stop start YAMAHA YZ450F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ450F, Model: YAMAHA YZ450F 2016Pages: 362, PDF Size: 10.49 MB

Page 99 of 362

ENGINE

3-15

ECA33DD018

NOTICE

• Since engine oil also lubricates the clutch,

the wrong oil types or additives could

cause clutch slippage. Therefore, do not

add any chemical additives.

• Do not allow foreign material to enter the

crankcase.

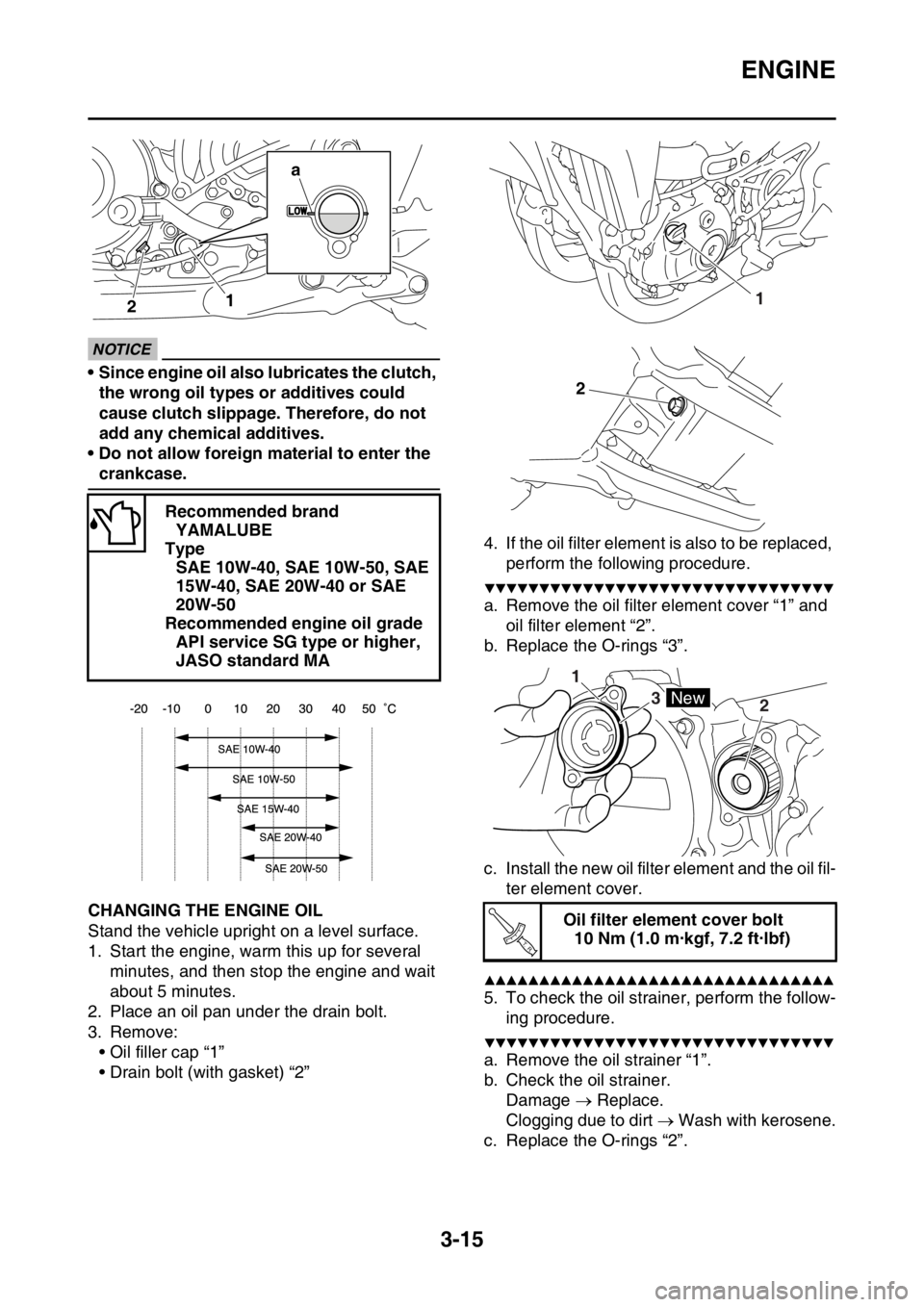

EASB111085CHANGING THE ENGINE OIL

Stand the vehicle upright on a level surface.

1. Start the engine, warm this up for several

minutes, and then stop the engine and wait

about 5 minutes.

2. Place an oil pan under the drain bolt.

3. Remove:

• Oil filler cap “1”

• Drain bolt (with gasket) “2”4. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter element cover “1” and

oil filter element “2”.

b. Replace the O-rings “3”.

c. Install the new oil filter element and the oil fil-

ter element cover.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. To check the oil strainer, perform the follow-

ing procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil strainer “1”.

b. Check the oil strainer.

Damage Replace.

Clogging due to dirt Wash with kerosene.

c. Replace the O-rings “2”. Recommended brand

YAMALUBE

Type

SAE 10W-40, SAE 10W-50, SAE

15W-40, SAE 20W-40 or SAE

20W-50

Recommended engine oil grade

API service SG type or higher,

JASO standard MA

12

a

Oil filter element cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

2

1

3

2

New

T R..

Page 194 of 362

CLUTCH......................................................................................................... 5-38

REMOVING THE CLUTCH ...................................................................... 5-41

CHECKING THE FRICTION PLATES...................................................... 5-41

CHECKING THE CLUTCH PLATES ........................................................ 5-41

CHECKING THE CLUTCH SPRINGS...................................................... 5-41

CHECKING THE CLUTCH HOUSING ..................................................... 5-42

CHECKING THE CLUTCH BOSS ............................................................ 5-42

CHECKING THE PRESSURE PLATE ..................................................... 5-42

CHECKING THE PUSH LEVER SHAFT .................................................. 5-42

CHECKING THE CLUTCH PUSH RODS ................................................ 5-42

CHECKING THE PRIMARY DRIVE GEAR .............................................. 5-42

CHECKING THE PRIMARY DRIVEN GEAR ........................................... 5-43

INSTALLING THE OIL SEAL................................................................... 5-43

INSTALLING THE RIGHT CRANKCASE COVER ................................... 5-43

INSTALLING THE CLUTCH ..................................................................... 5-44

INSTALLING THE KICKSTARTER LEVER ............................................. 5-46

KICKSTATER................................................................................................. 5-47

REMOVING THE KICK SHAFT ASSEMBLY ........................................... 5-48

CHECKING THE KICK SHAFT AND RATCHET WHEEL ........................ 5-48

CHECKING THE KICK GEAR, KICK IDLE GEAR AND RATCHET

WHEEL .................................................................................................... 5-48

INSTALLING THE KICK SHAFT ASSEMBLY .......................................... 5-48

INSTALLING THE KICK IDLE GEAR ....................................................... 5-49

SHIFT SHAFT................................................................................................. 5-50

REMOVING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 5-52

REMOVING THE SEGMENT ................................................................... 5-52

CHECKING THE SHIFT SHAFT .............................................................. 5-52

CHECKING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 5-52

CHECKING THE STOPPER LEVER ....................................................... 5-52

INSTALLING THE STOPPER LEVER ..................................................... 5-53

INSTALLING THE SEGMENT.................................................................. 5-53

INSTALLING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ....... 5-53

INSTALLING THE SHIFT SHAFT ............................................................ 5-54

INSTALLING THE SHIFT PEDAL ............................................................ 5-54

OIL PUMP AND BALANCER GEAR............................................................. 5-55

REMOVING THE BALANCER ................................................................. 5-57

CHECKING THE PRIMARY DRIVE GEAR, BALANCER SHAFT

DRIVE GEAR, AND BALANCER WEIGHT GEAR .................................. 5-57

CHECKING THE BALANCER .................................................................. 5-57

CHECKING THE OIL PUMP .................................................................... 5-57

ASSEMBLING THE OIL PUMP ................................................................ 5-58

INSTALLING THE OIL PUMP AND BALANCER GEAR .......................... 5-59

Page 289 of 362

THROTTLE BODY

7-8

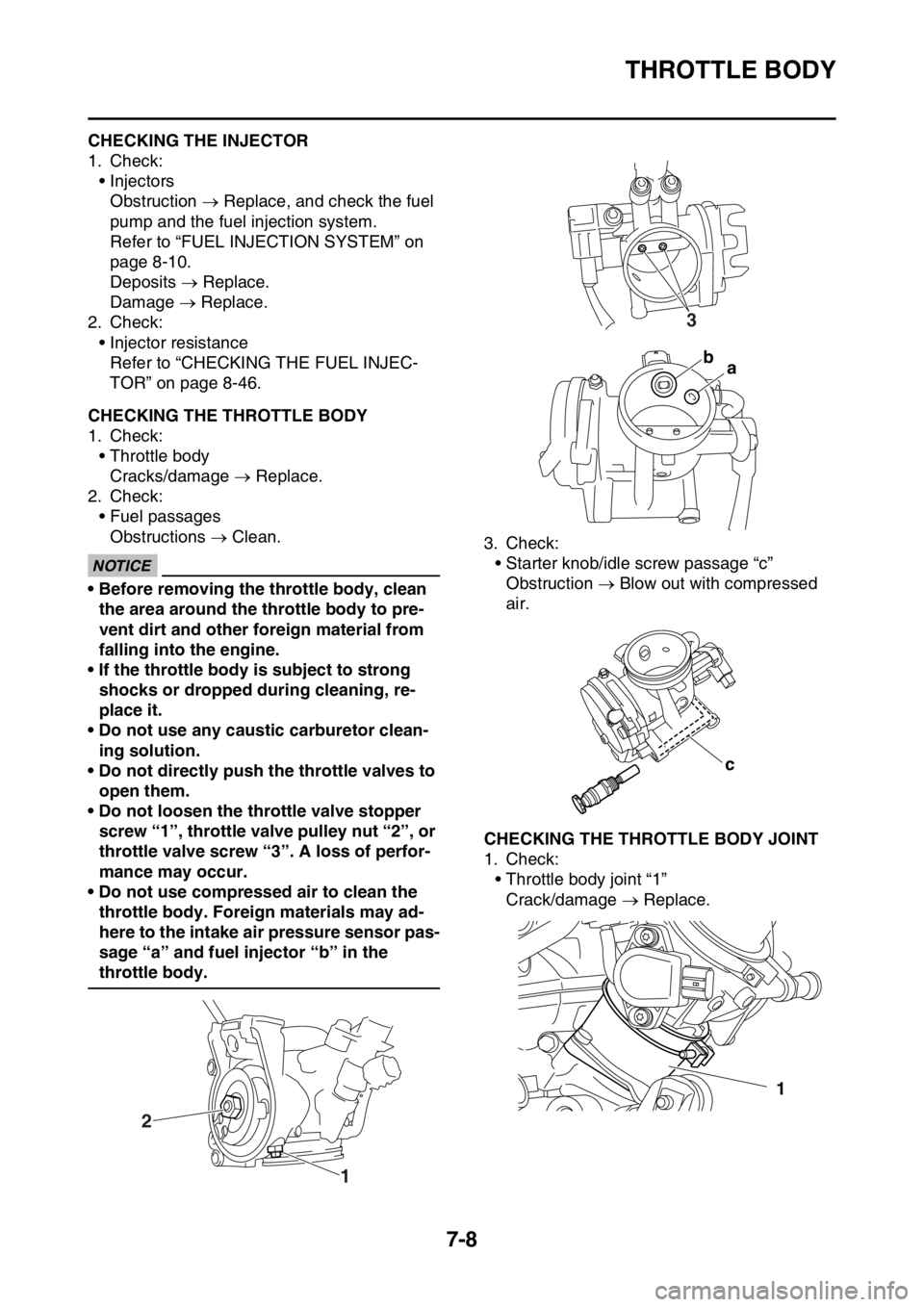

EASB111314CHECKING THE INJECTOR

1. Check:

• Injectors

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 8-10.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 8-46.

EASB111315CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EASB111316CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 342 of 362

TROUBLESHOOTING

9-1

EASB111348

TROUBLESHOOTING

EASB111349GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EASB111350STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in airElectrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

2. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

4. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

EASB111351INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

• Faulty spark plug cap

2. Ignition coil

• Broken or shorted primary or secondary

coils

• Cracked or broken ignition coil

Page 343 of 362

TROUBLESHOOTING

9-2

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

EASB111352POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 9-1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EASB111353SHIFTING IS DIFFICULT

Refer to “CLUTCH” on page 5-38.

EASB111354SHIFT PEDAL DOES NOT MOVE

Engine

1. Shift shaft

• Bent shift shaft

2. Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

3. Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EASB111355JUMPS OUT OF GEAR

Engine

1. Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

2. Shift forks

• Worn shift fork

3. Shift drum

• Incorrect axial play

• Worn shift drum groove

4. Transmission

• Worn gear dog

EASB111356

CLUTCH SLIPS

Engine

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

EASB111357CLUTCH DRAGS

Engine

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EASB111358OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe