Front YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 61 of 360

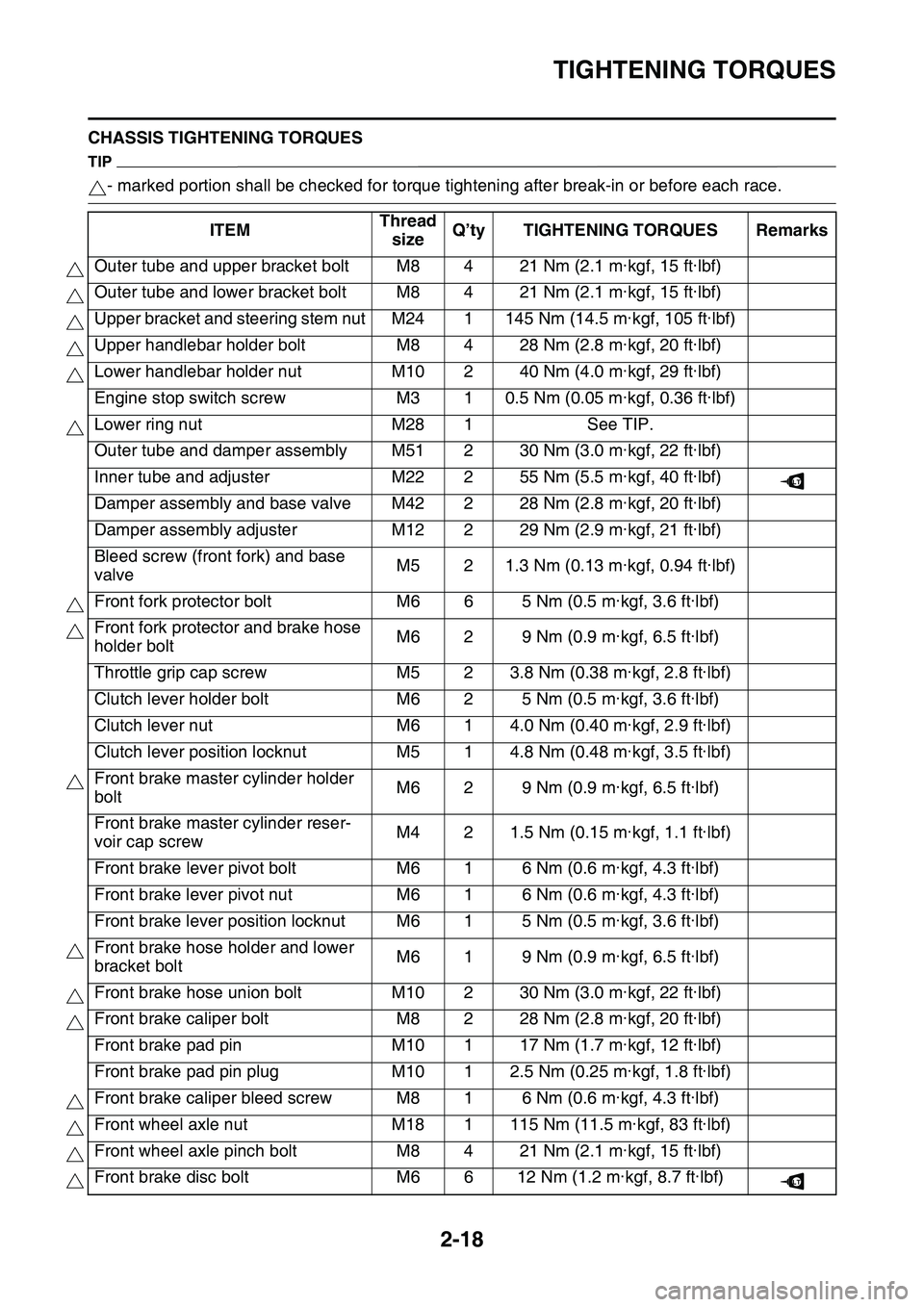

TIGHTENING TORQUES

2-18

CHASSIS TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’tyTIGHTENING TORQUESRemarks

Outer tube and upper bracket boltM8421 Nm (2.1 m·kgf, 15 ft·lbf)

Outer tube and lower bracket boltM8421 Nm (2.1 m·kgf, 15 ft·lbf)

Upper bracket and steering stem nutM241145 Nm (14.5 m·kgf, 105 ft·lbf)

Upper handlebar holder boltM8428 Nm (2.8 m·kgf, 20 ft·lbf)

Lower handlebar holder nutM10240 Nm (4.0 m·kgf, 29 ft·lbf)

Engine stop switch screwM310.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Lower ring nutM281See TIP.

Outer tube and damper assemblyM51230 Nm (3.0 m·kgf, 22 ft·lbf)

Inner tube and adjusterM22255 Nm (5.5 m·kgf, 40 ft·lbf)

Damper assembly and base valveM42228 Nm (2.8 m·kgf, 20 ft·lbf)

Damper assembly adjusterM12229 Nm (2.9 m·kgf, 21 ft·lbf)

Bleed screw (front fork) and base

valveM521.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Front fork protector boltM665 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front fork protector and brake hose

holder boltM629 Nm (0.9 m·kgf, 6.5 ft·lbf)

Throttle grip cap screwM523.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Clutch lever holder boltM625 Nm (0.5 m·kgf, 3.6 ft·lbf)

Clutch lever nutM614.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Clutch lever position locknutM514.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Front brake master cylinder holder

boltM629 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake master cylinder reser-

voir cap screwM421.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Front brake lever pivot boltM616 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever pivot nutM616 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever position locknutM615 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front brake hose holder and lower

bracket boltM619 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake hose union boltM10230 Nm (3.0 m·kgf, 22 ft·lbf)

Front brake caliper boltM8228 Nm (2.8 m·kgf, 20 ft·lbf)

Front brake pad pinM10117 Nm (1.7 m·kgf, 12 ft·lbf)

Front brake pad pin plugM1012.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Front brake caliper bleed screwM816 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front wheel axle nutM181115 Nm (11.5 m·kgf, 83 ft·lbf)

Front wheel axle pinch boltM8421 Nm (2.1 m·kgf, 15 ft·lbf)

Front brake disc boltM6612 Nm (1.2 m·kgf, 8.7 ft·lbf)

LT

LT

Page 62 of 360

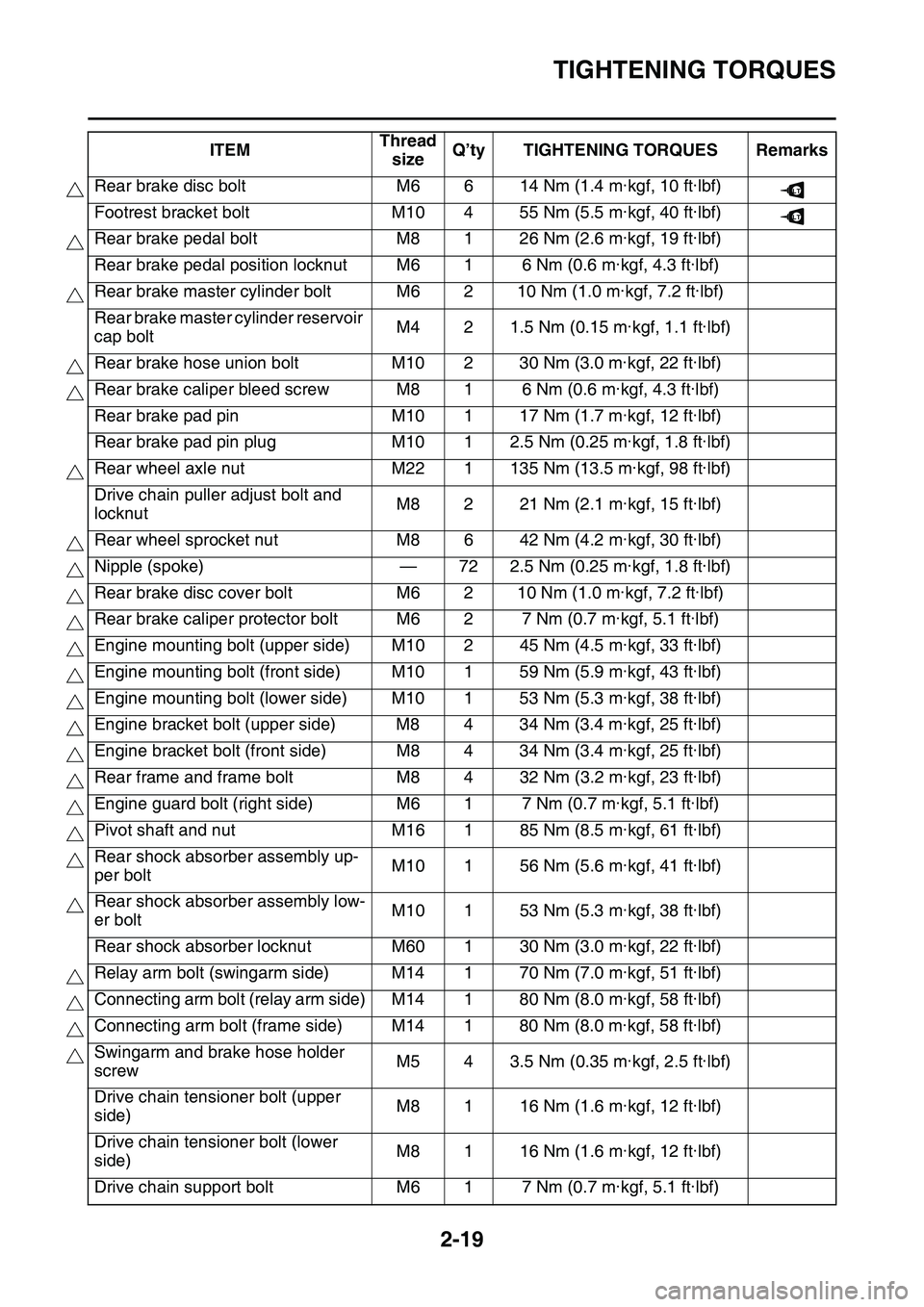

TIGHTENING TORQUES

2-19

Rear brake disc boltM6 6 14 Nm (1.4 m·kgf, 10 ft·lbf)

Footrest bracket bolt M10 4 55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear brake pedal bolt M8 1 26 Nm (2.6 m·kgf, 19 ft·lbf)

Rear brake pedal position locknut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake master cylinder bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake master cylinder reservoir

cap bolt M4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rear brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Rear brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Rear brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear wheel axle nut M22 1 135 Nm (13.5 m·kgf, 98 ft·lbf)

Drive chain puller adjust bolt and

locknut M8 2 21 Nm (2.1 m·kgf, 15 ft·lbf)

Rear wheel sprocket nut M8 6 42 Nm (4.2 m·kgf, 30 ft·lbf)

Nipple (spoke) — 72 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear brake disc cover bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake caliper protector bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Engine mounting bolt (upper side) M10 2 45 Nm (4.5 m·kgf, 33 ft·lbf)

Engine mounting bolt (front side) M 10 1 59 Nm (5.9 m·kgf, 43 ft·lbf)

Engine mounting bolt (lower side) M 10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Engine bracket bolt (upper side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Engine bracket bolt (front side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Rear frame and frame bolt M8 4 32 Nm (3.2 m·kgf, 23 ft·lbf)

Engine guard bolt (right side) M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Pivot shaft and nut M16 1 85 Nm (8.5 m·kgf, 61 ft·lbf)

Rear shock absorber assembly up-

per bolt M10 1 56 Nm (5.6 m·kgf, 41 ft·lbf)

Rear shock absorber assembly low-

er bolt M10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Rear shock absorber locknut M60 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Relay arm bolt (swingarm side) M14 1 70 Nm (7.0 m·kgf, 51 ft·lbf)

Connecting arm bolt (relay arm side) M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Connecting arm bolt (frame side) M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Swingarm and brake hose holder

screw M5 4 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Drive chain tensioner bolt (upper

side) M8 1 16 Nm (1.6 m·kgf, 12 ft·lbf)

Drive chain tensioner bolt (lower

side) M8 1 16 Nm (1.6 m·kgf, 12 ft·lbf)

Drive chain support bolt M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

ITEM

Thread

size Q’ty TIGHTENING TORQUES RemarksLT

LT

Page 63 of 360

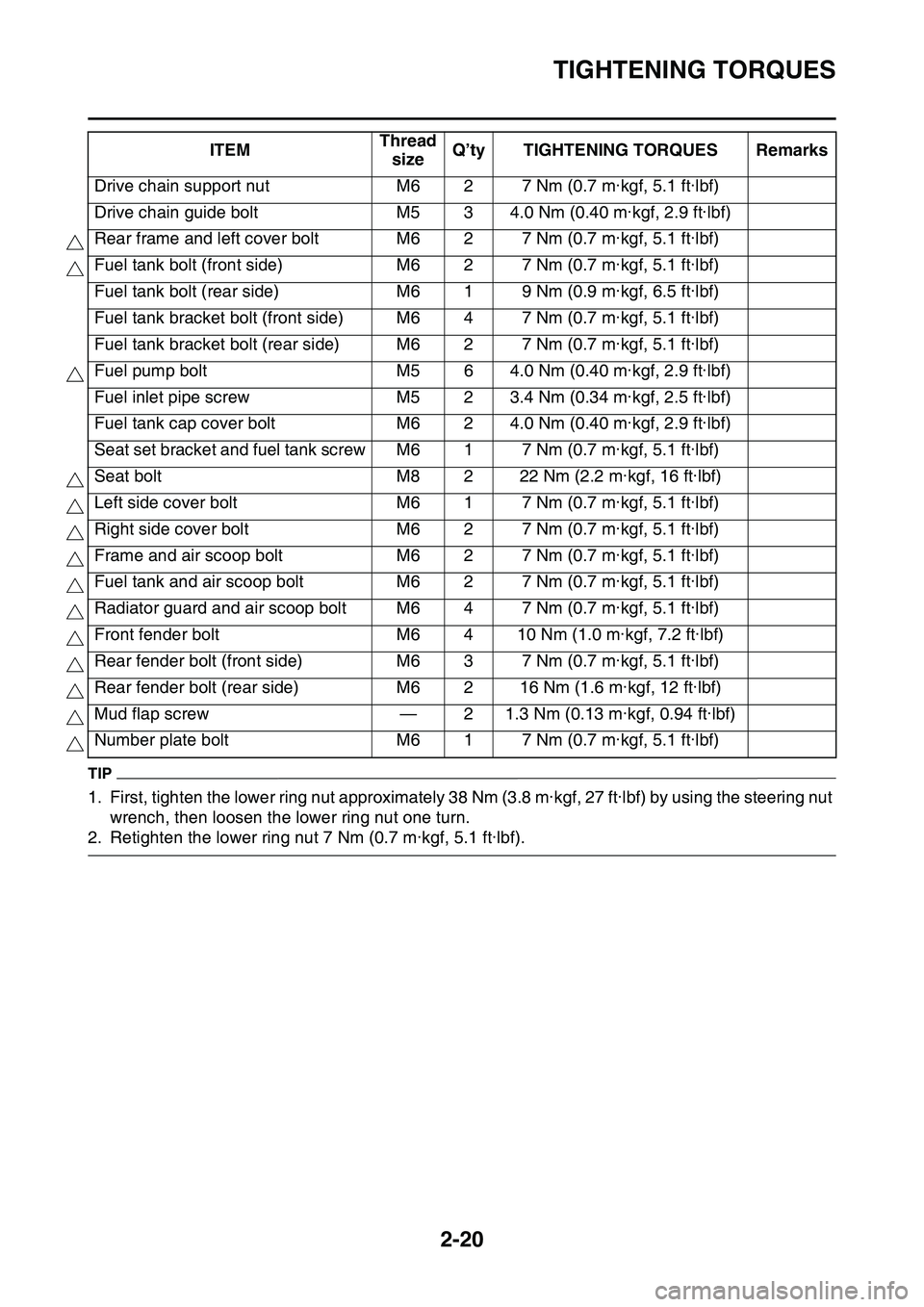

TIGHTENING TORQUES

2-20

TIP

1. First, tighten the lower ring nut approximately 38 Nm (3.8 m·kgf, 27 ft·lbf) by using the steering nut

wrench, then loosen the lower ring nut one turn.

2. Retighten the lower ring nut 7 Nm (0.7 m·kgf, 5.1 ft·lbf).

Drive chain support nutM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Drive chain guide boltM534.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Rear frame and left cover boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bolt (front side)M627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bolt (rear side)M619 Nm (0.9 m·kgf, 6.5 ft·lbf)

Fuel tank bracket bolt (front side)M647 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank bracket bolt (rear side)M627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel pump boltM564.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Fuel inlet pipe screwM523.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

Fuel tank cap cover boltM624.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Seat set bracket and fuel tank screwM617 Nm (0.7 m·kgf, 5.1 ft·lbf)

Seat boltM8222 Nm (2.2 m·kgf, 16 ft·lbf)

Left side cover boltM617 Nm (0.7 m·kgf, 5.1 ft·lbf)

Right side cover boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Frame and air scoop boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Fuel tank and air scoop boltM627 Nm (0.7 m·kgf, 5.1 ft·lbf)

Radiator guard and air scoop boltM647 Nm (0.7 m·kgf, 5.1 ft·lbf)

Front fender boltM6410 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear fender bolt (front side)M637 Nm (0.7 m·kgf, 5.1 ft·lbf)

Rear fender bolt (rear side)M6216 Nm (1.6 m·kgf, 12 ft·lbf)

Mud flap screw—21.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Number plate boltM617 Nm (0.7 m·kgf, 5.1 ft·lbf)

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Page 66 of 360

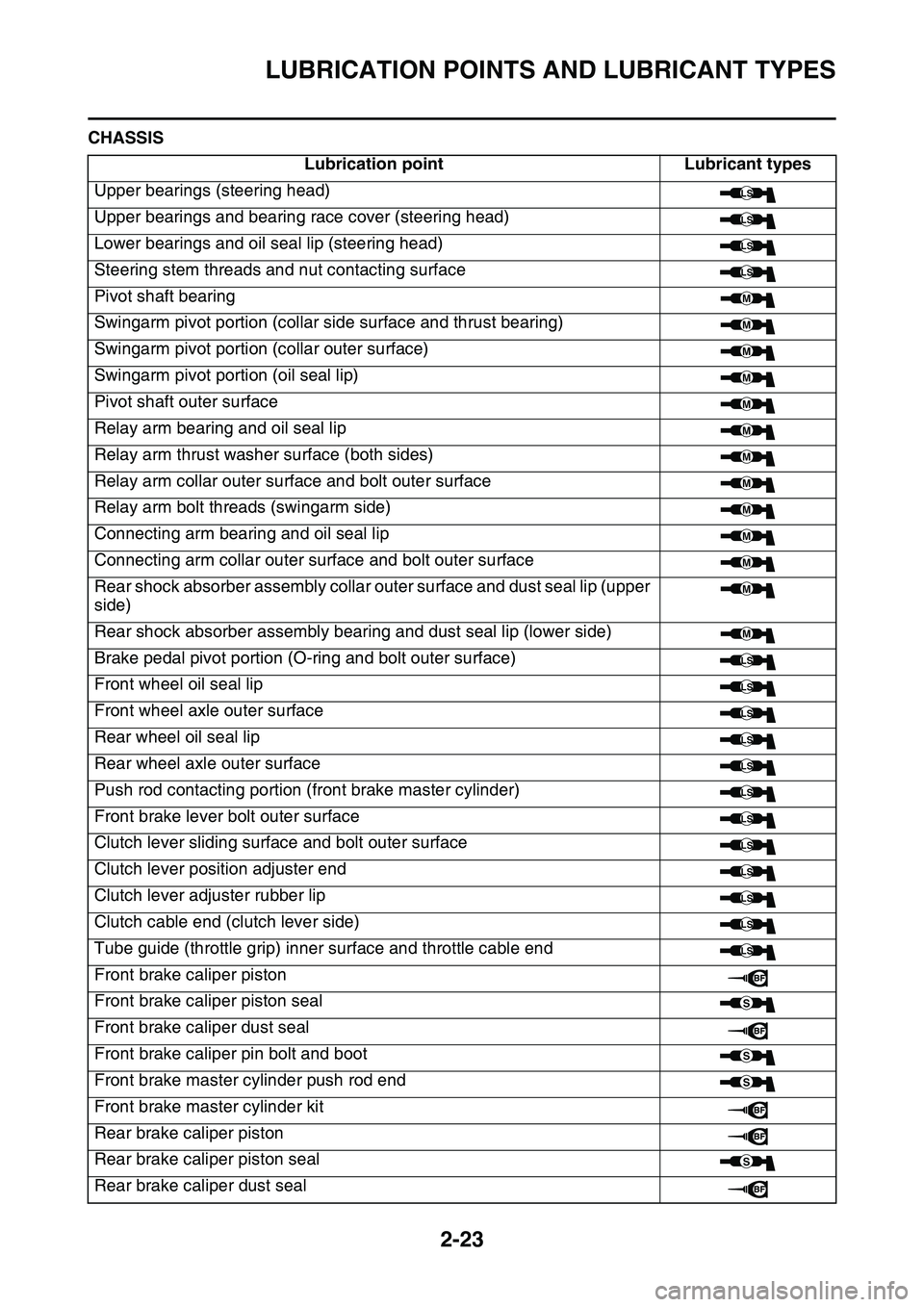

LUBRICATION POINTS AND LUBRICANT TYPES

2-23

CHASSIS

Lubrication pointLubricant types

Upper bearings (steering head)

Upper bearings and bearing race cover (steering head)

Lower bearings and oil seal lip (steering head)

Steering stem threads and nut contacting surface

Pivot shaft bearing

Swingarm pivot portion (collar side surface and thrust bearing)

Swingarm pivot portion (collar outer surface)

Swingarm pivot portion (oil seal lip)

Pivot shaft outer surface

Relay arm bearing and oil seal lip

Relay arm thrust washer surface (both sides)

Relay arm collar outer surface and bolt outer surface

Relay arm bolt threads (swingarm side)

Connecting arm bearing and oil seal lip

Connecting arm collar outer surface and bolt outer surface

Rear shock absorber assembly collar outer surface and dust seal lip (upper

side)

Rear shock absorber assembly bearing and dust seal lip (lower side)

Brake pedal pivot portion (O-ring and bolt outer surface)

Front wheel oil seal lip

Front wheel axle outer surface

Rear wheel oil seal lip

Rear wheel axle outer surface

Push rod contacting portion (front brake master cylinder)

Front brake lever bolt outer surface

Clutch lever sliding surface and bolt outer surface

Clutch lever position adjuster end

Clutch lever adjuster rubber lip

Clutch cable end (clutch lever side)

Tube guide (throttle grip) inner surface and throttle cable end

Front brake caliper piston

Front brake caliper piston seal

Front brake caliper dust seal

Front brake caliper pin bolt and boot

Front brake master cylinder push rod end

Front brake master cylinder kit

Rear brake caliper piston

Rear brake caliper piston seal

Rear brake caliper dust seal

LS

LS

LS

LS

M

M

M

M

M

M

M

M

M

M

M

M

M

LS

LS

LS

LS

LS

LS

LS

LS

LS

LS

LS

LS

S

S

S

S

Page 77 of 360

CABLE ROUTING DIAGRAM

2-34

1. Clutch cable

2. Throttle cable (pull)3. Throttle cable (return)

4. Cable holder

5. Engine stop switch lead6. Frame

7. Coupler for connecting optional part

8. Bracket9. Engine stop switch coupler

10. Rectifier/regulator coupler

11. Starter knob/idle screw12. Neutral switch lead

13. Crankcase cover

14. AC magneto lead15. Front engine bracket

16. Radiator hose

17. Coupler cover18. Rectifier/regulator lead

19. Tension arm

20. Main harness21. Tank rail

22. Radiator

23. Cylinder head breather hose24. Radiator breather hose

25. Down tube

26. Crankcase

A. Pass the engine stop switch lead between the

frame and the cable holder.

B. Pass the engine stop switch lead between the

coupler for connecting optional part and the

frame, where the main harness should face the

outside of the vehicle.

C. Insert the coupler for connecting optional part into

the connector, and fix it to the bracket.

D. Insert and fix the engine stop switch coupler to

the bracket.

E. Insert and fix the rectifier/regulator coupler to the

bracket.

F. Pass the AC magneto lead to the front of the ve-hicle beyond the starter knob/idle screw and to

the rear of the vehicle beyond the radiator. No

pinch is allowed between the radiator and the

tension arm.

G. 70 mm (2.76 in)

H. Bring the neutral switch lead into line with the

crankcase cover with no sag allowed.

I. Bring the AC magneto lead into line with the

clutch cable with no sag allowed.

J. Pass the neutral switch lead to the inside of the

front engine bracket (the side of the vehicle).

K. Clamp the clutch cable and the AC magneto lead

by the plastic locking tie. Regardless of the orien-tation of the lock on the plastic locking tie, cut the

end.

L. Pass the clutch cable with no downward sag al-lowed.

M. Bring the grommet of the clutch cable into contact

with the radiator hose, and pass it to the outside

of the neutral switch lead and the AC magneto

lead (the outside of the vehicle).

N. 40 mm (1.57 in)

O. Clamp the clutch cable, the AC magneto lead,

and the neutral switch lead by the plastic locking

tie. Make sure that they are clamped at the posi

-tioning tape in the clutch cable. Make the lock on

the plastic locking tie face the front of the vehicle,

and cut the end.

P. After connecting the neutral switch coupler, at-tach the coupler cover.Q. After connecting the AC magneto coupler, attach

the coupler cover.

R. Pass the rectifier/regulator lead to the inside of

the tension arm (the side of the vehicle).

S. Pass the main harness to the front of the radiator

hose (the front of the vehicle), and to the inside of

the clutch cable (the side of the vehicle).

T. Pass the engine stop switch lead between the

coupler for connecting optional part and the tank

rail, with the lead on the main harness side facing

the top of the vehicle.

U. Pass the radiator breather hose between the

down tubes.

V. Clamp the radiator breather hose, above the en-gine bracket (front). Clamp the lock on the plastic

tie with it located outside the vehicle, and face the

end toward the front of the vehicle.

W. Clamp the clutch cable at the front of the lead (the

front of the vehicle).

X. Make the lock on the plastic locking tie face the

front of the vehicle, and insert the projection into

the hole in the frame. Cut the end of the plastic

locking tie.

Page 79 of 360

CABLE ROUTING DIAGRAM

2-36

1. Bracket

2. Condenser3. Coolant temperature sensor

4. Coupler cover

5. Intake air temperature sensor coupler6. Intake air temperature sensor coupler

7. Radiator hoses

8. Radiator breather hose9. Joint coupler

10. Plate

11. Tension arm12. Throttle position sensor lead

13. Ground lead

14. Throttle position sensor coupler15. Radiator breather hose

16. Cylinder head breather hose

17. Engine guard18. Crankcase

19. Fuel pump coupler

20. Fuel hose21. Condenser lead

22. Fuel pump lead

23. Condenser coupler24. Ground lead terminal

25. Fuel tank

26. Damper27. Rear frame

28. Main harness

A. Insert the condenser into the bracket as far as it

will go.

B. Attach the coupler cover to the coolant tempera-ture sensor coupler.

C. Pass the radiator breather hose to the inside of

the radiator hose (the side of the vehicle).

D. Insert and fix the joint coupler to the plate. After

fixing it, attach the cover.

E. Pass the throttle position sensor lead to the out-side of the tension arm (the outside of the vehi-cle).

F. After connecting the throttle position sensor cou-pler, attach the cover.

G. Pass the radiator breather hose to the outside of

the tension arm and the throttle position sensor

lead (the outside of the vehicle), and to the inside

of the radiator hose (the side of the vehicle).

H. Pass the protector of the cylinder head breather

hose until it touches the holder.

I. Pass the cylinder head breather hose between

the engine guard and the crankcase.

J. Install the end of the cylinder head breather hose

with it facing downward.

K. After connecting the fuel pump coupler, attach

the coupler cover.

L. 55 mm (2.17 in) (seat load receiver)

M. Clamp the fuel hose and the fuel pump lead by

the holder. Make sure that the painted part on the

fuel hose is clamped, and face the lock on the

clamp toward the rear top of the vehicle.

N. Do not install the plastic locking tie to the seat

load receiver.

O. Make the lock on the plastic locking tie face the

front of the vehicle, and make the end face the

bottom of the vehicle. Do not cut the end.

P. Install the ground lead terminal between the plate

and the bolt.

Q. DetentR. Fix the ground lead terminal to the detent in the

plate. For the ground lead terminal, either side

will do.

S. Insert the projection on the plastic locking tie into

the hole in the rear frame.

T. Clamp the painted part on the fuel hose by the

plastic clamp. Make the lock on the plastic clamp

face the bottom of the vehicle, and cut the end.

Page 81 of 360

CABLE ROUTING DIAGRAM

2-38

1. Throttle cable

2. Clutch cable3. Engine stop switch lead

4. Cable guide

5. Head pipe6. Front brake hose

7. Brake hose guide

8. Number plate

A. Number plate band

B. Pass the clutch cable to the rear of the number

plate band.

C. Clamp the engine stop switch lead to the handle-bar by the plastic band. Do not cut the end of the

plastic band.

D. Pass the engine stop switch lead between the

head pipe and the cable guide.

E. Pass the front brake hose to the front of the num-ber plate.

F. 40°±10°G. Vertical direction

H. Pass the engine stop switch lead under the han-dlebar.

I. Pass the clutch cable to the guide in the number

plate.

Page 87 of 360

3

PERIODIC CHECKS AND ADJUSTMENTS

MAINTENANCE INTERVALS.......................................................................... 3-1

MAINTENANCE INTERVALS .................................................................... 3-1

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-7

GENERAL INSPECTION AND MAINTENANCE........................................ 3-7

ENGINE............................................................................................................ 3-8

CHECKING THE COOLANT LEVEL .......................................................... 3-8

CHECKING THE COOLING SYSTEM ....................................................... 3-8

CHANGING THE COOLANT...................................................................... 3-8

CHECKING THE RADIATOR CAP ............................................................ 3-9

CHECKING THE RADIATOR CAP OPENING PRESSURE ...................... 3-9

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-10

ADJUSTING THE CLUTCH LEVER POSITION ...................................... 3-10

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-10

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-11

LUBRICATING THE THROTTLE CABLE ................................................ 3-12

CLEANING THE AIR FILTER ELEMENT................................................. 3-12

CHECKING THE THROTTLE BODY JOINT ............................................ 3-13

CHECKING THE BREATHER HOSES .................................................... 3-13

CHECKING THE EXHAUST SYSTEM..................................................... 3-13

CHECKING THE FUEL LINE ................................................................... 3-14

CHECKING THE ENGINE OIL LEVEL..................................................... 3-14

CHANGING THE ENGINE OIL ................................................................ 3-15

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-16

ADJUSTING THE VALVE CLEARANCE ................................................. 3-17

CHASSIS........................................................................................................ 3-21

BLEEDING THE BRAKE SYSTEM .......................................................... 3-21

CHECKING THE BRAKE HOSE .............................................................. 3-22

ADJUSTING THE FRONT BRAKE .......................................................... 3-22

ADJUSTING THE REAR BRAKE ............................................................. 3-23

CHECKING THE FRONT BRAKE PADS ................................................. 3-23

CHECKING THE REAR BRAKE PADS ................................................... 3-25

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-26

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-26

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-27

CHECKING THE FRONT FORK LEGS ................................................... 3-28

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-28

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-28

AIR BLEEDING FROM FRONT FORK .................................................... 3-28

ADJUSTING THE FRONT FORK LEGS .................................................. 3-29

CHECKING THE SWINGARM OPERATION ........................................... 3-30

CHECKING THE REAR SUSPENSION ................................................... 3-30

ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY ................... 3-30

CHECKING THE TIRES ........................................................................... 3-32

CHECKING AND TIGHTENING THE SPOKES ....................................... 3-32

CHECKING THE WHEELS ...................................................................... 3-33

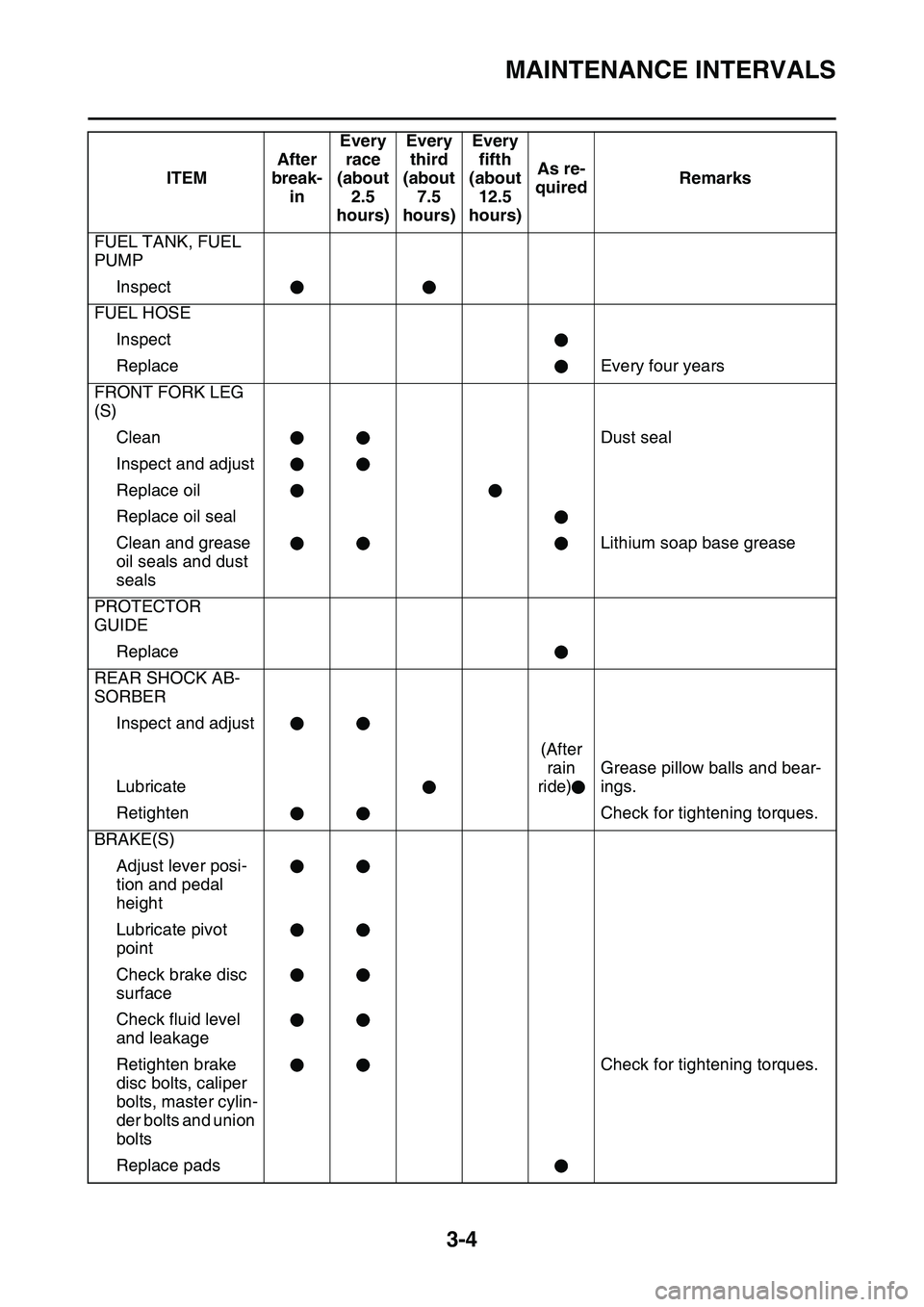

Page 92 of 360

MAINTENANCE INTERVALS

3-4

FUEL TANK, FUEL

PUMP

Inspect

FUEL HOSE

Inspect

ReplaceEvery four years

FRONT FORK LEG

(S)

CleanDust seal

Inspect and adjust

Replace oil

Replace oil seal

Clean and grease

oil seals and dust

sealsLithium soap base grease

PROTECTOR

GUIDE

Replace

REAR SHOCK AB-

SORBER

Inspect and adjust

Lubricate

(After

rain

ride)

Grease pillow balls and bear-

ings.

RetightenCheck for tightening torques.

BRAKE(S)

Adjust lever posi-

tion and pedal

height

Lubricate pivot

point

Check brake disc

surface

Check fluid level

and leakage

Retighten brake

disc bolts, caliper

bolts, master cylin

-

der bolts and union

bolts

Check for tightening torques.

Replace pads

ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 95 of 360

PRE-OPERATION INSPECTION AND MAINTENANCE

3-7

EAS1SL1067

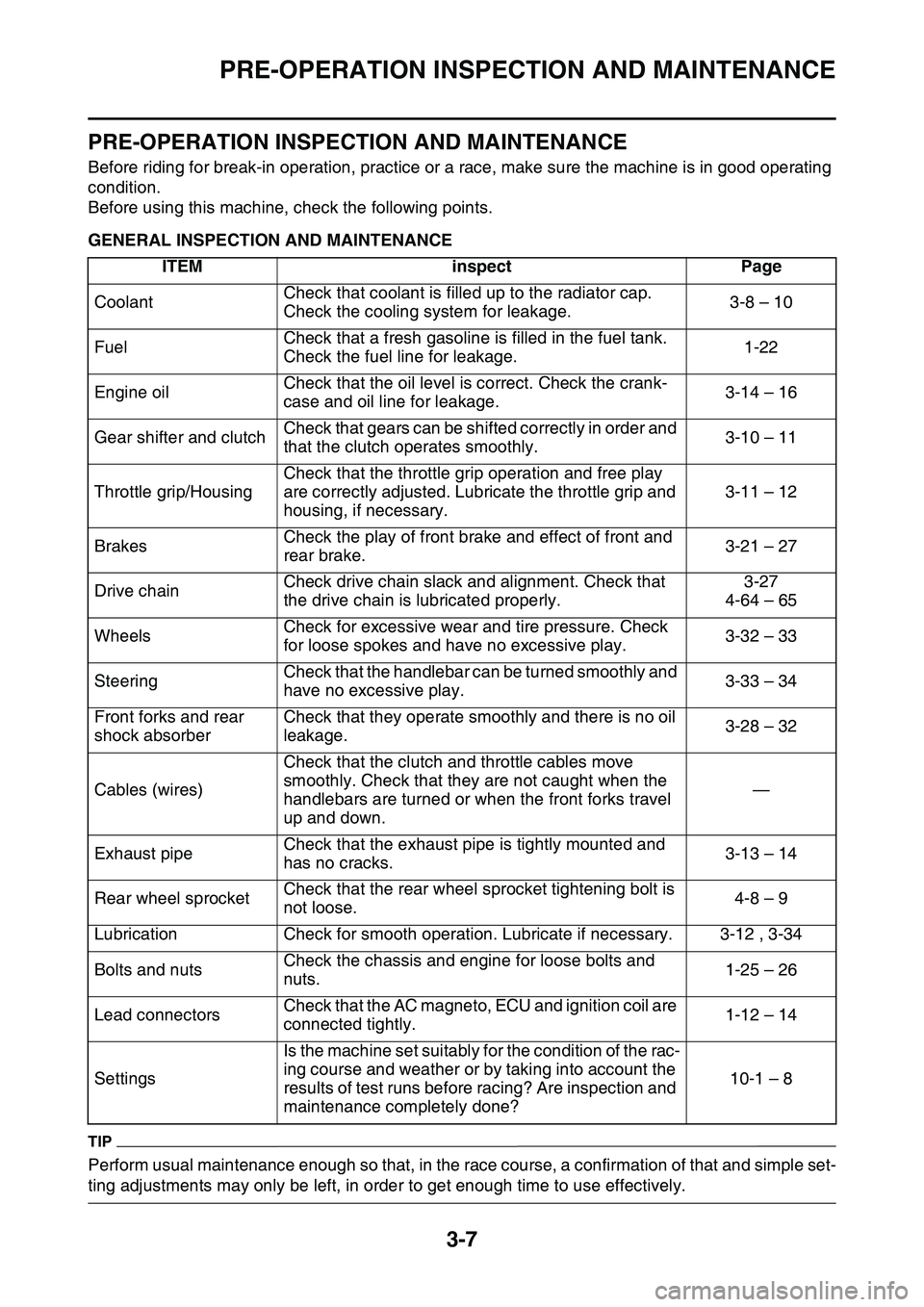

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS1SL1068GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.

ITEMinspectPage

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.3-8 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage.1-22

Engine oilCheck that the oil level is correct. Check the crank-

case and oil line for leakage.3-14 – 16

Gear shifter and clutchCheck that gears can be shifted correctly in order and

that the clutch operates smoothly.3-10 – 11

Throttle grip/Housing

Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary.

3-11 – 12

BrakesCheck the play of front brake and effect of front and

rear brake.3-21 – 27

Drive chainCheck drive chain slack and alignment. Check that

the drive chain is lubricated properly.3-27

4-64 – 65

WheelsCheck for excessive wear and tire pressure. Check

for loose spokes and have no excessive play.3-32 – 33

SteeringCheck that the handlebar can be turned smoothly and

have no excessive play.3-33 – 34

Front forks and rear

shock absorberCheck that they operate smoothly and there is no oil

leakage.3-28 – 32

Cables (wires)

Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and

has no cracks.3-13 – 14

Rear wheel sprocketCheck that the rear wheel sprocket tightening bolt is

not loose.4-8 – 9

LubricationCheck for smooth operation. Lubricate if necessary. 3-12 , 3-34

Bolts and nutsCheck the chassis and engine for loose bolts and

nuts.1-25 – 26

Lead connectorsCheck that the AC magneto, ECU and ignition coil are

connected tightly.1-12 – 14

Settings

Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?10-1 – 8