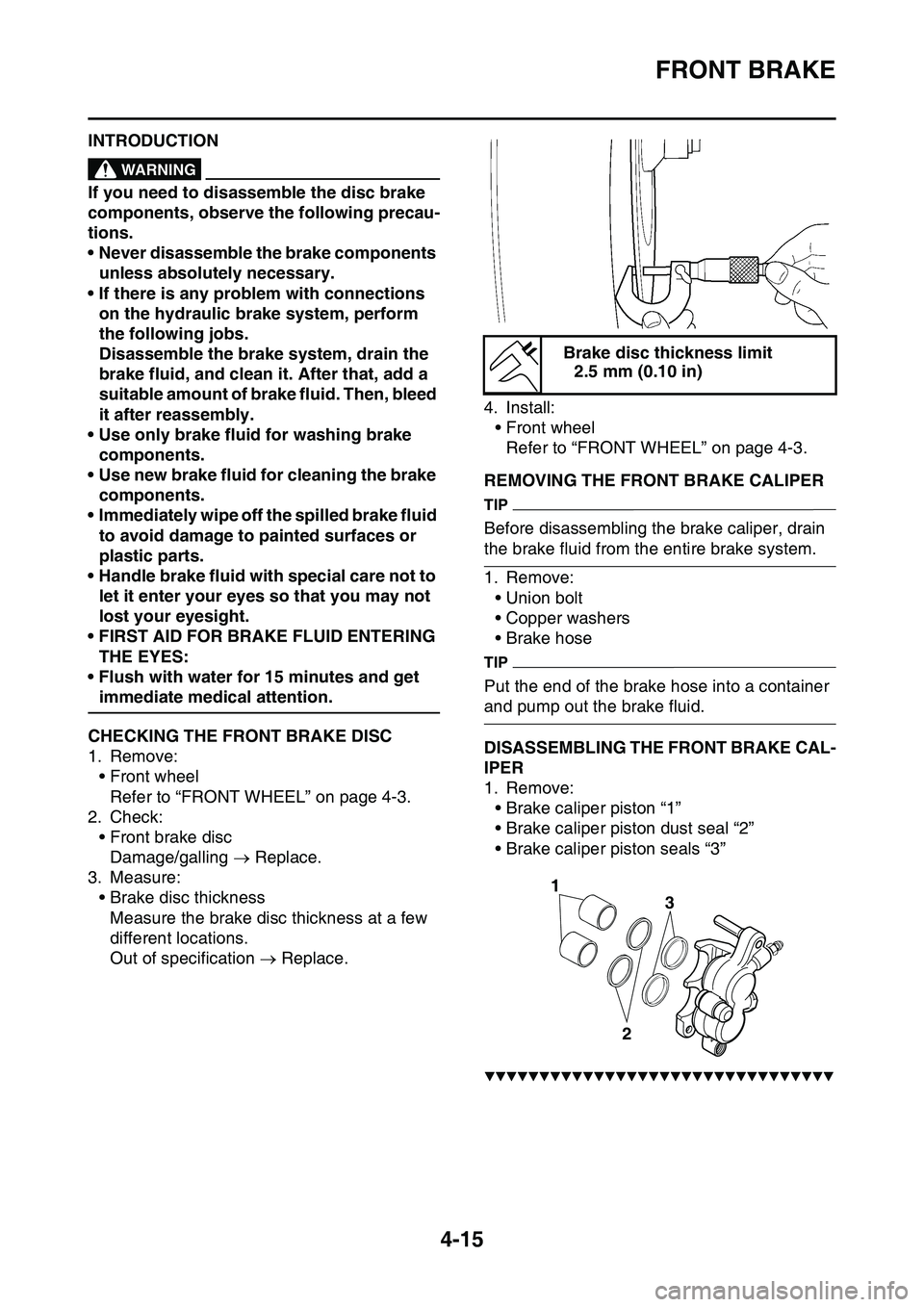

EAS1SL1137CHECKING THE FRONT BRAKE DISC

1. Remove:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

2. Check:

• Front brake disc

Damage/galling Replace.

3. Measure:

• Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.

4. Install:

• Front wheel

Refer to “FRONT WHEEL” on page 4-3.

EAS1SL1138REMOVING THE FRONT BRAKE CALIPER

TIP

Before disassembling the brake caliper, drain

the brake fluid from the entire brake system.

1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

Put the end of the brake hose into a container

and pump out the brake fluid.

EAS1SL1139DISASSEMBLING THE FRONT BRAKE CAL-

IPER

1. Remove:

• Brake caliper piston “1”

• Brake caliper piston dust seal “2”

• Brake caliper piston seals “3”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Brake disc thickness limit

2.5 mm (0.10 in)

3

2

1

Page 151 of 360

REAR BRAKE

4-25

EAS1SL1149INTRODUCTIONEWA14300

WARNING

If you need to disassemble the disc brake

components, observe the following precau

-

tions.

• Never disassemble the brake components

unless absolutely necessary.

• If there is any problem with connections

on the hydraulic brake system, perform

the following jobs.

Disassemble the brake system, drain the

brake fluid, and clean it. After that, add a

suitable amount of brake fluid. Then, bleed

it after reassembly.

• Use only brake fluid for washing internal

brake components.

• Use new brake fluid for cleaning the brake

components.

• Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

• Handle brake fluid with special care not to

let it enter your eyes so that you may not

lost your eyesight.

• FIRST AID FOR BRAKE FLUID ENTERING

THE EYES:

• Flush with water for 15 minutes and get

immediate medical attention.

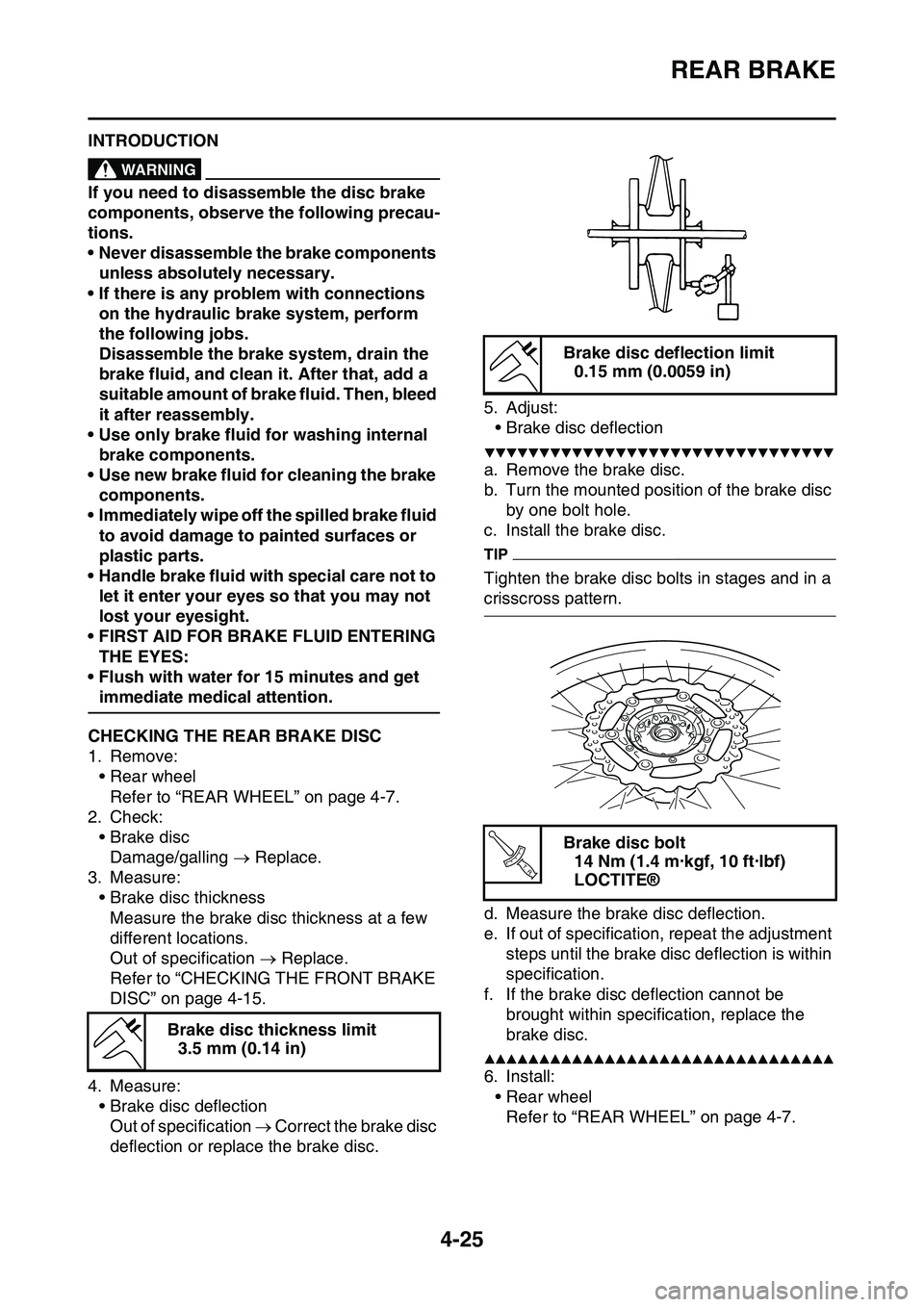

EAS1SL1150CHECKING THE REAR BRAKE DISC

1. Remove:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7.

2. Check:

• Brake disc

Damage/galling Replace.

3. Measure:

• Brake disc thickness

Measure the brake disc thickness at a few

different locations.

Out of specification Replace.

Refer to “CHECKING THE FRONT BRAKE

DISC” on page 4-15.

4. Measure:

• Brake disc deflection

Out of specification Correct the brake disc

deflection or replace the brake disc.

5. Adjust:

• Brake disc deflection

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the brake disc.

b. Turn the mounted position of the brake disc

by one bolt hole.

c. Install the brake disc.

TIP

Tighten the brake disc bolts in stages and in a

crisscross pattern.

d. Measure the brake disc deflection.

e. If out of specification, repeat the adjustment

steps until the brake disc deflection is within

specification.

f. If the brake disc deflection cannot be

brought within specification, replace the

brake disc.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7.

EAS1SL1151

Brake disc thickness limit

3.5 mm (0.14 in)

Brake disc deflection limit

0.15 mm (0.0059 in)

Brake disc bolt

14 Nm (1.4 m·kgf, 10 ft·lbf)

LOCTITE®

T R..

Page 179 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-53

EAS1SL1175

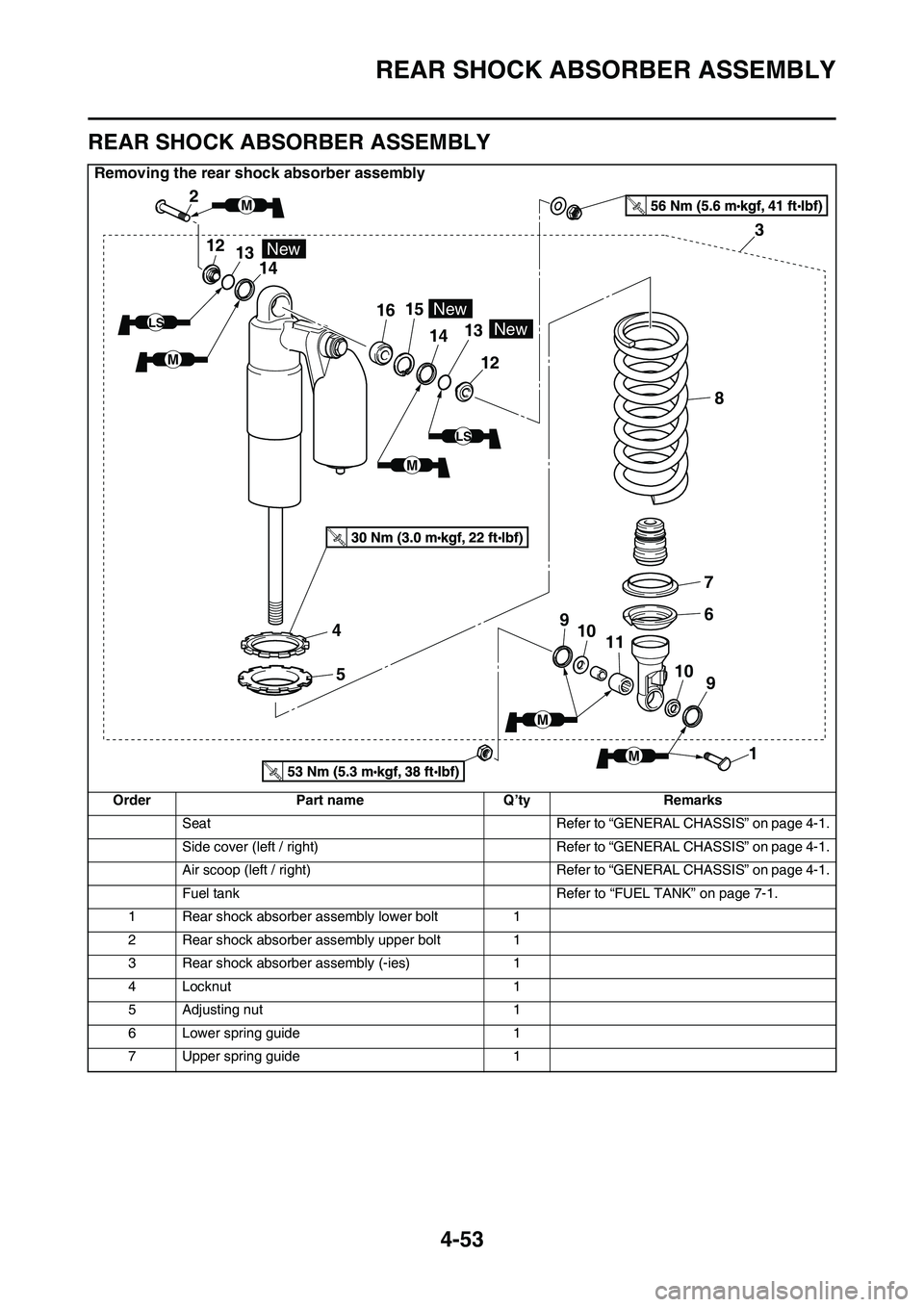

REAR SHOCK ABSORBER ASSEMBLY

Removing the rear shock absorber assembly

OrderPart nameQ’tyRemarks

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

1Rear shock absorber assembly lower bolt1

2Rear shock absorber assembly upper bolt1

3Rear shock absorber assembly (-ies)1

4Locknut1

5Adjusting nut1

6Lower spring guide1

7Upper spring guide1

2

12

1615

1413

12

14

4

5

7

6

83

9

9 10

10 11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 180 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-54

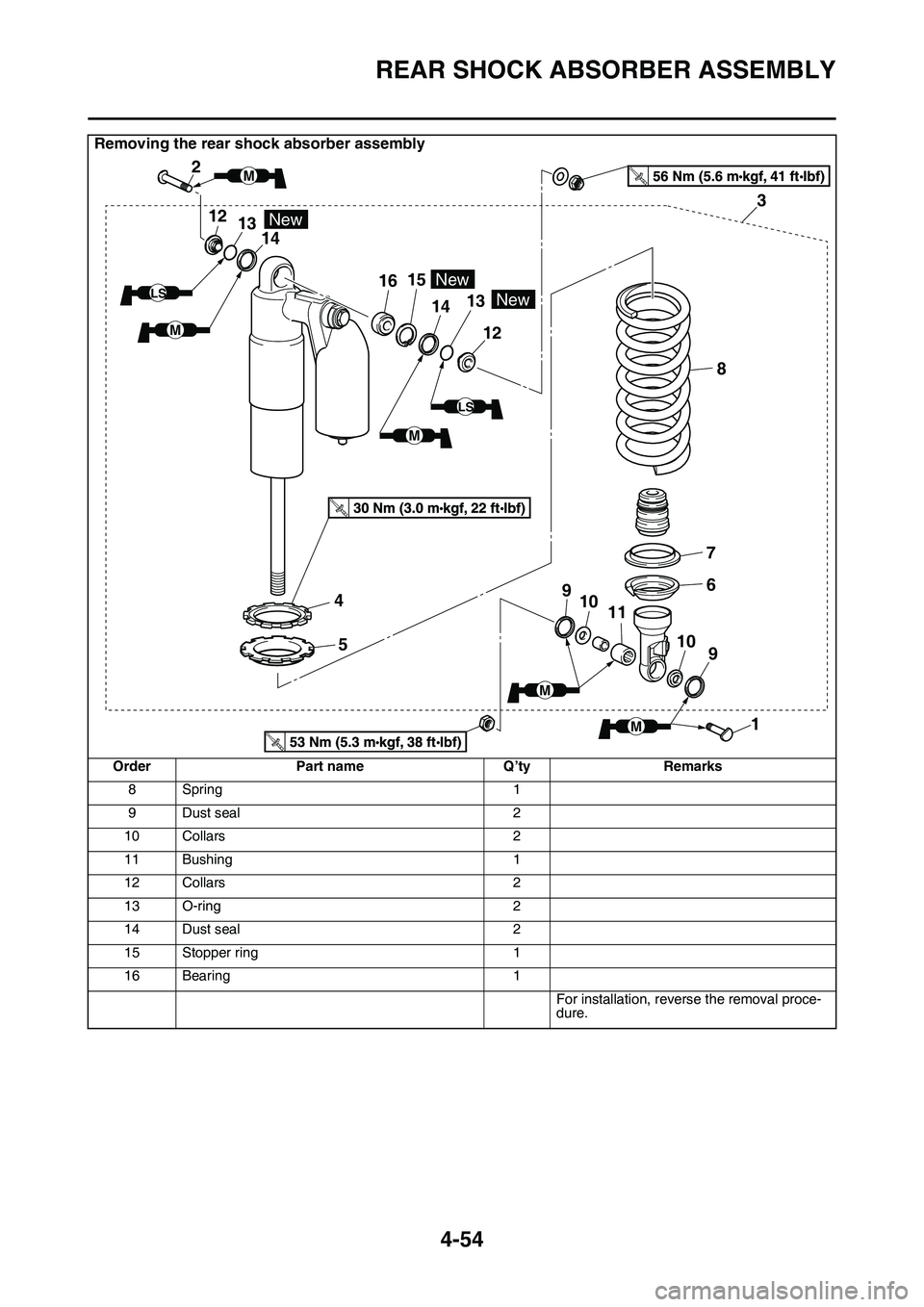

Removing the rear shock absorber assembly

OrderPart nameQ’tyRemarks

8Spring1

9Dust seal2

10Collars2

11Bushing1

12Collars2

13O-ring2

14Dust seal2

15Stopper ring1

16Bearing1

For installation, reverse the removal proce-dure.

2

12

1615

1413

12

14

4

5

7

6

83

9

9 10

10 11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 181 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-55

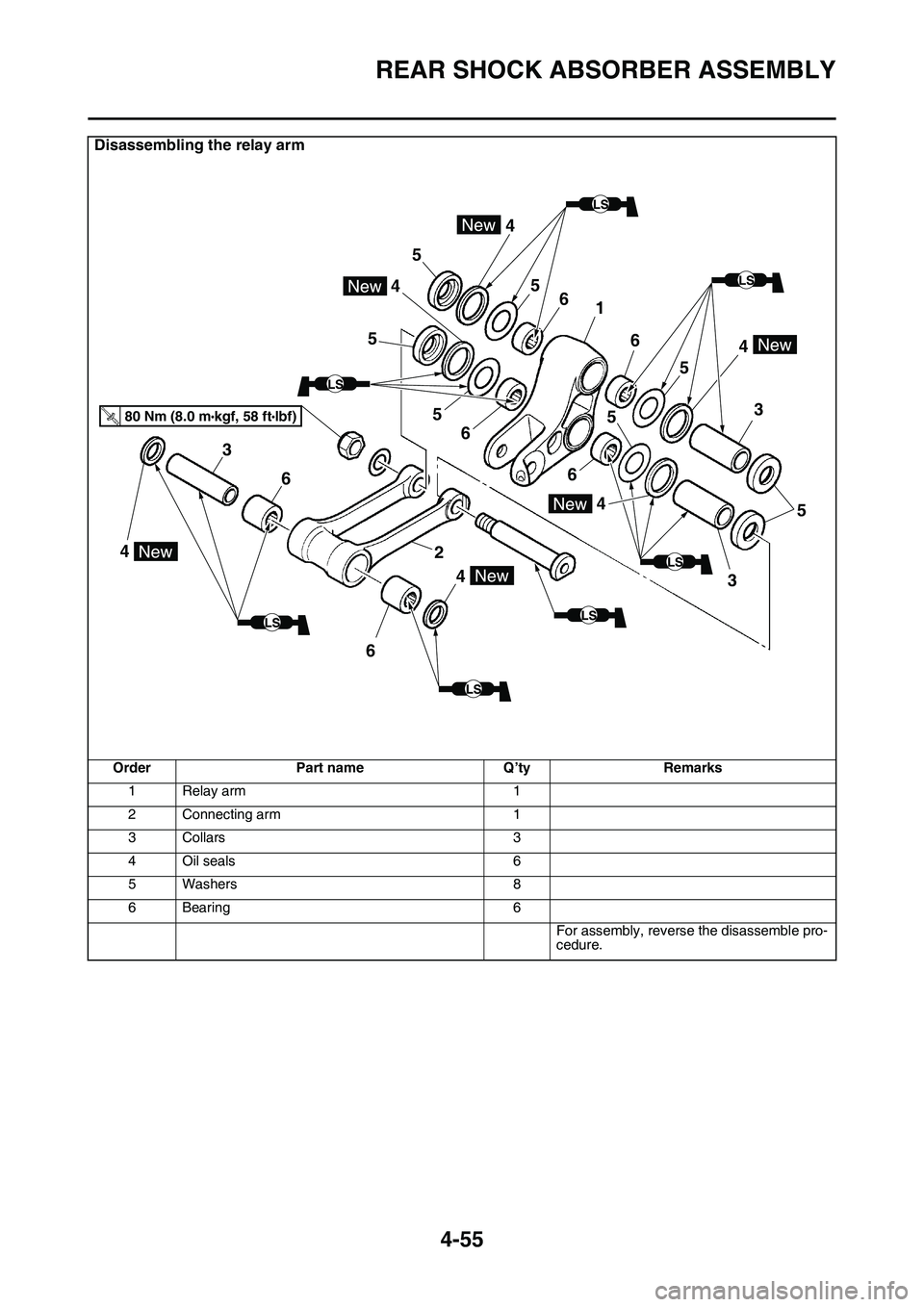

Disassembling the relay arm

OrderPart nameQ’tyRemarks

1Relay arm1

2Connecting arm1

3Collars3

4Oil seals6

5Washers8

6Bearing6

For assembly, reverse the disassemble pro-cedure.

5

3

5

6

165

4

5

5

4

5

6

6

5

4

3

2

4

6

6

3

4

4

T.R.80 Nm (8.0 mlbf) kgf, 58 ft

Page 182 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-56

EAS1SL1176HANDLING THE REAR SHOCK ABSORBEREWA13740

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure that you understand the following in

-

formation. The manufacturer cannot be held

responsible for property damage or person

-

al injury that may result from improper han-

dling of the rear shock absorber.

• Do not tamper or attempt to open the rear

shock absorber.

• Do not subject the rear shock absorber to

an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

• Do not deform or damage the rear shock

absorber in any way. Rear shock absorber

damage will result in poor damping perfor

-

mance.

TIP

A break-in is required up to about 50 km of run-

ning.

EAS1SL1177DISPOSING OF A REAR SHOCK ABSORB-

ER

Before disposing the rear shock absorber, be

sure to extract the nitrogen gas from valve “1”.

EWA33DD052

WARNING

• Wear protective glasses to prevent your

eyes from damage due to possible gas or

metal chips scattered.

• To dispose of a damaged or a worn-out

rear shock absorber, take the unit to your

Yamaha dealer for this disposal proce

-

dure.

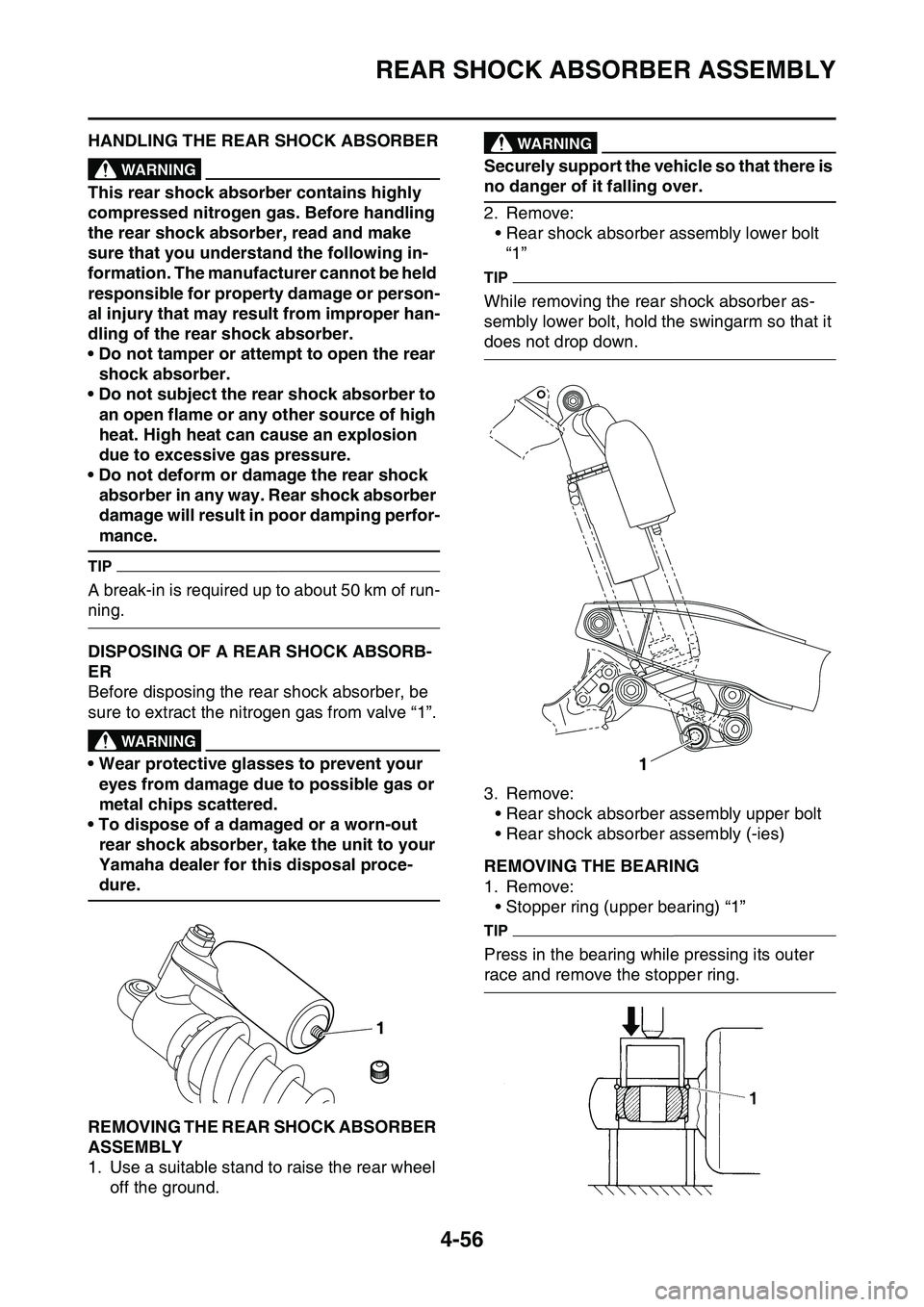

EAS1SL1178REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear shock absorber assembly lower bolt

“1”

TIP

While removing the rear shock absorber as-

sembly lower bolt, hold the swingarm so that it

does not drop down.

3. Remove:

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly (-ies)

EAS1SL1179REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) “1”

TIP

Press in the bearing while pressing its outer

race and remove the stopper ring.

1

1

Page 183 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-57

2. Remove:

• Upper bearing “1”

TIP

Remove the bearing by pressing its outer race.

3. Remove:

• Lower bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS1SL1180CHECKING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Check:

• Rear shock absorber rod

Bends/damage Replace the rear shock

absorber assembly.

• Rear shock absorber

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

•Spring

Damage/wear Replace

• Spring guide

Damage/wear Replace

• Bearing

Damage/wear Replace

•Bolts

Bends/damage/wear Replace.

EAS1SL1181

CHECKING THE CONNECTING ARM AND

RELAY ARM

1. Check:

• Connecting arm

• Relay arm

Damage/wear Replace

2. Check:

• Bearing

• Spacers

Damage/pitting/scratches Replace the

bearings and spacers as a set.

3. Check:

• Oil seals

Damage/pitting Replace.

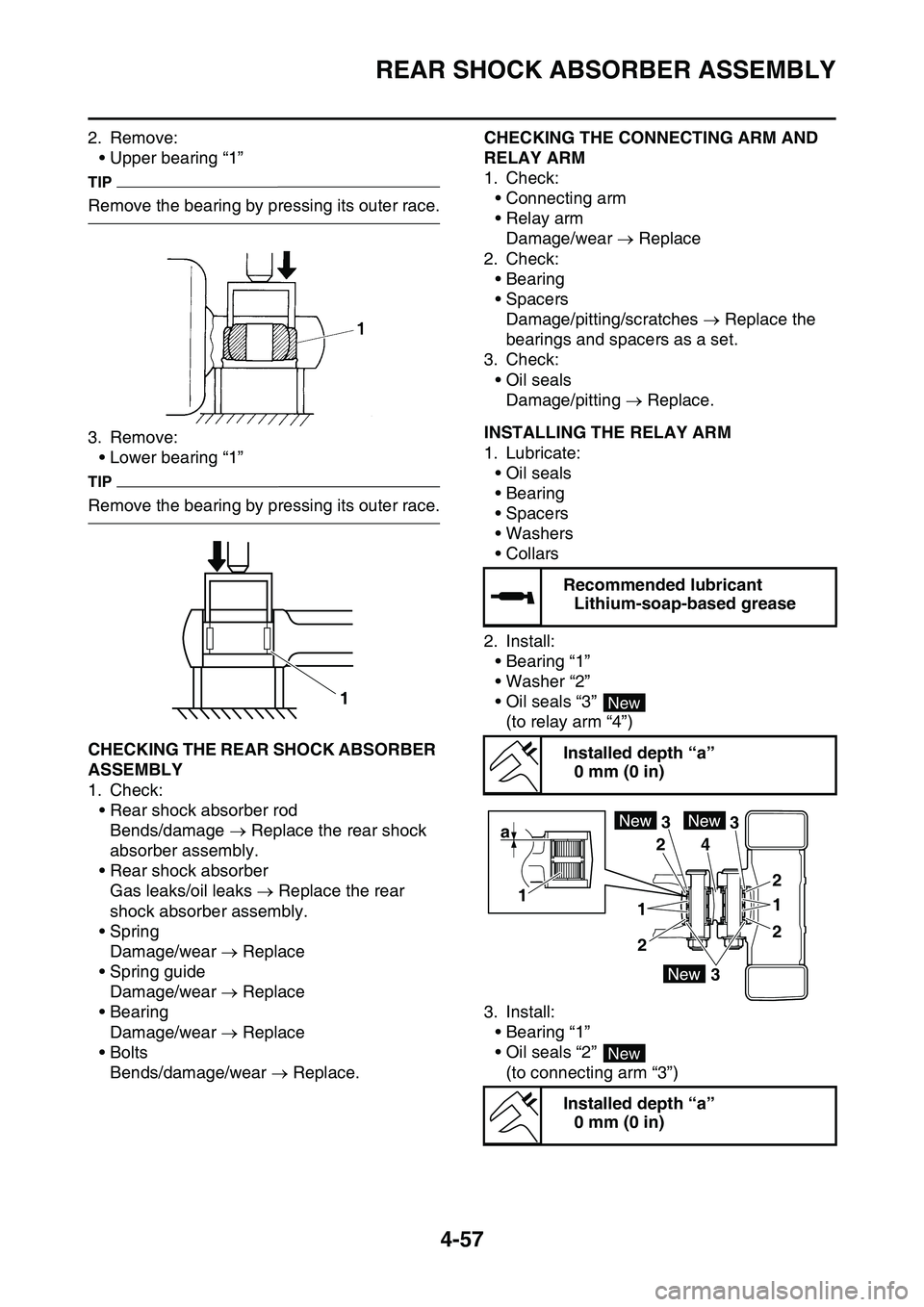

EAS1SL1182INSTALLING THE RELAY ARM

1. Lubricate:

• Oil seals

• Bearing

• Spacers

• Washers

•Collars

2. Install:

• Bearing “1”

• Washer “2”

• Oil seals “3”

(to relay arm “4”)

3. Install:

• Bearing “1”

• Oil seals “2”

(to connecting arm “3”)

1

Recommended lubricant

Lithium-soap-based grease

Installed depth “a”

0 mm (0 in)

Installed depth “a”

0 mm (0 in)

New

3 3

43

2 2

22

a

1

11

New