engine YAMAHA YZ450F 2016 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ450F, Model: YAMAHA YZ450F 2016Pages: 362, PDF Size: 10.49 MB

Page 105 of 362

ENGINE

3-21

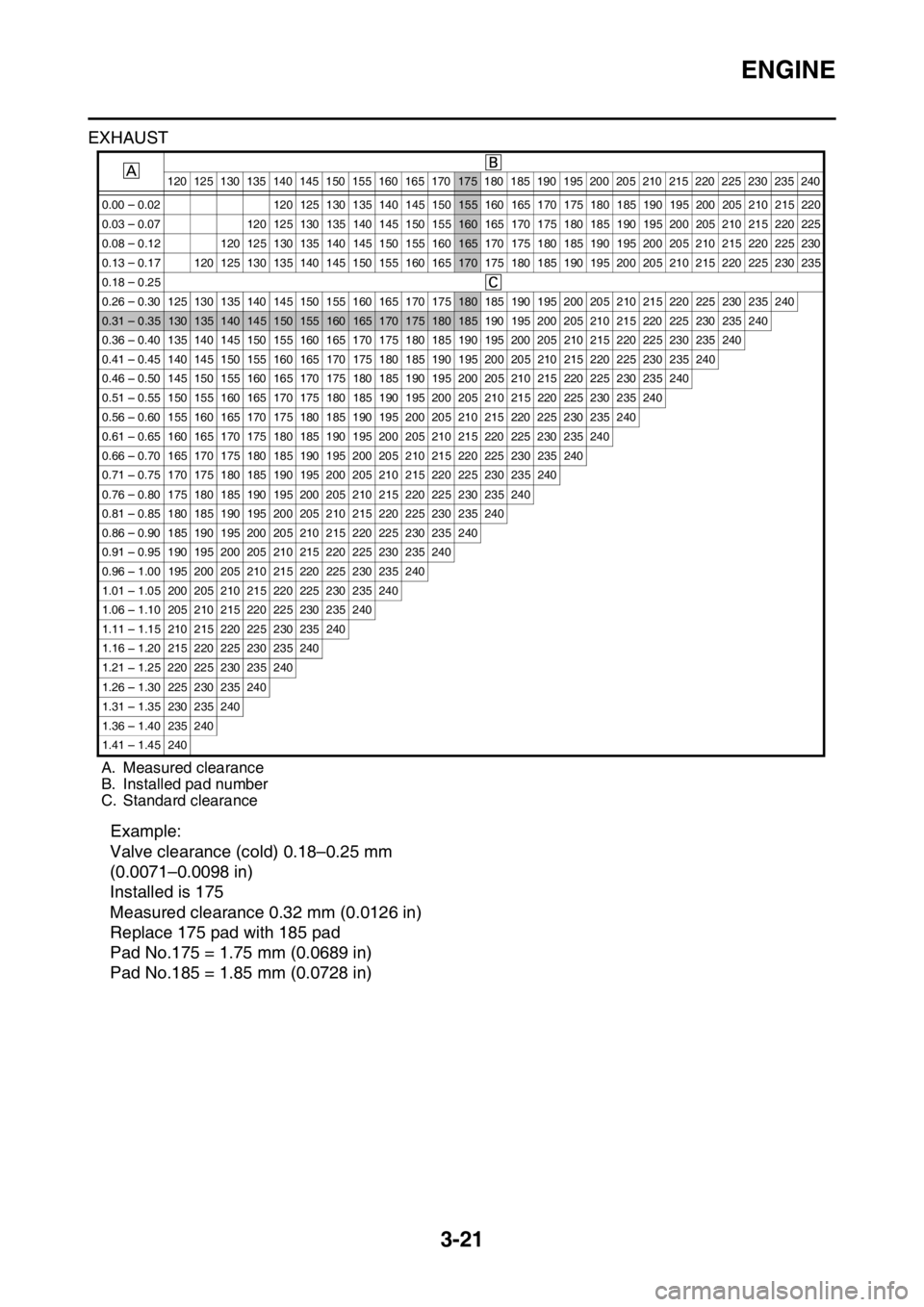

EXHAUST

Example:

Valve clearance (cold) 0.18–0.25 mm

(0.0071–0.0098 in)

Installed is 175

Measured clearance 0.32 mm (0.0126 in)

Replace 175 pad with 185 pad

Pad No.175 = 1.75 mm (0.0689 in)

Pad No.185 = 1.85 mm (0.0728 in)

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00 0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220

0.03 0.07 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.08 0.12 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.13 0.17 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.18 0.25

0.26 0.30 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.31 0.35 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.36 0.40 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.41 0.45 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.46 0.50 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.51 0.55 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.56 0.60 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.61 0.65 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.66 0.70 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.71 0.75 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.76 0.80 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.81 0.85 180 185 190 195 200 205 210 215 220 225 230 235 240

0.86 0.90 185 190 195 200 205 210 215 220 225 230 235 240

0.91 0.95 190 195 200 205 210 215 220 225 230 235 240

0.96 1.00 195 200 205 210 215 220 225 230 235 240

1.01 1.05 200 205 210 215 220 225 230 235 240

1.06 1.10 205 210 215 220 225 230 235 240

1.11 1.15 210 215 220 225 230 235 240

1.16 1.20 215 220 225 230 235 240

1.21 1.25 220 225 230 235 240

1.26 1.30 225 230 235 240

1.31 1.35 230 235 240

1.36 1.40 235 240

1.41 1.45 240

A. Measured clearance

B. Installed pad number

C. Standard clearance

Page 112 of 362

CHASSIS

3-28

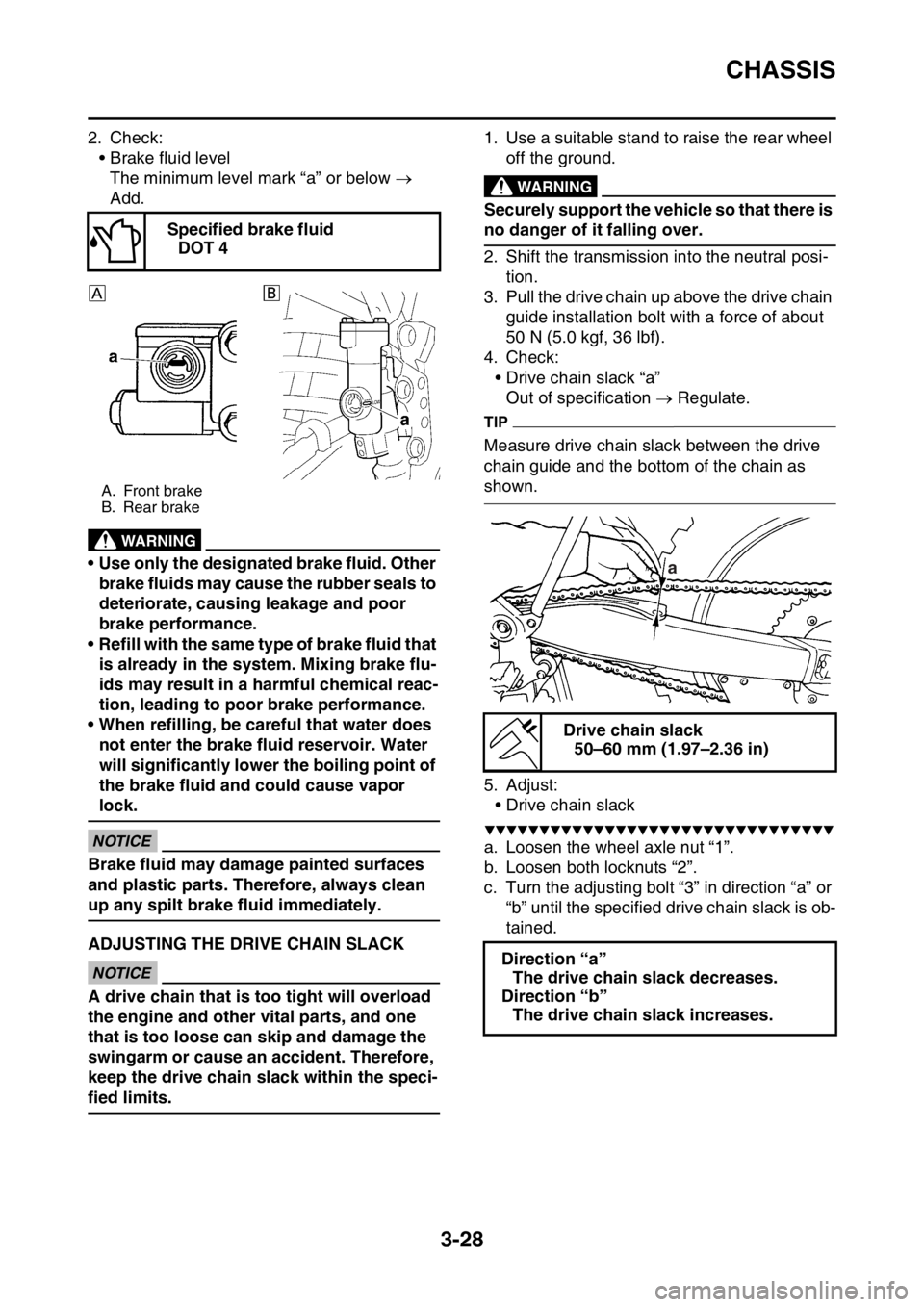

2. Check:

• Brake fluid level

The minimum level mark “a” or below

Add.

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

EASB111097ADJUSTING THE DRIVE CHAIN SLACKECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.

5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or

“b” until the specified drive chain slack is ob-

tained. Specified brake fluid

DOT 4

A. Front brake

B. Rear brake

Drive chain slack

50–60 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

a

Page 122 of 362

ELECTRICAL SYSTEM

3-38

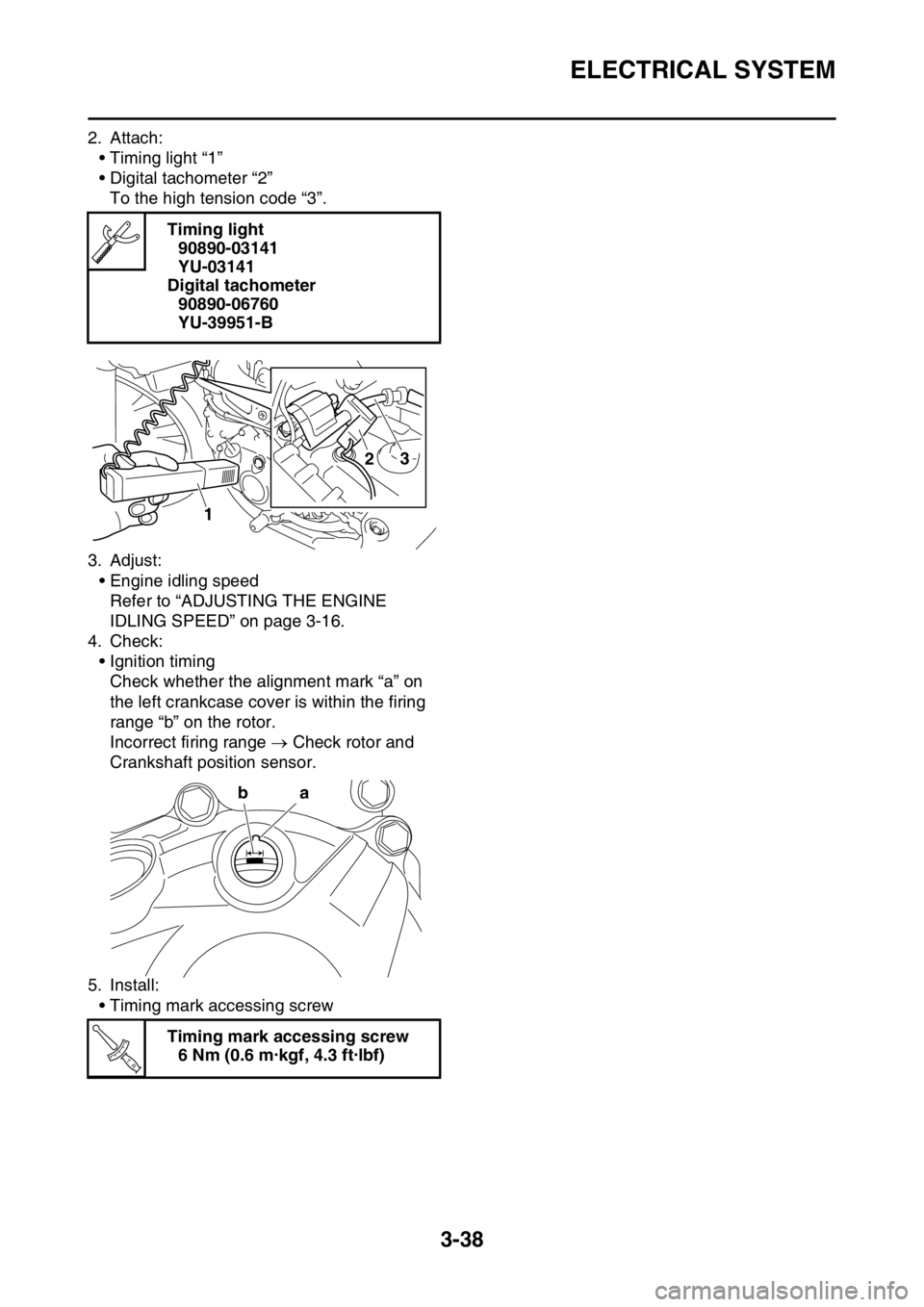

2. Attach:

• Timing light “1”

• Digital tachometer “2”

To the high tension code “3”.

3. Adjust:

• Engine idling speed

Refer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-16.

4. Check:

• Ignition timing

Check whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install:

• Timing mark accessing screwTiming light

90890-03141

YU-03141

Digital tachometer

90890-06760

YU-39951-B

Timing mark accessing screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

a

b

T R..

Page 125 of 362

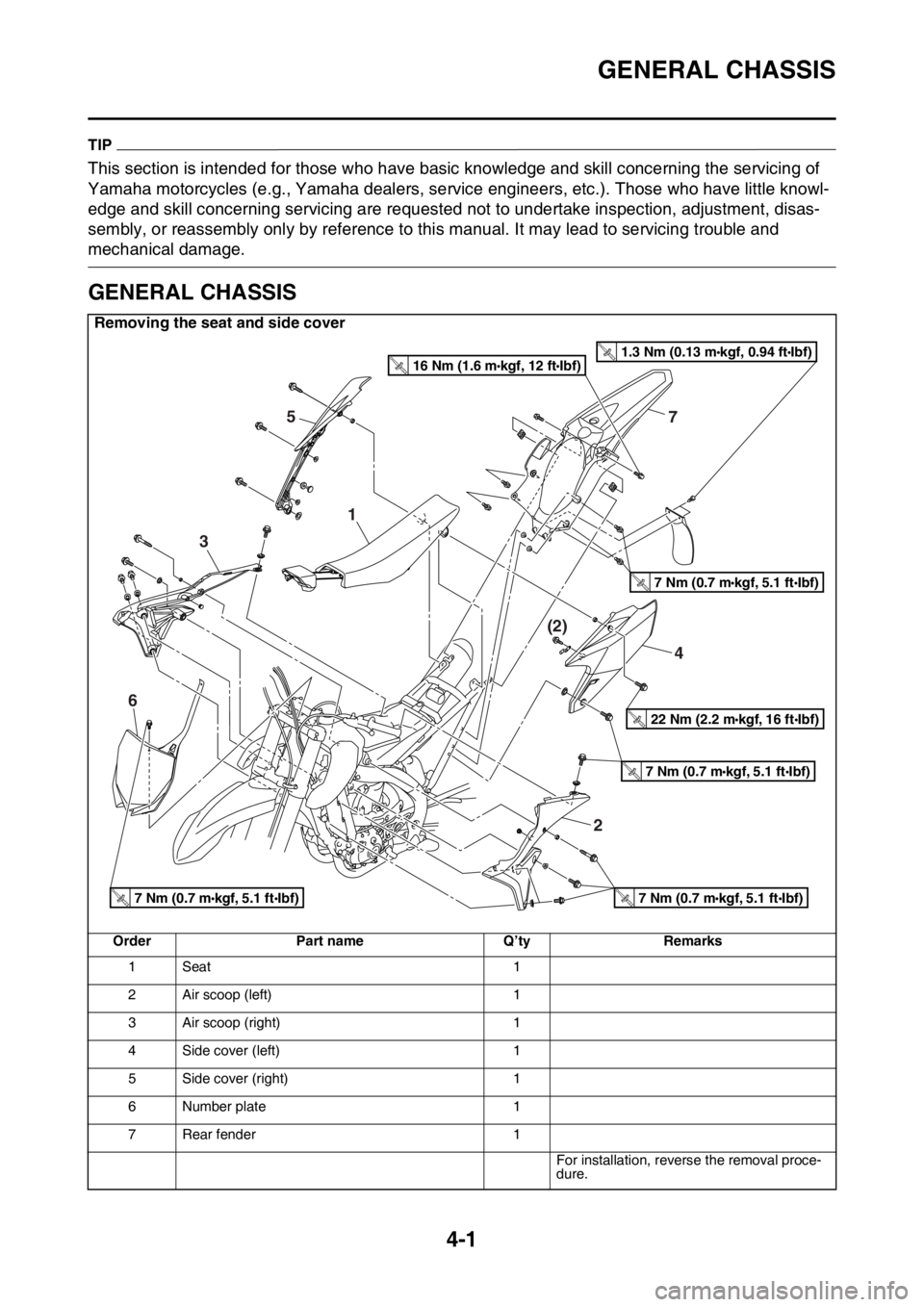

GENERAL CHASSIS

4-1

EASB111116

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EASB111117

GENERAL CHASSIS

Removing the seat and side cover

Order Part name Q’ty Remarks

1 Seat 1

2 Air scoop (left) 1

3 Air scoop (right) 1

4 Side cover (left) 1

5 Side cover (right) 1

6 Number plate 1

7 Rear fender 1

For installation, reverse the removal proce-

dure.

4 (2)

75

1

3

6

2

7 Nm (0.7 m•kgf, 5.1 ftIbf)T.R.7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

7 Nm (0.7 mkgf, 5.1 ftIbf)T.R.

22 Nm (2.2 mkgf, 16 ftIbf)T.R.

1.3 Nm (0.13 mkgf, 0.94 ftIbf)T.R.16 Nm (1.6 mkgf, 12 ftIbf)T.R.

Page 156 of 362

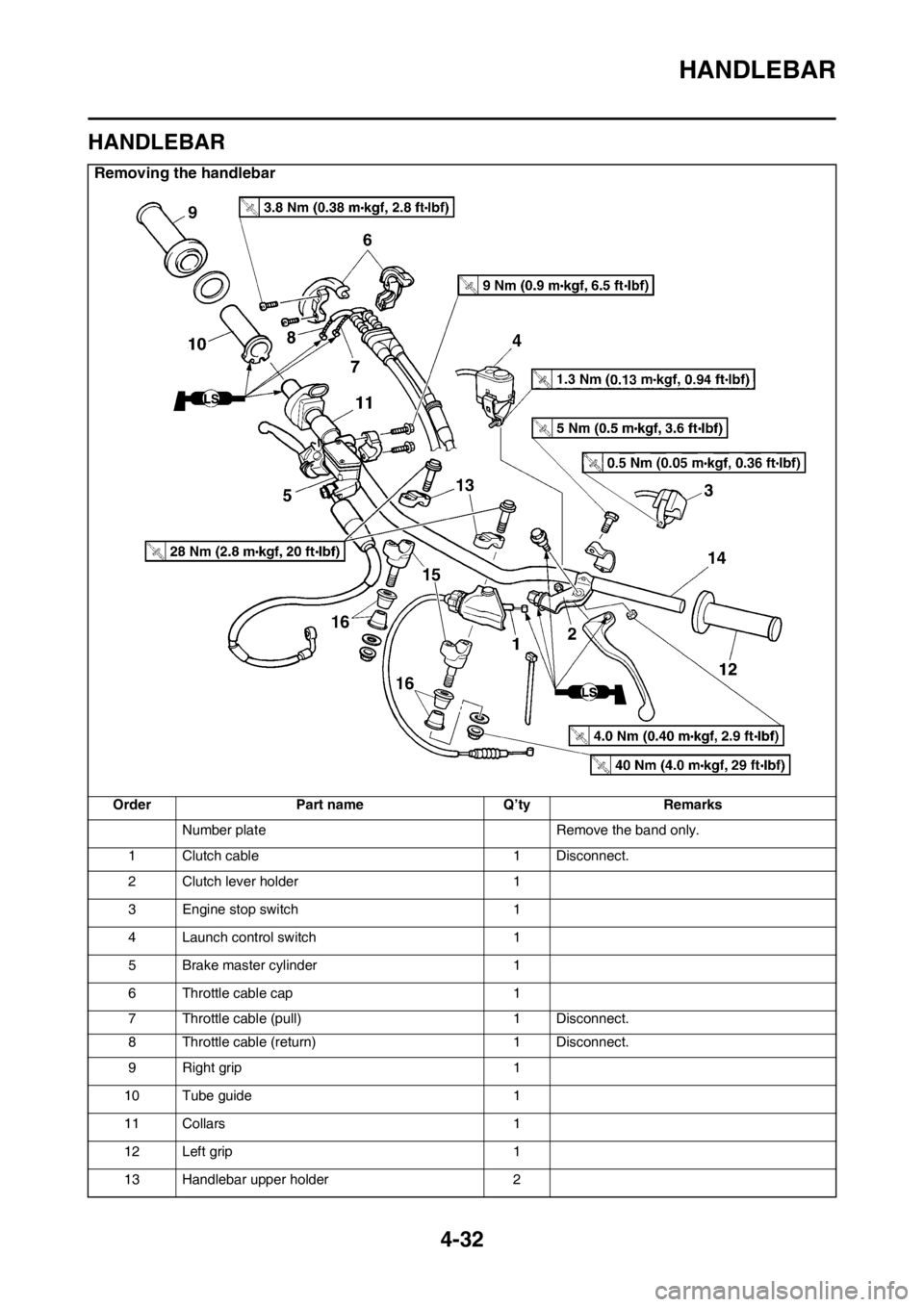

HANDLEBAR

4-32

EASB111160

HANDLEBAR

Removing the handlebar

Order Part name Q’ty Remarks

Number plate Remove the band only.

1 Clutch cable 1 Disconnect.

2 Clutch lever holder 1

3 Engine stop switch 1

4 Launch control switch 1

5 Brake master cylinder 1

6 Throttle cable cap 1

7 Throttle cable (pull) 1 Disconnect.

8 Throttle cable (return) 1 Disconnect.

9 Right grip 1

10 Tube guide 1

11 Collars 1

12 Left grip 1

13 Handlebar upper holder 2

Page 159 of 362

HANDLEBAR

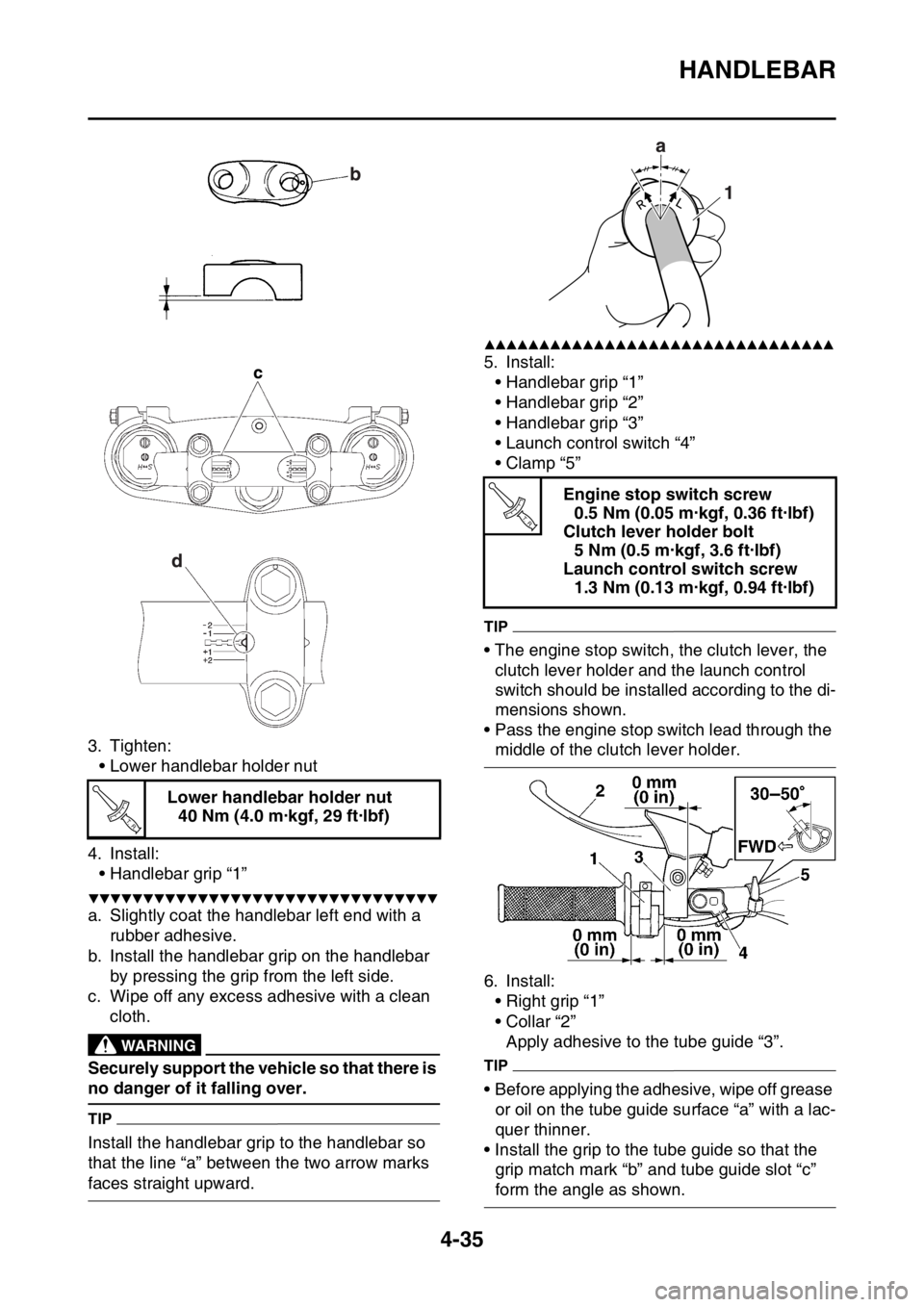

4-35

3. Tighten:

• Lower handlebar holder nut

4. Install:

• Handlebar grip “1”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly coat the handlebar left end with a

rubber adhesive.

b. Install the handlebar grip on the handlebar

by pressing the grip from the left side.

c. Wipe off any excess adhesive with a clean

cloth.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

TIP

Install the handlebar grip to the handlebar so

that the line “a” between the two arrow marks

faces straight upward.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Handlebar grip “1”

• Handlebar grip “2”

• Handlebar grip “3”

• Launch control switch “4”

•Clamp “5”

TIP

• The engine stop switch, the clutch lever, the

clutch lever holder and the launch control

switch should be installed according to the di-

mensions shown.

• Pass the engine stop switch lead through the

middle of the clutch lever holder.

6. Install:

• Right grip “1”

• Collar “2”

Apply adhesive to the tube guide “3”.

TIP

• Before applying the adhesive, wipe off grease

or oil on the tube guide surface “a” with a lac-

quer thinner.

• Install the grip to the tube guide so that the

grip match mark “b” and tube guide slot “c”

form the angle as shown. Lower handlebar holder nut

40 Nm (4.0 m·kgf, 29 ft·lbf)

T R..

Engine stop switch screw

0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Clutch lever holder bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Launch control switch screw

1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

T R..

Page 189 of 362

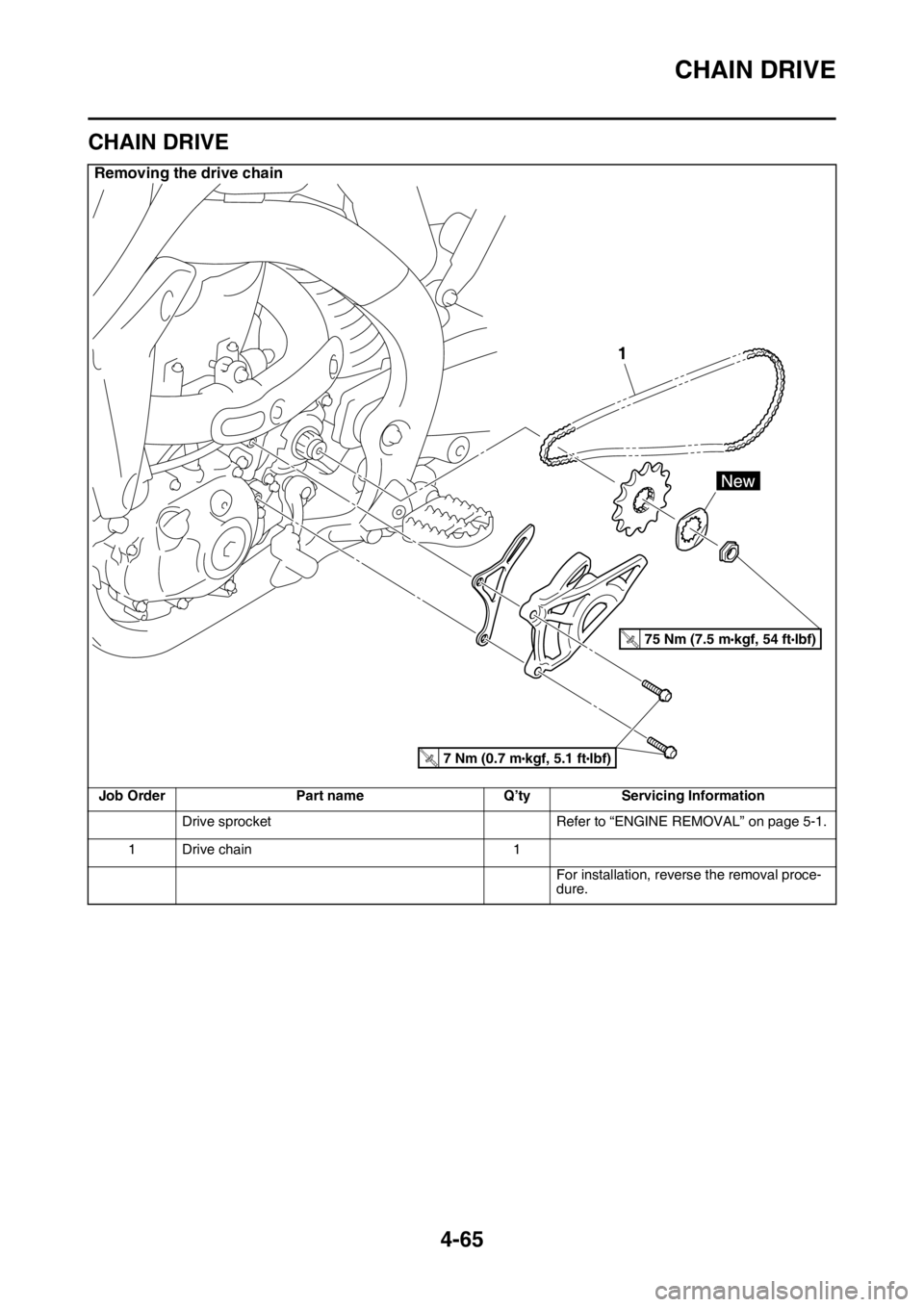

CHAIN DRIVE

4-65

EASB111188

CHAIN DRIVE

Removing the drive chain

Job Order Part name Q’ty Servicing Information

Drive sprocket Refer to “ENGINE REMOVAL” on page 5-1.

1 Drive chain 1

For installation, reverse the removal proce-

dure.

1

T.R.75 Nm (7.5 mlbf) kgf, 54 ft

T.R.7 Nm (0.7 mlbf) kgf, 5.1 ft

Page 191 of 362

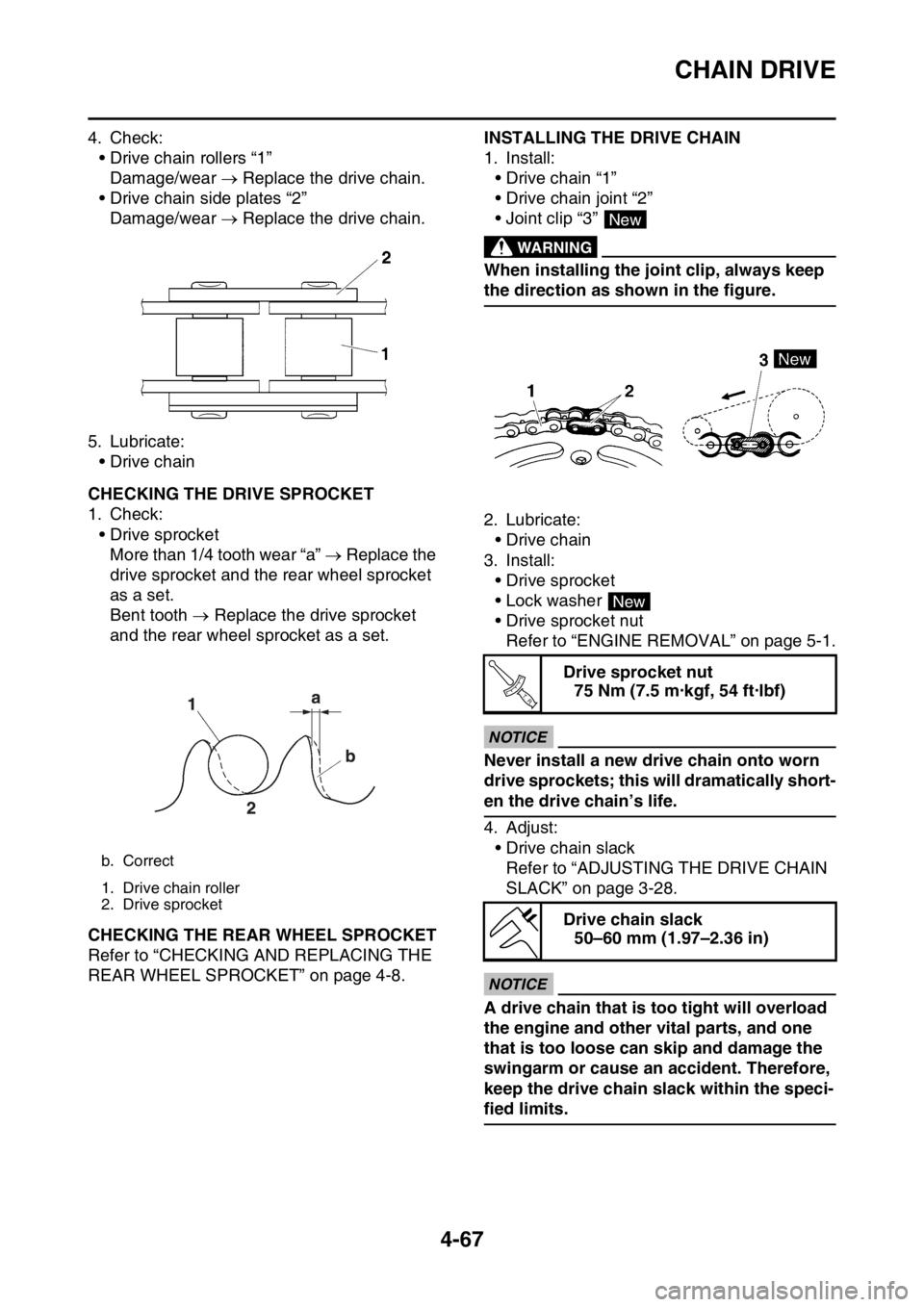

CHAIN DRIVE

4-67

4. Check:

• Drive chain rollers “1”

Damage/wear Replace the drive chain.

• Drive chain side plates “2”

Damage/wear Replace the drive chain.

5. Lubricate:

•Drive chain

EASB111191CHECKING THE DRIVE SPROCKET

1. Check:

• Drive sprocket

More than 1/4 tooth wear “a” Replace the

drive sprocket and the rear wheel sprocket

as a set.

Bent tooth Replace the drive sprocket

and the rear wheel sprocket as a set.

EASB111192CHECKING THE REAR WHEEL SPROCKET

Refer to “CHECKING AND REPLACING THE

REAR WHEEL SPROCKET” on page 4-8.

EASB111193

INSTALLING THE DRIVE CHAIN

1. Install:

• Drive chain “1”

• Drive chain joint “2”

• Joint clip “3”

EWA

WARNING

When installing the joint clip, always keep

the direction as shown in the figure.

2. Lubricate:

•Drive chain

3. Install:

• Drive sprocket

• Lock washer

• Drive sprocket nut

Refer to “ENGINE REMOVAL” on page 5-1.

ECA1DX1014

NOTICE

Never install a new drive chain onto worn

drive sprockets; this will dramatically short-

en the drive chain’s life.

4. Adjust:

• Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-28.

ECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

b. Correct

1. Drive chain roller

2. Drive sprocket

Drive sprocket nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive chain slack

50–60 mm (1.97–2.36 in)

New

New

T R..

Page 193 of 362

5

ENGINE

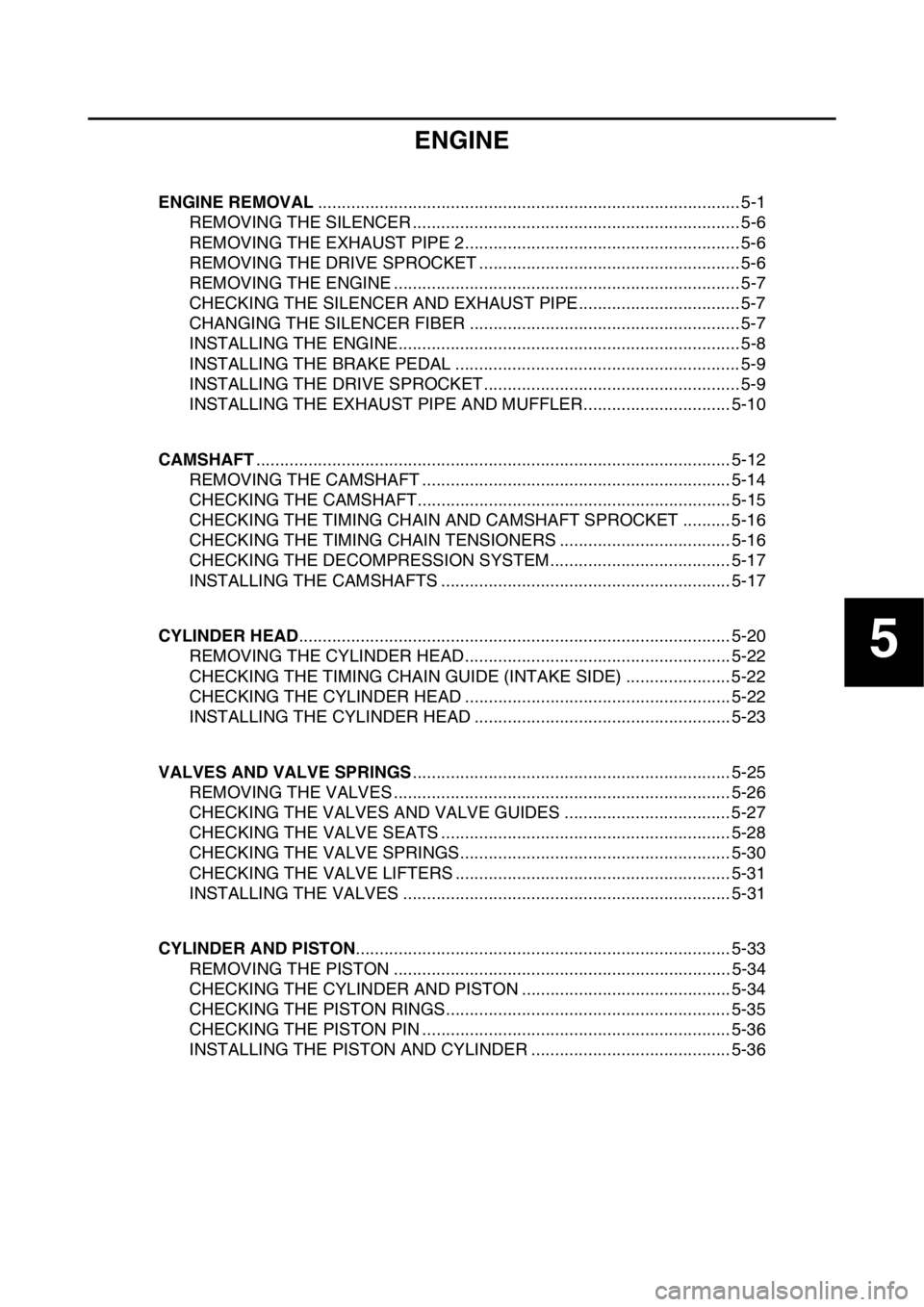

ENGINE REMOVAL......................................................................................... 5-1

REMOVING THE SILENCER ..................................................................... 5-6

REMOVING THE EXHAUST PIPE 2.......................................................... 5-6

REMOVING THE DRIVE SPROCKET ....................................................... 5-6

REMOVING THE ENGINE ......................................................................... 5-7

CHECKING THE SILENCER AND EXHAUST PIPE.................................. 5-7

CHANGING THE SILENCER FIBER ......................................................... 5-7

INSTALLING THE ENGINE........................................................................ 5-8

INSTALLING THE BRAKE PEDAL ............................................................ 5-9

INSTALLING THE DRIVE SPROCKET...................................................... 5-9

INSTALLING THE EXHAUST PIPE AND MUFFLER............................... 5-10

CAMSHAFT.................................................................................................... 5-12

REMOVING THE CAMSHAFT ................................................................. 5-14

CHECKING THE CAMSHAFT.................................................................. 5-15

CHECKING THE TIMING CHAIN AND CAMSHAFT SPROCKET .......... 5-16

CHECKING THE TIMING CHAIN TENSIONERS .................................... 5-16

CHECKING THE DECOMPRESSION SYSTEM...................................... 5-17

INSTALLING THE CAMSHAFTS ............................................................. 5-17

CYLINDER HEAD........................................................................................... 5-20

REMOVING THE CYLINDER HEAD........................................................ 5-22

CHECKING THE TIMING CHAIN GUIDE (INTAKE SIDE) ...................... 5-22

CHECKING THE CYLINDER HEAD ........................................................ 5-22

INSTALLING THE CYLINDER HEAD ...................................................... 5-23

VALVES AND VALVE SPRINGS................................................................... 5-25

REMOVING THE VALVES ....................................................................... 5-26

CHECKING THE VALVES AND VALVE GUIDES ................................... 5-27

CHECKING THE VALVE SEATS ............................................................. 5-28

CHECKING THE VALVE SPRINGS......................................................... 5-30

CHECKING THE VALVE LIFTERS .......................................................... 5-31

INSTALLING THE VALVES ..................................................................... 5-31

CYLINDER AND PISTON............................................................................... 5-33

REMOVING THE PISTON ....................................................................... 5-34

CHECKING THE CYLINDER AND PISTON ............................................ 5-34

CHECKING THE PISTON RINGS............................................................ 5-35

CHECKING THE PISTON PIN ................................................................. 5-36

INSTALLING THE PISTON AND CYLINDER .......................................... 5-36

Page 196 of 362

ENGINE REMOVAL

5-1

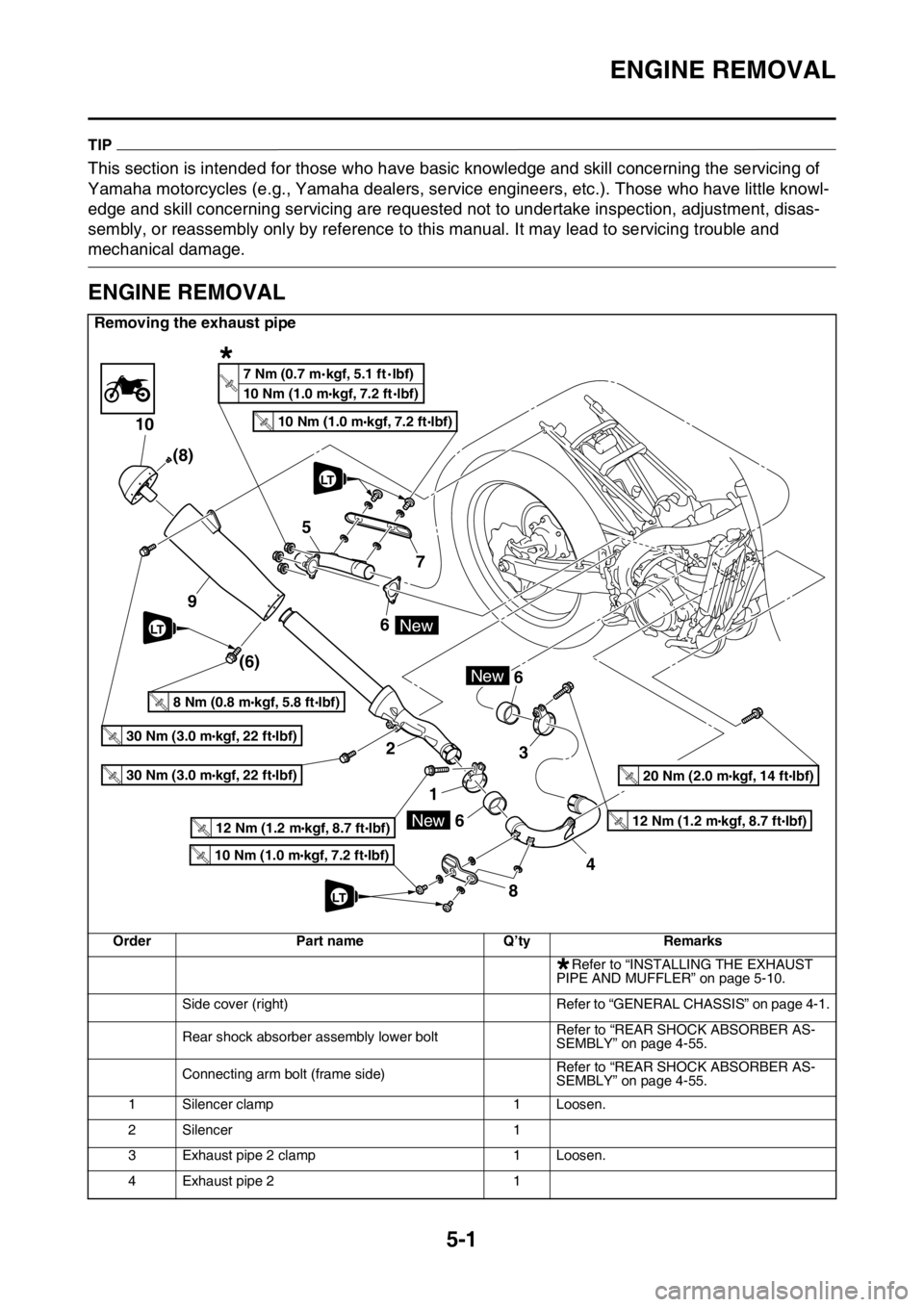

EASB111194

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EASB111195

ENGINE REMOVAL

Removing the exhaust pipe

Order Part name Q’ty Remarks

Refer to “INSTALLING THE EXHAUST

PIPE AND MUFFLER” on page 5-10.

Side cover (right) Refer to “GENERAL CHASSIS” on page 4-1.

Rear shock absorber assembly lower boltRefer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-55.

Connecting arm bolt (frame side)Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-55.

1 Silencer clamp 1 Loosen.

2 Silencer 1

3 Exhaust pipe 2 clamp 1 Loosen.

4 Exhaust pipe 2 1

10

5

9

2 6

1

66

3

84 7 (8)

(6)

30 Nm (3.0 m kgf, 22 ft Ibf)T

.R.

30 Nm (3.0 m kgf, 22 ft Ibf)T

.R.

8 Nm (0.8 m kgf, 5.8 ft Ibf)T

.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

New

New

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

20 Nm (2.0 m kgf, 14 ft Ibf)T

.R.

New

7 Nm (0.7 m kgf, 5.1 ft lbf)

10 Nm (1.0 m kgf, 7.2 ft lbf)T

.R.

LT

LT

LT

*

*