radiator YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 95 of 360

PRE-OPERATION INSPECTION AND MAINTENANCE

3-7

EAS1SL1067

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS1SL1068GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.

ITEMinspectPage

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.3-8 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage.1-22

Engine oilCheck that the oil level is correct. Check the crank-

case and oil line for leakage.3-14 – 16

Gear shifter and clutchCheck that gears can be shifted correctly in order and

that the clutch operates smoothly.3-10 – 11

Throttle grip/Housing

Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary.

3-11 – 12

BrakesCheck the play of front brake and effect of front and

rear brake.3-21 – 27

Drive chainCheck drive chain slack and alignment. Check that

the drive chain is lubricated properly.3-27

4-64 – 65

WheelsCheck for excessive wear and tire pressure. Check

for loose spokes and have no excessive play.3-32 – 33

SteeringCheck that the handlebar can be turned smoothly and

have no excessive play.3-33 – 34

Front forks and rear

shock absorberCheck that they operate smoothly and there is no oil

leakage.3-28 – 32

Cables (wires)

Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and

has no cracks.3-13 – 14

Rear wheel sprocketCheck that the rear wheel sprocket tightening bolt is

not loose.4-8 – 9

LubricationCheck for smooth operation. Lubricate if necessary. 3-12 , 3-34

Bolts and nutsCheck the chassis and engine for loose bolts and

nuts.1-25 – 26

Lead connectorsCheck that the AC magneto, ECU and ignition coil are

connected tightly.1-12 – 14

Settings

Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?10-1 – 8

Page 96 of 360

ENGINE

3-8

EAS1SL1069

ENGINE

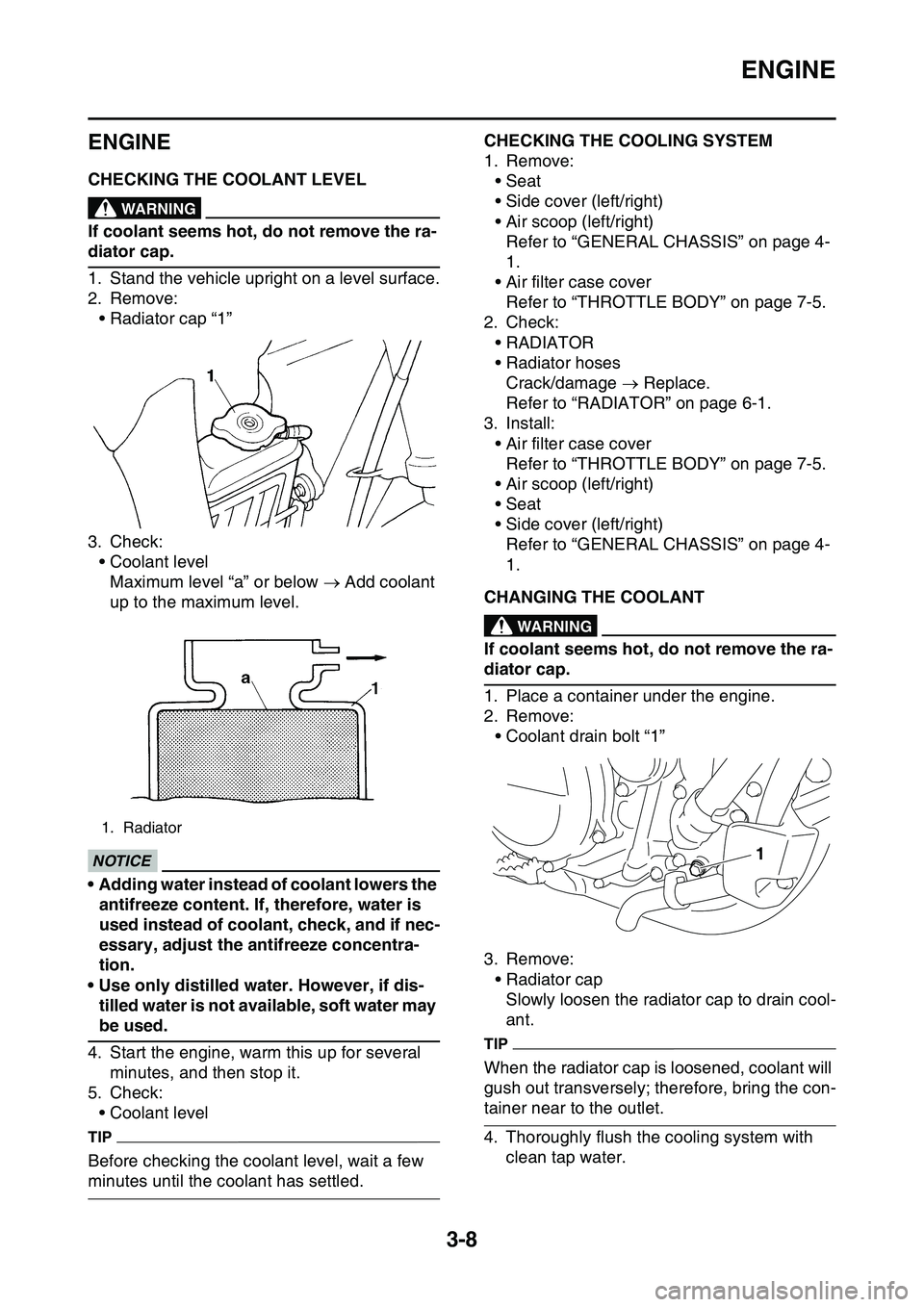

EAS1SL1070CHECKING THE COOLANT LEVELEWA1DX1003

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:

• Radiator cap “1”

3. Check:

• Coolant level

Maximum level “a” or below Add coolant

up to the maximum level.

ECA1DX1004

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec

-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for several

minutes, and then stop it.

5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS1SL1071CHECKING THE COOLING SYSTEM

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

2. Check:

•RADIATOR

• Radiator hoses

Crack/damage Replace.

Refer to “RADIATOR” on page 6-1.

3. Install:

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1072CHANGING THE COOLANTEWA1DX1004

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Place a container under the engine.

2. Remove:

• Coolant drain bolt “1”

3. Remove:

• Radiator cap

Slowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con

-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

1. Radiator

1

Page 97 of 360

ENGINE

3-9

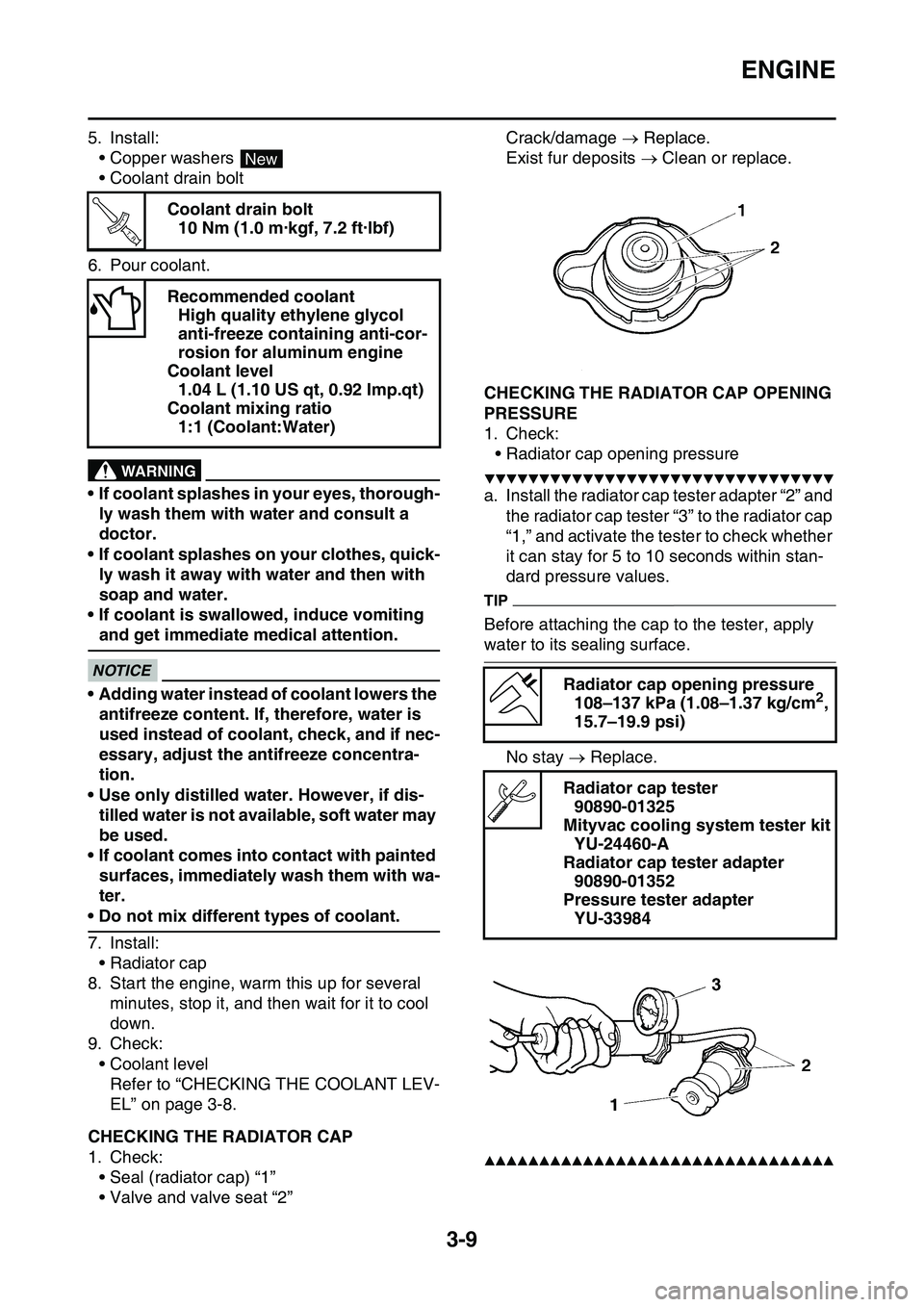

5. Install:

• Copper washers

• Coolant drain bolt

6. Pour coolant.

EWA13040

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA13480

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec

-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa

-

ter.

• Do not mix different types of coolant.

7. Install:

• Radiator cap

8. Start the engine, warm this up for several

minutes, stop it, and then wait for it to cool

down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-8.

EAS1SL1073CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”

• Valve and valve seat “2”

Crack/damage Replace.

Exist fur deposits Clean or replace.

EAS1SL1074CHECKING THE RADIATOR CAP OPENING

PRESSURE

1. Check:

• Radiator cap opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan

-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1075

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor

-

rosion for aluminum engine

Coolant level

1.04 L (1.10 US qt, 0.92 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap opening pressure

108–137 kPa (1.08–1.37 kg/cm2,

15.7–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 98 of 360

ENGINE

3-10

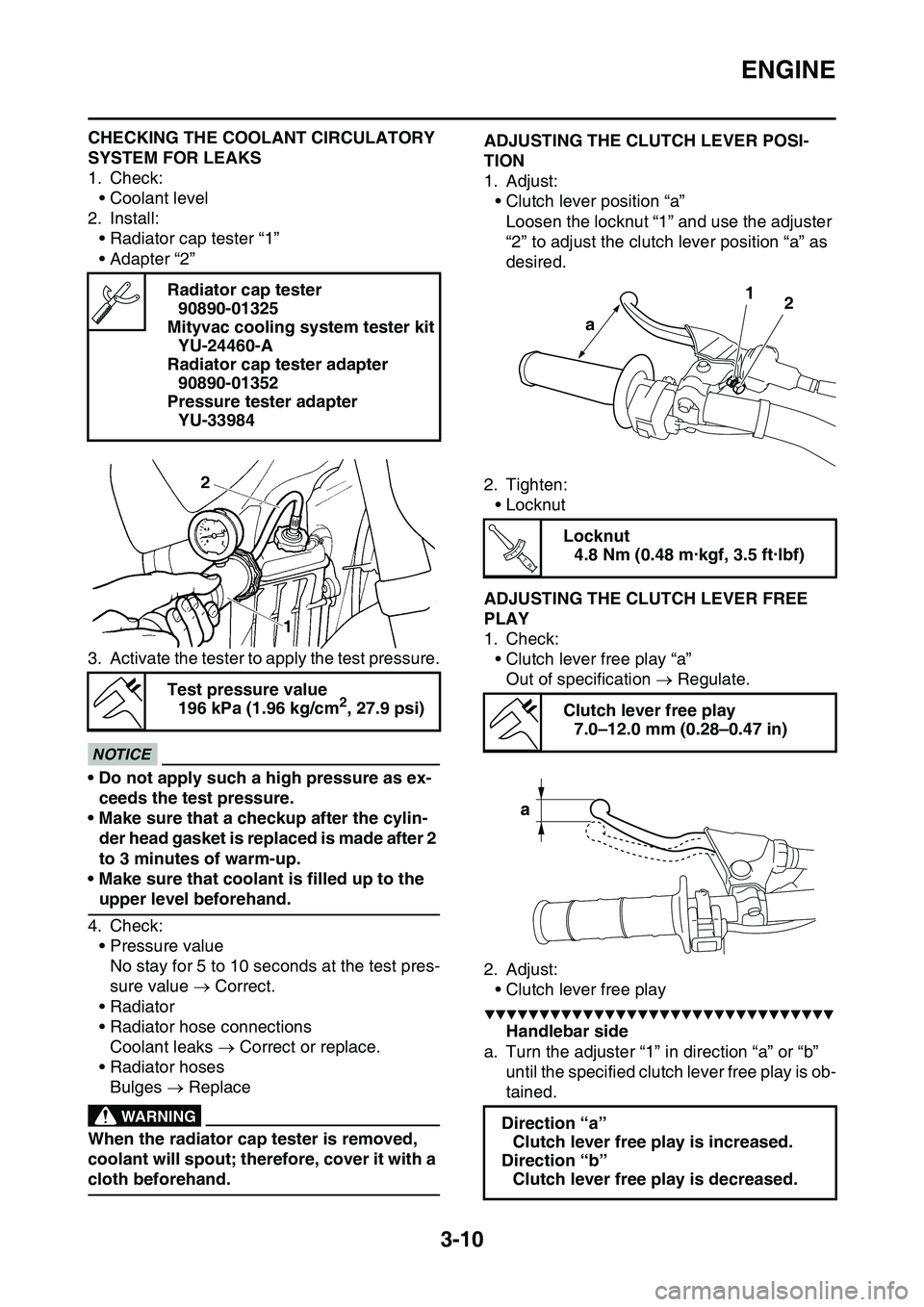

CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA@

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 2

to 3 minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.

4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges ReplaceEWA@

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

EAS1SL1076ADJUSTING THE CLUTCH LEVER POSI-

TION

1. Adjust:

• Clutch lever position “a”

Loosen the locknut “1” and use the adjuster

“2” to adjust the clutch lever position “a” as

desired.

2. Tighten:

• Locknut

EAS1SL1077ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob

-

tained.

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm2, 27.9 psi)

Locknut

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

1

2

a

T R..

Page 214 of 360

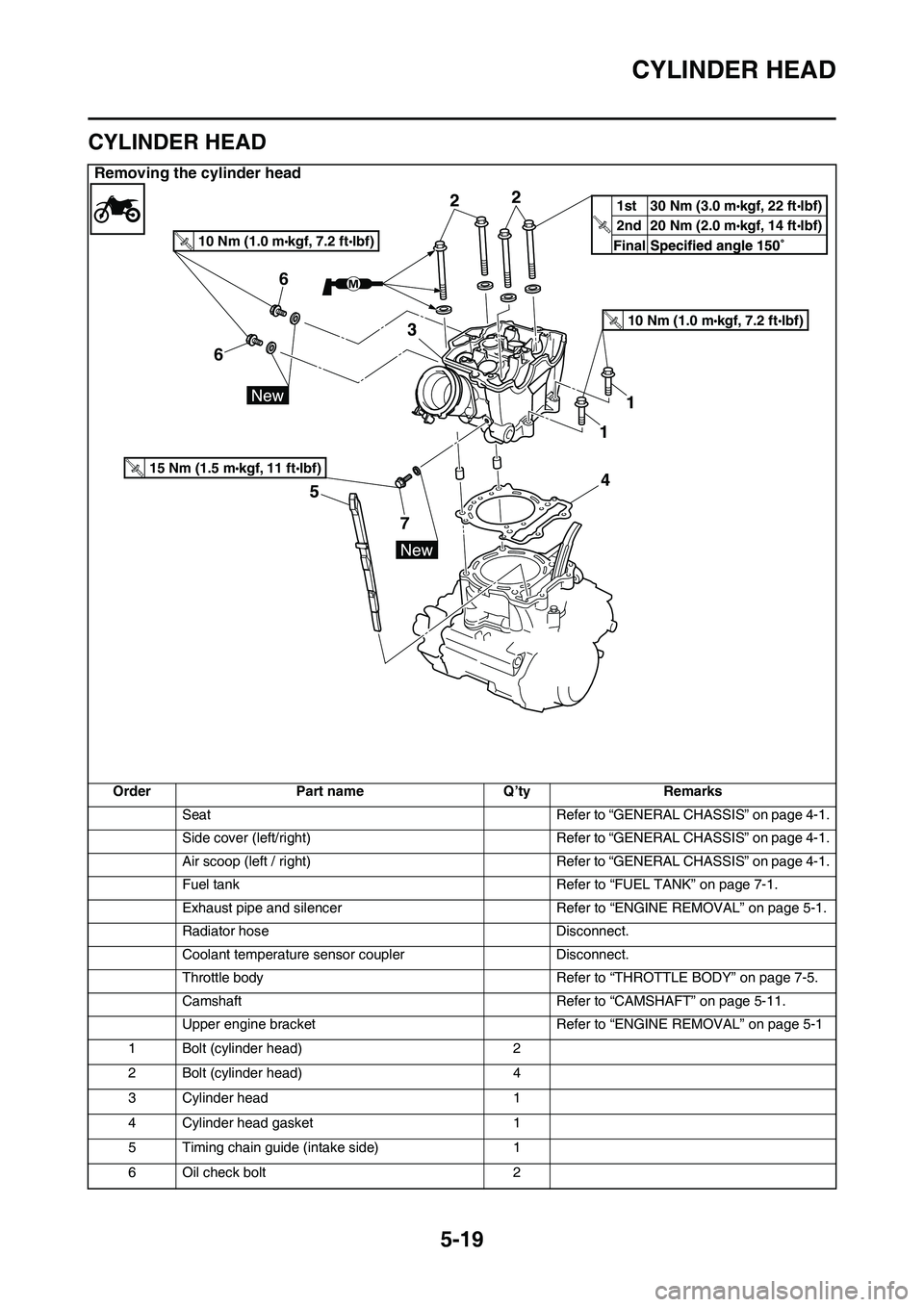

CYLINDER HEAD

5-19

EAS1SL1214

CYLINDER HEAD

Removing the cylinder head

OrderPart nameQ’tyRemarks

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

Exhaust pipe and silencerRefer to “ENGINE REMOVAL” on page 5-1.

Radiator hoseDisconnect.

Coolant temperature sensor couplerDisconnect.

Throttle bodyRefer to “THROTTLE BODY” on page 7-5.

CamshaftRefer to “CAMSHAFT” on page 5-11.

Upper engine bracketRefer to “ENGINE REMOVAL” on page 5-1

1Bolt (cylinder head)2

2Bolt (cylinder head)4

3Cylinder head1

4Cylinder head gasket1

5Timing chain guide (intake side)1

6Oil check bolt2

7 66

1st

2nd

Final20 Nm (2.0 m

kgf, 14 ftIbf)T.

R.

30 Nm (3.0 mkgf, 22 ftIbf)

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

15 Nm (1.5 mkgf, 11 ftIbf)T.

R

.

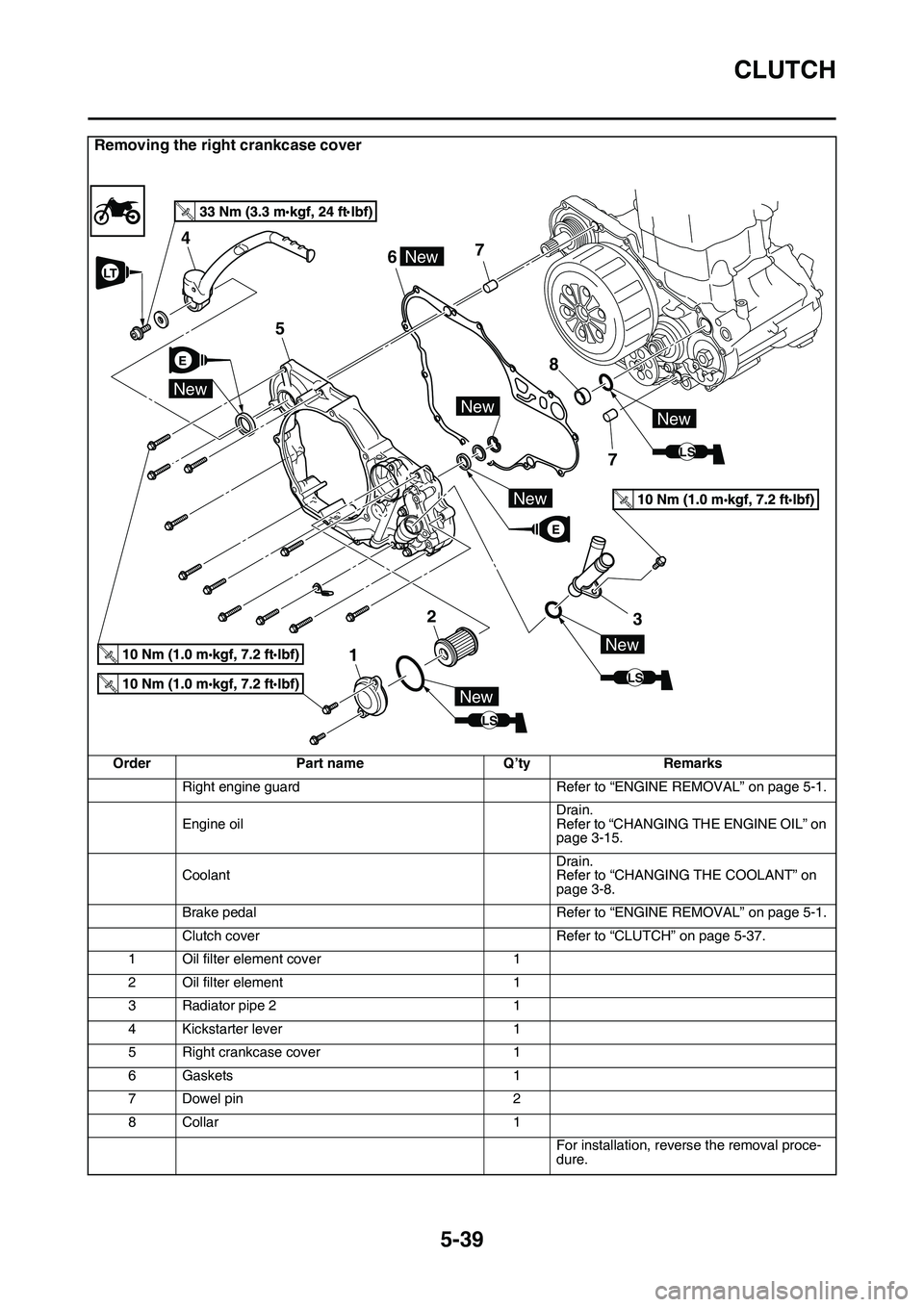

Page 234 of 360

CLUTCH

5-39

Removing the right crankcase cover

OrderPart nameQ’tyRemarks

Right engine guardRefer to “ENGINE REMOVAL” on page 5-1.

Engine oilDrain.Refer to “CHANGING THE ENGINE OIL” on page 3-15.

CoolantDrain.Refer to “CHANGING THE COOLANT” on page 3-8.

Brake pedalRefer to “ENGINE REMOVAL” on page 5-1.

Clutch coverRefer to “CLUTCH” on page 5-37.

1Oil filter element cover1

2Oil filter element1

3Radiator pipe 21

4Kickstarter lever1

5Right crankcase cover1

6Gaskets1

7Dowel pin2

8Collar1

For installation, reverse the removal proce-dure.

T.R.

E

E

LS

New

New

67

2

5

4

1

7 8

New

3

LS

New

New

LS

NewNew

LT

Page 271 of 360

6

COOLING SYSTEM

RADIATOR....................................................................................................... 6-1

HANDLING NOTE ...................................................................................... 6-3

CHECKING THE RADIATOR ..................................................................... 6-3

WATER PUMP.................................................................................................. 6-4

REMOVING THE OIL SEAL ....................................................................... 6-5

CHECKING THE WATER PUMP ............................................................... 6-5

CHECKING THE BEARING....................................................................... 6-5

INSTALLING THE OIL SEAL..................................................................... 6-5

ASSEMBLING THE WATER PUMP........................................................... 6-5

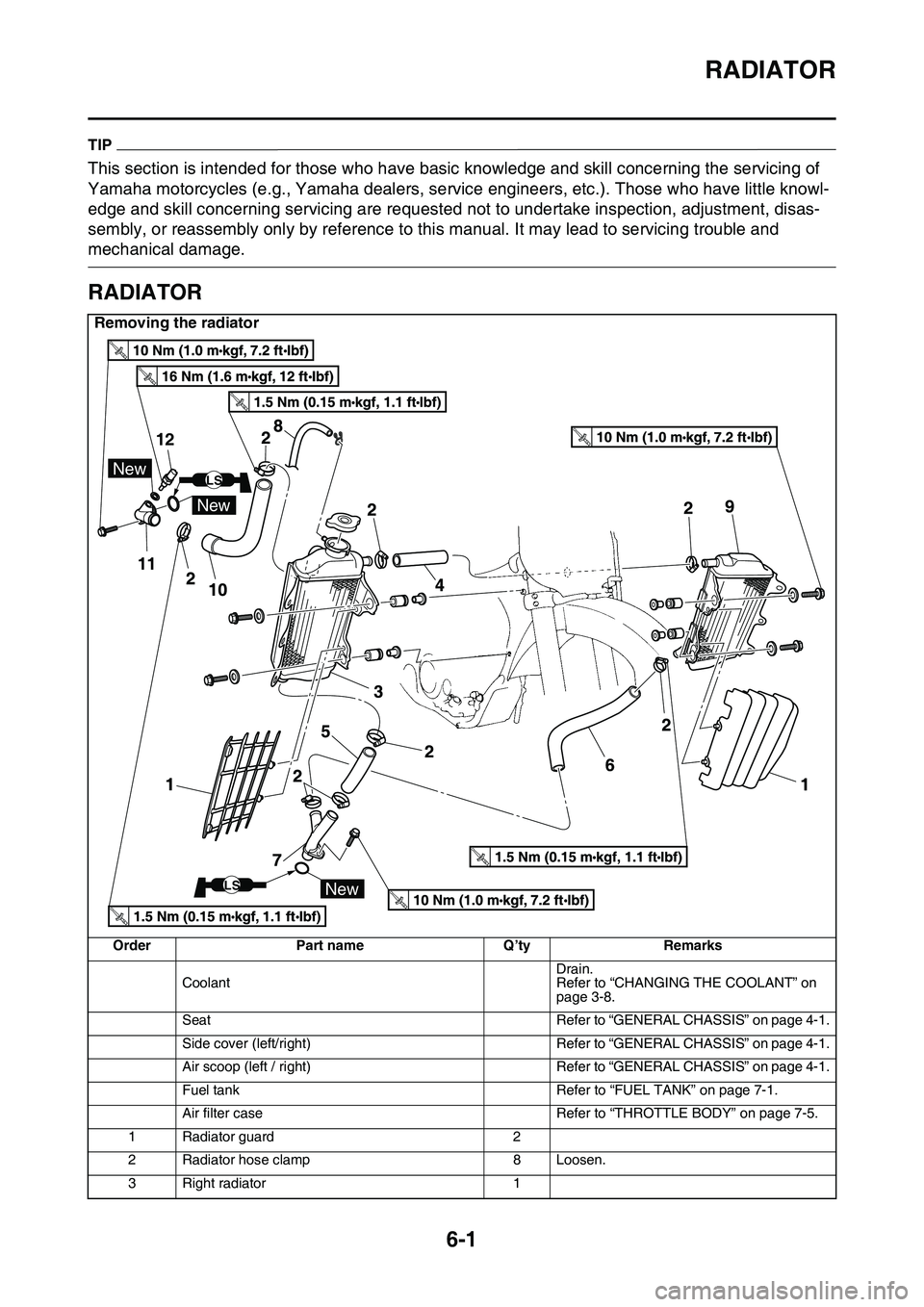

Page 272 of 360

RADIATOR

6-1

EAS1SL1294

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl

-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS1SL1295

RADIATOR

Removing the radiator

OrderPart nameQ’tyRemarks

CoolantDrain.Refer to “CHANGING THE COOLANT” on page 3-8.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

Air filter caseRefer to “THROTTLE BODY” on page 7-5.

1Radiator guard2

2Radiator hose clamp8Loosen.

3Right radiator1

11

12

New

New

New

LS

LS

Page 273 of 360

RADIATOR

6-2

4Radiator hose 21

5Radiator hose 31

6Radiator hose 41

7Radiator pipe 21

8Radiator breather hose1

9Left radiator1

10Radiator hose 11

11Radiator pipe 11

12Coolant temperature sensor1

For installation, reverse the removal proce-dure.

Removing the radiator

Order Part name Q’ty Remarks

11

12

New

New

New

LS

LS

Page 274 of 360

RADIATOR

6-3

EAS1SL1296HANDLING NOTEEWA1DX1007

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

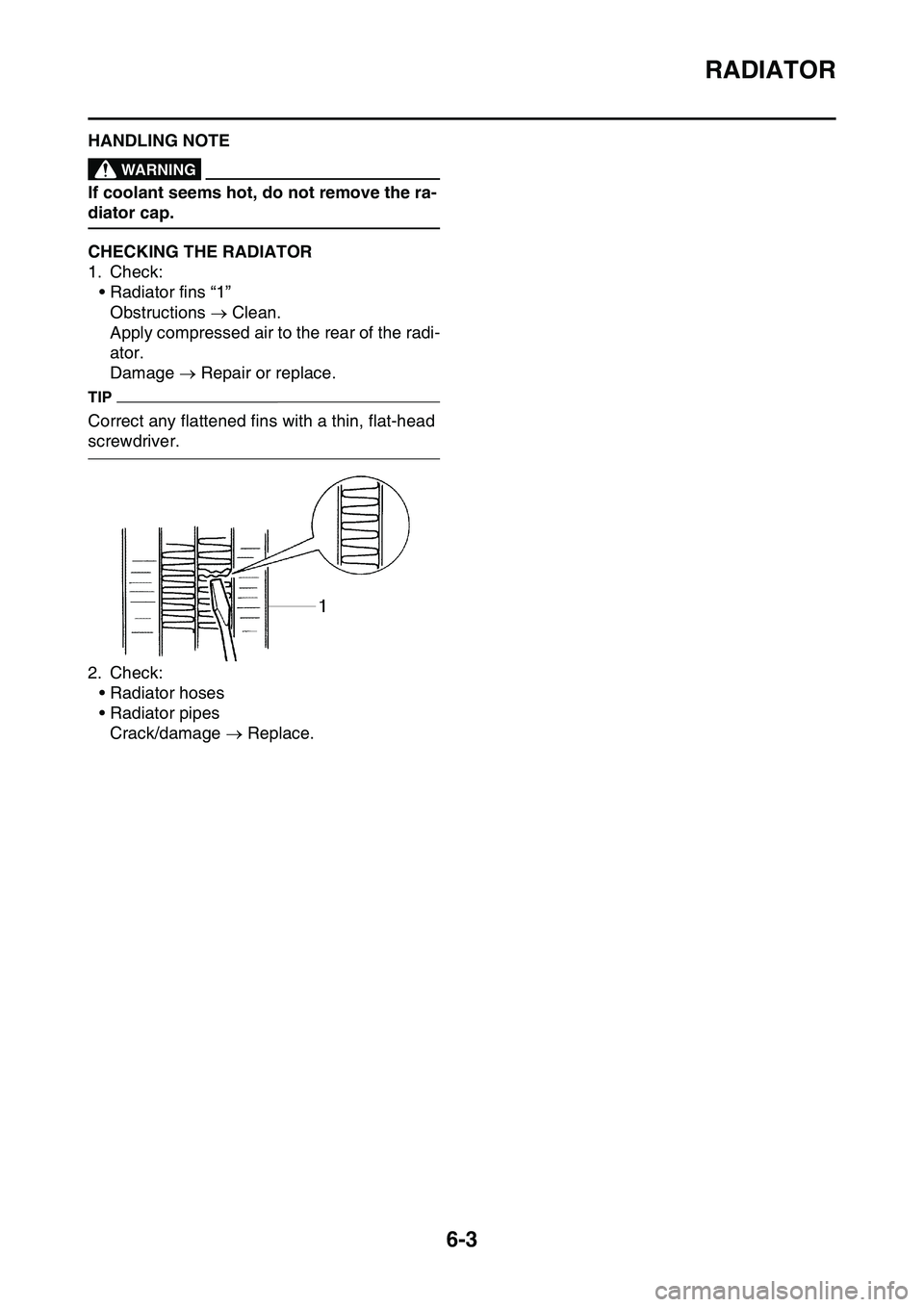

EAS1SL1297CHECKING THE RADIATOR

1. Check:

• Radiator fins “1”

Obstructions Clean.

Apply compressed air to the rear of the radi-

ator.

Damage Repair or replace.

TIP

Correct any flattened fins with a thin, flat-head

screwdriver.

2. Check:

• Radiator hoses

• Radiator pipes

Crack/damage Replace.