air filter YAMAHA YZ450F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 18 of 360

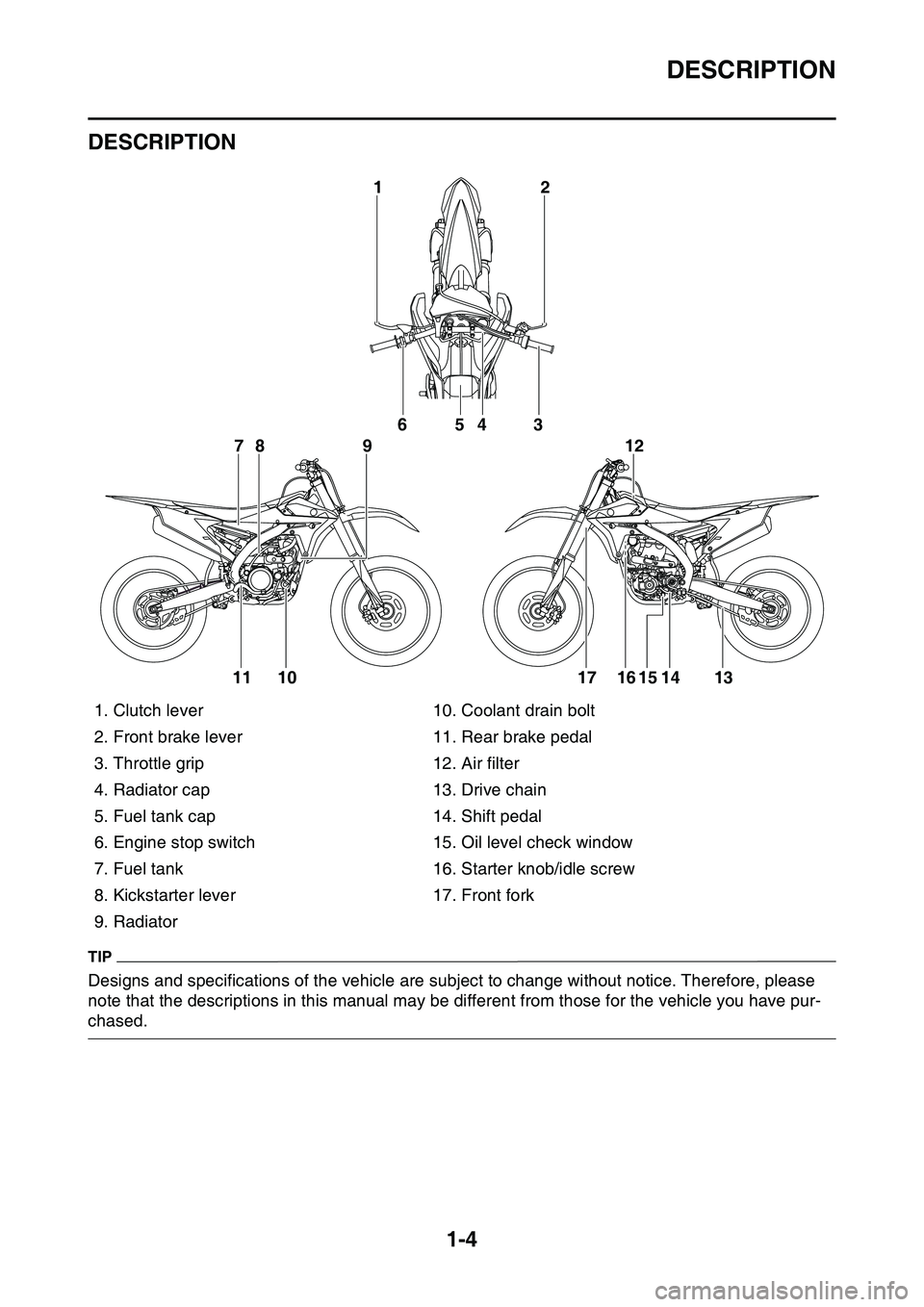

DESCRIPTION

1-4

EAS1SL1009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur

-

chased.

1. Clutch lever10. Coolant drain bolt

2. Front brake lever11. Rear brake pedal

3. Throttle grip12. Air filter

4. Radiator cap13. Drive chain

5. Fuel tank cap14. Shift pedal

6. Engine stop switch15. Oil level check window

7. Fuel tank16. Starter knob/idle screw

8. Kickstarter lever17. Front fork

9. Radiator

2 1

6

78 954 3

11 10 17 16 15 14 1312

Page 21 of 360

FEATURES

1-7

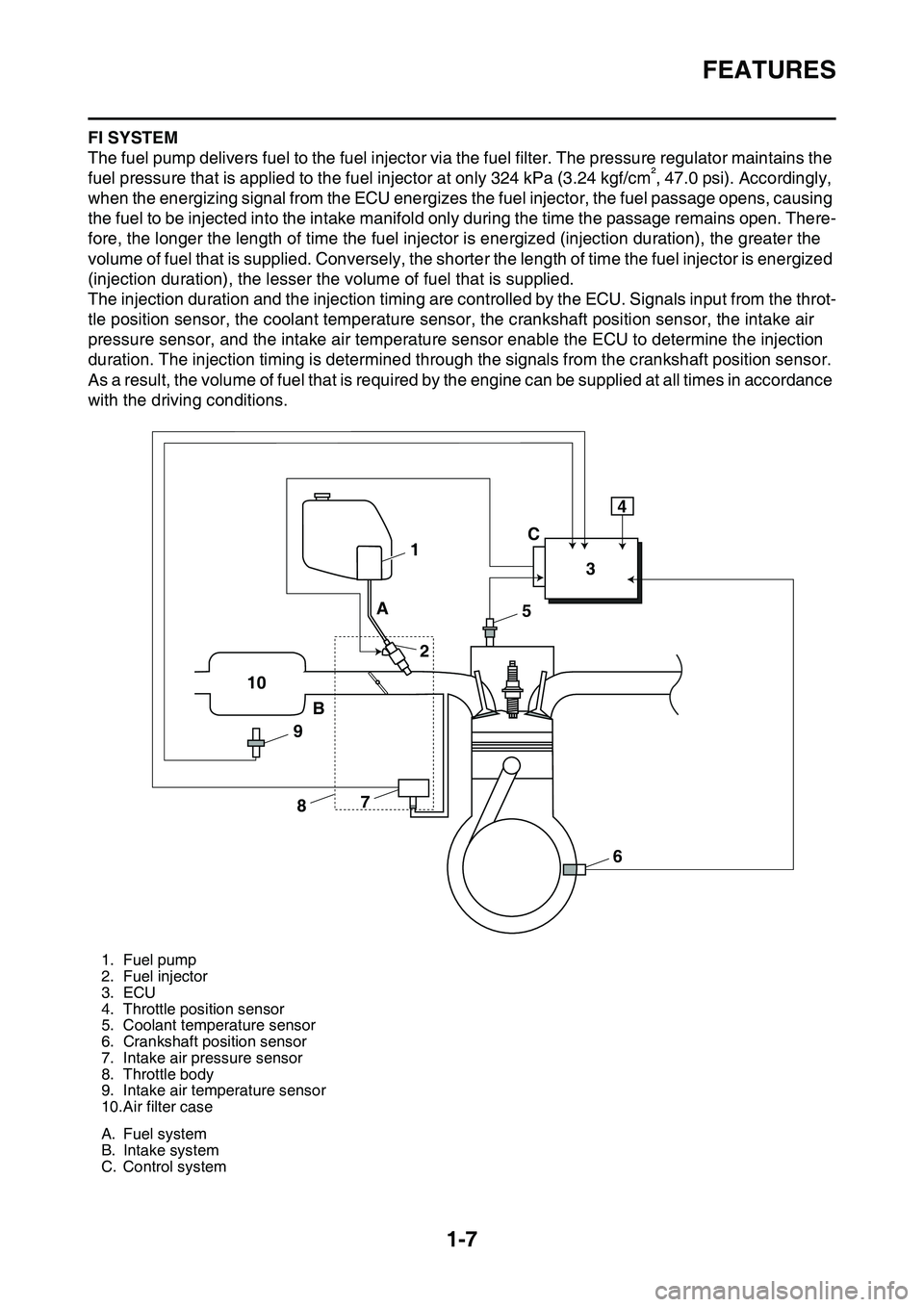

FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 324 kPa (3.24 kgf/cm², 47.0 psi). Accordingly,

when the energizing signal from the ECU energizes the fuel injector, the fuel passage opens, causing

the fuel to be injected into the intake manifold only during the time the passage remains open. There

-

fore, the longer the length of time the fuel injector is energized (injection duration), the greater the

volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized

(injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals input from the throt-

tle position sensor, the coolant temperature sensor, the crankshaft position sensor, the intake air

pressure sensor, and the intake air temperature sensor enable the ECU to determine the injection

duration. The injection timing is determined through the signals from the crankshaft position sensor.

As a result, the volume of fuel that is required by the engine can be supplied at all times in accordance

with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10.Air filter case

A. Fuel system

B. Intake system

C. Control system

1

234

5

6 7

8 9 10A

BC

Page 37 of 360

STARTING AND BREAK-IN

1-23

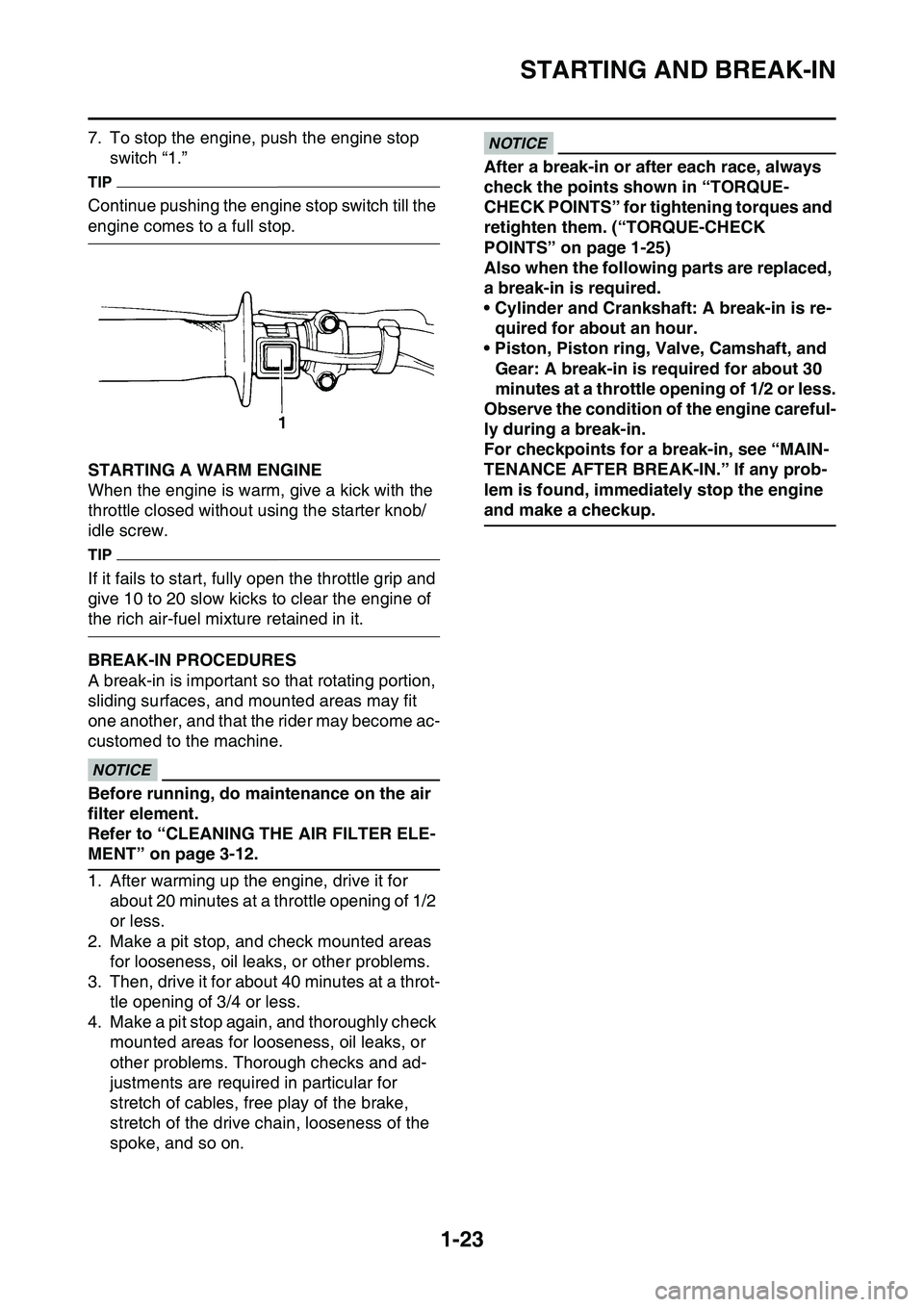

7. To stop the engine, push the engine stop

switch “1.”

TIP

Continue pushing the engine stop switch till the

engine comes to a full stop.

EAS1SL1044STARTING A WARM ENGINE

When the engine is warm, give a kick with the

throttle closed without using the starter knob/

idle screw.

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

EAS1SL1045BREAK-IN PROCEDURES

A break-in is important so that rotating portion,

sliding surfaces, and mounted areas may fit

one another, and that the rider may become ac

-

customed to the machine.ECA

NOTICE

Before running, do maintenance on the air

filter element.

Refer to “CLEANING THE AIR FILTER ELE-

MENT” on page 3-12.

1. After warming up the engine, drive it for

about 20 minutes at a throttle opening of 1/2

or less.

2. Make a pit stop, and check mounted areas

for looseness, oil leaks, or other problems.

3. Then, drive it for about 40 minutes at a throt-

tle opening of 3/4 or less.

4. Make a pit stop again, and thoroughly check

mounted areas for looseness, oil leaks, or

other problems. Thorough checks and ad

-

justments are required in particular for

stretch of cables, free play of the brake,

stretch of the drive chain, looseness of the

spoke, and so on.

ECA

NOTICE

After a break-in or after each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (

“TORQUE-CHECK

POINTS” on page 1-25)

Also when the following parts are replaced,

a break-in is required.

• Cylinder and Crankshaft: A break-in is re-

quired for about an hour.

• Piston, Piston ring, Valve, Camshaft, and

Gear: A break-in is required for about 30

minutes at a throttle opening of 1/2 or less.

Observe the condition of the engine careful-

ly during a break-in.

For checkpoints for a break-in, see “MAIN-

TENANCE AFTER BREAK-IN.” If any prob-

lem is found, immediately stop the engine

and make a checkup.

EAS1SL1046

Page 50 of 360

ENGINE SPECIFICATIONS

2-7

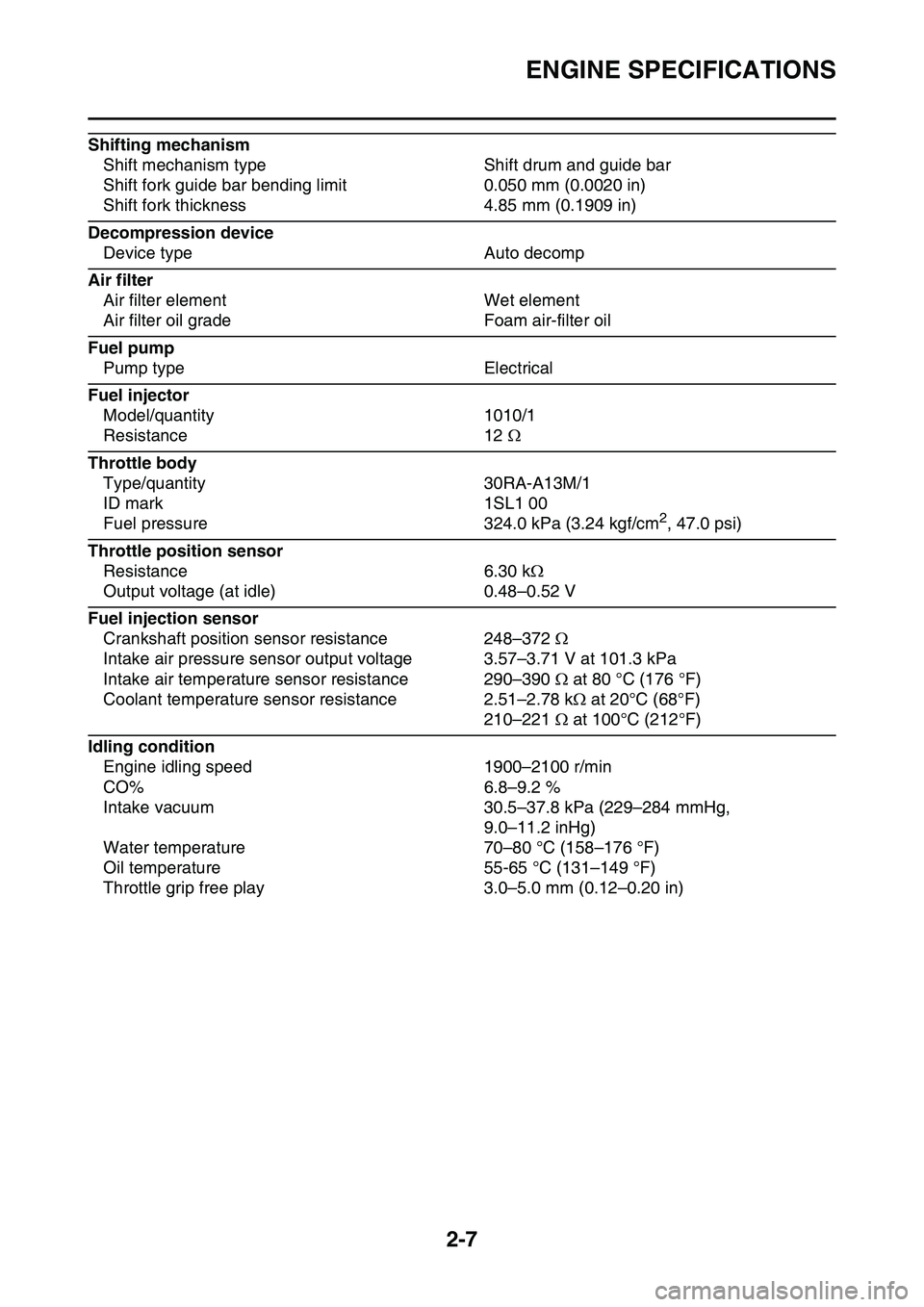

Shifting mechanism

Shift mechanism type Shift drum and guide bar

Shift fork guide bar bending limit 0.050 mm (0.0020 in)

Shift fork thickness 4.85 mm (0.1909 in)

Decompression device

Device type Auto decomp

Air filter

Air filter element Wet element

Air filter oil grade Foam air-filter oil

Fuel pump

Pump type Electrical

Fuel injector

Model/quantity 1010/1

Resistance 12

Throttle body

Type/quantity 30RA-A13M/1

ID mark 1SL1 00

Fuel pressure 324.0 kPa (3.24 kgf/cm2, 47.0 psi)

Throttle position sensor

Resistance 6.30 k

Output voltage (at idle) 0.48–0.52 V

Fuel injection sensor

Crankshaft position sensor resistance 248–372

Intake air pressure sensor output voltage 3.57–3.71 V at 101.3 kPa

Intake air temperature sensor resistance 290–390 at 80 °C (176 °F)

Coolant temperature sensor resistance 2.51–2.78 k at 20°C (68°F)

210–221 at 100°C (212°F)

Idling condition

Engine idling speed 1900–2100 r/min

CO% 6.8–9.2 %

Intake vacuum 30.5–37.8 kPa (229–284 mmHg,

9.0–11.2 inHg)

Water temperature 70–80 °C (158–176 °F)

Oil temperature 55-65 °C (131–149 °F)

Throttle grip free play 3.0–5.0 mm (0.12–0.20 in)

Page 57 of 360

TIGHTENING TORQUES

2-14

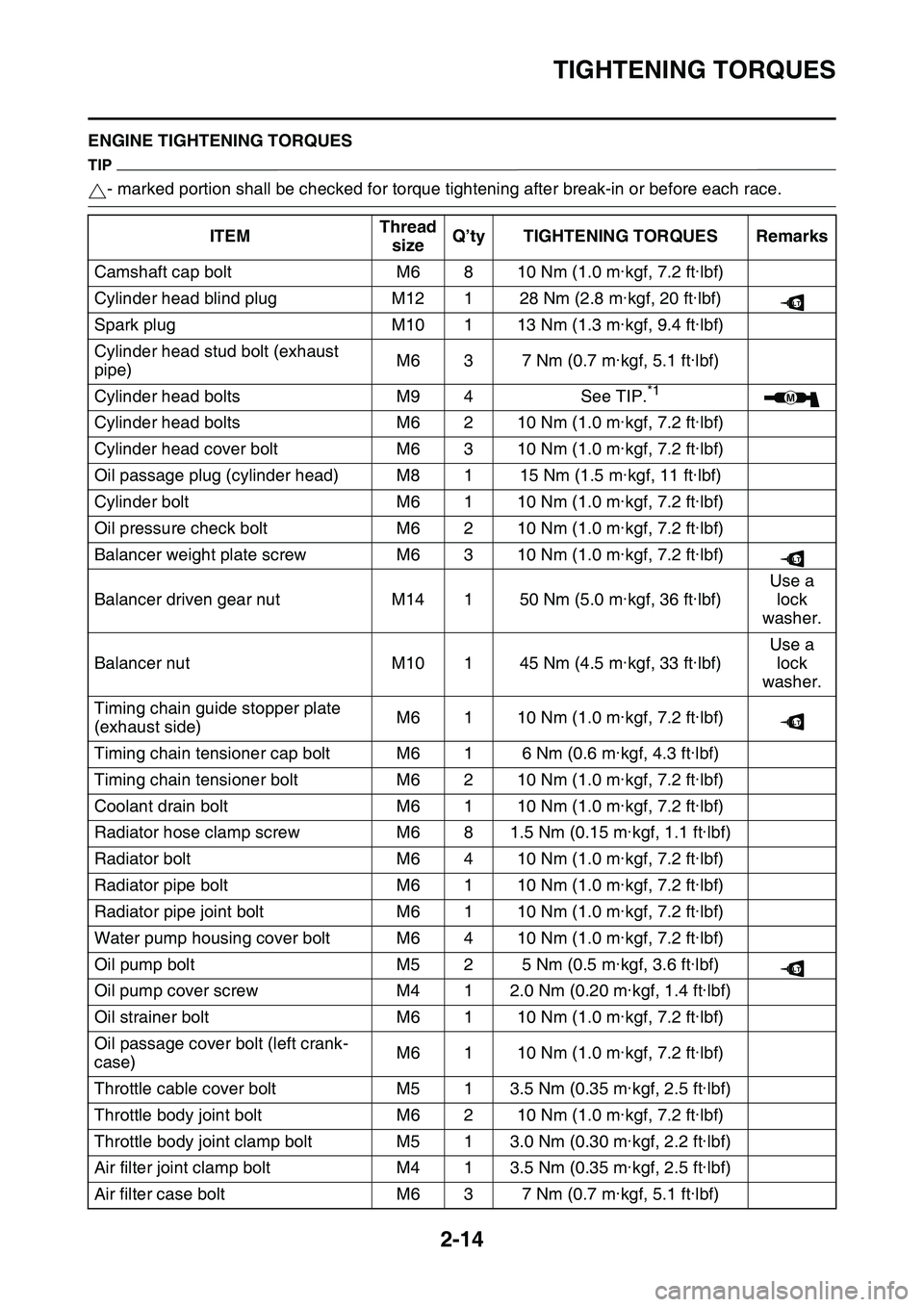

EAS1SL1057ENGINE TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’tyTIGHTENING TORQUESRemarks

Camshaft cap boltM6810 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head blind plugM12128 Nm (2.8 m·kgf, 20 ft·lbf)

Spark plugM10113 Nm (1.3 m·kgf, 9.4 ft·lbf)

Cylinder head stud bolt (exhaust

pipe)M637 Nm (0.7 m·kgf, 5.1 ft·lbf)

Cylinder head boltsM94See TIP.*1

Cylinder head boltsM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head cover boltM6310 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil passage plug (cylinder head)M8115 Nm (1.5 m·kgf, 11 ft·lbf)

Cylinder boltM6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pressure check boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer weight plate screwM6310 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer driven gear nutM14150 Nm (5.0 m·kgf, 36 ft·lbf)

Use a

lock

washer.

Balancer nutM10145 Nm (4.5 m·kgf, 33 ft·lbf)

Use a

lock

washer.

Timing chain guide stopper plate

(exhaust side)M6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing chain tensioner cap boltM616 Nm (0.6 m·kgf, 4.3 ft·lbf)

Timing chain tensioner boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain boltM6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator hose clamp screwM681.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Radiator boltM6410 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe bolt M6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe joint bolt M6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Water pump housing cover boltM6410 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pump boltM525 Nm (0.5 m·kgf, 3.6 ft·lbf)

Oil pump cover screwM412.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil strainer boltM6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil passage cover bolt (left crank-

case)M6110 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle cable cover boltM513.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Throttle body joint boltM6210 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle body joint clamp boltM513.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

Air filter joint clamp boltM413.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Air filter case boltM637 Nm (0.7 m·kgf, 5.1 ft·lbf)

LT

M

LT

LT

LT

Page 58 of 360

TIGHTENING TORQUES

2-15

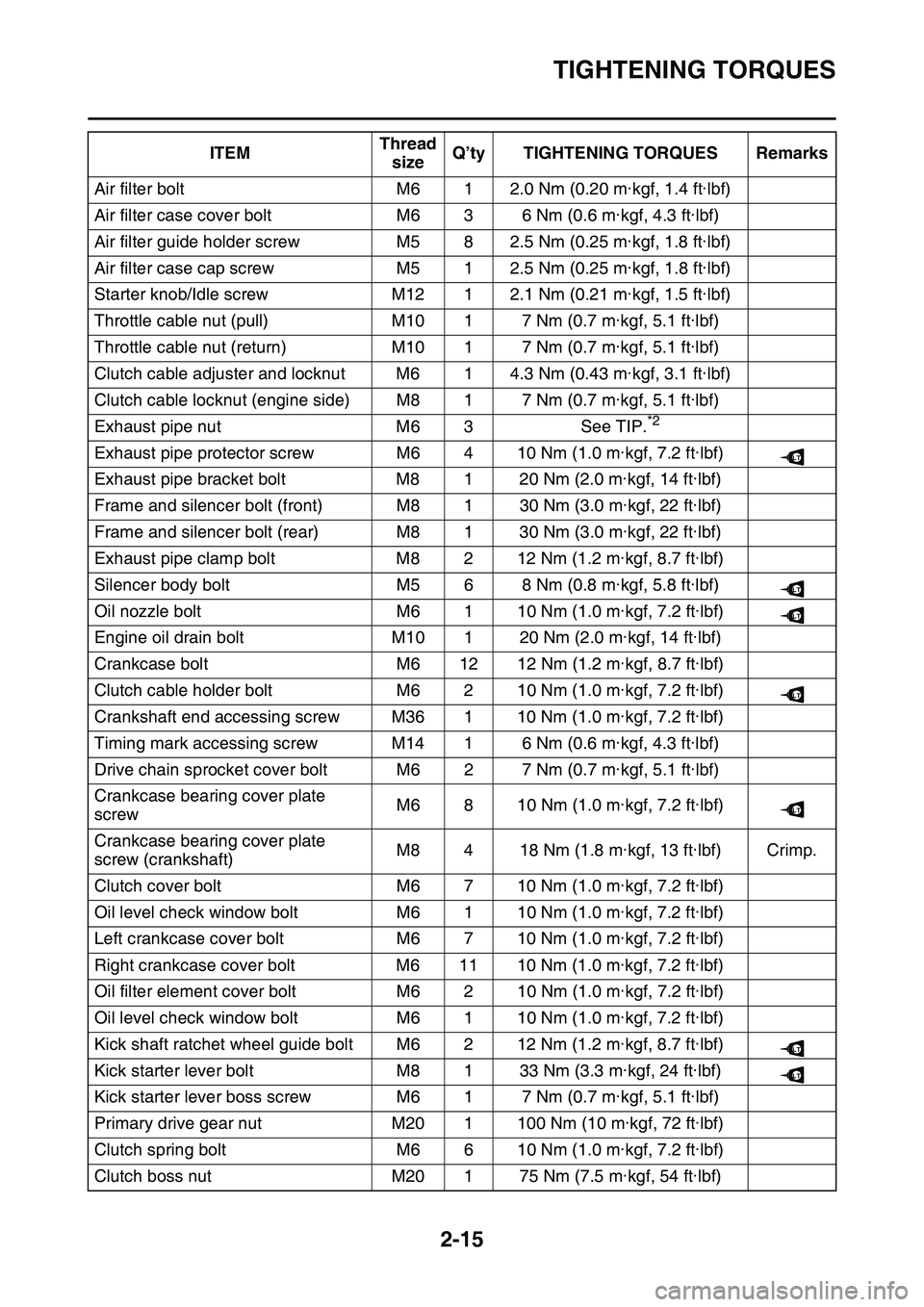

Air filter boltM6 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Air filter case cover bolt M6 3 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Air filter guide holder screw M5 8 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Air filter case cap screw M5 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Starter knob/Idle screw M12 1 2.1 Nm (0.21 m·kgf, 1.5 ft·lbf)

Throttle cable nut (pull) M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle cable nut (return) M10 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Clutch cable adjuster and locknut M6 1 4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

Clutch cable locknut (engine side) M8 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Exhaust pipe nut M6 3See TIP.

*2

Exhaust pipe protector screw M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Exhaust pipe bracket bolt M8 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Frame and silencer bolt (front) M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Frame and silencer bolt (rear) M 8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Exhaust pipe clamp bolt M8 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer body bolt M5 6 8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Oil nozzle bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Engine oil drain bolt M10 1 20 Nm (2.0 m·kgf, 14 ft·lbf)

Crankcase bolt M6 12 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Clutch cable holder bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankshaft end accessing screw M36 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing mark accessing screw M14 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Drive chain sprocket cover bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankcase bearing cover plate

screw M6 8 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Crankcase bearing cover plate

screw (crankshaft) M8 4 18 Nm (1.8 m·kgf, 13 ft·lbf) Crimp.

Clutch cover bolt M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil level check window bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Left crankcase cover bolt M6 7 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Right crankcase cover bolt M6 11 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element cover bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil level check window bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Kick shaft ratchet wheel guide bolt M6 2 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Kick starter lever bolt M8 1 33 Nm (3.3 m·kgf, 24 ft·lbf)

Kick starter lever boss screw M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Primary drive gear nut M20 1 100 Nm (10 m·kgf, 72 ft·lbf)

Clutch spring bolt M6 6 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Clutch boss nut M20 1 75 Nm (7.5 m·kgf, 54 ft·lbf)

ITEM

Thread

size Q’ty TIGHTENING TORQUES RemarksLT

LT

LT

LT

LT

LT

LT

Page 83 of 360

CABLE ROUTING DIAGRAM

2-40

1. Main harness

2. Radiator3. Throttle position sensor lead

4. Joint coupler

5. Intake air temperature sensor lead6. Intake air pressure sensor lead

7. Frame

8. Fuel hose9. High tension cord

10. Spark plug cap

11. Cylinder head cover12. Sub-wire harness

13. Injector coupler

14. Injector lead15. Throttle body

16. Air filter case

17. ECU18. Sub-wire harness coupler

A. Fix the main harness by the plastic clamp, and in-sert the projection of the plastic clamp into the

hole in the sheet metal of the radiator.

B. Insert the projection of the main harness into the

hole in the frame.

C. To the sub-wire harness

D. Pass the high tension cord above the fuel hose.

E. ±10°F. Install the spark plug cap with this facing the right

of the vehicle.

G. Push the spark plug cap home, where there shall

be no gap between it and the cylinder head cover.

H. Pass the injector lead to the top of the vehicle be-yond the fuel hose.I. Insert the coupler of the sub-wire harness into the

rib of the air filter case.

J. Pass the sub-wire harness between the ECU and

the air filter case.

Page 87 of 360

3

PERIODIC CHECKS AND ADJUSTMENTS

MAINTENANCE INTERVALS.......................................................................... 3-1

MAINTENANCE INTERVALS .................................................................... 3-1

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-7

GENERAL INSPECTION AND MAINTENANCE........................................ 3-7

ENGINE............................................................................................................ 3-8

CHECKING THE COOLANT LEVEL .......................................................... 3-8

CHECKING THE COOLING SYSTEM ....................................................... 3-8

CHANGING THE COOLANT...................................................................... 3-8

CHECKING THE RADIATOR CAP ............................................................ 3-9

CHECKING THE RADIATOR CAP OPENING PRESSURE ...................... 3-9

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-10

ADJUSTING THE CLUTCH LEVER POSITION ...................................... 3-10

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-10

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-11

LUBRICATING THE THROTTLE CABLE ................................................ 3-12

CLEANING THE AIR FILTER ELEMENT................................................. 3-12

CHECKING THE THROTTLE BODY JOINT ............................................ 3-13

CHECKING THE BREATHER HOSES .................................................... 3-13

CHECKING THE EXHAUST SYSTEM..................................................... 3-13

CHECKING THE FUEL LINE ................................................................... 3-14

CHECKING THE ENGINE OIL LEVEL..................................................... 3-14

CHANGING THE ENGINE OIL ................................................................ 3-15

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-16

ADJUSTING THE VALVE CLEARANCE ................................................. 3-17

CHASSIS........................................................................................................ 3-21

BLEEDING THE BRAKE SYSTEM .......................................................... 3-21

CHECKING THE BRAKE HOSE .............................................................. 3-22

ADJUSTING THE FRONT BRAKE .......................................................... 3-22

ADJUSTING THE REAR BRAKE ............................................................. 3-23

CHECKING THE FRONT BRAKE PADS ................................................. 3-23

CHECKING THE REAR BRAKE PADS ................................................... 3-25

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-26

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-26

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-27

CHECKING THE FRONT FORK LEGS ................................................... 3-28

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-28

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-28

AIR BLEEDING FROM FRONT FORK .................................................... 3-28

ADJUSTING THE FRONT FORK LEGS .................................................. 3-29

CHECKING THE SWINGARM OPERATION ........................................... 3-30

CHECKING THE REAR SUSPENSION ................................................... 3-30

ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY ................... 3-30

CHECKING THE TIRES ........................................................................... 3-32

CHECKING AND TIGHTENING THE SPOKES ....................................... 3-32

CHECKING THE WHEELS ...................................................................... 3-33

Page 91 of 360

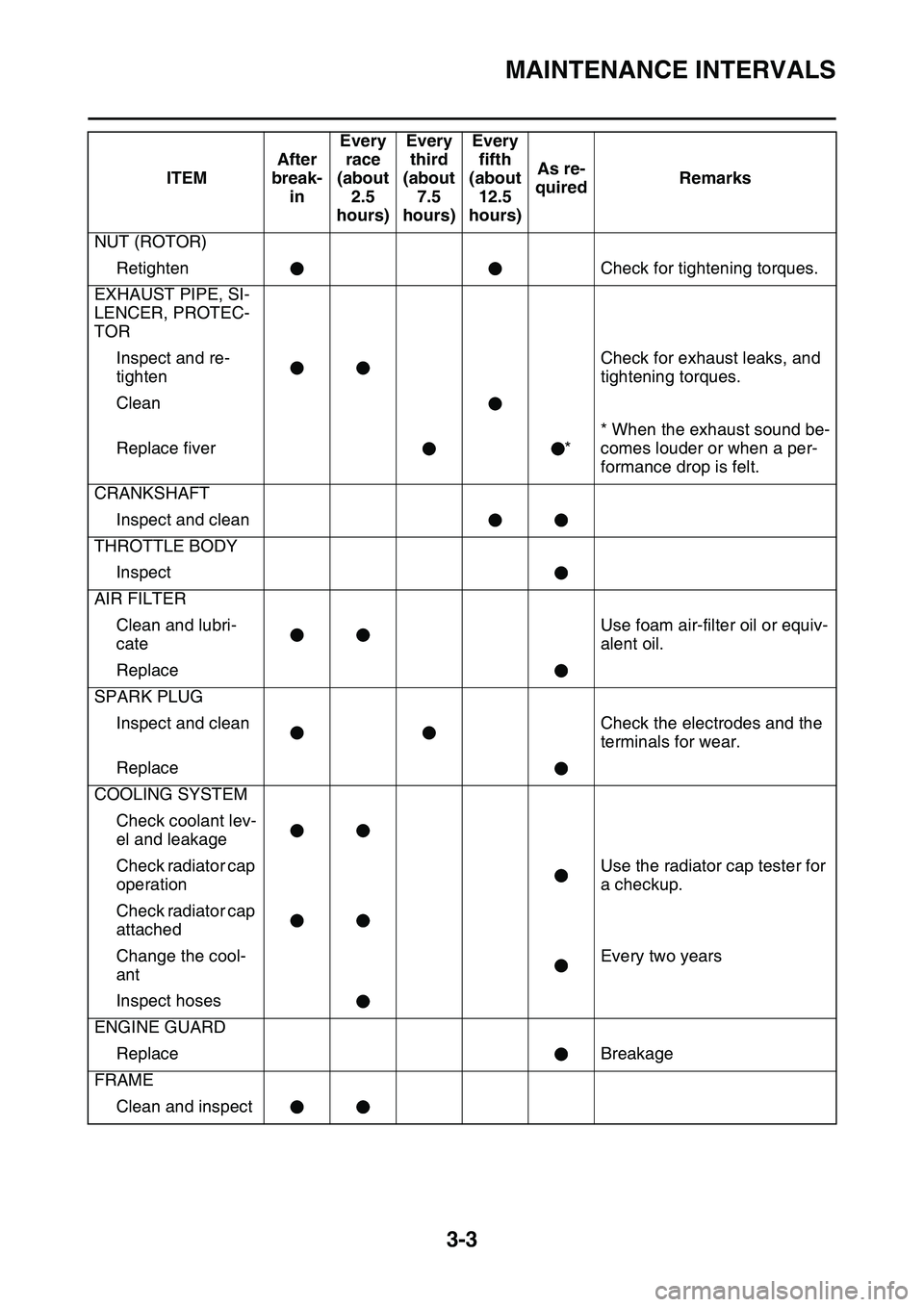

MAINTENANCE INTERVALS

3-3

NUT (ROTOR)

RetightenCheck for tightening torques.

EXHAUST PIPE, SI-

LENCER, PROTEC-

TOR

Inspect and re-

tighten

Check for exhaust leaks, and

tightening torques.

Clean

Replace fiver*

* When the exhaust sound be-

comes louder or when a per-

formance drop is felt.

CRANKSHAFT

Inspect and clean

THROTTLE BODY

Inspect

AIR FILTER

Clean and lubri-

cate

Use foam air-filter oil or equiv-

alent oil.

Replace

SPARK PLUG

Inspect and cleanCheck the electrodes and the

terminals for wear.

Replace

COOLING SYSTEM

Check coolant lev-

el and leakage

Check radiator cap

operationUse the radiator cap tester for

a checkup.

Check radiator cap

attached

Change the cool-

ant

Every two years

Inspect hoses

ENGINE GUARD

ReplaceBreakage

FRAME

Clean and inspect

ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 96 of 360

ENGINE

3-8

EAS1SL1069

ENGINE

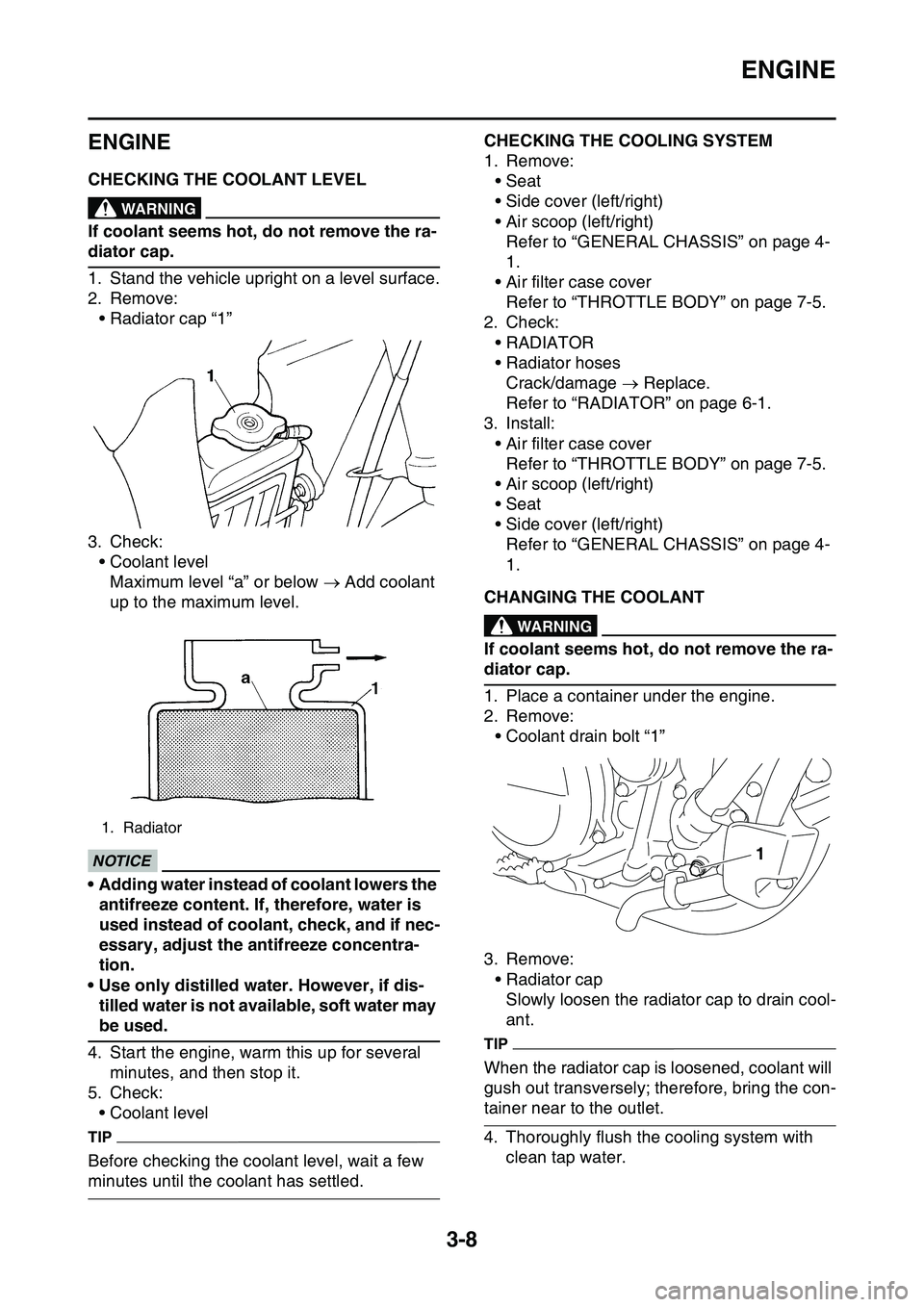

EAS1SL1070CHECKING THE COOLANT LEVELEWA1DX1003

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:

• Radiator cap “1”

3. Check:

• Coolant level

Maximum level “a” or below Add coolant

up to the maximum level.

ECA1DX1004

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec

-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for several

minutes, and then stop it.

5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS1SL1071CHECKING THE COOLING SYSTEM

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

2. Check:

•RADIATOR

• Radiator hoses

Crack/damage Replace.

Refer to “RADIATOR” on page 6-1.

3. Install:

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1072CHANGING THE COOLANTEWA1DX1004

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Place a container under the engine.

2. Remove:

• Coolant drain bolt “1”

3. Remove:

• Radiator cap

Slowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con

-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

1. Radiator

1