YAMAHA YZ450F 2014 Owners Manual

Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 341 of 360

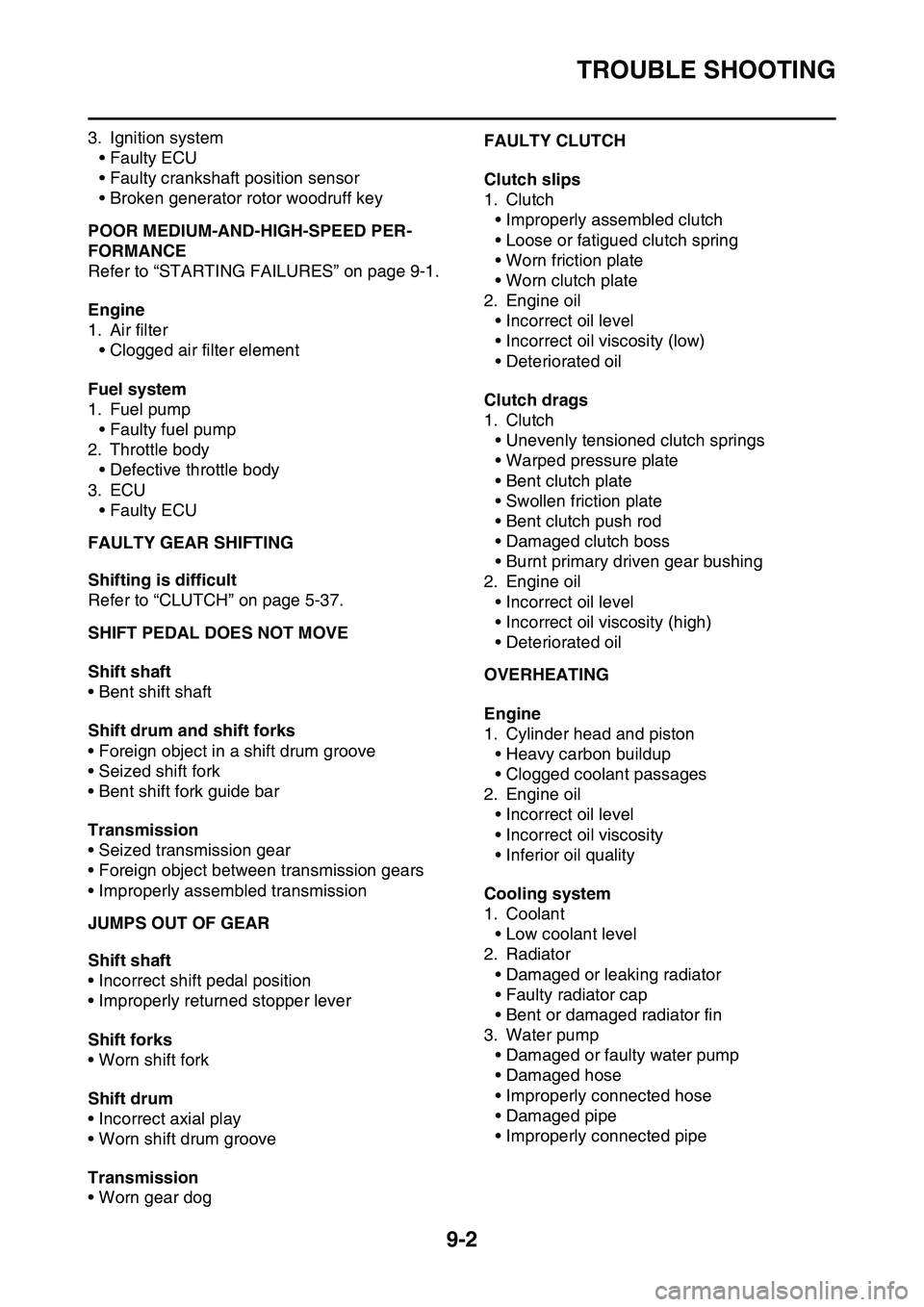

TROUBLE SHOOTING

9-2

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

EAS1SL1353POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 9-1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EAS1SL1354FAULTY GEAR SHIFTING

Shifting is difficult

Refer to “CLUTCH” on page 5-37.

EAS1SL1355SHIFT PEDAL DOES NOT MOVE

Shift shaft

• Bent shift shaft

Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EAS1SL1356JUMPS OUT OF GEAR

Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

Shift forks

• Worn shift fork

Shift drum

• Incorrect axial play

• Worn shift drum groove

Transmission

• Worn gear dog

EAS1SL1357FAULTY CLUTCH

Clutch slips

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

Clutch drags

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EAS1SL1358OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Page 342 of 360

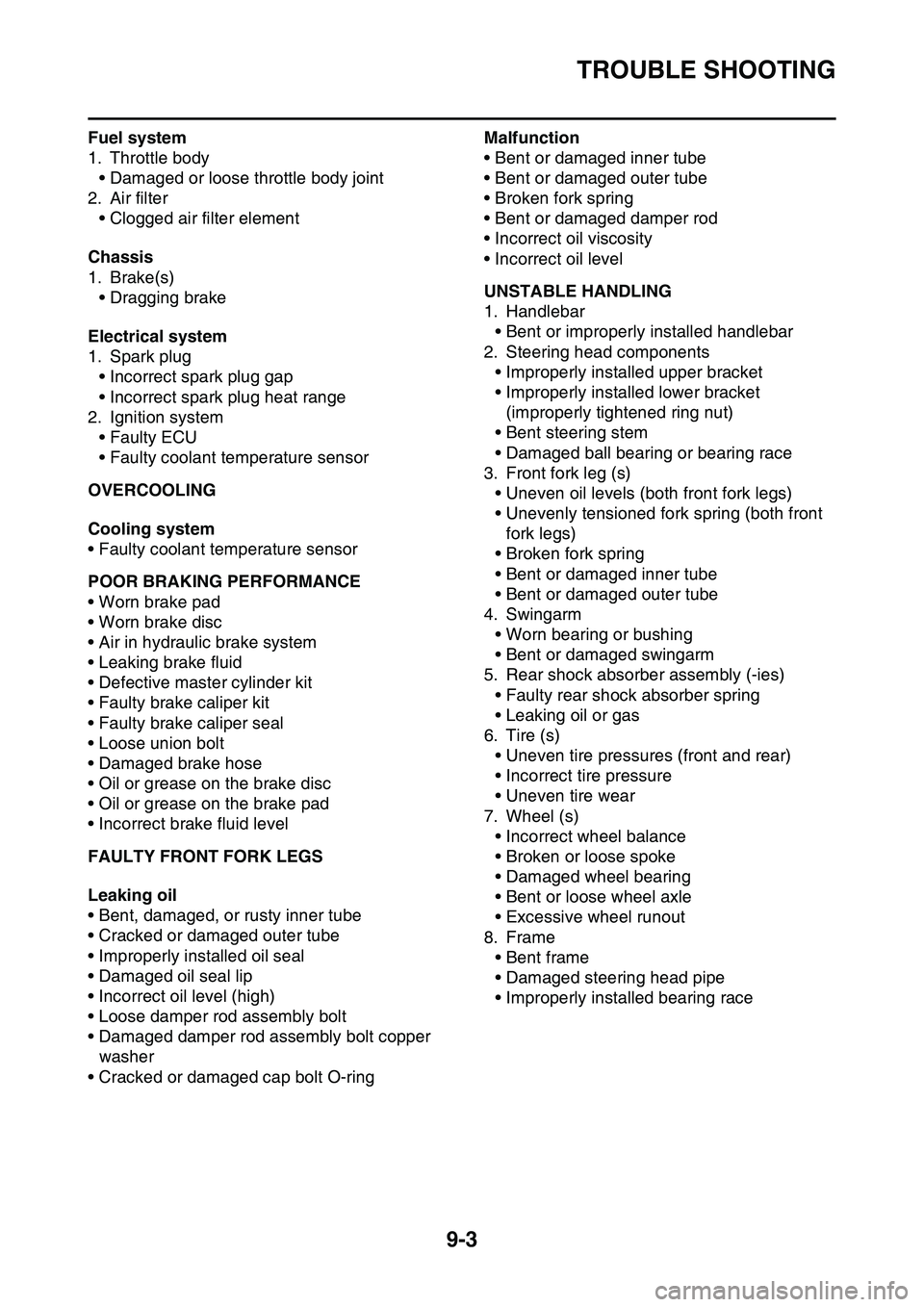

TROUBLE SHOOTING

9-3

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

2. Air filter

• Clogged air filter element

Chassis

1. Brake(s)

• Dragging brake

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system

• Faulty ECU

• Faulty coolant temperature sensor

EAS1SL1359OVERCOOLING

Cooling system

• Faulty coolant temperature sensor

EAS1SL1360POOR BRAKING PERFORMANCE

• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS1SL1361FAULTY FRONT FORK LEGS

Leaking oil

• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

Malfunction

• Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS1SL1362UNSTABLE HANDLING

1. Handlebar

• Bent or improperly installed handlebar

2. Steering head components

• Improperly installed upper bracket

• Improperly installed lower bracket

(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s)

• Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front

fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm

• Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies)

• Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s)

• Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

7. Wheel (s)

• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame

• Bent frame

• Damaged steering head pipe

• Improperly installed bearing race

Page 343 of 360

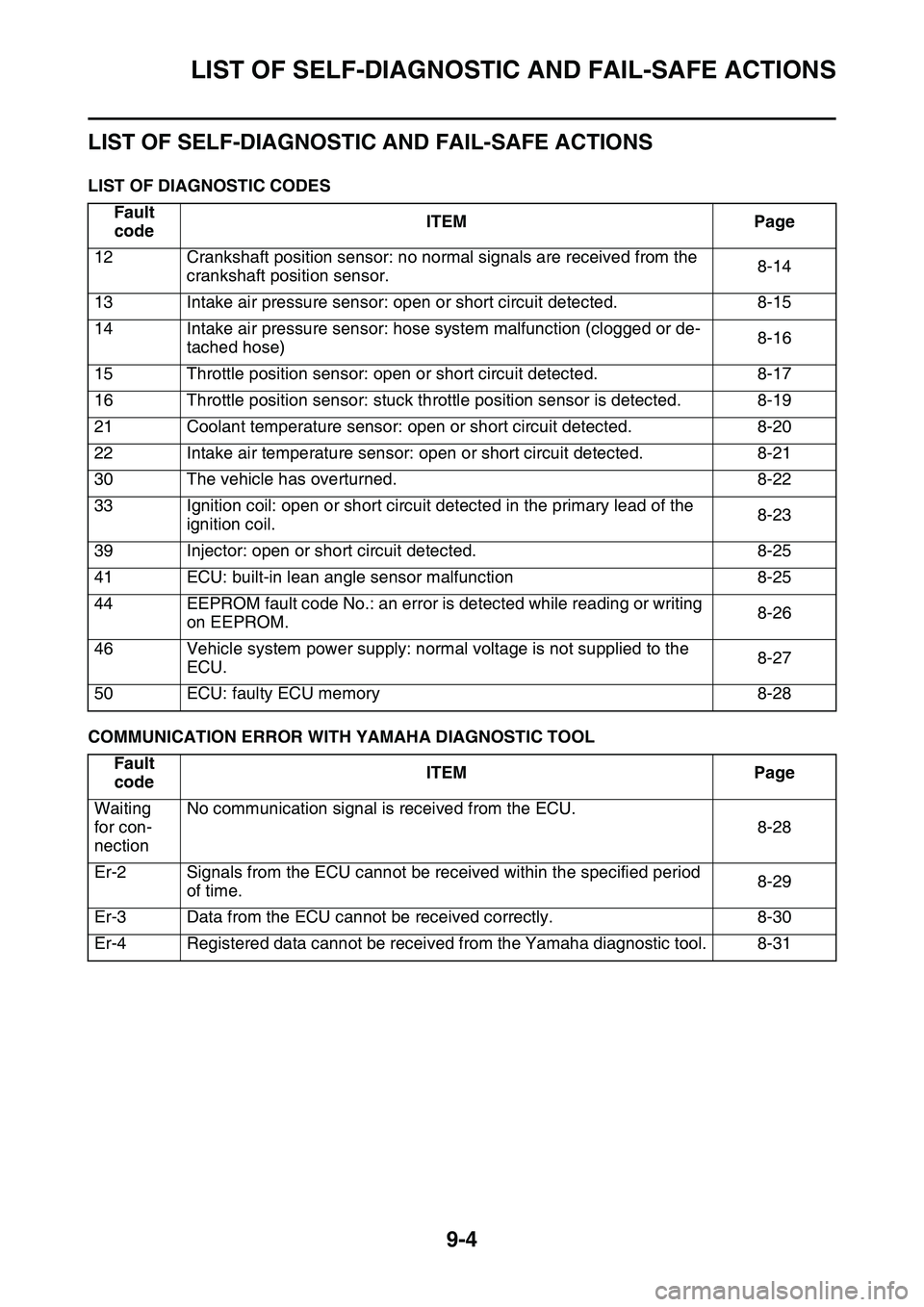

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-4

EAS1SL1363

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

LIST OF DIAGNOSTIC CODES

COMMUNICATION ERROR WITH YAMAHA DIAGNOSTIC TOOL

Fault

codeITEMPage

12Crankshaft position sensor: no normal signals are received from the

crankshaft position sensor.8-14

13Intake air pressure sensor: open or short circuit detected.8-15

14Intake air pressure sensor: hose system malfunction (clogged or de-

tached hose)8-16

15Throttle position sensor: open or short circuit detected.8-17

16Throttle position sensor: stuck throttle position sensor is detected.8-19

21Coolant temperature sensor: open or short circuit detected.8-20

22Intake air temperature sensor: open or short circuit detected.8-21

30The vehicle has overturned.8-22

33Ignition coil: open or short circuit detected in the primary lead of the

ignition coil.8-23

39Injector: open or short circuit detected.8-25

41ECU: built-in lean angle sensor malfunction8-25

44EEPROM fault code No.: an error is detected while reading or writing

on EEPROM.8-26

46Vehicle system power supply: normal voltage is not supplied to the

ECU.8-27

50ECU: faulty ECU memory8-28

Fault

codeITEMPage

Waiting

for con

-

nection

No communication signal is received from the ECU.

8-28

Er-2Signals from the ECU cannot be received within the specified period

of time.8-29

Er-3Data from the ECU cannot be received correctly.8-30

Er-4Registered data cannot be received from the Yamaha diagnostic tool.8-31

Page 344 of 360

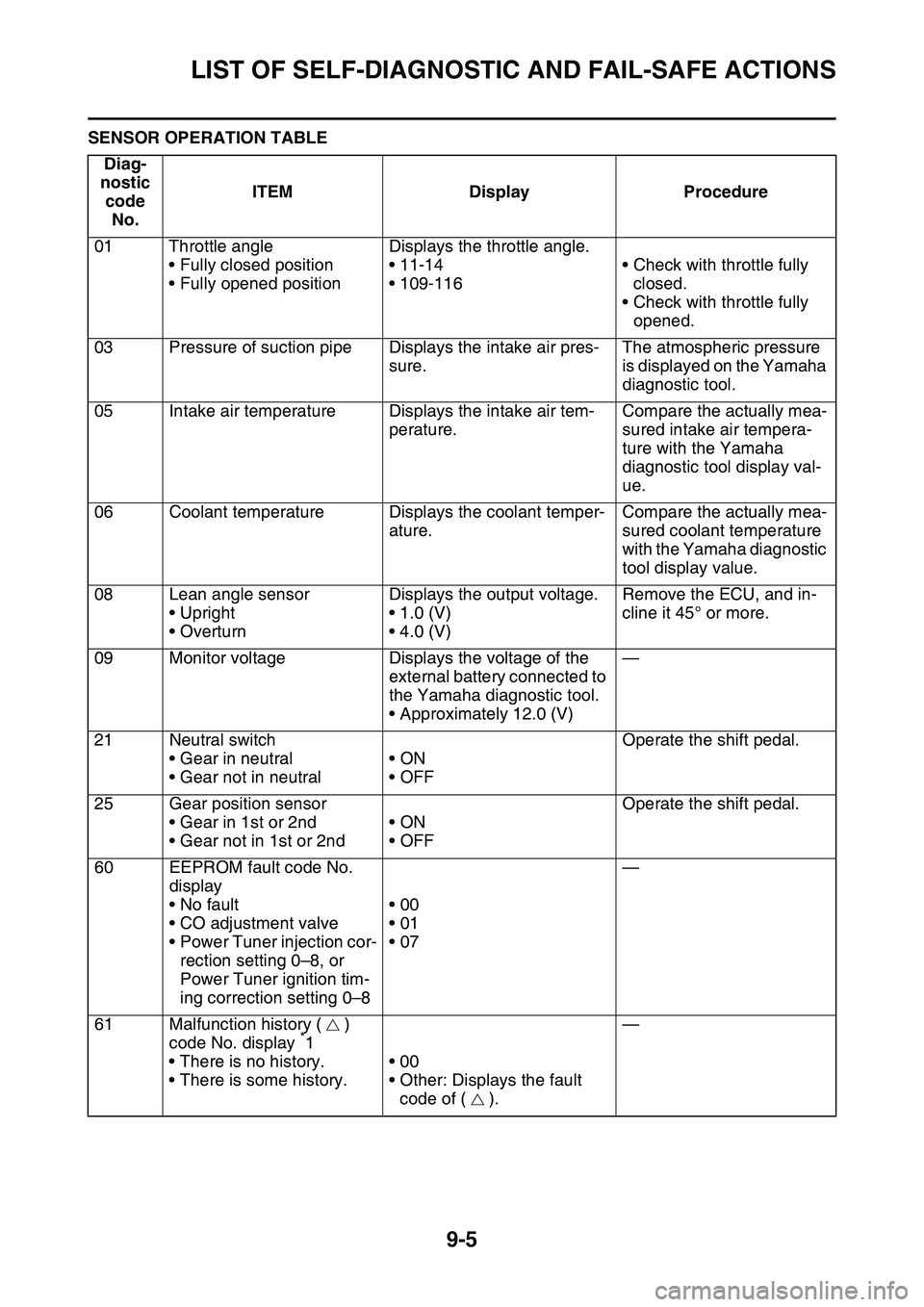

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-5

SENSOR OPERATION TABLEDiag-

nostic code No. ITEM Display Procedure

01 Throttle angle • Fully closed position

• Fully opened position Displays the throttle angle.

• 11-14

• 109-116

• Check with throttle fully

closed.

• Check with throttle fully opened.

03 Pressure of suction pipe Displays the intake air pres- sure.The atmospheric pressure

is displayed on the Yamaha

diagnostic tool.

05 Intake air temperature Displays the intake air tem- perature.Compare the actually mea-

sured intake air tempera-

ture with the Yamaha

diagnostic tool display val-

ue.

06 Coolant temperature Displays the coolant temper- ature.Compare the actually mea-

sured coolant temperature

with the Yamaha diagnostic

tool display value.

08 Lean angle sensor • Upright

•Overturn Displays the output voltage.

• 1.0 (V)

• 4.0 (V) Remove the ECU, and in-

cline it 45° or more.

09 Monitor voltage Displays the voltage of the external battery connected to

the Yamaha diagnostic tool.

• Approximately 12.0 (V)—

21 Neutral switch • Gear in neutral

• Gear not in neutral •ON

•OFF Operate the shift pedal.

25 Gear position sensor • Gear in 1st or 2nd

• Gear not in 1st or 2nd •ON

•OFF Operate the shift pedal.

60 EEPROM fault code No. display

• No fault

• CO adjustment valve

• Power Tuner injection cor-rection setting 0–8, or

Power Tuner ignition tim-

ing correction setting 0–8 •00

•01

•07

—

61 Malfunction history ( ) code No. display

*1

• There is no history.

• There is some history. •00

• Other: Displays the fault

code of ( ). —

Page 345 of 360

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-6

*1 Symbols used in the explanations of the malfunction history: Normal

: There is currently a malfunction or abnormal condition. : A malfunction or abnormal condition occurred prev iously, but the affected system or component

is currently operating normally.

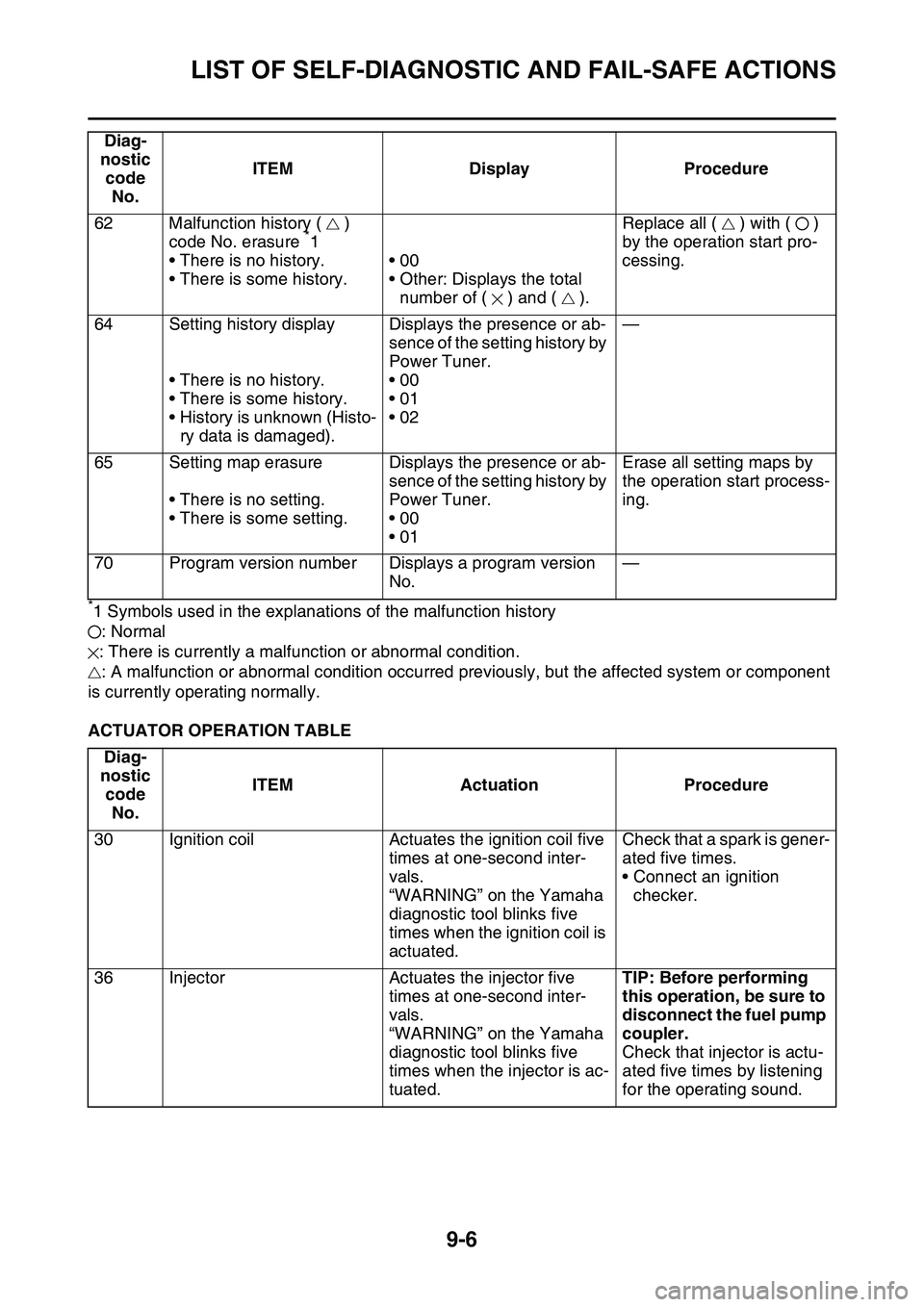

ACTUATOR OPERATION TABLE 62 Malfunction history ( )

code No. erasure

*1

• There is no history.

• There is some history. •00

• Other: Displays the total

number of ( ) and ( ). Replace all ( ) with ( )

by the operation start pro-

cessing.

64 Setting history display • There is no history.

• There is some history.

• History is unknown (Histo-ry data is damaged). Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01

•02

—

65 Setting map erasure • There is no setting.

• There is some setting. Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01 Erase all setting maps by

the operation start process-

ing.

70 Program version number Displays a program version No.—

Diag-

nostic code No. ITEM Actuation Procedure

30 Ignition coil Actuates the ignition coil five times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the ignition coil is

actuated.Check that a spark is gener-

ated five times.

• Connect an ignition

checker.

36 Injector Actuates the injector five times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the injector is ac-

tuated.TIP: Before performing

this operation, be sure to

disconnect the fuel pump

coupler.

Check that injector is actu-

ated five times by listening

for the operating sound.

Diag-

nostic code No. ITEM Display Procedure

Page 346 of 360

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-7

Page 347 of 360

10

TUNING

CHASSIS........................................................................................................ 10-1

SELECTION OF THE SECONDARY REDUCTION

RATIO (SPROCKET) .............................................................................. 10-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS ................ 10-1

TIRE PRESSURE..................................................................................... 10-2

FRONT FORK SETTING.......................................................................... 10-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL.......... 10-2

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-3

FRONT FORK SETTING PARTS............................................................. 10-3

REAR SUSPENSION SETTING .............................................................. 10-3

CHOOSING SET LENGTH ...................................................................... 10-3

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-4

REAR SHOCK ABSORBER SETTING PARTS ....................................... 10-5

SUSPENSION SETTING (FRONT FORK)............................................... 10-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ......................... 10-7

Page 348 of 360

CHASSIS

10-1

EAS1SL1365

CHASSIS

EAS1SL1366SELECTION OF THE SECONDARY REDUC-

TION RATIO (SPROCKET)

• It is generally said that the secondary gear ra-

tio should be reduced for a longer straight por-

tion of a speed course and should be

increased for a course with many corners. Ac

-

tually, however, as the speed depends on the

ground condition of the day of the race, be

sure to run through the circuit to set the ma

-

chine suitable for the entire course.

• In actuality, it is very difficult to achieve set-

tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the race

result. In such a case, run through the entire

course while making notes of lap times to find

the best balance; then, determine the second

-

ary reduction ratio.

• If a course has a long straight portion where a

machine can run at maximum speed, the ma

-

chine is generally set such that it can develop

its maximum revolutions toward the end of the

straight line, with care taken to avoid the en

-

gine over-revving.

TIP

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider's settings from the beginning but

choose your own setting according to the level

of your riding technique.

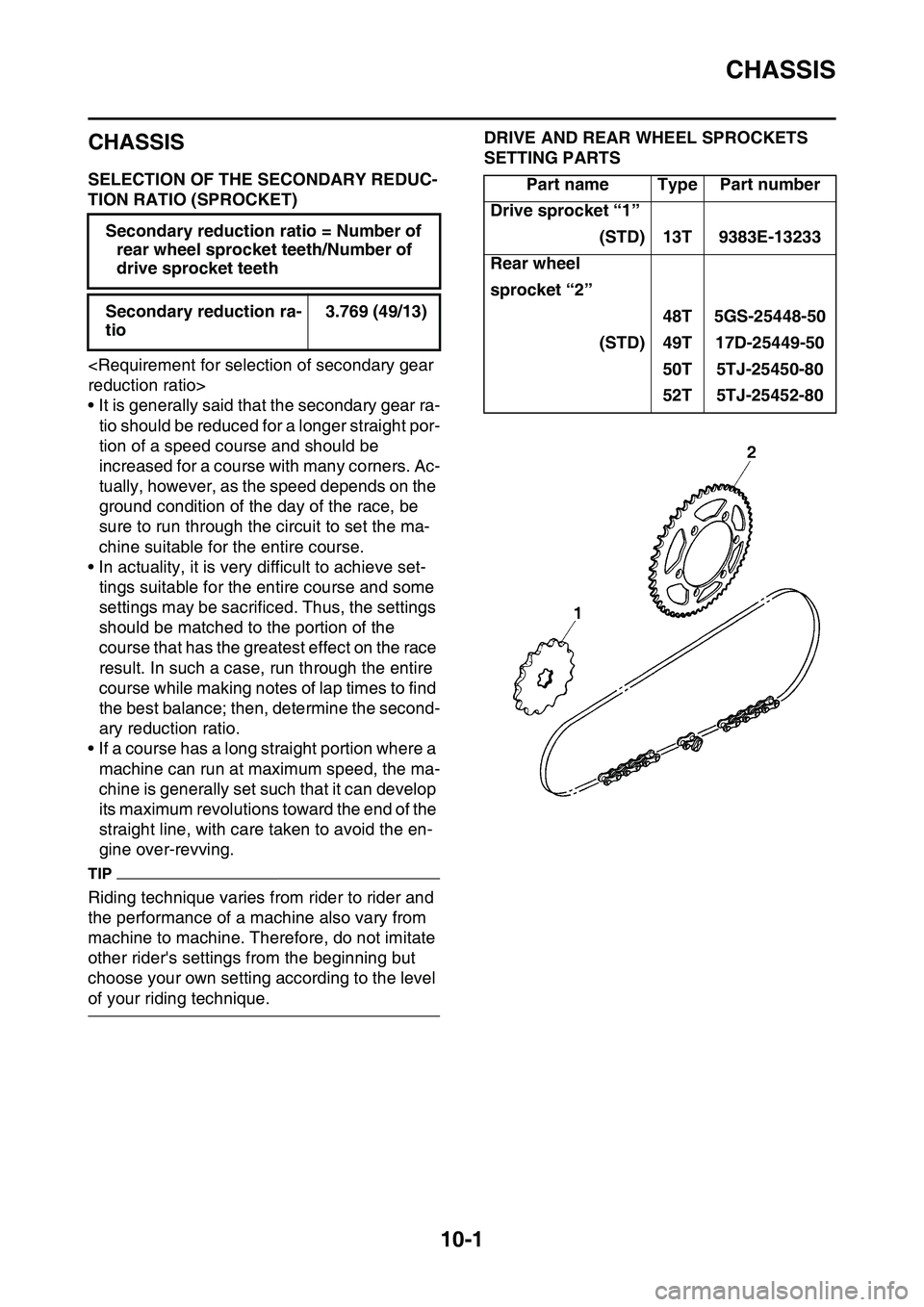

EAS1SL1367

DRIVE AND REAR WHEEL SPROCKETS

SETTING PARTS

EAS1SL1368

Secondary reduction ratio = Number of

rear wheel sprocket teeth/Number of

drive sprocket teeth

Secondary reduction ra-

tio

3.769 (49/13)

Part nameTypePart number

Drive sprocket “1”

(STD)13T9383E-13233

Rear wheel

sprocket “2”

48T5GS-25448-50

(STD)49T17D-25449-50

50T5TJ-25450-80

52T5TJ-25452-80

Page 349 of 360

CHASSIS

10-2

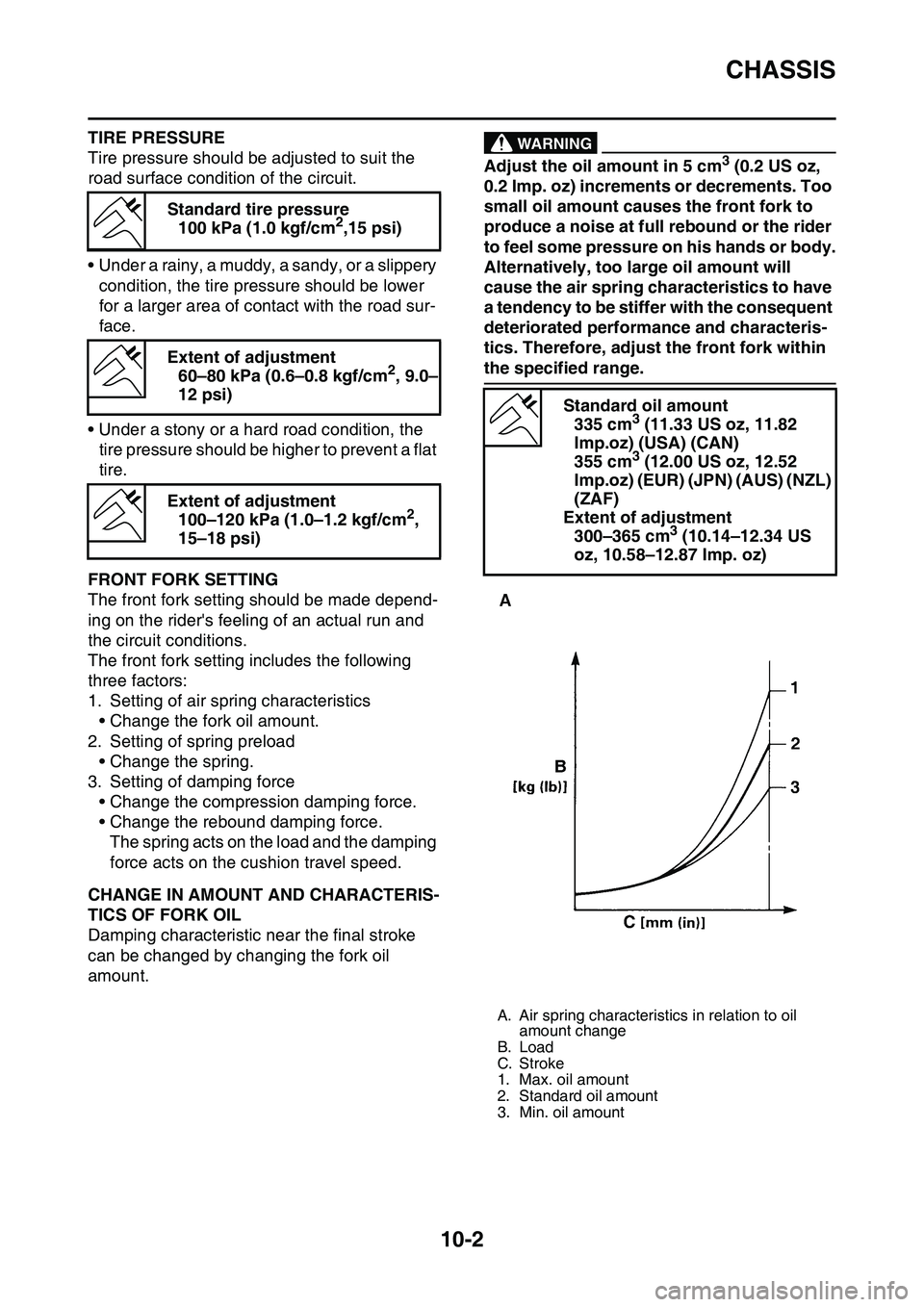

TIRE PRESSURE

Tire pressure should be adjusted to suit the

road surface condition of the circuit.

• Under a rainy, a muddy, a sandy, or a slippery

condition, the tire pressure should be lower

for a larger area of contact with the road sur

-

face.

• Under a stony or a hard road condition, the

tire pressure should be higher to prevent a flat

tire.

EAS1SL1369FRONT FORK SETTING

The front fork setting should be made depend-

ing on the rider's feeling of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damping force.

• Change the rebound damping force.

The spring acts on the load and the damping

force acts on the cushion travel speed.

EAS1SL1370CHANGE IN AMOUNT AND CHARACTERIS-

TICS OF FORK OIL

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

EWA1DX4001

WARNING

Adjust the oil amount in 5 cm3 (0.2 US oz,

0.2 Imp. oz) increments or decrements. Too

small oil amount causes the front fork to

produce a noise at full rebound or the rider

to feel some pressure on his hands or body.

Alternatively, too large oil amount will

cause the air spring characteristics to have

a tendency to be stiffer with the consequent

deteriorated performance and characteris

-

tics. Therefore, adjust the front fork within

the specified range.

EAS1SL1371

Standard tire pressure

100 kPa (1.0 kgf/cm2,15 psi)

Extent of adjustment

60–80 kPa (0.6–0.8 kgf/cm2, 9.0–

12 psi)

Extent of adjustment

100–120 kPa (1.0–1.2 kgf/cm2,

15–18 psi)

Standard oil amount

335 cm3 (11.33 US oz, 11.82

lmp.oz) (USA) (CAN)

355 cm3 (12.00 US oz, 12.52

lmp.oz) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Extent of adjustment

300–365 cm3 (10.14–12.34 US

oz, 10.58–12.87 Imp. oz)

A. Air spring characteristics in relation to oil

amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

Page 350 of 360

CHASSIS

10-3

SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

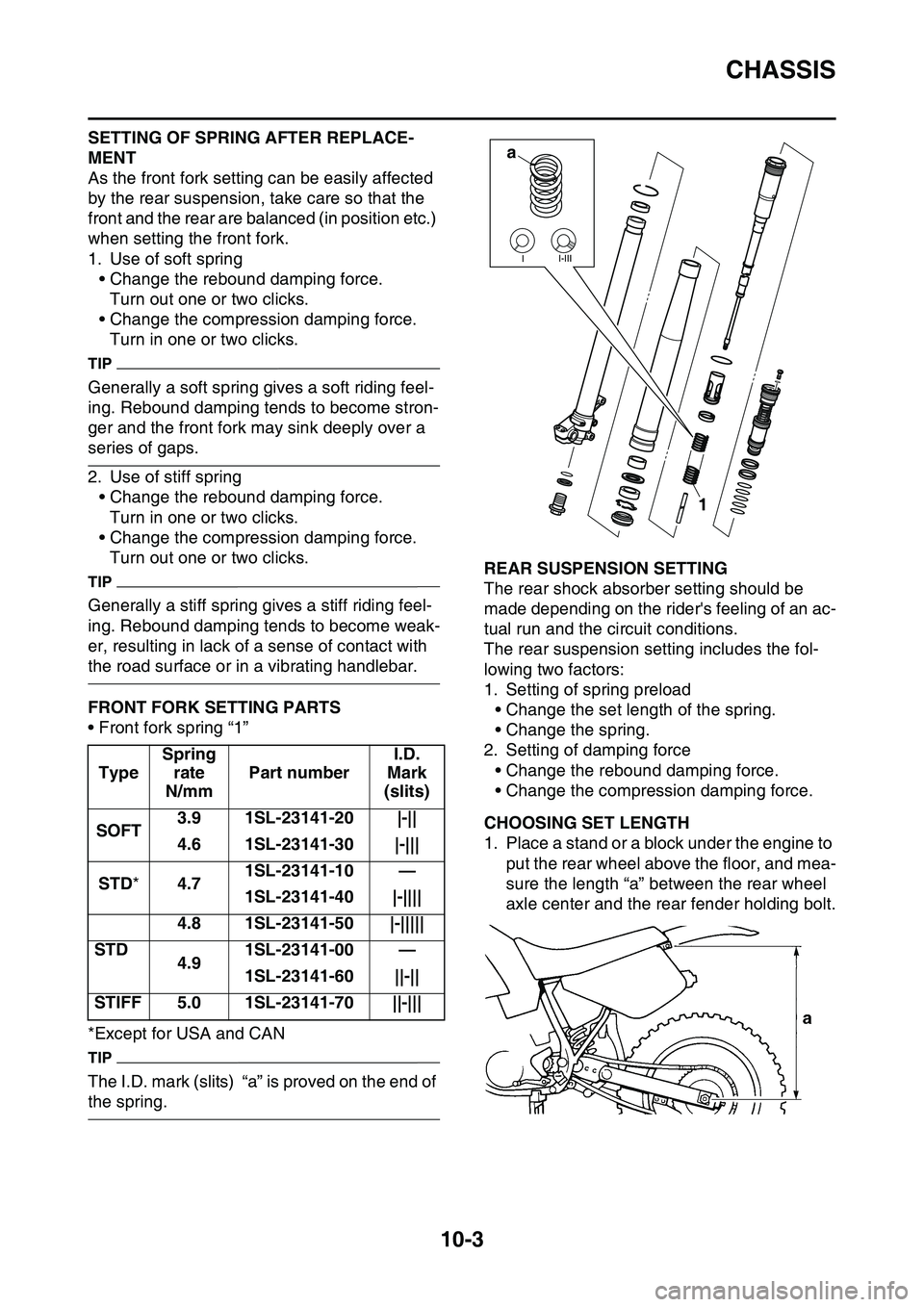

EAS1SL1372FRONT FORK SETTING PARTS

• Front fork spring “1”

*Except for USA and CAN

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS1SL1373REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider's feeling of an ac

-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS1SL1374CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea

-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

Type

Spring

rate

N/mm

Part number

I.D.

Mark

(slits)

SOFT3.91SL-23141-20|-||

4.61SL-23141-30|-|||

STD*4.71SL-23141-10—

1SL-23141-40|-||||

4.81SL-23141-50|-|||||

STD4.91SL-23141-00—

1SL-23141-60||-||

STIFF5.01SL-23141-70||-|||

a

1