engine YAMAHA YZ85 2002 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 462 of 504

7 - 1

TUN

EC700000

TUNING

EC710000

ENGINE

Carburetor setting

lThe role of fuel is to cool the engine, and in

the case of a 2-stroke engine, to lubricate the

engine in addition to power generation.

Accordingly, if a mixture of air and fuel is too

lean, abnormal combustion will occur, and

engine seizure may result. If the mixture is

too rich, spark plugs will get wet with oil, thus

making it impossible to bring the engine into

full play or if the worst comes to the worst,

the engine may stall.

lThe richness of the air-fuel mixture required

for the engine will vary with atmospheric con-

ditions of the day and therefore, the settings

of the carburetor must be properly suited to

the atmospheric conditions (air pressure,

humidity and temperature).

lFinally, the rider himself must make a test

run and check his machine for conditions

(pick-up of engine speed, road surface con-

ditions) and for the discoloration of the spark

plug(s).

After taking these into consideration, he must

select the best possible carburetor settings.

* It is advisable to make a note of settings,

atmospheric conditions, road surface condi-

tion, lap-time, etc. so that the memorandum

can be used as a reference useful for future.

Atmospheric conditions and carburetor

settings

The air density (i.e., concentration of oxygen

in the air) determines the richness or lean-

ness of the air/fuel mixture. Therefore, refer

to the above table for mixture settings.

Air temp. HumidityAir

pressure

(altitude)Mixture Setting

High High Low (high) Richer Leaner

Low Low High (low) Leaner Richer

SETTING

7

Page 464 of 504

7 - 2

TUN

That is:

lHigher temperature expands the air with its

resultant reduced density.

lHigher humidity reduces the amount of oxy-

gen in the air by so much of the water vapor

in the same air.

lLower atmospheric pressure (at a high alti-

tude) reduces the density of the air.

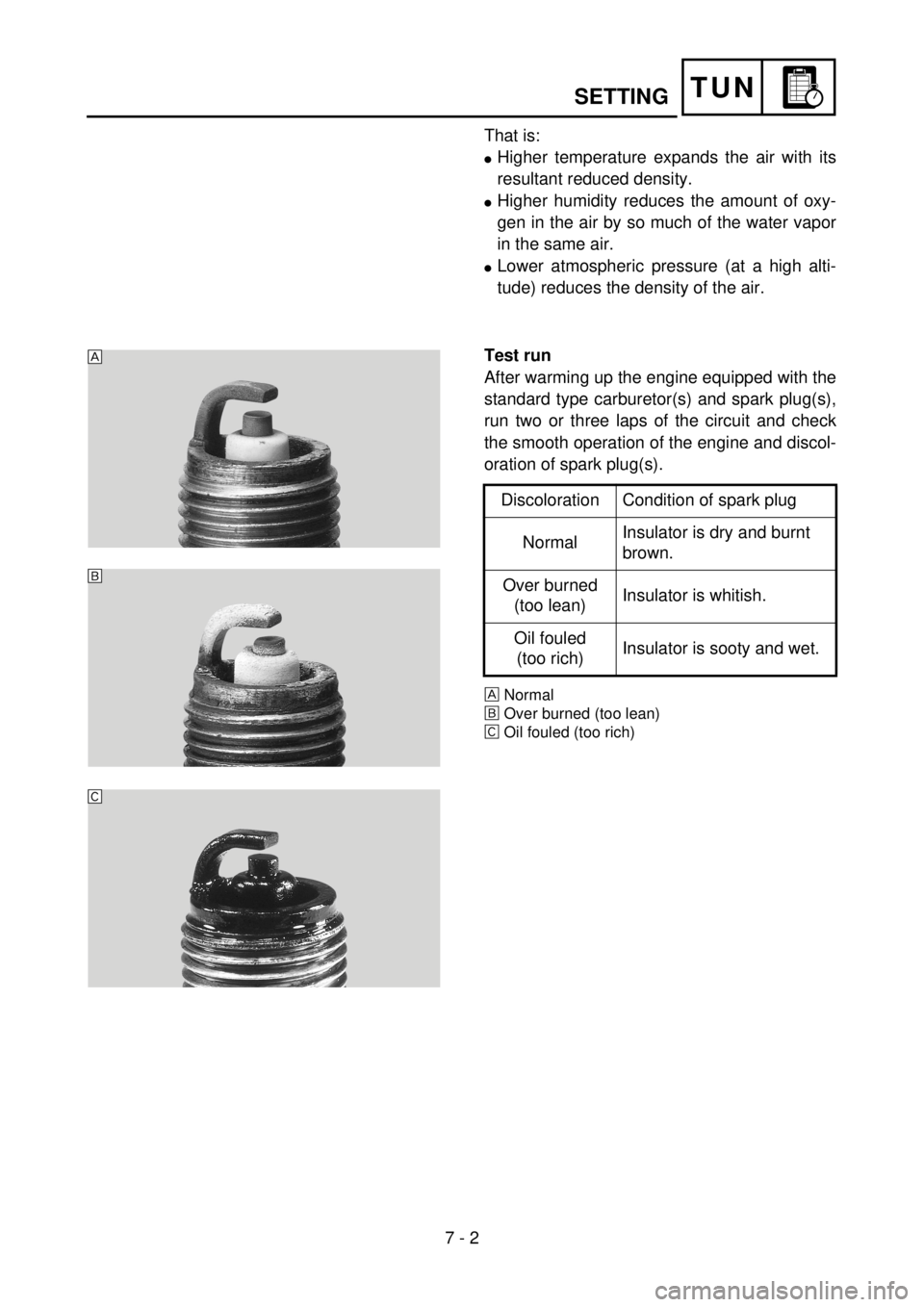

Test run

After warming up the engine equipped with the

standard type carburetor(s) and spark plug(s),

run two or three laps of the circuit and check

the smooth operation of the engine and discol-

oration of spark plug(s).

ÈNormal

ÉOver burned (too lean)

ÊOil fouled (too rich)

Discoloration Condition of spark plug

NormalInsulator is dry and burnt

brown.

Over burned

(too lean)Insulator is whitish.

Oil fouled

(too rich)Insulator is sooty and wet.

5PA70010

È

É

Ê

SETTING

Page 470 of 504

7 - 5

TUNSETTING

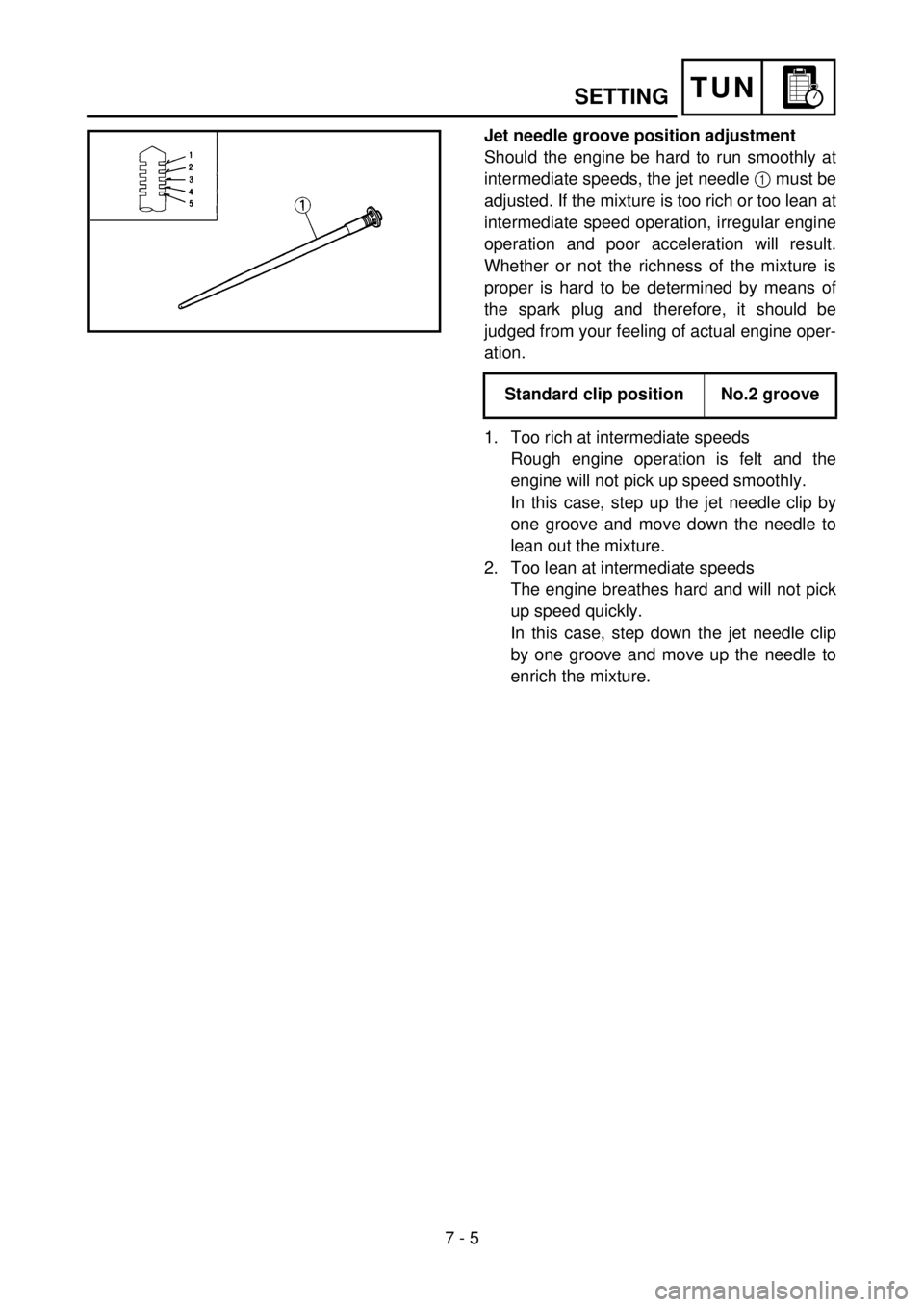

Jet needle groove position adjustment

Should the engine be hard to run smoothly at

intermediate speeds, the jet needle 1 must be

adjusted. If the mixture is too rich or too lean at

intermediate speed operation, irregular engine

operation and poor acceleration will result.

Whether or not the richness of the mixture is

proper is hard to be determined by means of

the spark plug and therefore, it should be

judged from your feeling of actual engine oper-

ation.

1. Too rich at intermediate speeds

Rough engine operation is felt and the

engine will not pick up speed smoothly.

In this case, step up the jet needle clip by

one groove and move down the needle to

lean out the mixture.

2. Too lean at intermediate speeds

The engine breathes hard and will not pick

up speed quickly.

In this case, step down the jet needle clip

by one groove and move up the needle to

enrich the mixture. Standard clip position No.2 groove

5PA70090

Page 474 of 504

7 - 7

TUN

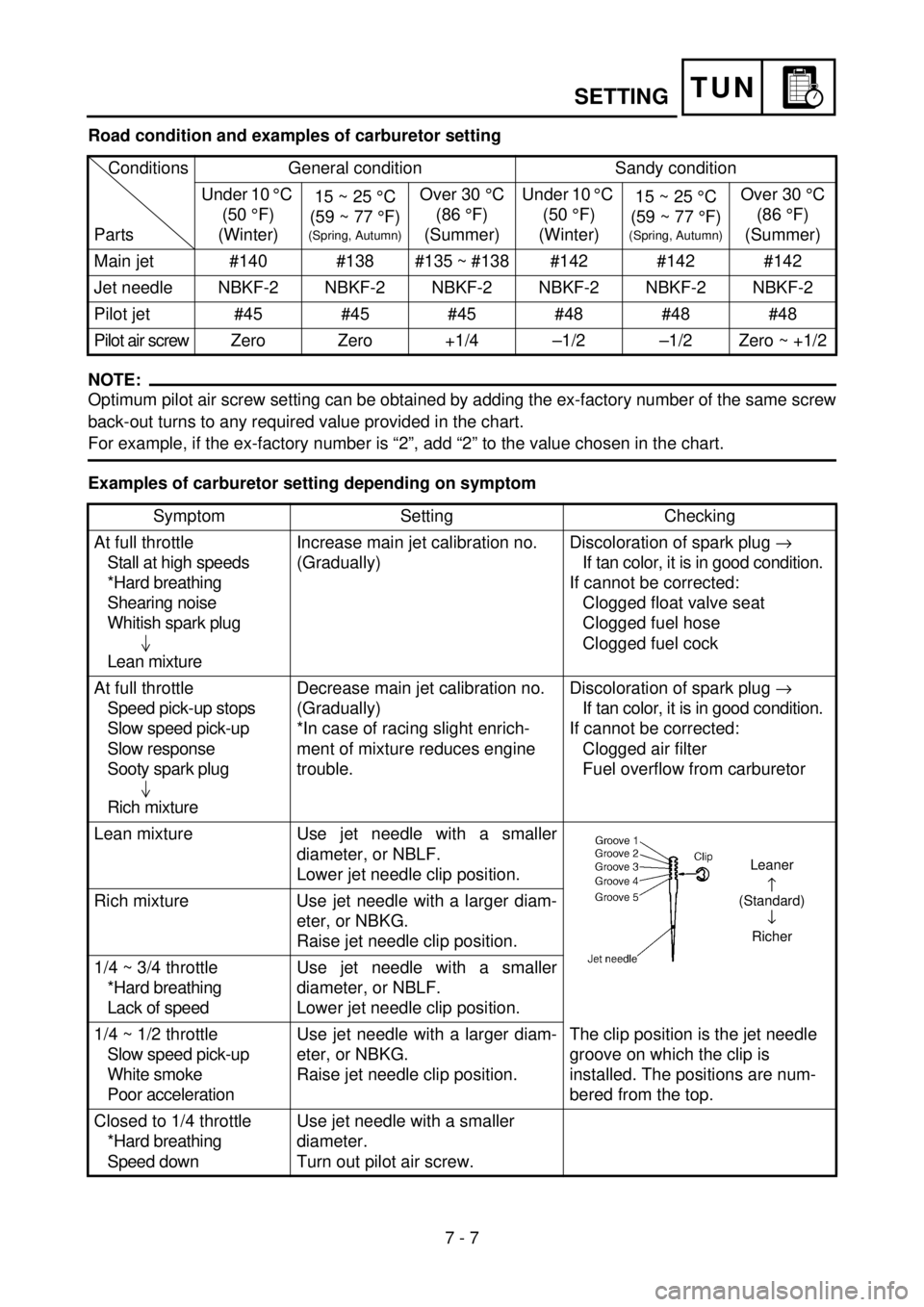

Road condition and examples of carburetor setting

NOTE:

Optimum pilot air screw setting can be obtained by adding the ex-factory number of the same screw

back-out turns to any required value provided in the chart.

For example, if the ex-factory number is “2”, add “2” to the value chosen in the chart.

Examples of carburetor setting depending on symptomConditions

PartsGeneral condition Sandy condition

Under 10 °C

(50 °F)

(Winter)15 ~ 25 °C

(59 ~ 77 °F)

(Spring, Autumn)

Over 30 °C

(86 °F)

(Summer)Under 10 °C

(50 °F)

(Winter)15 ~ 25 °C

(59 ~ 77 °F)

(Spring, Autumn)

Over 30 °C

(86 °F)

(Summer)

Main jet #140 #138 #135 ~ #138 #142 #142 #142

Jet needle NBKF-2 NBKF-2 NBKF-2 NBKF-2 NBKF-2 NBKF-2

Pilot jet #45 #45 #45 #48 #48 #48

Pilot air screw Zero Zero +1/4 –1/2 –1/2 Zero ~ +1/2

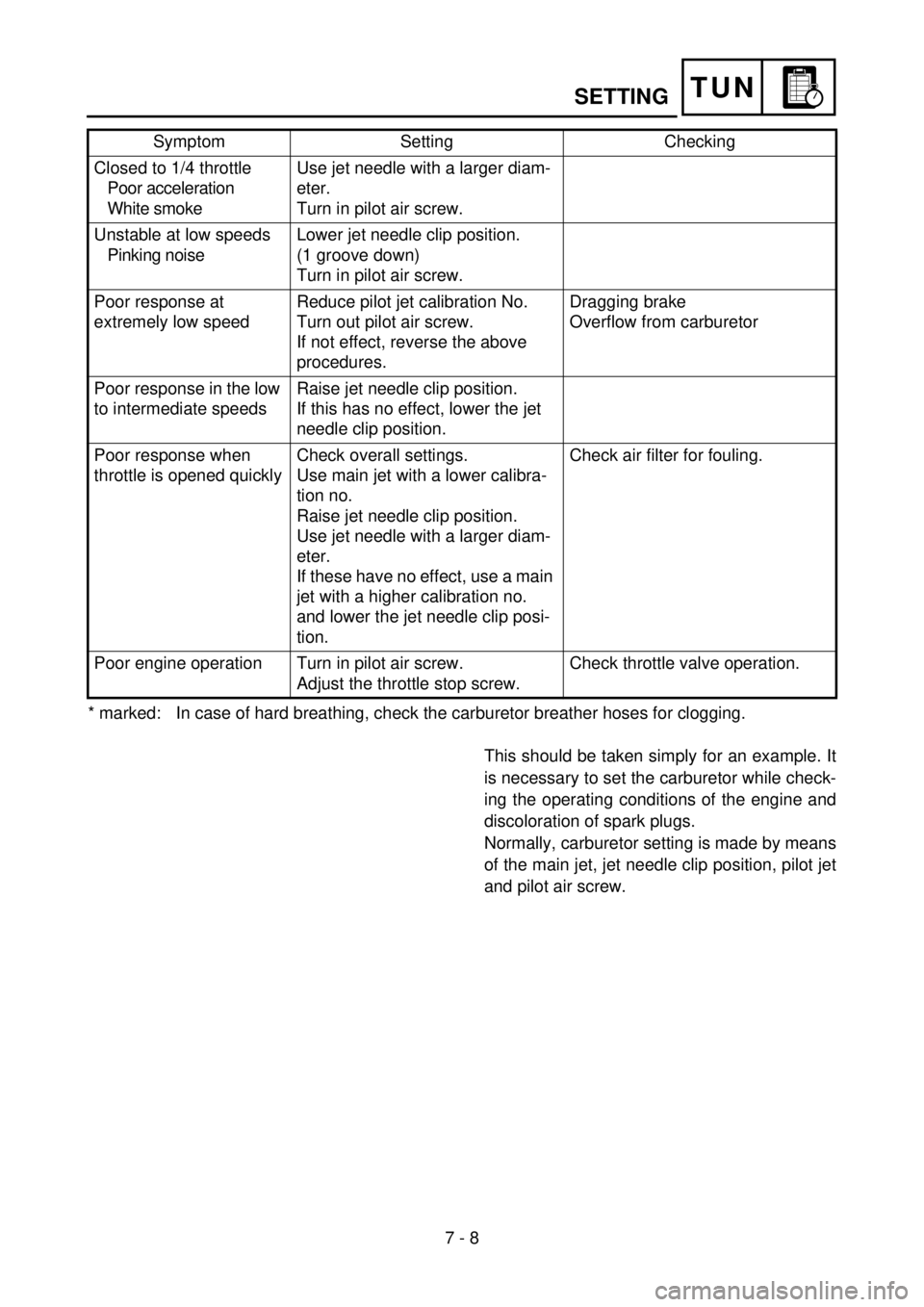

Symptom Setting Checking

At full throttle

Stall at high speeds

*Hard breathing

Shearing noise

Whitish spark plug

Lean mixtureIncrease main jet calibration no.

(Gradually)Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

At full throttle

Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug

Rich mixtureDecrease main jet calibration no.

(Gradually)

*In case of racing slight enrich-

ment of mixture reduces engine

trouble.Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged air filter

Fuel overflow from carburetor

Lean mixture Use jet needle with a smaller

diameter, or NBLF.

Lower jet needle clip position.

The clip position is the jet needle

groove on which the clip is

installed. The positions are num-

bered from the top. Rich mixture Use jet needle with a larger diam-

eter, or NBKG.

Raise jet needle clip position.

1/4 ~ 3/4 throttle

*Hard breathing

Lack of speedUse jet needle with a smaller

diameter, or NBLF.

Lower jet needle clip position.

1/4 ~ 1/2 throttle

Slow speed pick-up

White smoke

Poor accelerationUse jet needle with a larger diam-

eter, or NBKG.

Raise jet needle clip position.

Closed to 1/4 throttle

*Hard breathing

Speed downUse jet needle with a smaller

diameter.

Turn out pilot air screw.

Leaner

(Standard)

¯

Richer

SETTING

Page 475 of 504

7 - 8

TUN

* marked: In case of hard breathing, check the carburetor breather hoses for clogging. Closed to 1/4 throttle

Poor acceleration

White smokeUse jet needle with a larger diam-

eter.

Turn in pilot air screw.

Unstable at low speeds

Pinking noiseLower jet needle clip position.

(1 groove down)

Turn in pilot air screw.

Poor response at

extremely low speedReduce pilot jet calibration No.

Turn out pilot air screw.

If not effect, reverse the above

procedures.Dragging brake

Overflow from carburetor

Poor response in the low

to intermediate speedsRaise jet needle clip position.

If this has no effect, lower the jet

needle clip position.

Poor response when

throttle is opened quicklyCheck overall settings.

Use main jet with a lower calibra-

tion no.

Raise jet needle clip position.

Use jet needle with a larger diam-

eter.

If these have no effect, use a main

jet with a higher calibration no.

and lower the jet needle clip posi-

tion.Check air filter for fouling.

Poor engine operation Turn in pilot air screw.

Adjust the throttle stop screw.Check throttle valve operation. Symptom Setting Checking

This should be taken simply for an example. It

is necessary to set the carburetor while check-

ing the operating conditions of the engine and

discoloration of spark plugs.

Normally, carburetor setting is made by means

of the main jet, jet needle clip position, pilot jet

and pilot air screw.

SETTING

Page 480 of 504

7 - 9

TUNSETTING

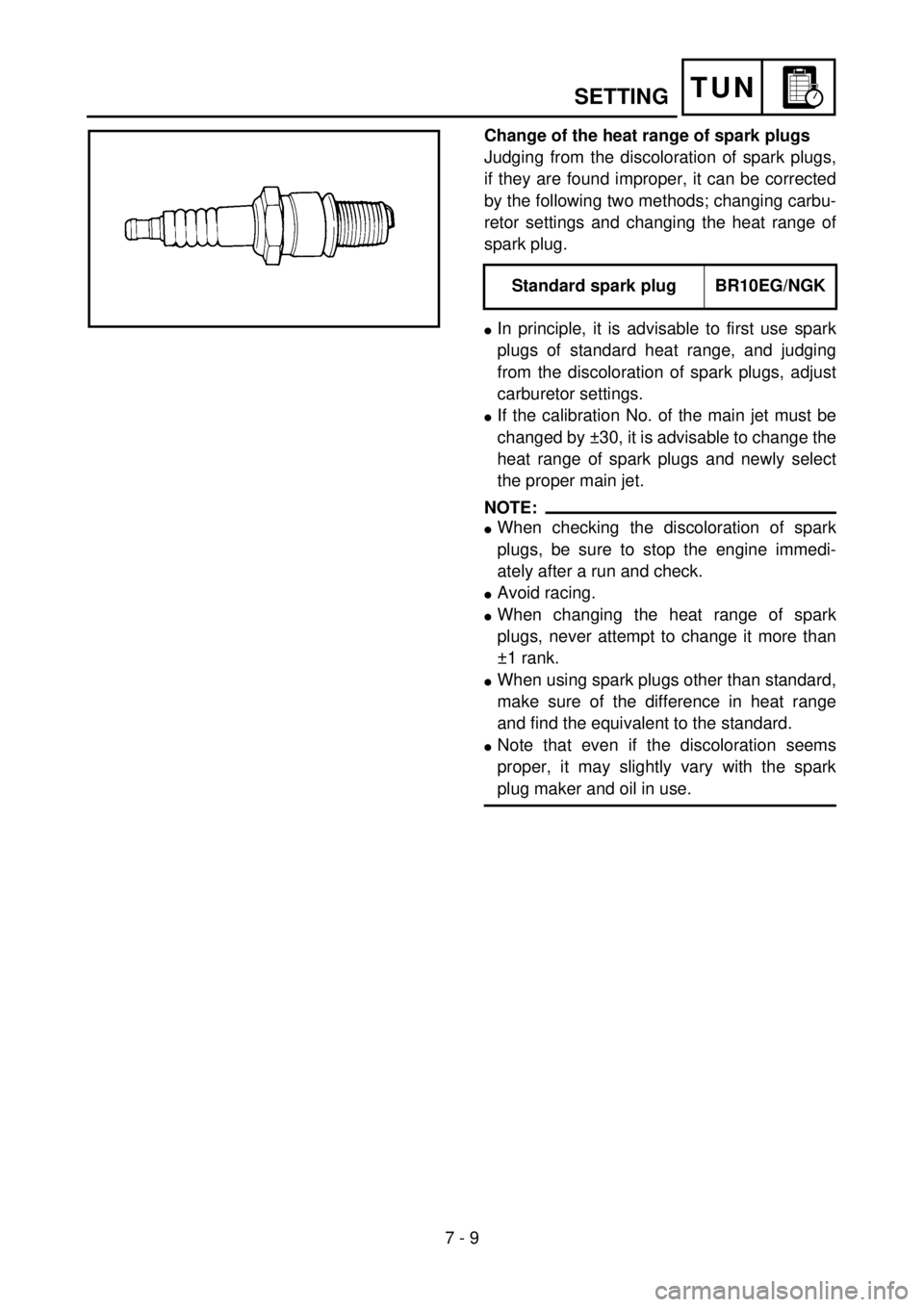

Change of the heat range of spark plugs

Judging from the discoloration of spark plugs,

if they are found improper, it can be corrected

by the following two methods; changing carbu-

retor settings and changing the heat range of

spark plug.

lIn principle, it is advisable to first use spark

plugs of standard heat range, and judging

from the discoloration of spark plugs, adjust

carburetor settings.

lIf the calibration No. of the main jet must be

changed by ±30, it is advisable to change the

heat range of spark plugs and newly select

the proper main jet.

NOTE:

lWhen checking the discoloration of spark

plugs, be sure to stop the engine immedi-

ately after a run and check.

lAvoid racing.

lWhen changing the heat range of spark

plugs, never attempt to change it more than

±1 rank.

lWhen using spark plugs other than standard,

make sure of the difference in heat range

and find the equivalent to the standard.

lNote that even if the discoloration seems

proper, it may slightly vary with the spark

plug maker and oil in use.Standard spark plug BR10EG/NGK

5PA70110

Page 482 of 504

7 - 10

TUNSETTING

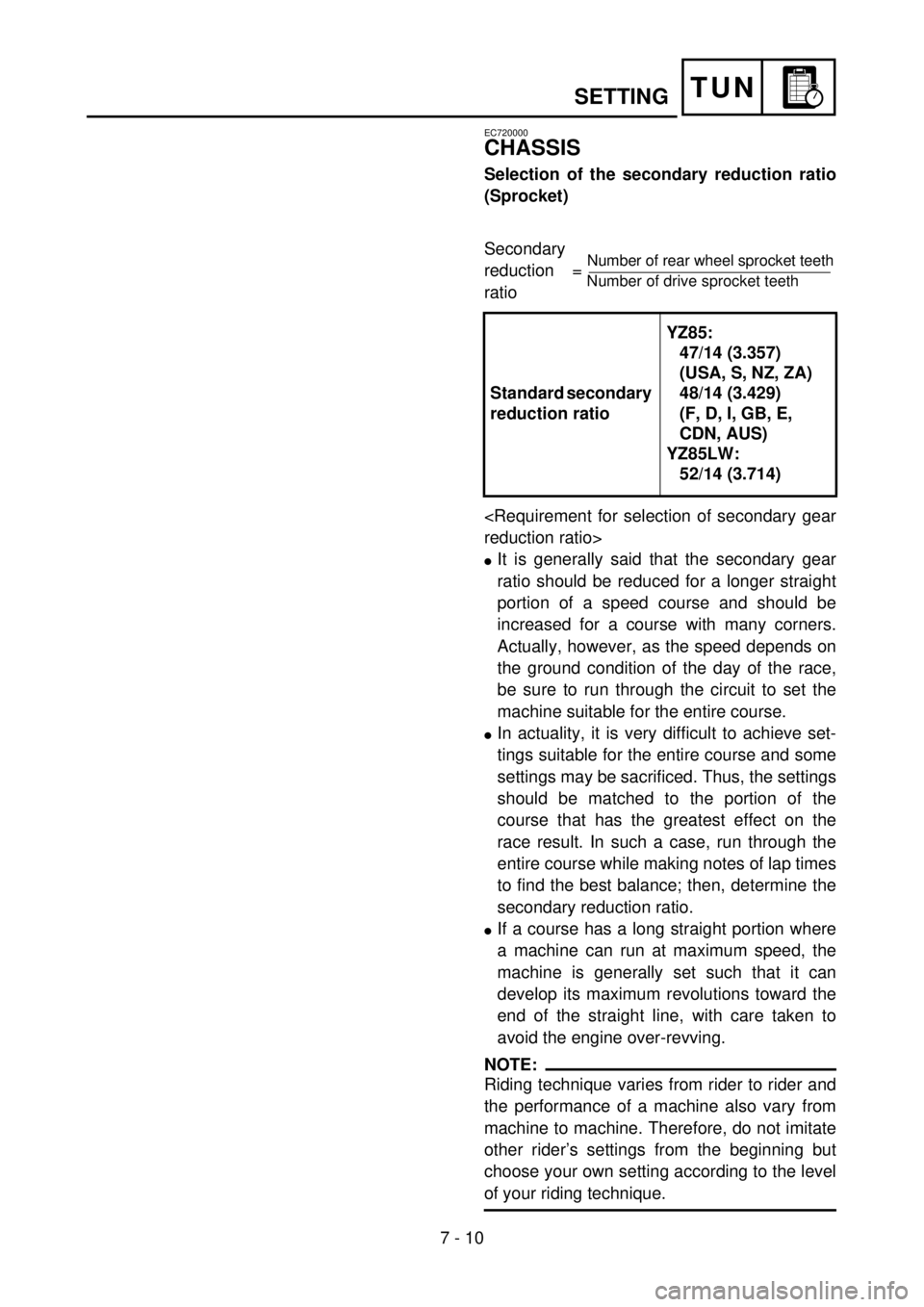

EC720000

CHASSIS

Selection of the secondary reduction ratio

(Sprocket)

Secondary

reduction =

ratio

lIt is generally said that the secondary gear

ratio should be reduced for a longer straight

portion of a speed course and should be

increased for a course with many corners.

Actually, however, as the speed depends on

the ground condition of the day of the race,

be sure to run through the circuit to set the

machine suitable for the entire course.

lIn actuality, it is very difficult to achieve set-

tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the

race result. In such a case, run through the

entire course while making notes of lap times

to find the best balance; then, determine the

secondary reduction ratio.

lIf a course has a long straight portion where

a machine can run at maximum speed, the

machine is generally set such that it can

develop its maximum revolutions toward the

end of the straight line, with care taken to

avoid the engine over-revving.

NOTE:

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider’s settings from the beginning but

choose your own setting according to the level

of your riding technique.Standard secondary

reduction ratioYZ85:

47/14 (3.357)

(USA, S, NZ, ZA)

48/14 (3.429)

(F, D, I, GB, E,

CDN, AUS)

YZ85LW:

52/14 (3.714)

Number of rear wheel sprocket teeth

Number of drive sprocket teeth

Page 492 of 504

7 - 15

TUNSETTING

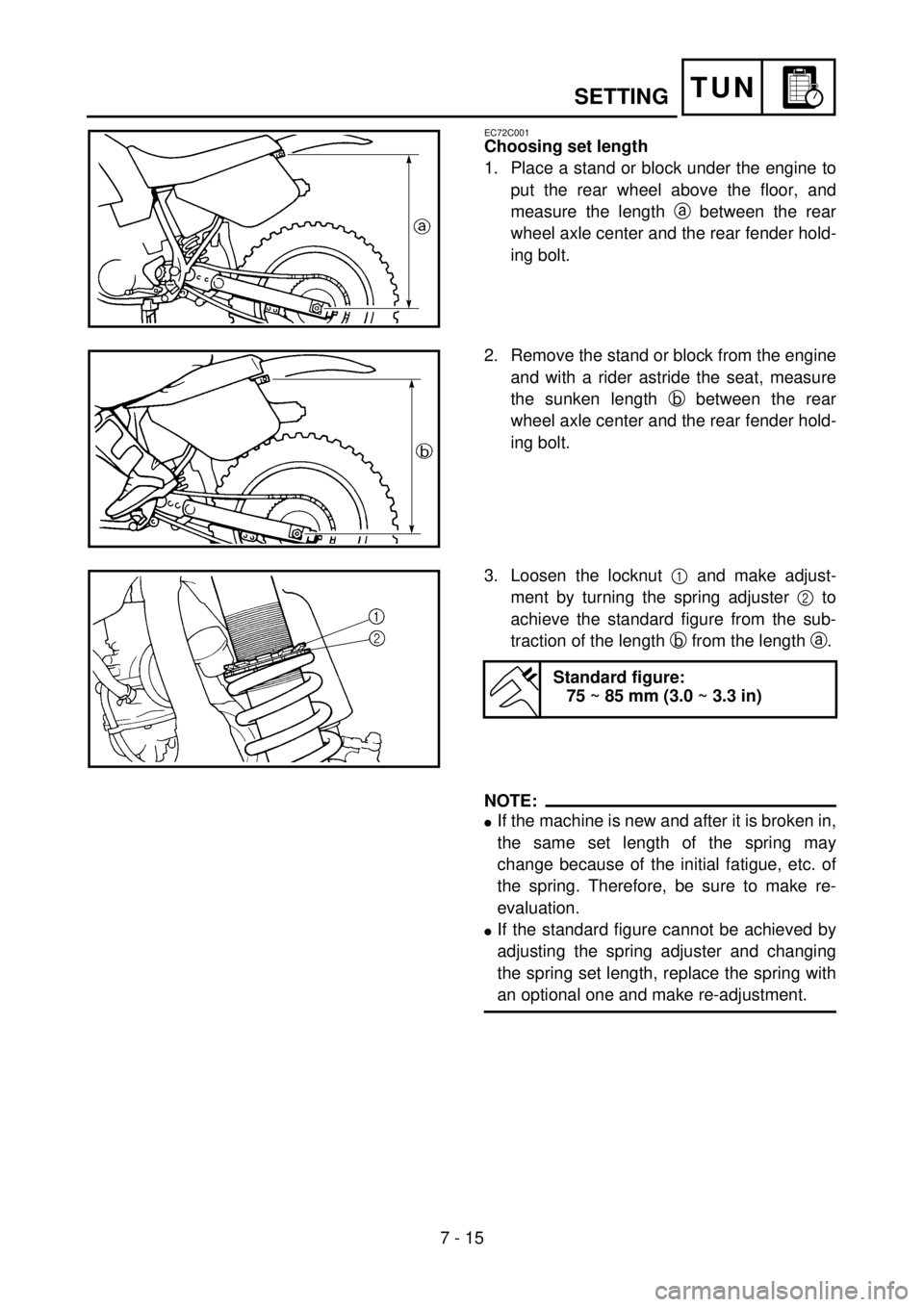

EC72C001

Choosing set length

1. Place a stand or block under the engine to

put the rear wheel above the floor, and

measure the length a between the rear

wheel axle center and the rear fender hold-

ing bolt.

5PA70160

2. Remove the stand or block from the engine

and with a rider astride the seat, measure

the sunken length b between the rear

wheel axle center and the rear fender hold-

ing bolt.

5PA70170

3. Loosen the locknut 1 and make adjust-

ment by turning the spring adjuster 2 to

achieve the standard figure from the sub-

traction of the length b from the length a.

Standard figure:

75 ~ 85 mm (3.0 ~ 3.3 in)

5PA70180

NOTE:

lIf the machine is new and after it is broken in,

the same set length of the spring may

change because of the initial fatigue, etc. of

the spring. Therefore, be sure to make re-

evaluation.

lIf the standard figure cannot be achieved by

adjusting the spring adjuster and changing

the spring set length, replace the spring with

an optional one and make re-adjustment.