ABS YAMAHA YZ450F 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 184 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-58

EAS1SL1183INSTALLING THE REAR SHOCK ABSORB-

ER ASSEMBLY

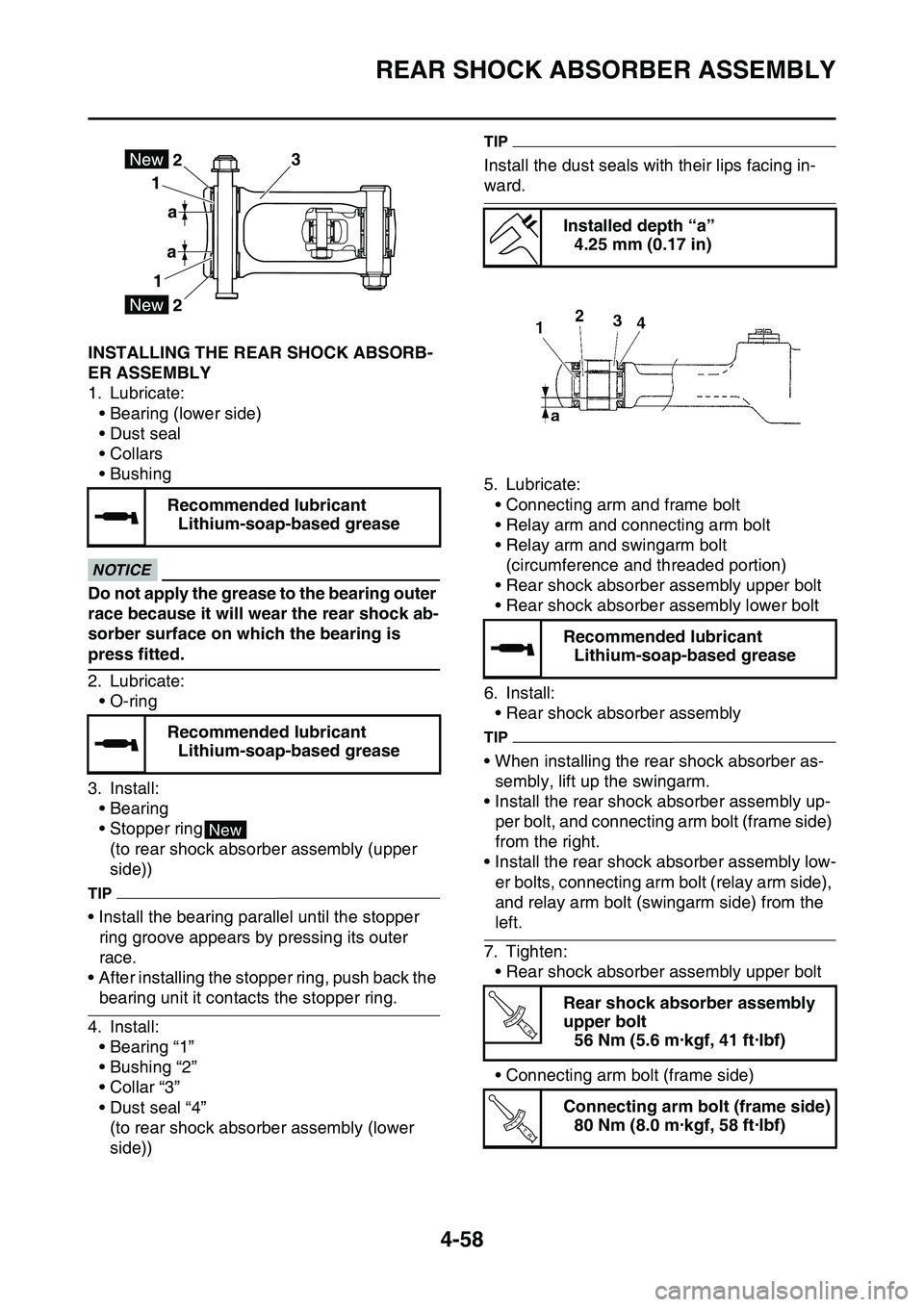

1. Lubricate:

• Bearing (lower side)

•Dust seal

•Collars

• Bushing

ECA1DX1012

NOTICE

Do not apply the grease to the bearing outer

race because it will wear the rear shock ab

-

sorber surface on which the bearing is

press fitted.

2. Lubricate:

• O-ring

3. Install:

• Bearing

• Stopper ring

(to rear shock absorber assembly (upper

side))

TIP

• Install the bearing parallel until the stopper

ring groove appears by pressing its outer

race.

• After installing the stopper ring, push back the

bearing unit it contacts the stopper ring.

4. Install:

• Bearing “1”

• Bushing “2”

• Collar “3”

• Dust seal “4”

(to rear shock absorber assembly (lower

side))

TIP

Install the dust seals with their lips facing in-

ward.

5. Lubricate:

• Connecting arm and frame bolt

• Relay arm and connecting arm bolt

• Relay arm and swingarm bolt

(circumference and threaded portion)

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly lower bolt

6. Install:

• Rear shock absorber assembly

TIP

• When installing the rear shock absorber as-

sembly, lift up the swingarm.

• Install the rear shock absorber assembly up-

per bolt, and connecting arm bolt (frame side)

from the right.

• Install the rear shock absorber assembly low-

er bolts, connecting arm bolt (relay arm side),

and relay arm bolt (swingarm side) from the

left.

7. Tighten:

• Rear shock absorber assembly upper bolt

• Connecting arm bolt (frame side)

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

3

a 1

12

a

2

New

Installed depth “a”

4.25 mm (0.17 in)

Recommended lubricant

Lithium-soap-based grease

Rear shock absorber assembly

upper bolt

56 Nm (5.6 m·kgf, 41 ft·lbf)

Connecting arm bolt (frame side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

T R..

T R..

Page 185 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-59

• Connecting arm bolt (relay arm side)

• Relay arm bolt (swingarm side)

• Rear shock absorber assembly lower bolt

Connecting arm bolt (relay arm

side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

Relay arm bolt (swingarm side)

70 Nm (7.0 m·kgf, 51 ft·lbf)

Rear shock absorber assembly

lower bolt

53 Nm (5.3 m·kgf, 38 ft·lbf)

T R..

T R..

T R..

Page 196 of 360

ENGINE REMOVAL

5-1

EAS1SL1195

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl

-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SL1196

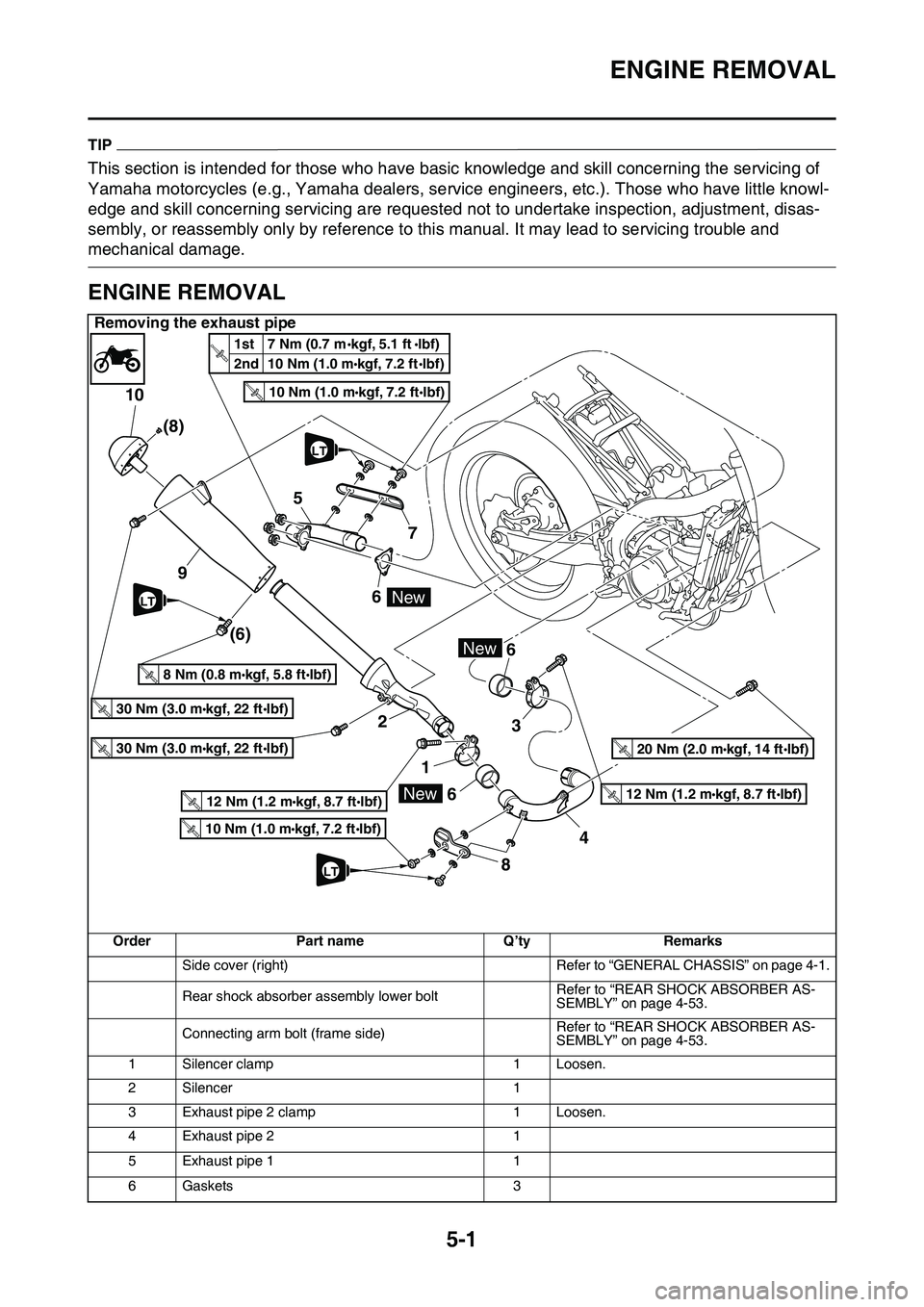

ENGINE REMOVAL

Removing the exhaust pipe

OrderPart nameQ’tyRemarks

Side cover (right)Refer to “GENERAL CHASSIS” on page 4-1.

Rear shock absorber assembly lower boltRefer to “REAR SHOCK ABSORBER AS-SEMBLY” on page 4-53.

Connecting arm bolt (frame side)Refer to “REAR SHOCK ABSORBER AS-SEMBLY” on page 4-53.

1Silencer clamp1Loosen.

2Silencer1

3Exhaust pipe 2 clamp1Loosen.

4Exhaust pipe 21

5Exhaust pipe 11

6Gaskets3

10

5

9

2 6

1

66

3

84 7 (8)

(6)

30 Nm (3.0 mkgf, 22 ftIbf)T.R.

30 Nm (3.0 mkgf, 22 ftIbf)T.R.

8 Nm (0.8 mkgf, 5.8 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

New

New

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

12 Nm (1.2 mkgf, 8.7 ftIbf)T.R.12 Nm (1.2 mkgf, 8.7 ftIbf)T.R.

20 Nm (2.0 mkgf, 14 ftIbf)T.R.

New

1st 7 Nm (0.7 mkgf, 5.1 ftlbf)

2nd 10 Nm (1.0 m

kgf, 7.2 ftlbf)T.

R

.

LT

LT

LT

Page 201 of 360

ENGINE REMOVAL

5-6

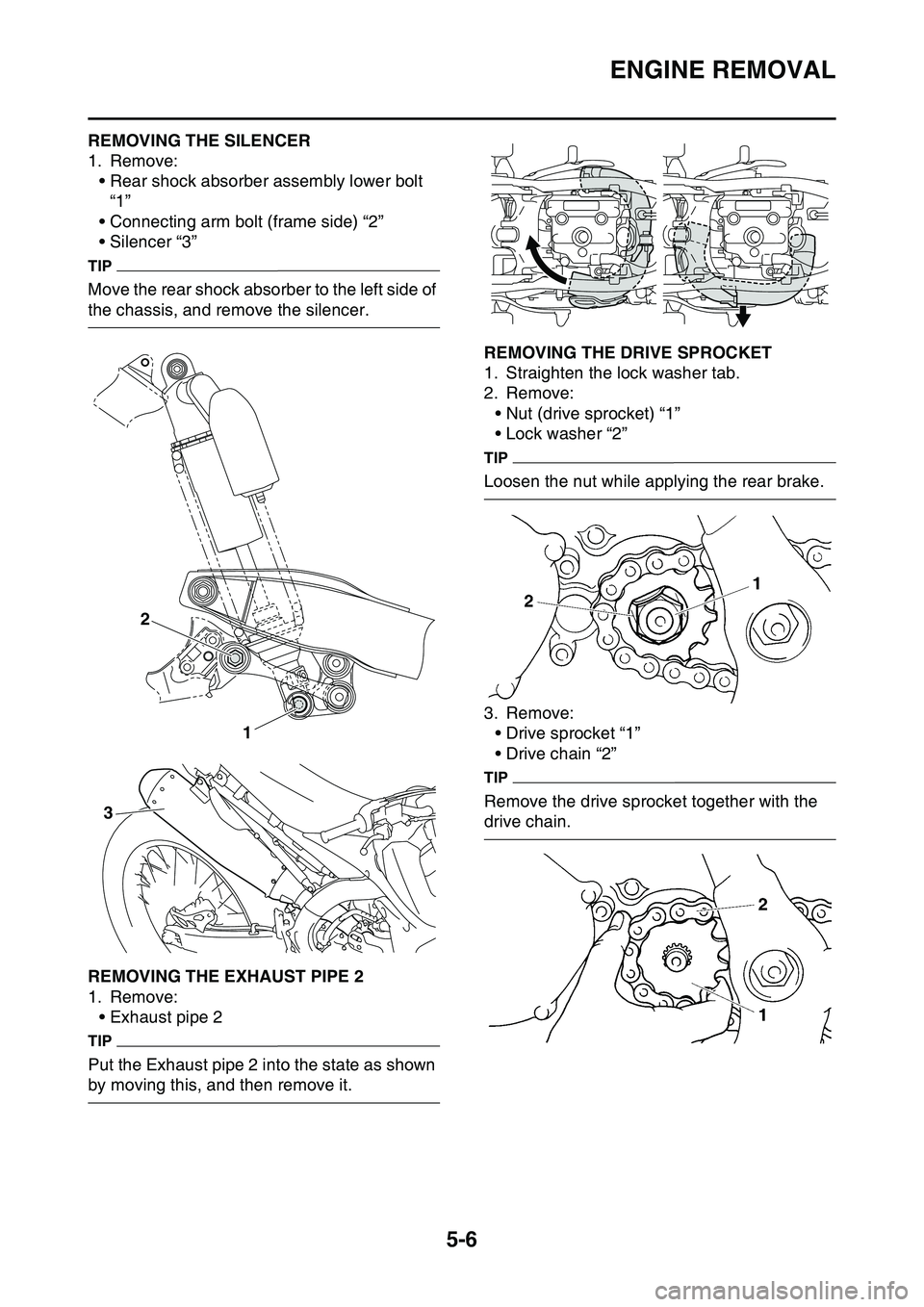

EAS1SL1197REMOVING THE SILENCER

1. Remove:

• Rear shock absorber assembly lower bolt

“1”

• Connecting arm bolt (frame side) “2”

• Silencer “3”

TIP

Move the rear shock absorber to the left side of

the chassis, and remove the silencer.

EAS1SL1198REMOVING THE EXHAUST PIPE 2

1. Remove:

• Exhaust pipe 2

TIP

Put the Exhaust pipe 2 into the state as shown

by moving this, and then remove it.

EAS1SL1199REMOVING THE DRIVE SPROCKET

1. Straighten the lock washer tab.

2. Remove:

• Nut (drive sprocket) “1”

• Lock washer “2”

TIP

Loosen the nut while applying the rear brake.

3. Remove:

• Drive sprocket “1”

• Drive chain “2”

TIP

Remove the drive sprocket together with the

drive chain.

EAS1SL1200

1 2

3

Page 342 of 360

TROUBLE SHOOTING

9-3

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

2. Air filter

• Clogged air filter element

Chassis

1. Brake(s)

• Dragging brake

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system

• Faulty ECU

• Faulty coolant temperature sensor

EAS1SL1359OVERCOOLING

Cooling system

• Faulty coolant temperature sensor

EAS1SL1360POOR BRAKING PERFORMANCE

• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS1SL1361FAULTY FRONT FORK LEGS

Leaking oil

• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

Malfunction

• Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS1SL1362UNSTABLE HANDLING

1. Handlebar

• Bent or improperly installed handlebar

2. Steering head components

• Improperly installed upper bracket

• Improperly installed lower bracket

(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s)

• Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front

fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm

• Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies)

• Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s)

• Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

7. Wheel (s)

• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame

• Bent frame

• Damaged steering head pipe

• Improperly installed bearing race

Page 347 of 360

10

TUNING

CHASSIS........................................................................................................ 10-1

SELECTION OF THE SECONDARY REDUCTION

RATIO (SPROCKET) .............................................................................. 10-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS ................ 10-1

TIRE PRESSURE..................................................................................... 10-2

FRONT FORK SETTING.......................................................................... 10-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL.......... 10-2

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-3

FRONT FORK SETTING PARTS............................................................. 10-3

REAR SUSPENSION SETTING .............................................................. 10-3

CHOOSING SET LENGTH ...................................................................... 10-3

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-4

REAR SHOCK ABSORBER SETTING PARTS ....................................... 10-5

SUSPENSION SETTING (FRONT FORK)............................................... 10-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ......................... 10-7

Page 350 of 360

CHASSIS

10-3

SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

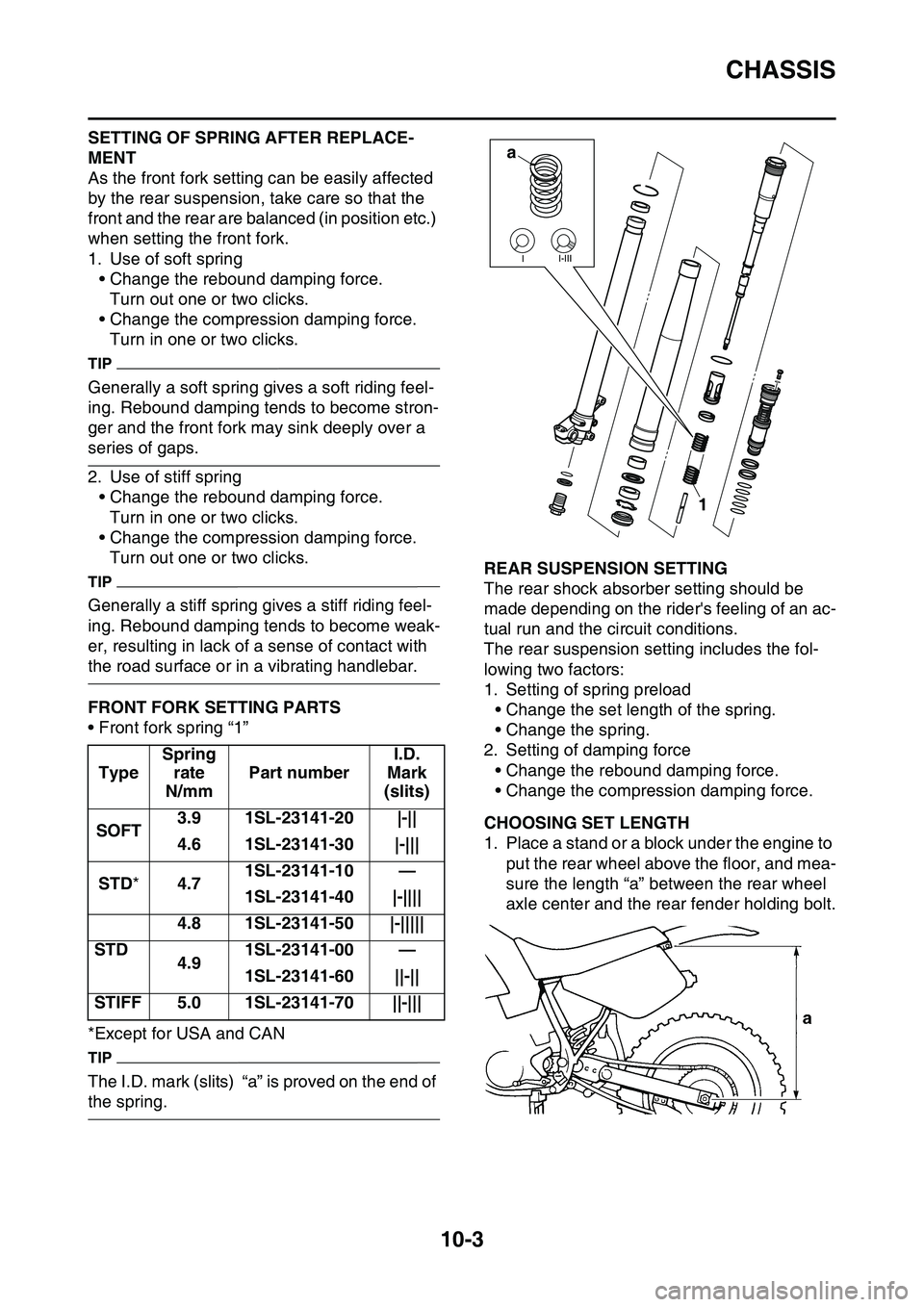

EAS1SL1372FRONT FORK SETTING PARTS

• Front fork spring “1”

*Except for USA and CAN

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS1SL1373REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider's feeling of an ac

-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS1SL1374CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea

-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

Type

Spring

rate

N/mm

Part number

I.D.

Mark

(slits)

SOFT3.91SL-23141-20|-||

4.61SL-23141-30|-|||

STD*4.71SL-23141-10—

1SL-23141-40|-||||

4.81SL-23141-50|-|||||

STD4.91SL-23141-00—

1SL-23141-60||-||

STIFF5.01SL-23141-70||-|||

a

1

Page 351 of 360

CHASSIS

10-4

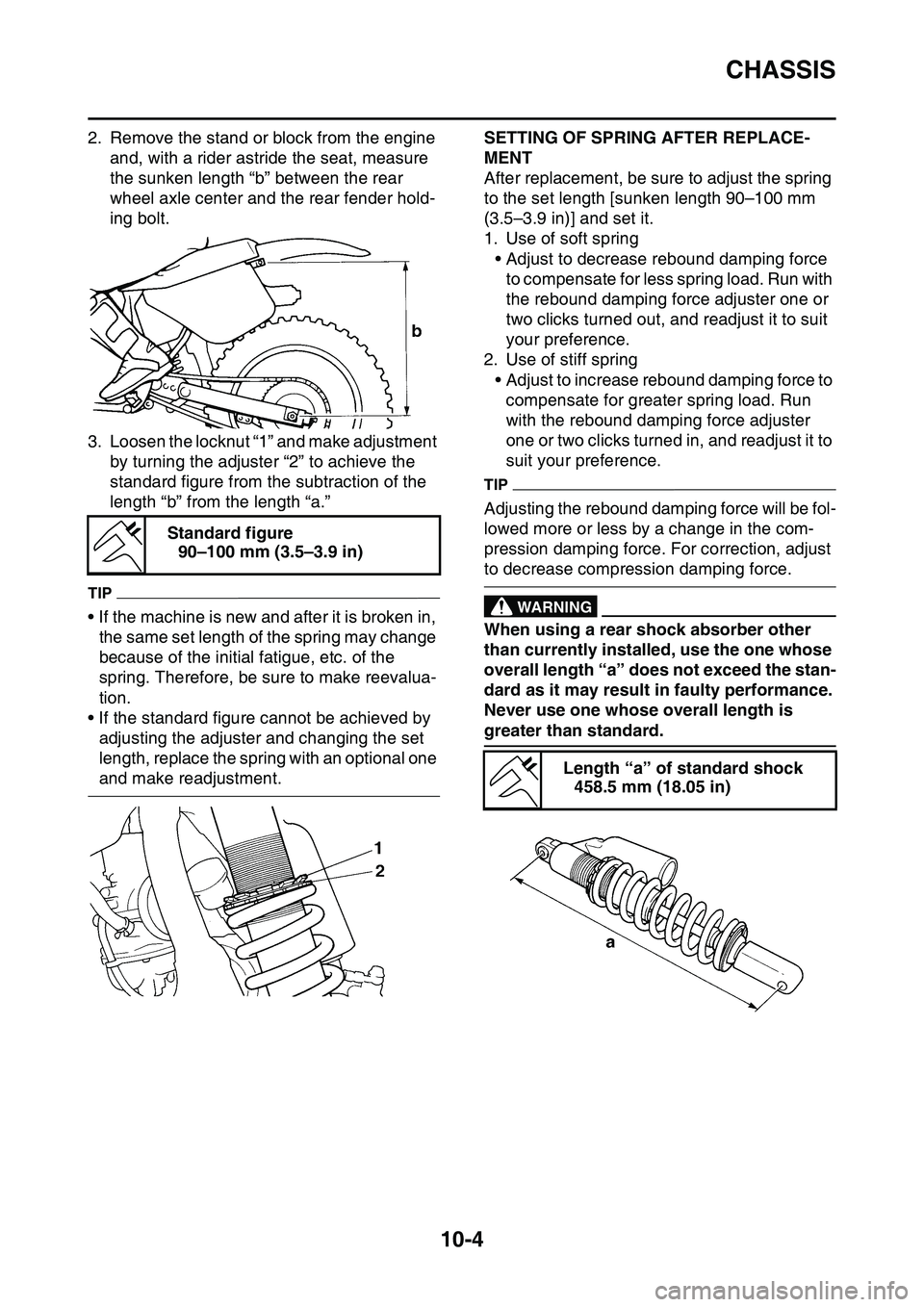

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold

-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a.”

TIP

• If the machine is new and after it is broken in,

the same set length of the spring may change

because of the initial fatigue, etc. of the

spring. Therefore, be sure to make reevalua

-

tion.

• If the standard figure cannot be achieved by

adjusting the adjuster and changing the set

length, replace the spring with an optional one

and make readjustment.

EAS1SL1375

SETTING OF SPRING AFTER REPLACE-

MENT

After replacement, be sure to adjust the spring

to the set length [sunken length 90–100 mm

(3.5–3.9 in)] and set it.

1. Use of soft spring

• Adjust to decrease rebound damping force

to compensate for less spring load. Run with

the rebound damping force adjuster one or

two clicks turned out, and readjust it to suit

your preference.

2. Use of stiff spring

• Adjust to increase rebound damping force to

compensate for greater spring load. Run

with the rebound damping force adjuster

one or two clicks turned in, and readjust it to

suit your preference.

TIP

Adjusting the rebound damping force will be fol-

lowed more or less by a change in the com-

pression damping force. For correction, adjust

to decrease compression damping force.

EWA1DX4002

WARNING

When using a rear shock absorber other

than currently installed, use the one whose

overall length “a” does not exceed the stan

-

dard as it may result in faulty performance.

Never use one whose overall length is

greater than standard.

EAS1SL1376

Standard figure

90–100 mm (3.5–3.9 in)

Length “a” of standard shock

458.5 mm (18.05 in)

Page 352 of 360

CHASSIS

10-5

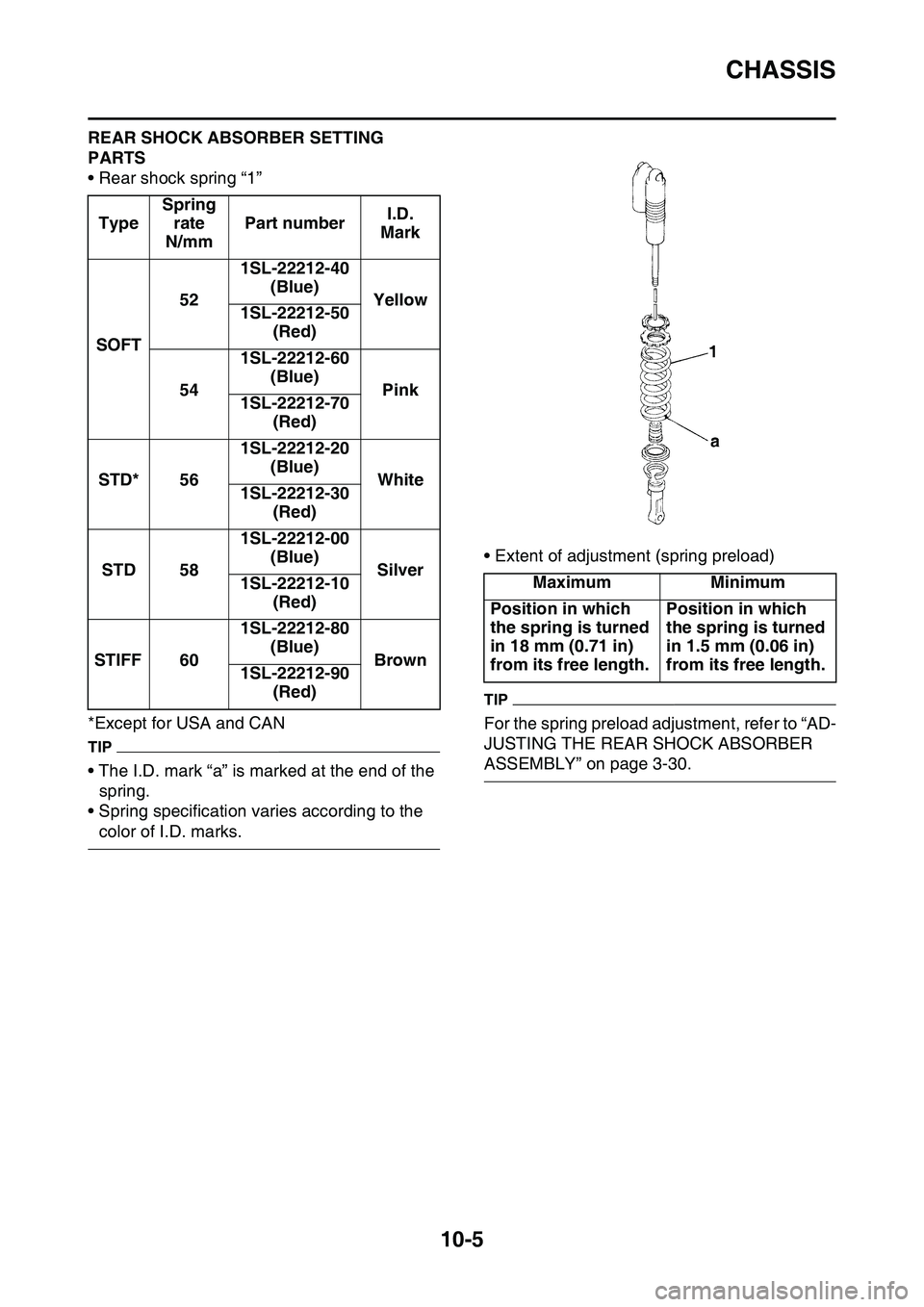

REAR SHOCK ABSORBER SETTING

PARTS

• Rear shock spring “1”

*Except for USA and CAN

TIP

• The I.D. mark “a” is marked at the end of the

spring.

• Spring specification varies according to the

color of I.D. marks.

• Extent of adjustment (spring preload)

TIP

For the spring preload adjustment, refer to “AD-

JUSTING THE REAR SHOCK ABSORBER

ASSEMBLY” on page 3-30.

Type

Spring

rate

N/mm

Part numberI.D.

Mark

SOFT

52

1SL-22212-40

(Blue)

Yellow1SL-22212-50

(Red)

54

1SL-22212-60

(Blue)

Pink1SL-22212-70

(Red)

STD*56

1SL-22212-20

(Blue)

White1SL-22212-30

(Red)

STD58

1SL-22212-00

(Blue)

Silver1SL-22212-10

(Red)

STIFF60

1SL-22212-80

(Blue)

Brown1SL-22212-90

(Red)

MaximumMinimum

Position in which

the spring is turned

in 18 mm (0.71 in)

from its free length.Position in which

the spring is turned

in 1.5 mm (0.06 in)

from its free length.

Page 353 of 360

CHASSIS

10-6

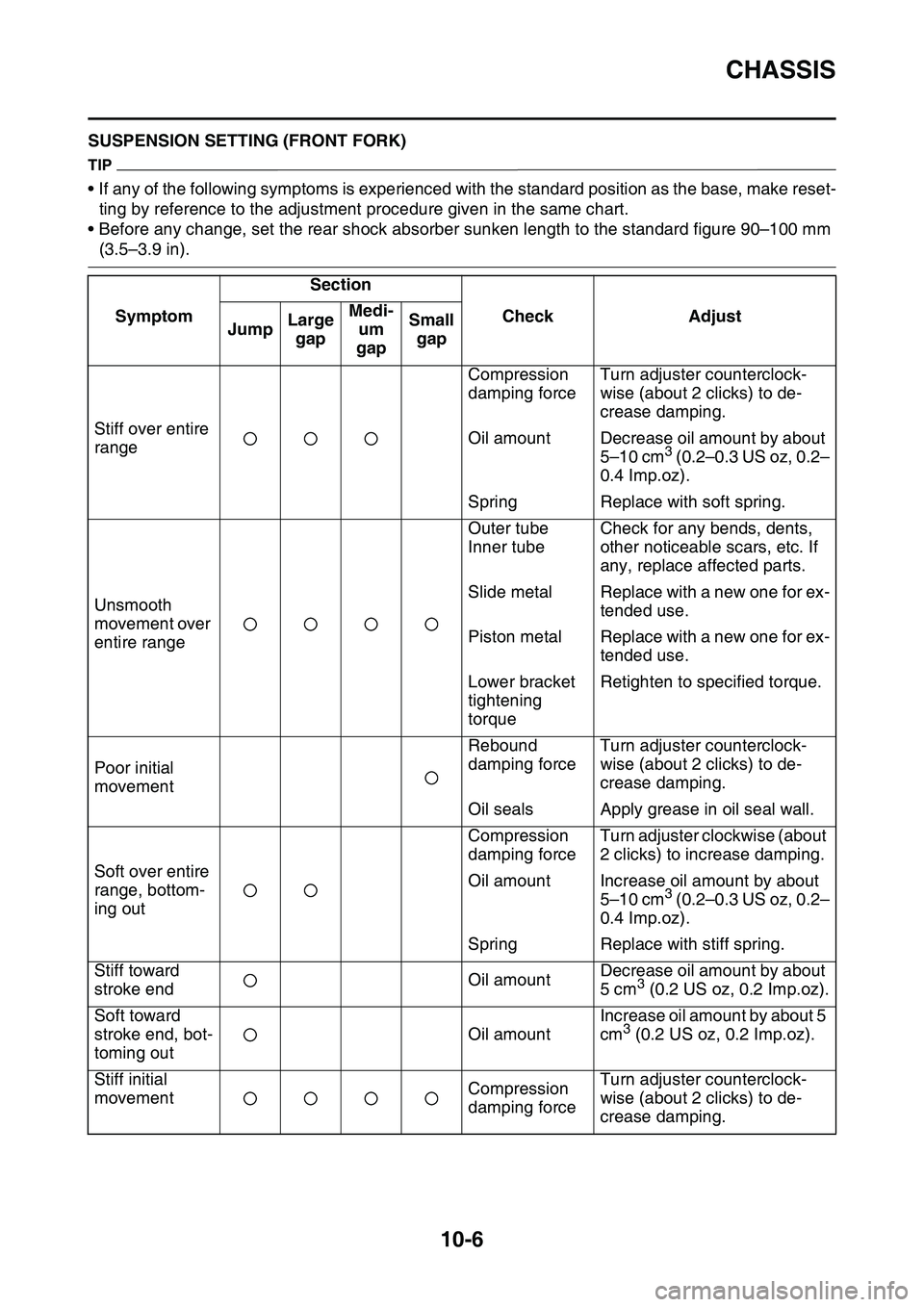

EAS1SL1377SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

Symptom

Section

CheckAdjustJumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

range

Compression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amountDecrease oil amount by about

5–10 cm3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SpringReplace with soft spring.

Unsmooth

movement over

entire range

Outer tube

Inner tube

Check for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metalReplace with a new one for ex-

tended use.

Piston metalReplace with a new one for ex-

tended use.

Lower bracket

tightening

torqueRetighten to specified torque.

Poor initial

movement

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil sealsApply grease in oil seal wall.

Soft over entire

range, bottom

-

ing out

Compression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Oil amountIncrease oil amount by about

5–10 cm3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SpringReplace with stiff spring.

Stiff toward

stroke endOil amountDecrease oil amount by about

5 cm3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot

-

toming out

Oil amount

Increase oil amount by about 5

cm3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movementCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.