diagram YAMAHA YZ450F 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 86 of 360

CABLE ROUTING DIAGRAM

2-43

Page 143 of 360

FRONT BRAKE

4-17

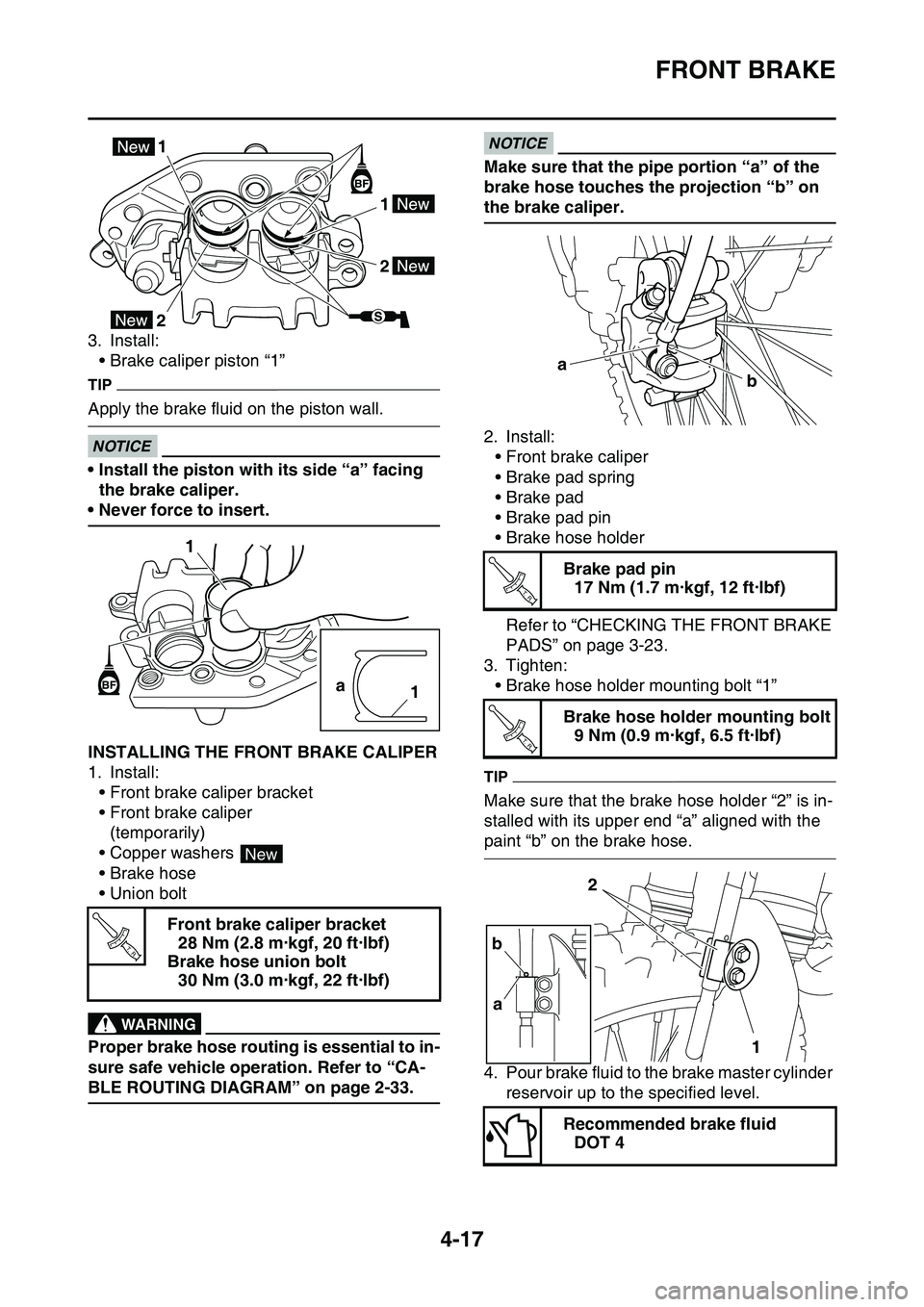

3. Install:

• Brake caliper piston “1”

TIP

Apply the brake fluid on the piston wall.

ECA33DD047

NOTICE

• Install the piston with its side “a” facing

the brake caliper.

• Never force to insert.

EAS1SL1143INSTALLING THE FRONT BRAKE CALIPER

1. Install:

• Front brake caliper bracket

• Front brake caliper

(temporarily)

• Copper washers

• Brake hose

• Union bolt

EWA13530

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation. Refer to “CA-

BLE ROUTING DIAGRAM” on page 2-33.

ECA14170

NOTICE

Make sure that the pipe portion “a” of the

brake hose touches the projection “b” on

the brake caliper.

2. Install:

• Front brake caliper

• Brake pad spring

• Brake pad

• Brake pad pin

• Brake hose holder

Refer to “CHECKING THE FRONT BRAKE

PADS” on page 3-23.

3. Tighten:

• Brake hose holder mounting bolt “1”

TIP

Make sure that the brake hose holder “2” is in-

stalled with its upper end “a” aligned with the

paint “b” on the brake hose.

4. Pour brake fluid to the brake master cylinder

reservoir up to the specified level.

EWA13090

Front brake caliper bracket

28 Nm (2.8 m·kgf, 20 ft·lbf)

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

1

1

22

1

a

1

New

T R..

Brake pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Brake hose holder mounting bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Recommended brake fluid

DOT 4

a

b

T R..

T R..

2

1 b

a

Page 146 of 360

FRONT BRAKE

4-20

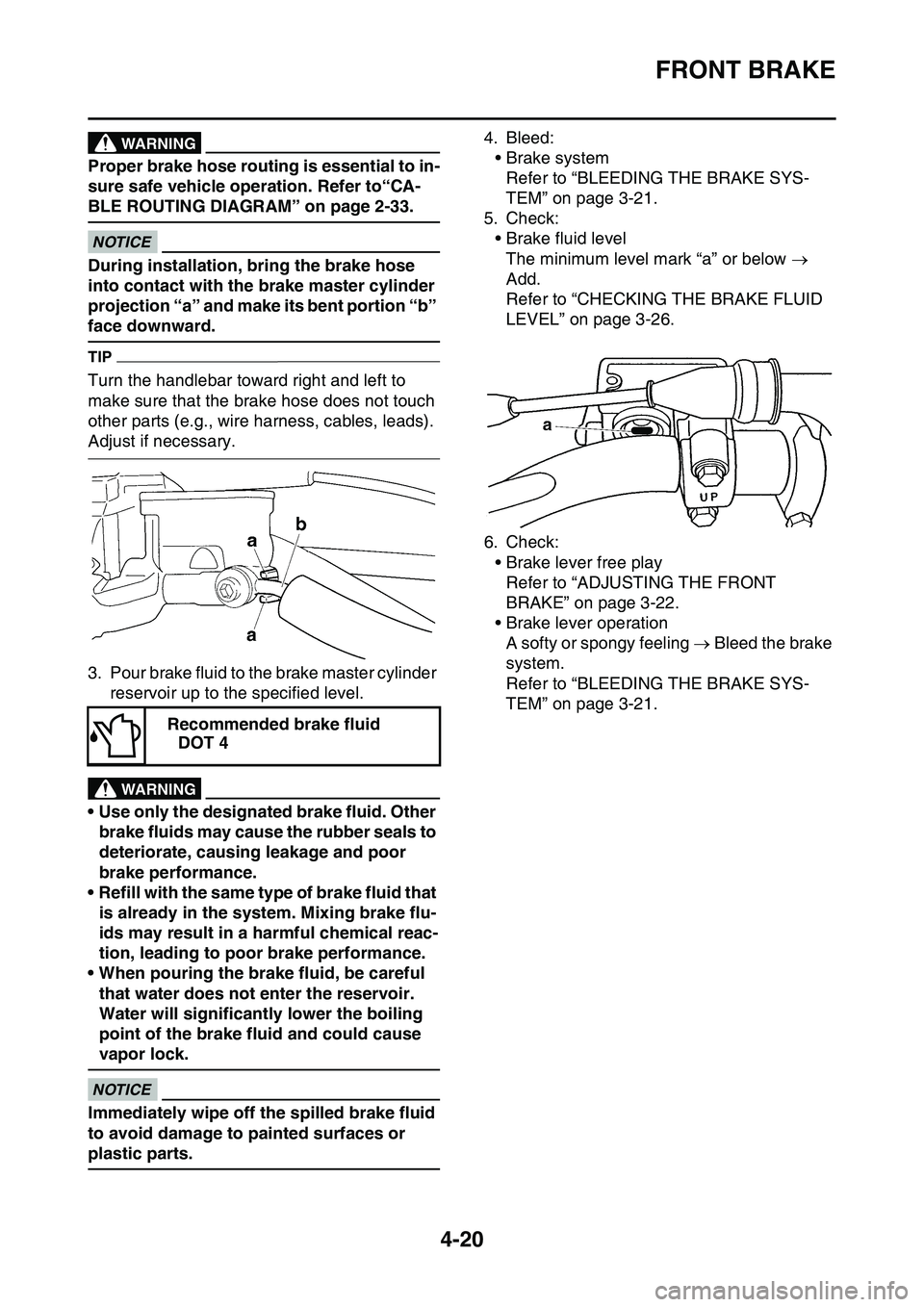

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation. Refer to“CA-

BLE ROUTING DIAGRAM” on page 2-33.

ECA1DX1007

NOTICE

During installation, bring the brake hose

into contact with the brake master cylinder

projection “a” and make its bent portion “b”

face downward.

TIP

Turn the handlebar toward right and left to

make sure that the brake hose does not touch

other parts (e.g., wire harness, cables, leads).

Adjust if necessary.

3. Pour brake fluid to the brake master cylinder

reservoir up to the specified level.

EWA13540

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu

-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When pouring the brake fluid, be careful

that water does not enter the reservoir.

Water will significantly lower the boiling

point of the brake fluid and could cause

vapor lock.

ECA13540

NOTICE

Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

4. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

5. Check:

• Brake fluid level

The minimum level mark “a” or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-26.

6. Check:

• Brake lever free play

Refer to “ADJUSTING THE FRONT

BRAKE” on page 3-22.

• Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

Recommended brake fluid

DOT 4

Page 153 of 360

REAR BRAKE

4-27

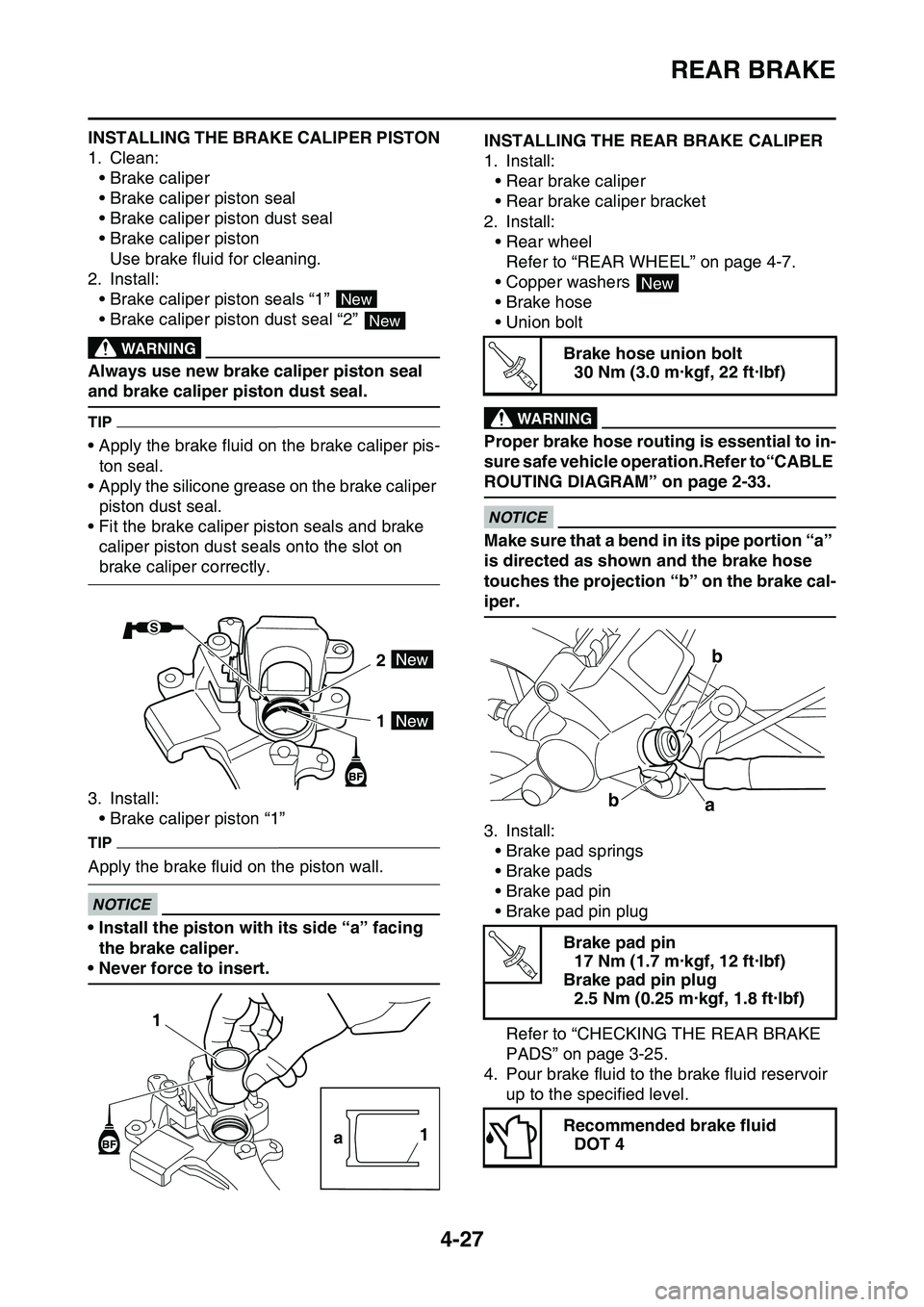

INSTALLING THE BRAKE CALIPER PISTON

1. Clean:

• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper piston

Use brake fluid for cleaning.

2. Install:

• Brake caliper piston seals “1”

• Brake caliper piston dust seal “2” EWA33DD033

WARNING

Always use new brake caliper piston seal

and brake caliper piston dust seal.

TIP

• Apply the brake fluid on the brake caliper pis-

ton seal.

• Apply the silicone grease on the brake caliper

piston dust seal.

• Fit the brake caliper piston seals and brake

caliper piston dust seals onto the slot on

brake caliper correctly.

3. Install:

• Brake caliper piston “1”

TIP

Apply the brake fluid on the piston wall.

ECA33DD047

NOTICE

• Install the piston with its side “a” facing

the brake caliper.

• Never force to insert.

EAS1SL1156INSTALLING THE REAR BRAKE CALIPER

1. Install:

• Rear brake caliper

• Rear brake caliper bracket

2. Install:

• Rear wheel

Refer to “REAR WHEEL” on page 4-7.

• Copper washers

• Brake hose

• Union bolt

EWA13530

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.Refer to“CABLE

ROUTING DIAGRAM” on page 2-33.

ECA14170

NOTICE

Make sure that a bend in its pipe portion “a”

is directed as shown and the brake hose

touches the projection “b” on the brake cal

-

iper.

3. Install:

• Brake pad springs

• Brake pads

• Brake pad pin

• Brake pad pin plug

Refer to “CHECKING THE REAR BRAKE

PADS” on page 3-25.

4. Pour brake fluid to the brake fluid reservoir

up to the specified level.

EWA13090

New

New

2

1

1

a1

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

Brake pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Brake pad pin plug

2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Recommended brake fluid

DOT 4

New

T R..

b

b

a

T R..

Page 155 of 360

REAR BRAKE

4-29

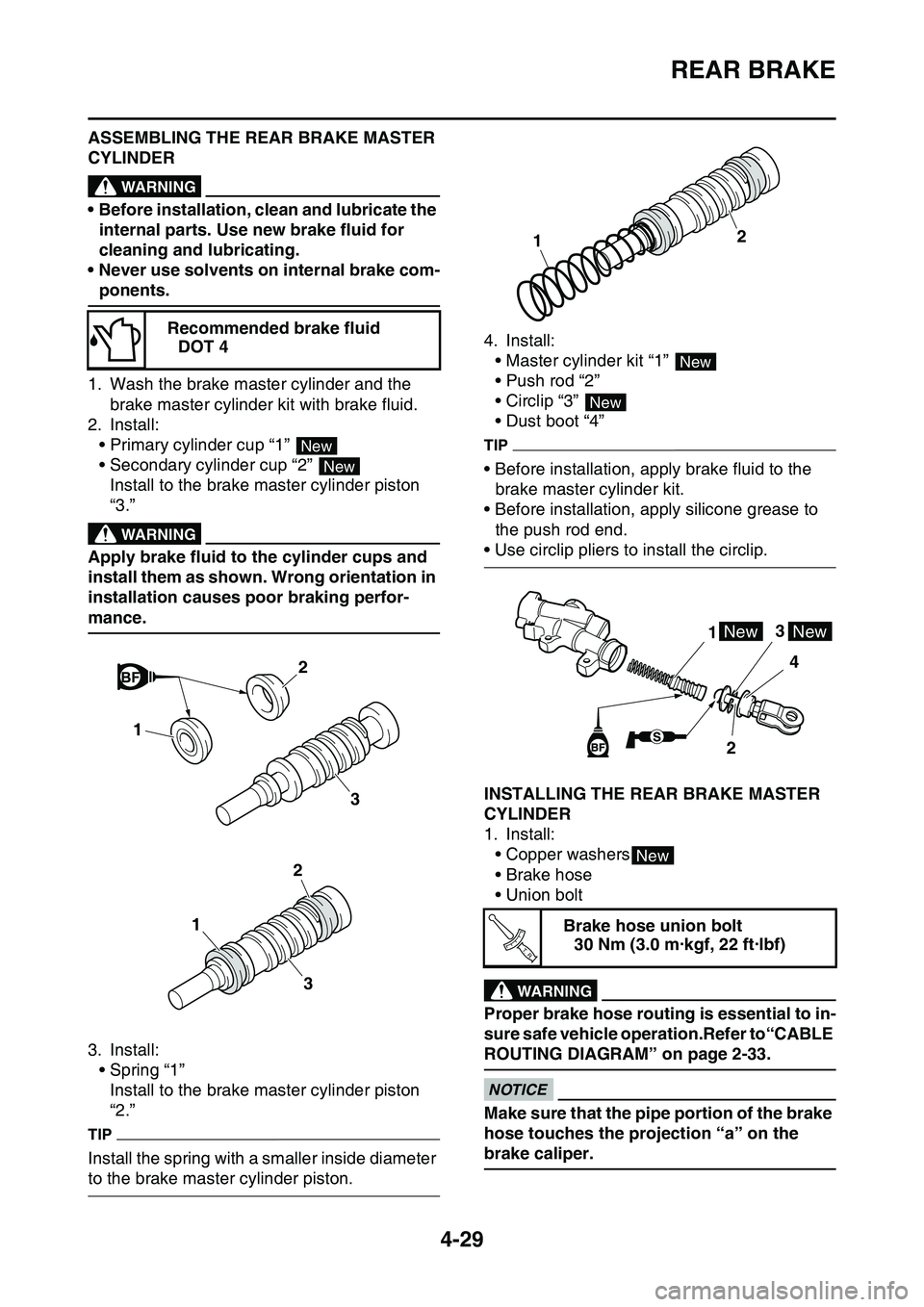

ASSEMBLING THE REAR BRAKE MASTER

CYLINDER

EWA13520

WARNING

• Before installation, clean and lubricate the

internal parts. Use new brake fluid for

cleaning and lubricating.

• Never use solvents on internal brake com-

ponents.

1. Wash the brake master cylinder and the

brake master cylinder kit with brake fluid.

2. Install:

• Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3.”

EWA13520

WARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor

-

mance.

3. Install:

• Spring “1”

Install to the brake master cylinder piston

“2.”

TIP

Install the spring with a smaller inside diameter

to the brake master cylinder piston.

4. Install:

• Master cylinder kit “1”

• Push rod “2”

• Circlip “3”

• Dust boot “4”

TIP

• Before installation, apply brake fluid to the

brake master cylinder kit.

• Before installation, apply silicone grease to

the push rod end.

• Use circlip pliers to install the circlip.

EAS1SL1160INSTALLING THE REAR BRAKE MASTER

CYLINDER

1. Install:

• Copper washers

• Brake hose

• Union bolt

EWA13530

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.Refer to“CABLE

ROUTING DIAGRAM” on page 2-33.

ECA1DX1008

NOTICE

Make sure that the pipe portion of the brake

hose touches the projection “a” on the

brake caliper.

Recommended brake fluid

DOT 4

New

New

2

3

1

2

3

1Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

12

New

New

13

4

2NewNew

New

T R..

Page 256 of 360

AC MAGNETO

5-61

2. Install:

• Woodruff key “1”

• Rotor “2”

TIP

• Clean the contact surfaces of the tapered por-

tions of the crankshaft and rotor.

• When installing the woodruff key, make sure

that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the rotor, align the keyway “c”

of the rotor with the woodruff key.

3. Install:

• Washers

• Nut (rotor) “1”

4. Install:

• Dowel pin “1”

• Gasket (left crankcase cover) “2”

• Left crankcase cover “3”

• Lead holder “4”

• Bolt (left crankcase cover) “5”

TIP

Tighten the bolts in stages and in a crisscross

pattern.

5. Connect:

• AC magneto lead

Refer to “CABLE ROUTING DIAGRAM” on

page 2-33.

Nut (rotor)

65 Nm (6.5 m·kgf, 47 ft·lbf)

Bolt (left crankcase cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

b11

c

2 a

T R..

1

New

T R..

1

1

2

3

5

5

5

5

4

45

Page 289 of 360

8

ELECTRICAL SYSTEM

IGNITION SYSTEM.......................................................................................... 8-2

CIRCUIT DIAGRAM ................................................................................... 8-2

TROUBLESHOOTING ............................................................................... 8-4

CHARGING SYSTEM....................................................................................... 8-6

CIRCUIT DIAGRAM ................................................................................... 8-6

TROUBLE SHOOTING .............................................................................. 8-8

FUEL INJECTION SYSTEM........................................................................... 8-10

CIRCUIT DIAGRAM ................................................................................. 8-10

YAMAHA DIAGNOSTIC TOOL ................................................................ 8-12

TROUBLESHOOTING DETAILS ............................................................. 8-13

FUEL PUMP SYSTEM.................................................................................... 8-32

CIRCUIT DIAGRAM ................................................................................. 8-32

TROUBLESHOOTING ............................................................................. 8-34

ELECTRICAL COMPONENTS....................................................................... 8-36

CHECKING THE SWITCHES .................................................................. 8-38

CHECKING THE IGNITION SPARK GAP................................................ 8-41

CHECKING THE SPARK PLUG CAP ...................................................... 8-41

CHECKING THE IGNITION COIL ............................................................ 8-41

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 8-42

CHECKING THE ECU .............................................................................. 8-43

CHECKING THE STATOR COIL ............................................................. 8-43

CHECKING THE RECTIFIER/REGULATOR ........................................... 8-43

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 8-44

CHECKING THE THROTTLE POSITION SENSOR ................................ 8-44

CHECKING THE THROTTLE POSITION SENSOR

INPUT VOLTAGE .................................................................................... 8-43

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 8-46

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 8-46

CHECKING THE NEUTRAL SWITCH ..................................................... 8-46

CHECKING THE FUEL INJECTOR ......................................................... 8-47

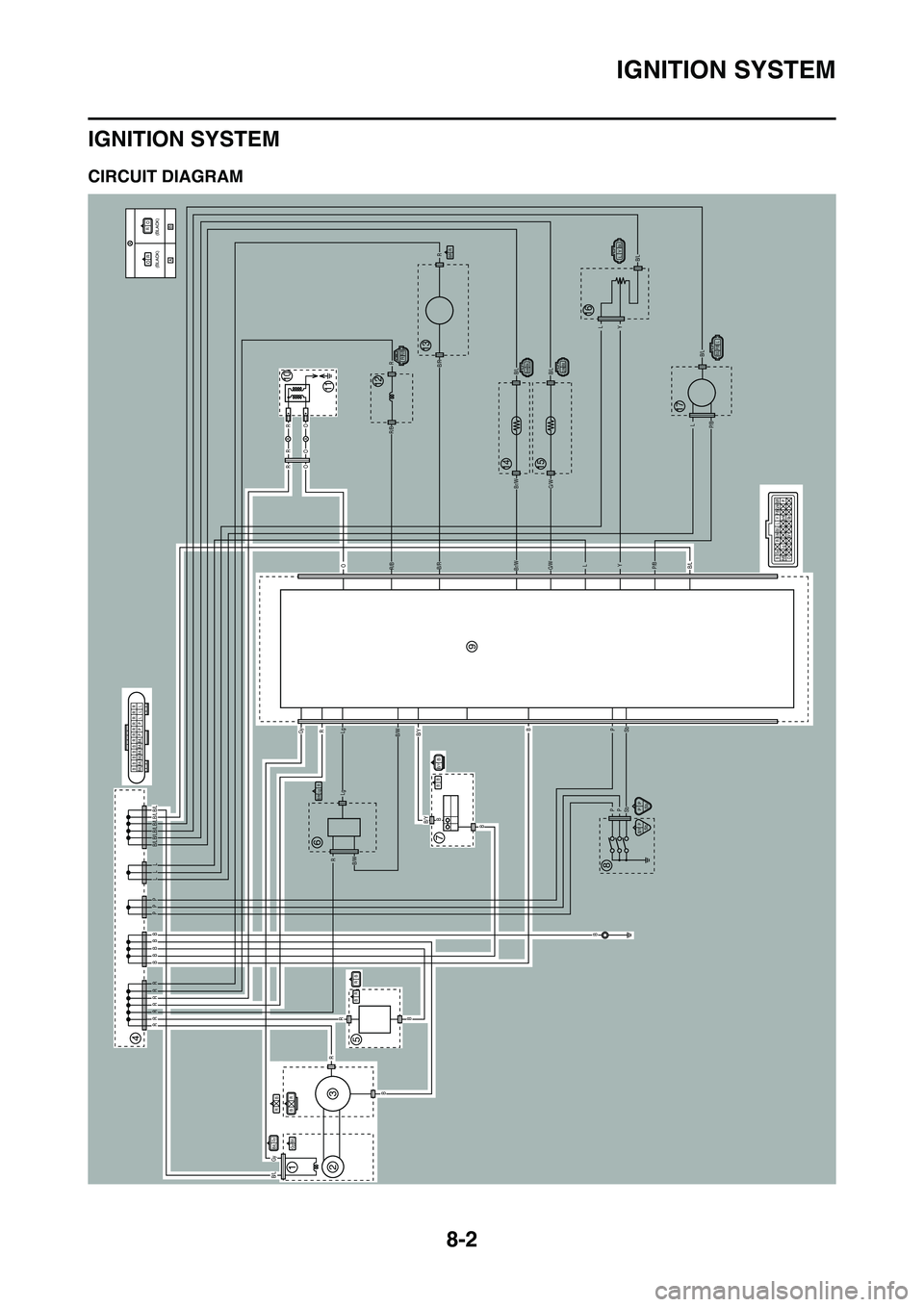

Page 292 of 360

IGNITION SYSTEM

8-2

IGNITION SYSTEM

EAS1SL1321CIRCUIT DIAGRAM

B/LGy

BR

A

A

AA

B

RR R R R R R

B

B

B

RR

R

Lg

LgB/WB/Y

B/YB

B

BP

PP

Sb

B/LP/B

P/B

YL

YL

L

G/WBr/W

G/WBr/W

B/LB/L

B/L

B/L

B/R

B/R

R/B

R/B

O

OROR

OR

R

R

SbB

GyR

B/W

P L B/L

B/L Gy B/L B/L B/L B/L B/L

LL

PP

BBBB

PP

Sb

RB

B/RR

RB

B/Y PSb

BB

RR/B

LYB/L

B/W RLg

B/LBr/W

B/L P/B LB/LG/W

BB/Y

BB/L B/L B/L B/L B/L B/LBBBBRR

PPPL L LRR RR R

B

O P

Gy

R

B/Y Sb

P/B

R/B Lg B/RG/WBr/WB/L L Y

RB

B/L

Gy

R

O

O

R(BLACK) (BLACK)

B/W

4

1

3

2

5

67

8

10

9

1211

13

1415

16

17

Page 295 of 360

IGNITION SYSTEM

8-5

8. Check the ignition system wire har-

ness.

Refer to “CIRCUIT DIAGRAM” on

page 8-2.

NG

Repair or replace the wire harness.

OK

Replace the ECU.

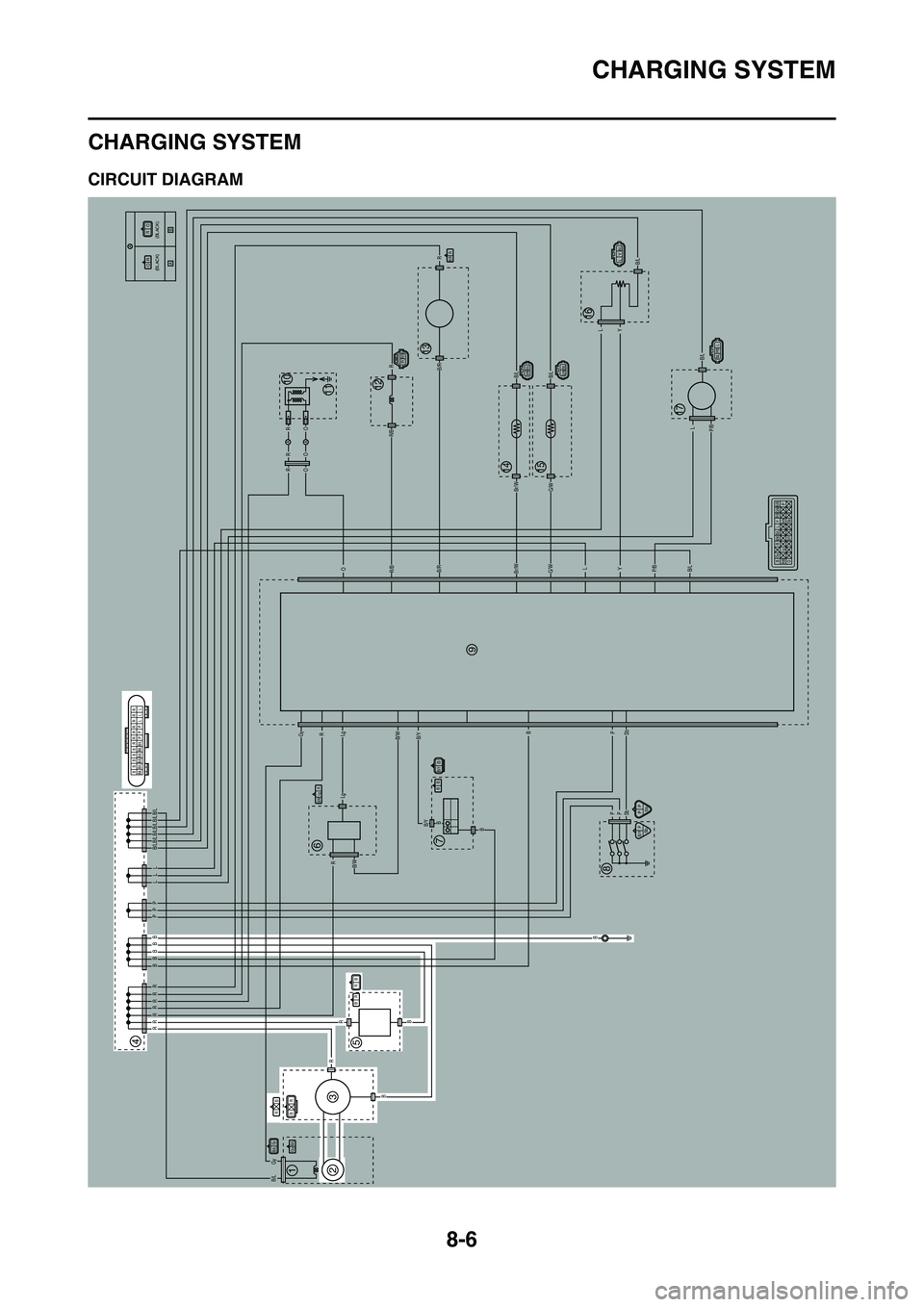

Page 296 of 360

CHARGING SYSTEM

8-6

EAS27200

CHARGING SYSTEM

EAS1SL1323CIRCUIT DIAGRAM

B/LGy

BR

A

A

AA

B

RR R R R R R

B

B

B

RR

R

Lg

LgB/WB/Y

B/YB

B

BP

PP

Sb

B/LP/B

P/B

YL

YL

L

G/WBr/W

G/WBr/W

B/LB/L

B/L

B/L

B/R

B/R

R/B

R/B

O

OROR

OR

R

R

SbB

GyR

B/W

P L B/L

B/L Gy B/L B/L B/L B/L B/L

LL

PP

BBBB

PP

Sb

RB

B/RR

RB

B/Y PSb

BB

RR/B

LYB/L

B/W RLg

B/LBr/W

B/L P/B LB/LG/W

BB/Y

BB/L B/L B/L B/L B/L B/LBBBBRR

PPPL L LRR RR R

B

O P

Gy

R

B/Y Sb

P/B

R/B Lg B/RG/WBr/WB/L L Y

RB

B/L

Gy

R

O

O

R(BLACK) (BLACK)

B/W

4

1

3

2

5

67

8

10

9

1211

13

1415

16

17