ECU YAMAHA YZ450F 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 176 of 360

STEERING HEAD

4-50

EAS1SL1172REMOVING THE LOWER BRACKET

1. Use a suitable stand to raise the front wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

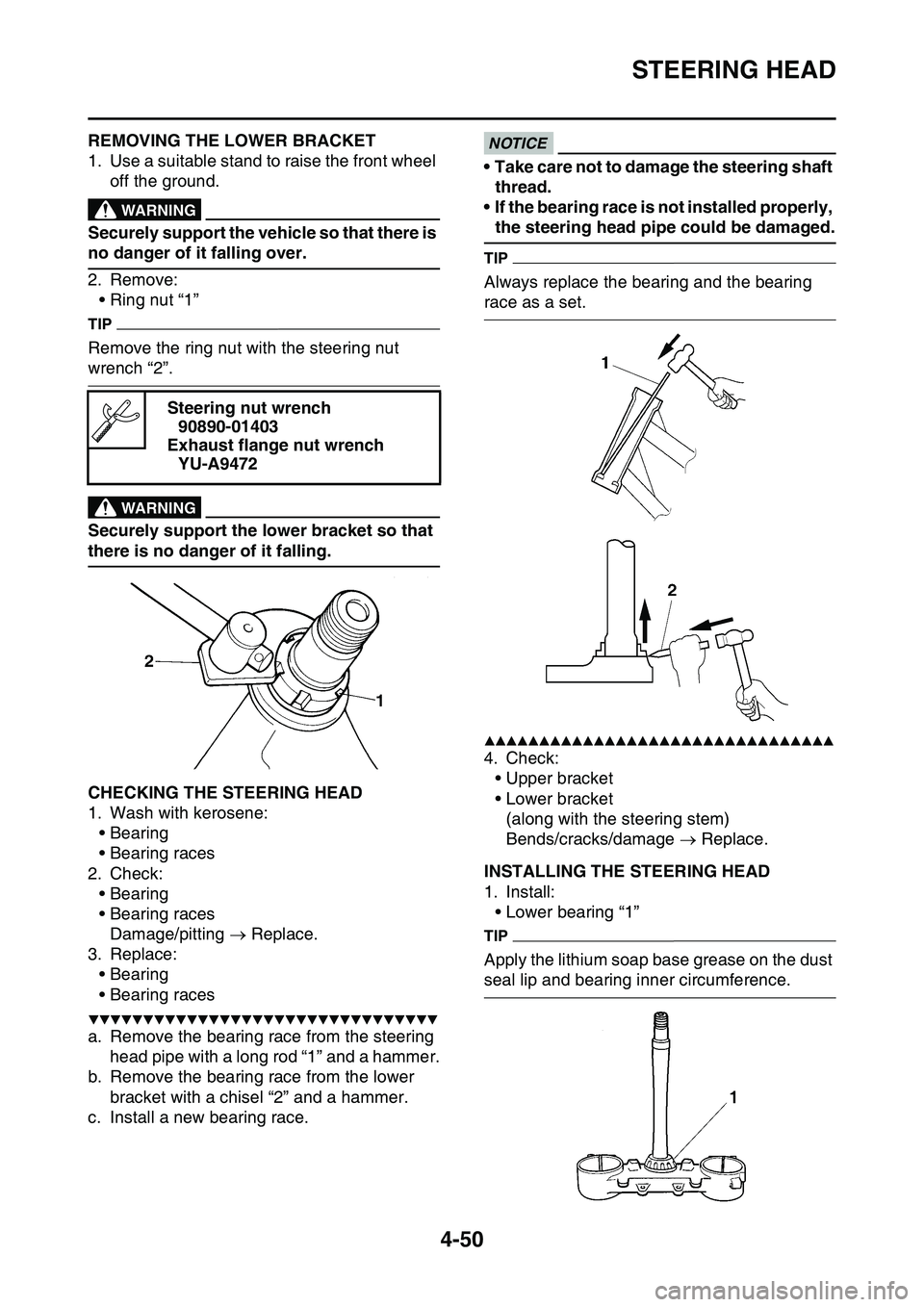

2. Remove:

• Ring nut “1”

TIP

Remove the ring nut with the steering nut

wrench “2”.

EWA13730

WARNING

Securely support the lower bracket so that

there is no danger of it falling.

EAS1SL1173CHECKING THE STEERING HEAD

1. Wash with kerosene:

• Bearing

• Bearing races

2. Check:

• Bearing

• Bearing races

Damage/pitting Replace.

3. Replace:

• Bearing

• Bearing races

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

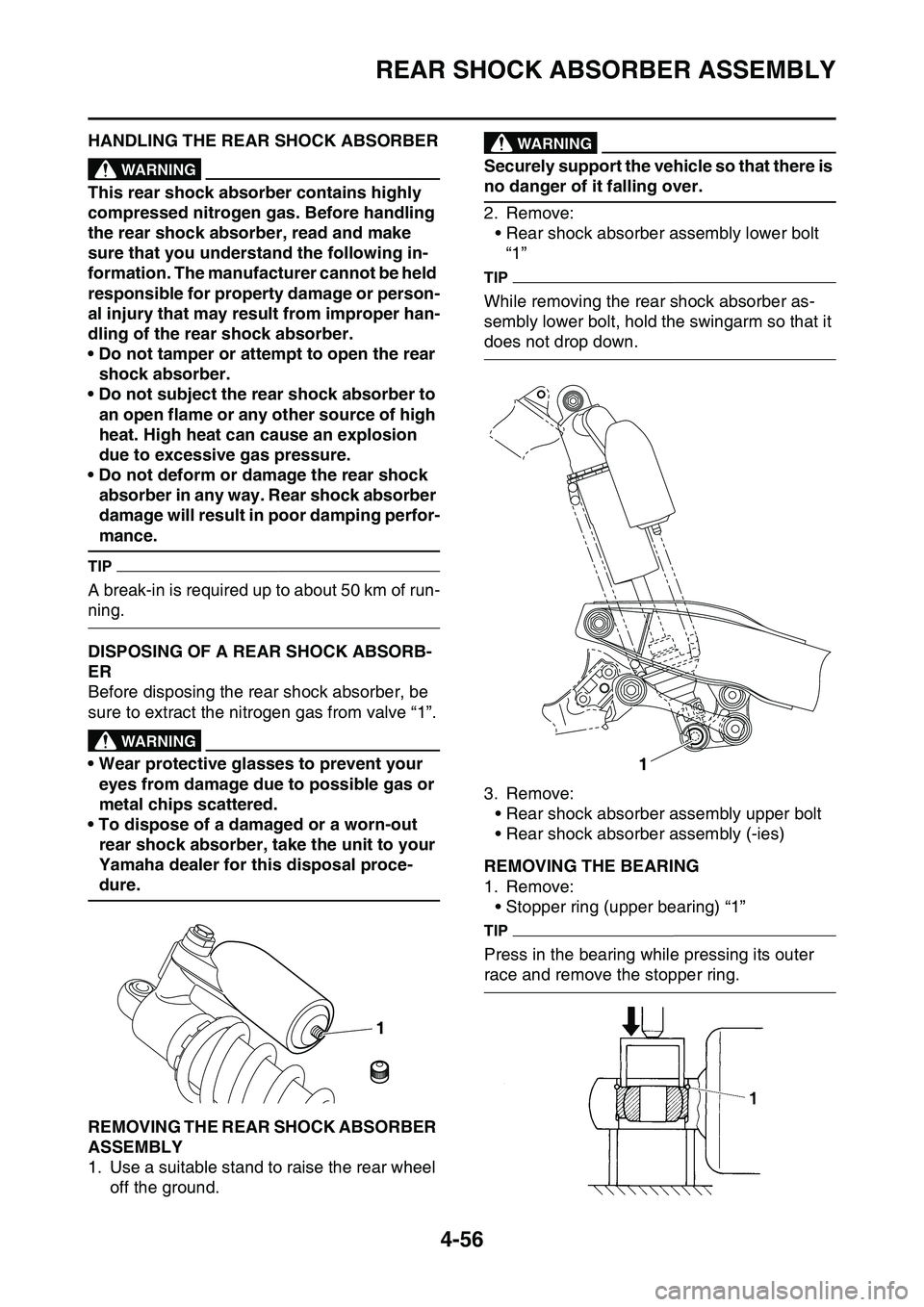

a. Remove the bearing race from the steering

head pipe with a long rod “1” and a hammer.

b. Remove the bearing race from the lower

bracket with a chisel “2” and a hammer.

c. Install a new bearing race.ECA14270

NOTICE

• Take care not to damage the steering shaft

thread.

• If the bearing race is not installed properly,

the steering head pipe could be damaged.

TIP

Always replace the bearing and the bearing

race as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Check:

• Upper bracket

• Lower bracket

(along with the steering stem)

Bends/cracks/damage Replace.

EAS1SL1174INSTALLING THE STEERING HEAD

1. Install:

• Lower bearing “1”

TIP

Apply the lithium soap base grease on the dust

seal lip and bearing inner circumference.

Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

Page 182 of 360

REAR SHOCK ABSORBER ASSEMBLY

4-56

EAS1SL1176HANDLING THE REAR SHOCK ABSORBEREWA13740

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure that you understand the following in

-

formation. The manufacturer cannot be held

responsible for property damage or person

-

al injury that may result from improper han-

dling of the rear shock absorber.

• Do not tamper or attempt to open the rear

shock absorber.

• Do not subject the rear shock absorber to

an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

• Do not deform or damage the rear shock

absorber in any way. Rear shock absorber

damage will result in poor damping perfor

-

mance.

TIP

A break-in is required up to about 50 km of run-

ning.

EAS1SL1177DISPOSING OF A REAR SHOCK ABSORB-

ER

Before disposing the rear shock absorber, be

sure to extract the nitrogen gas from valve “1”.

EWA33DD052

WARNING

• Wear protective glasses to prevent your

eyes from damage due to possible gas or

metal chips scattered.

• To dispose of a damaged or a worn-out

rear shock absorber, take the unit to your

Yamaha dealer for this disposal proce

-

dure.

EAS1SL1178REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

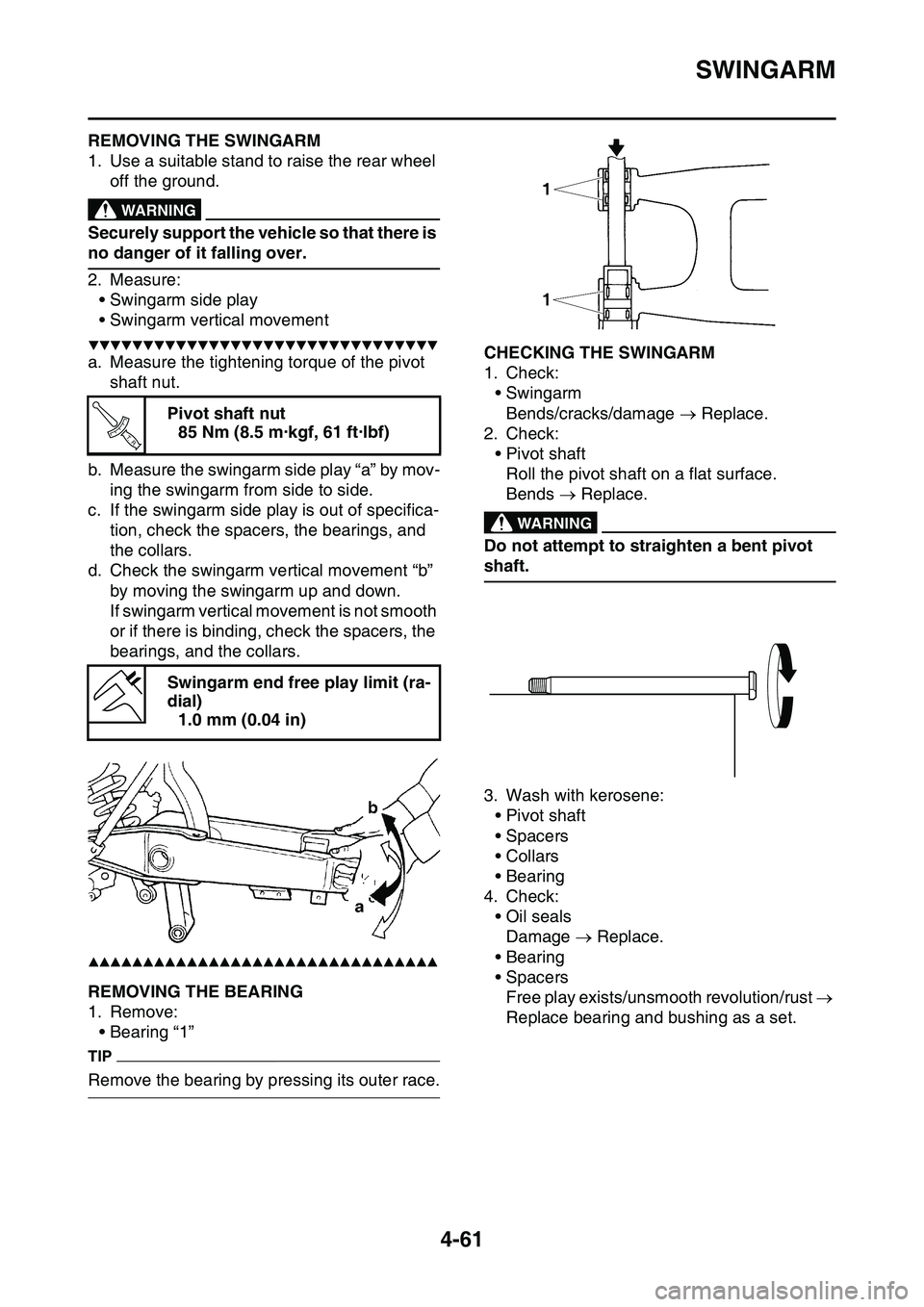

2. Remove:

• Rear shock absorber assembly lower bolt

“1”

TIP

While removing the rear shock absorber as-

sembly lower bolt, hold the swingarm so that it

does not drop down.

3. Remove:

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly (-ies)

EAS1SL1179REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) “1”

TIP

Press in the bearing while pressing its outer

race and remove the stopper ring.

1

1

Page 187 of 360

SWINGARM

4-61

EAS1SL1185REMOVING THE SWINGARM

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Measure:

• Swingarm side play

• Swingarm vertical movement

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure the tightening torque of the pivot

shaft nut.

b. Measure the swingarm side play “a” by mov-

ing the swingarm from side to side.

c. If the swingarm side play is out of specifica-

tion, check the spacers, the bearings, and

the collars.

d. Check the swingarm vertical movement “b”

by moving the swingarm up and down.

If swingarm vertical movement is not smooth

or if there is binding, check the spacers, the

bearings, and the collars.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1186REMOVING THE BEARING

1. Remove:

• Bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS1SL1187CHECKING THE SWINGARM

1. Check:

• Swingarm

Bends/cracks/damage Replace.

2. Check:

• Pivot shaft

Roll the pivot shaft on a flat surface.

Bends Replace.EWA13770

WARNING

Do not attempt to straighten a bent pivot

shaft.

3. Wash with kerosene:

• Pivot shaft

• Spacers

•Collars

• Bearing

4. Check:

• Oil seals

Damage Replace.

• Bearing

• Spacers

Free play exists/unsmooth revolution/rust

Replace bearing and bushing as a set.

EAS1SL1188

Pivot shaft nut

85 Nm (8.5 m·kgf, 61 ft·lbf)

Swingarm end free play limit (ra-

dial)

1.0 mm (0.04 in)

T R..

Page 190 of 360

CHAIN DRIVE

4-64

EAS1SL1190REMOVING THE DRIVE CHAIN

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Joint clip

• Drive chain joint “1”

• Drive chain “2”

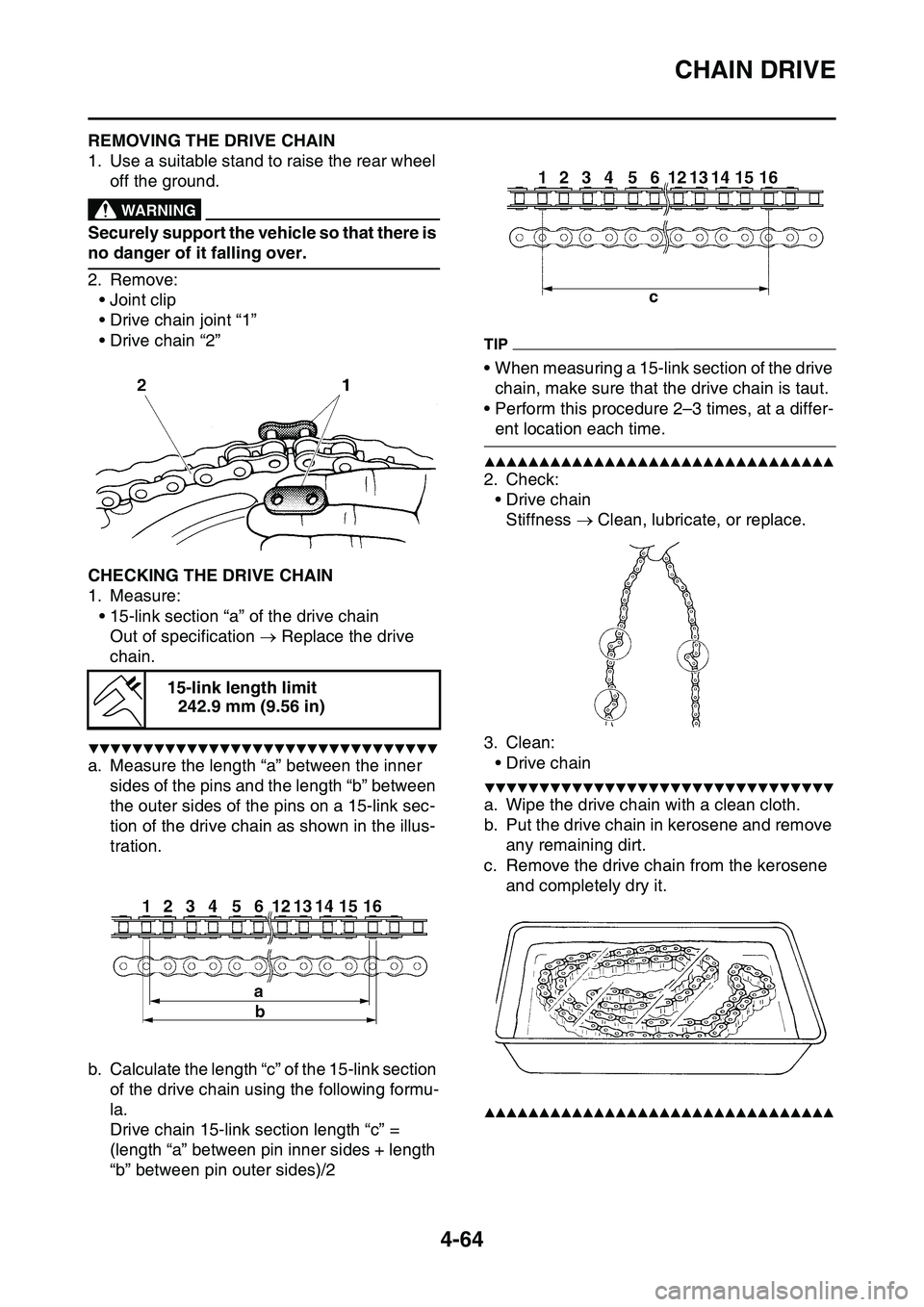

EAS1SL1191CHECKING THE DRIVE CHAIN

1. Measure:

• 15-link section “a” of the drive chain

Out of specification Replace the drive

chain.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure the length “a” between the inner

sides of the pins and the length “b” between

the outer sides of the pins on a 15-link sec

-

tion of the drive chain as shown in the illus-

tration.

b. Calculate the length “c” of the 15-link section

of the drive chain using the following formu

-

la.

Drive chain 15-link section length “c” =

(length “a” between pin inner sides + length

“b” between pin outer sides)/2

TIP

• When measuring a 15-link section of the drive

chain, make sure that the drive chain is taut.

• Perform this procedure 2–3 times, at a differ-

ent location each time.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check:

•Drive chain

Stiffness Clean, lubricate, or replace.

3. Clean:

•Drive chain

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Wipe the drive chain with a clean cloth.

b. Put the drive chain in kerosene and remove

any remaining dirt.

c. Remove the drive chain from the kerosene

and completely dry it.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

15-link length limit

242.9 mm (9.56 in)

Page 198 of 360

ENGINE REMOVAL

5-3

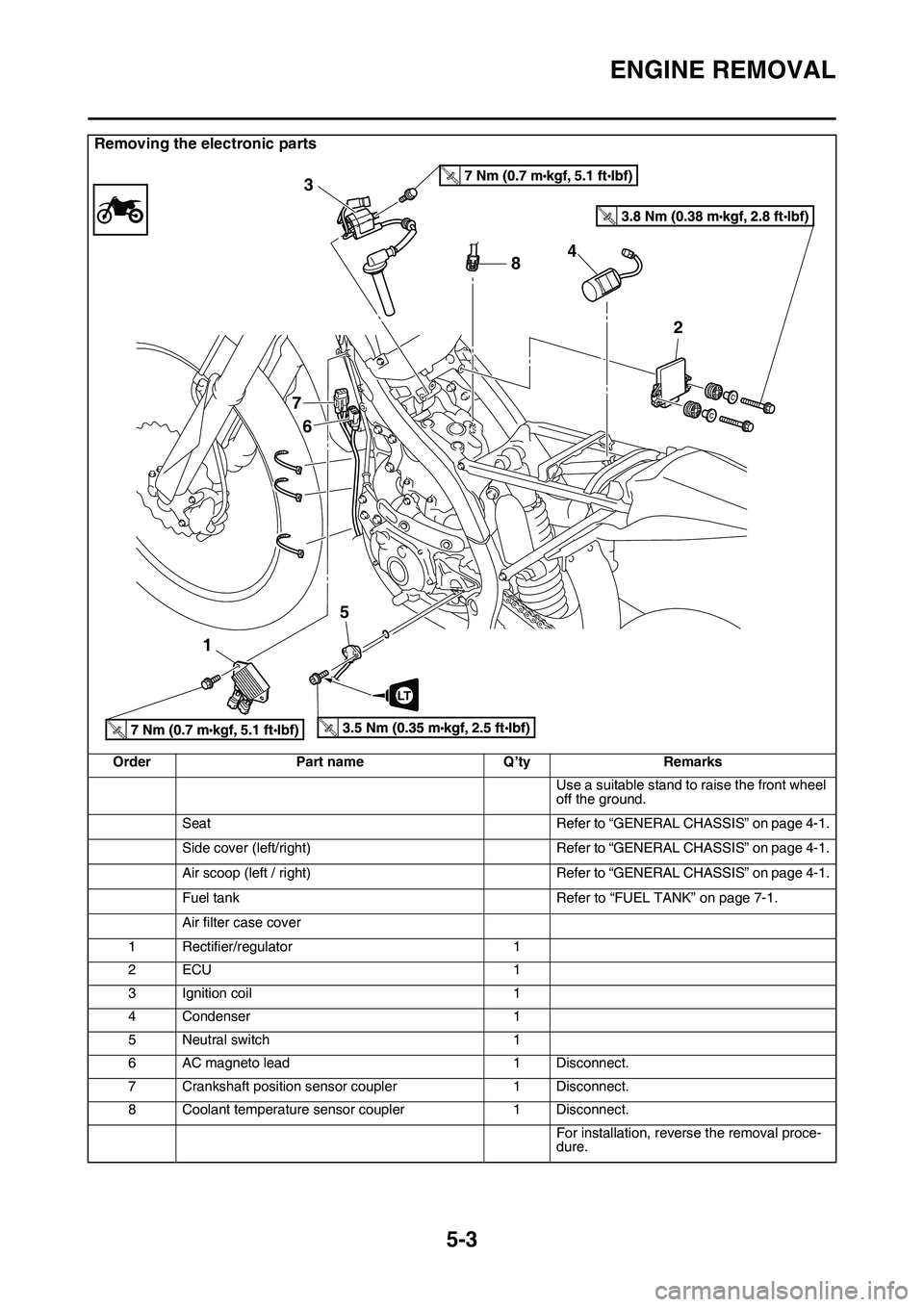

Removing the electronic parts

OrderPart nameQ’tyRemarks

Use a suitable stand to raise the front wheel

off the ground.

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left / right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

Air filter case cover

1Rectifier/regulator1

2ECU1

3Ignition coil1

4Condenser1

5Neutral switch1

6AC magneto lead1Disconnect.

7Crankshaft position sensor coupler1Disconnect.

8Coolant temperature sensor coupler1Disconnect.

For installation, reverse the removal proce-dure.

T.R.

T.R.

T.R.T.R.

8 3

7

6

154

2

LT

Page 282 of 360

FUEL TANK

7-3

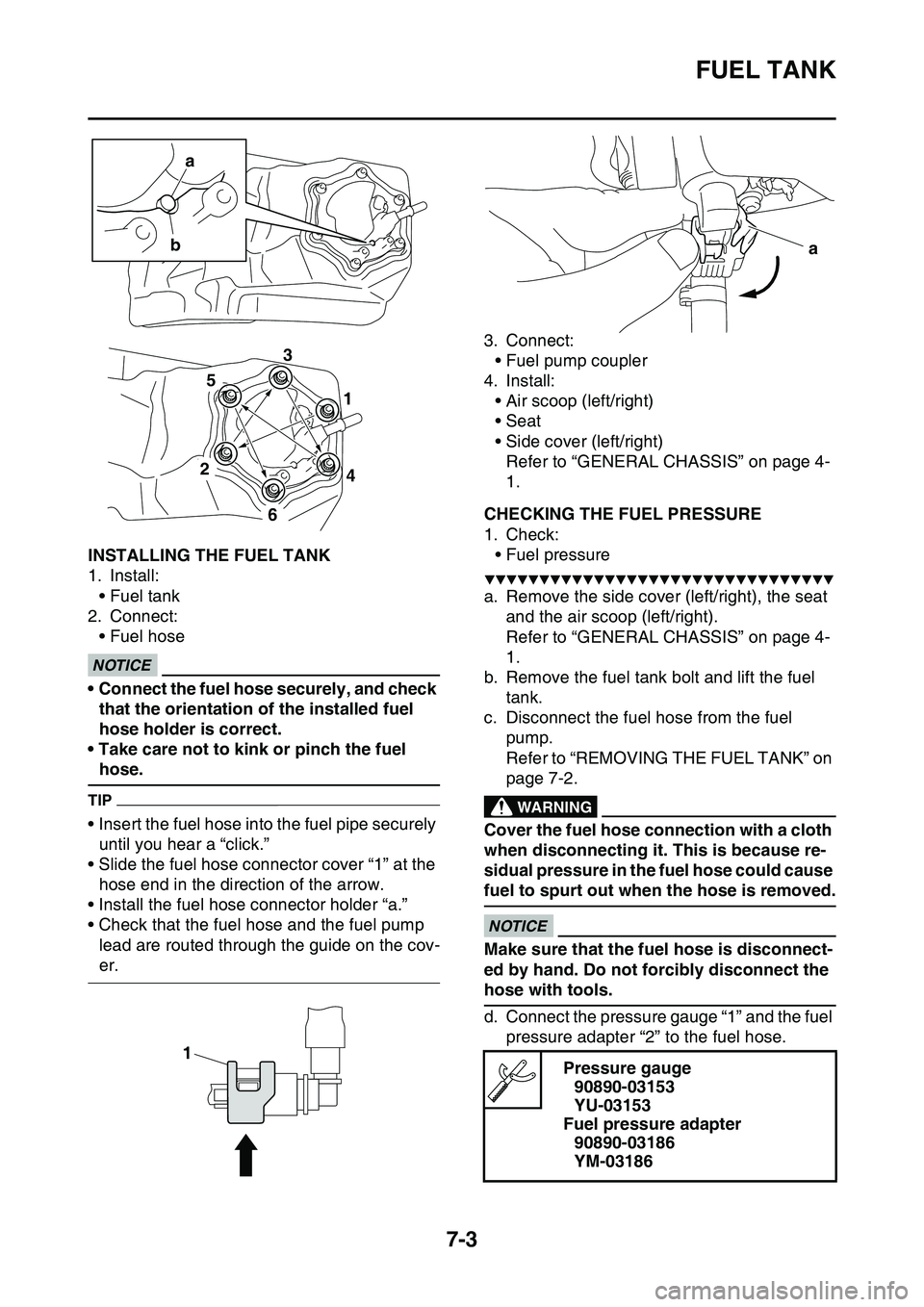

EAS1SL1310INSTALLING THE FUEL TANK

1. Install:

• Fuel tank

2. Connect:

• Fuel hoseECA33DD069

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

TIP

• Insert the fuel hose into the fuel pipe securely

until you hear a “click.”

• Slide the fuel hose connector cover “1” at the

hose end in the direction of the arrow.

• Install the fuel hose connector holder “a.”

• Check that the fuel hose and the fuel pump

lead are routed through the guide on the cov

-

er.

3. Connect:

• Fuel pump coupler

4. Install:

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1311CHECKING THE FUEL PRESSURE

1. Check:

• Fuel pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the side cover (left/right), the seat

and the air scoop (left/right).

Refer to “GENERAL CHASSIS” on page 4-

1.

b. Remove the fuel tank bolt and lift the fuel

tank.

c. Disconnect the fuel hose from the fuel

pump.

Refer to “REMOVING THE FUEL TANK” on

page 7-2.EWA1DX1008

WARNING

Cover the fuel hose connection with a cloth

when disconnecting it. This is because re

-

sidual pressure in the fuel hose could cause

fuel to spurt out when the hose is removed.

ECA1DX1025

NOTICE

Make sure that the fuel hose is disconnect-

ed by hand. Do not forcibly disconnect the

hose with tools.

d. Connect the pressure gauge “1” and the fuel

pressure adapter “2” to the fuel hose.

a

b

4 1

2

6

53

1Pressure gauge

90890-03153

YU-03153

Fuel pressure adapter

90890-03186

YM-03186

a

Page 284 of 360

THROTTLE BODY

7-5

EAS1SL1314

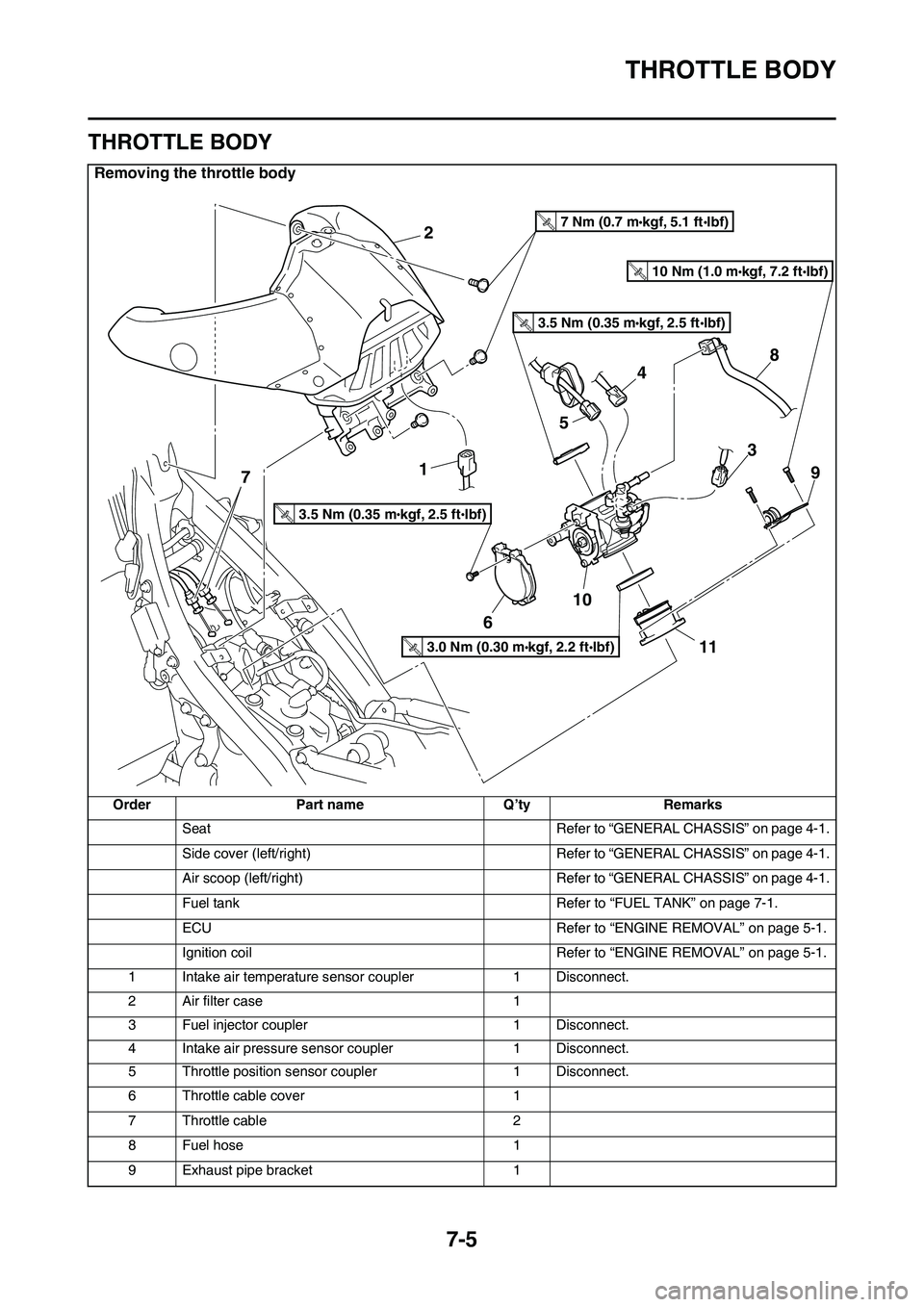

THROTTLE BODY

Removing the throttle body

OrderPart nameQ’tyRemarks

SeatRefer to “GENERAL CHASSIS” on page 4-1.

Side cover (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Air scoop (left/right)Refer to “GENERAL CHASSIS” on page 4-1.

Fuel tankRefer to “FUEL TANK” on page 7-1.

ECURefer to “ENGINE REMOVAL” on page 5-1.

Ignition coilRefer to “ENGINE REMOVAL” on page 5-1.

1Intake air temperature sensor coupler1Disconnect.

2Air filter case1

3Fuel injector coupler1Disconnect.

4Intake air pressure sensor coupler1Disconnect.

5Throttle position sensor coupler1Disconnect.

6Throttle cable cover1

7Throttle cable2

8Fuel hose1

9Exhaust pipe bracket1

2

1

6

10

11

9

8

3

7

5

4

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

3.5 Nm (0.35 mkgf, 2.5 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

3.0 Nm (0.30 mkgf, 2.2 ftIbf)T.R.

10 Nm (1.0 mkgf, 7.2 ftIbf)T.R.

Page 289 of 360

8

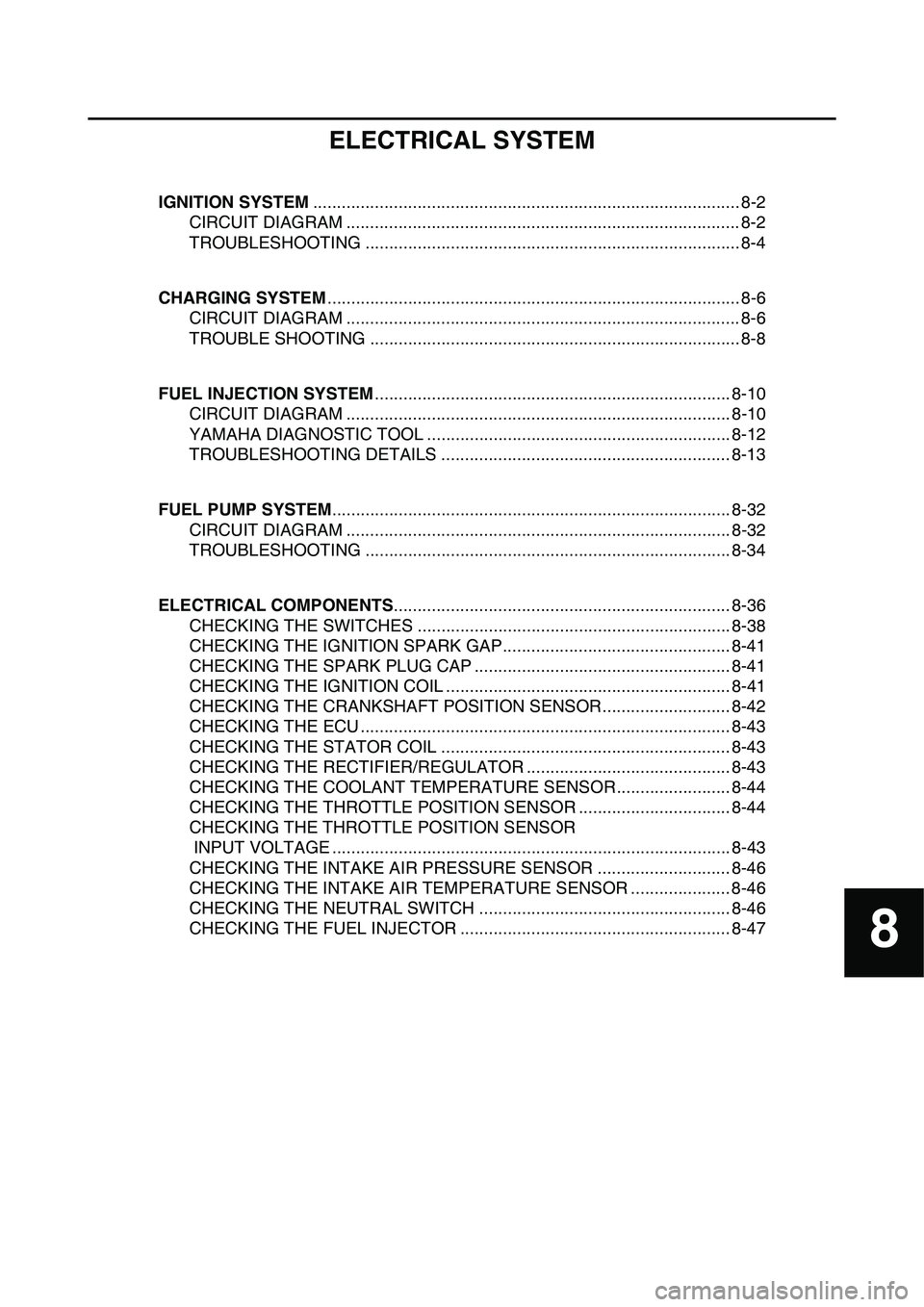

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 8-2

CIRCUIT DIAGRAM ................................................................................... 8-2

TROUBLESHOOTING ............................................................................... 8-4

CHARGING SYSTEM....................................................................................... 8-6

CIRCUIT DIAGRAM ................................................................................... 8-6

TROUBLE SHOOTING .............................................................................. 8-8

FUEL INJECTION SYSTEM........................................................................... 8-10

CIRCUIT DIAGRAM ................................................................................. 8-10

YAMAHA DIAGNOSTIC TOOL ................................................................ 8-12

TROUBLESHOOTING DETAILS ............................................................. 8-13

FUEL PUMP SYSTEM.................................................................................... 8-32

CIRCUIT DIAGRAM ................................................................................. 8-32

TROUBLESHOOTING ............................................................................. 8-34

ELECTRICAL COMPONENTS....................................................................... 8-36

CHECKING THE SWITCHES .................................................................. 8-38

CHECKING THE IGNITION SPARK GAP................................................ 8-41

CHECKING THE SPARK PLUG CAP ...................................................... 8-41

CHECKING THE IGNITION COIL ............................................................ 8-41

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 8-42

CHECKING THE ECU .............................................................................. 8-43

CHECKING THE STATOR COIL ............................................................. 8-43

CHECKING THE RECTIFIER/REGULATOR ........................................... 8-43

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 8-44

CHECKING THE THROTTLE POSITION SENSOR ................................ 8-44

CHECKING THE THROTTLE POSITION SENSOR

INPUT VOLTAGE .................................................................................... 8-43

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 8-46

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 8-46

CHECKING THE NEUTRAL SWITCH ..................................................... 8-46

CHECKING THE FUEL INJECTOR ......................................................... 8-47

Page 293 of 360

IGNITION SYSTEM

8-3

EAS1SL1322

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

9. ECU

10.Ignition coil

11.Spark plug

Page 295 of 360

IGNITION SYSTEM

8-5

8. Check the ignition system wire har-

ness.

Refer to “CIRCUIT DIAGRAM” on

page 8-2.

NG

Repair or replace the wire harness.

OK

Replace the ECU.