engine YAMAHA YZ85 2002 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 140 of 504

3 - 10

INSP

ADJTHROTTLE CABLE ADJUSTMENT/

THROTTLE LUBRICATION

EC35A001

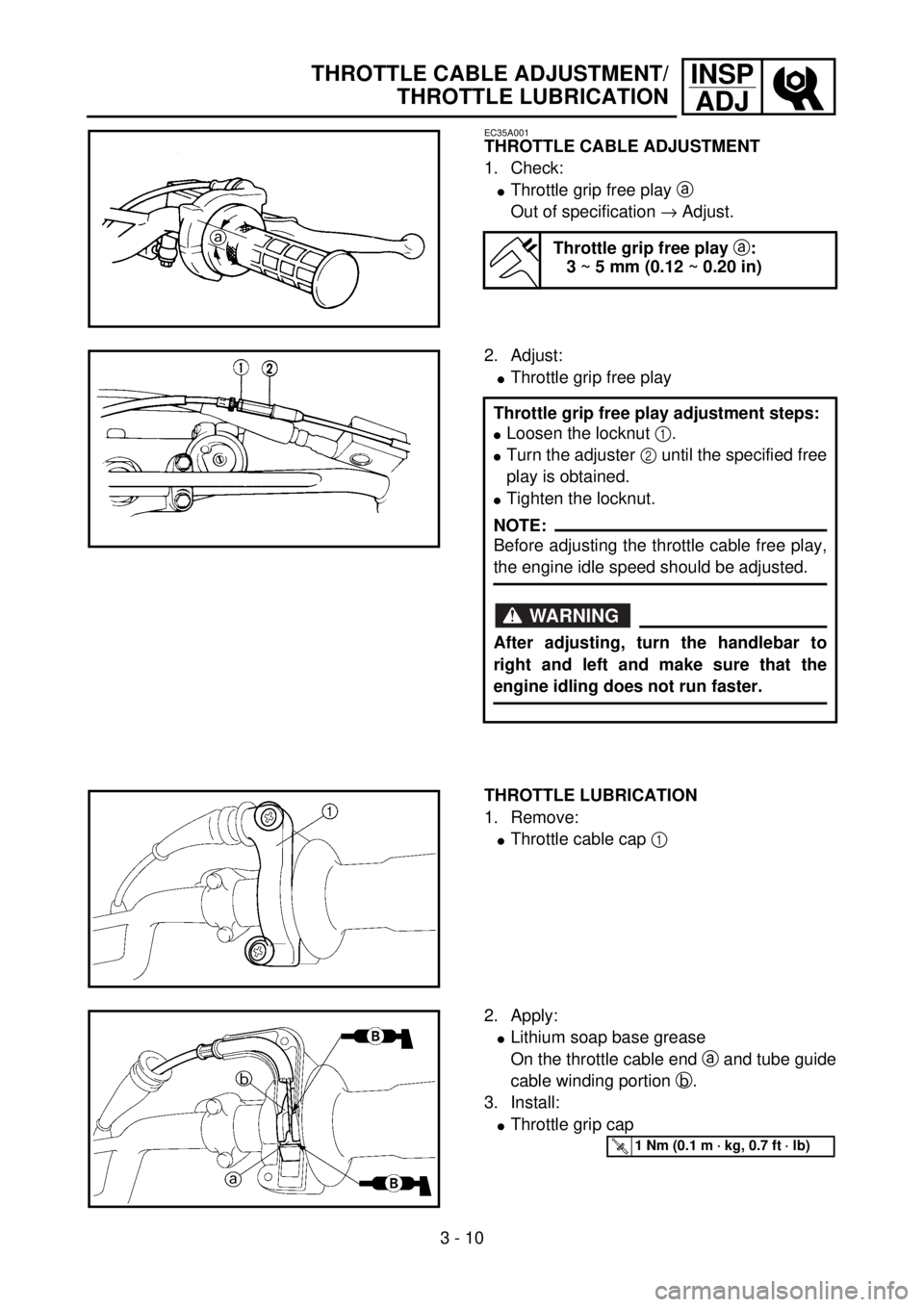

THROTTLE CABLE ADJUSTMENT

1. Check:

lThrottle grip free play a

Out of specification ® Adjust.

Throttle grip free play

a:

3 ~ 5 mm (0.12 ~ 0.20 in)

5PA30110

2. Adjust:

lThrottle grip free play

Throttle grip free play adjustment steps:

lLoosen the locknut 1.

lTurn the adjuster 2 until the specified free

play is obtained.

lTighten the locknut.

NOTE:

Before adjusting the throttle cable free play,

the engine idle speed should be adjusted.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

5PA30120

THROTTLE LUBRICATION

1. Remove:

lThrottle cable cap 1

5PA30130

2. Apply:

lLithium soap base grease

On the throttle cable end a and tube guide

cable winding portion b.

3. Install:

lThrottle grip cap

5PA30140

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

Page 142 of 504

3 - 11

INSP

ADJ

AIR FILTER CLEANING

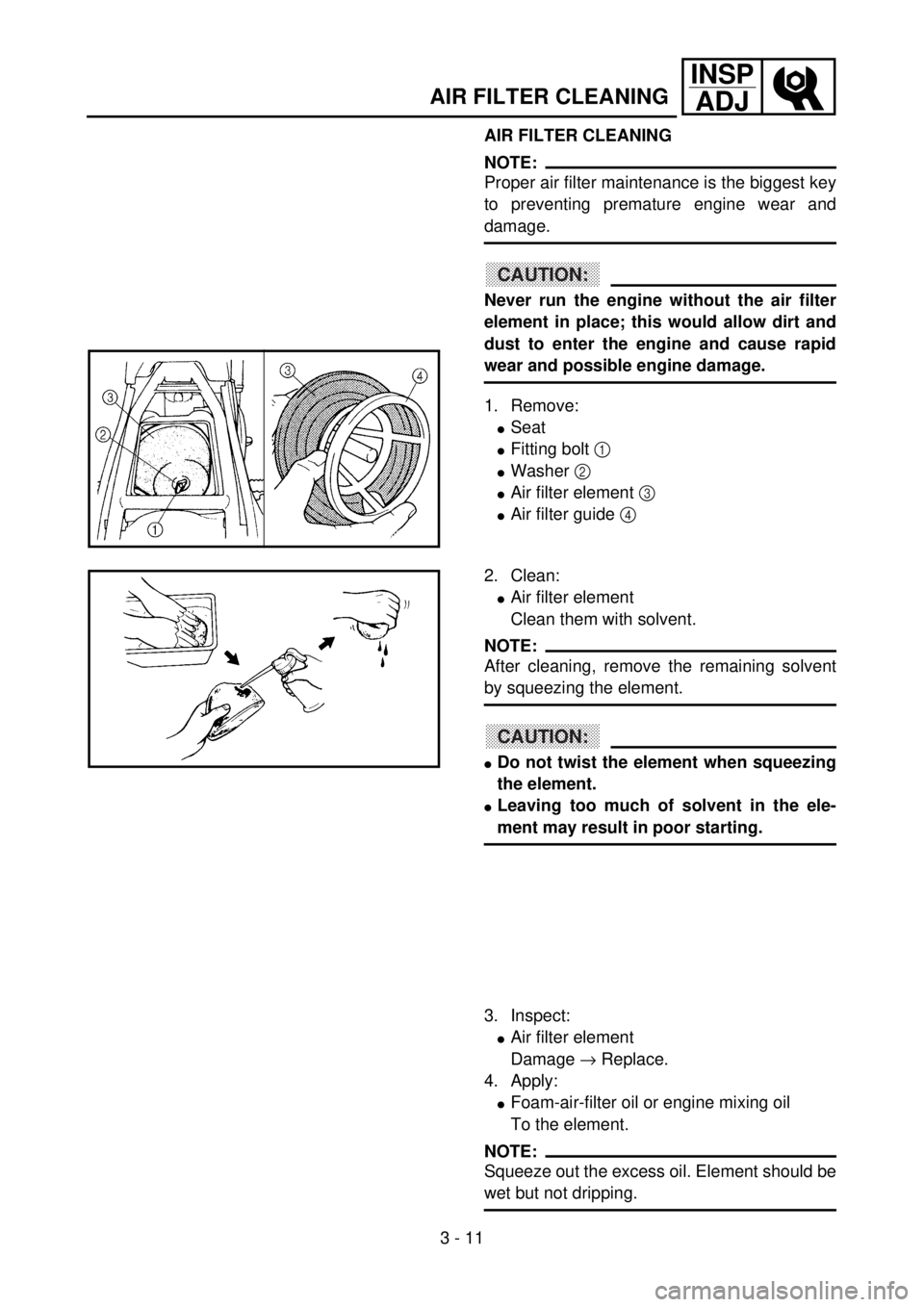

AIR FILTER CLEANING

NOTE:

Proper air filter maintenance is the biggest key

to preventing premature engine wear and

damage.

CAUTION:

Never run the engine without the air filter

element in place; this would allow dirt and

dust to enter the engine and cause rapid

wear and possible engine damage.

1. Remove:

lSeat

lFitting bolt 1

lWasher 2

lAir filter element 3

lAir filter guide 4

5PA30150

2. Clean:

lAir filter element

Clean them with solvent.

NOTE:

After cleaning, remove the remaining solvent

by squeezing the element.

CAUTION:

lDo not twist the element when squeezing

the element.

lLeaving too much of solvent in the ele-

ment may result in poor starting.

5PA30160

3. Inspect:

lAir filter element

Damage ® Replace.

4. Apply:

lFoam-air-filter oil or engine mixing oil

To the element.

NOTE:

Squeeze out the excess oil. Element should be

wet but not dripping.

Page 144 of 504

3 - 12

INSP

ADJ

TRANSMISSION OIL REPLACEMENT

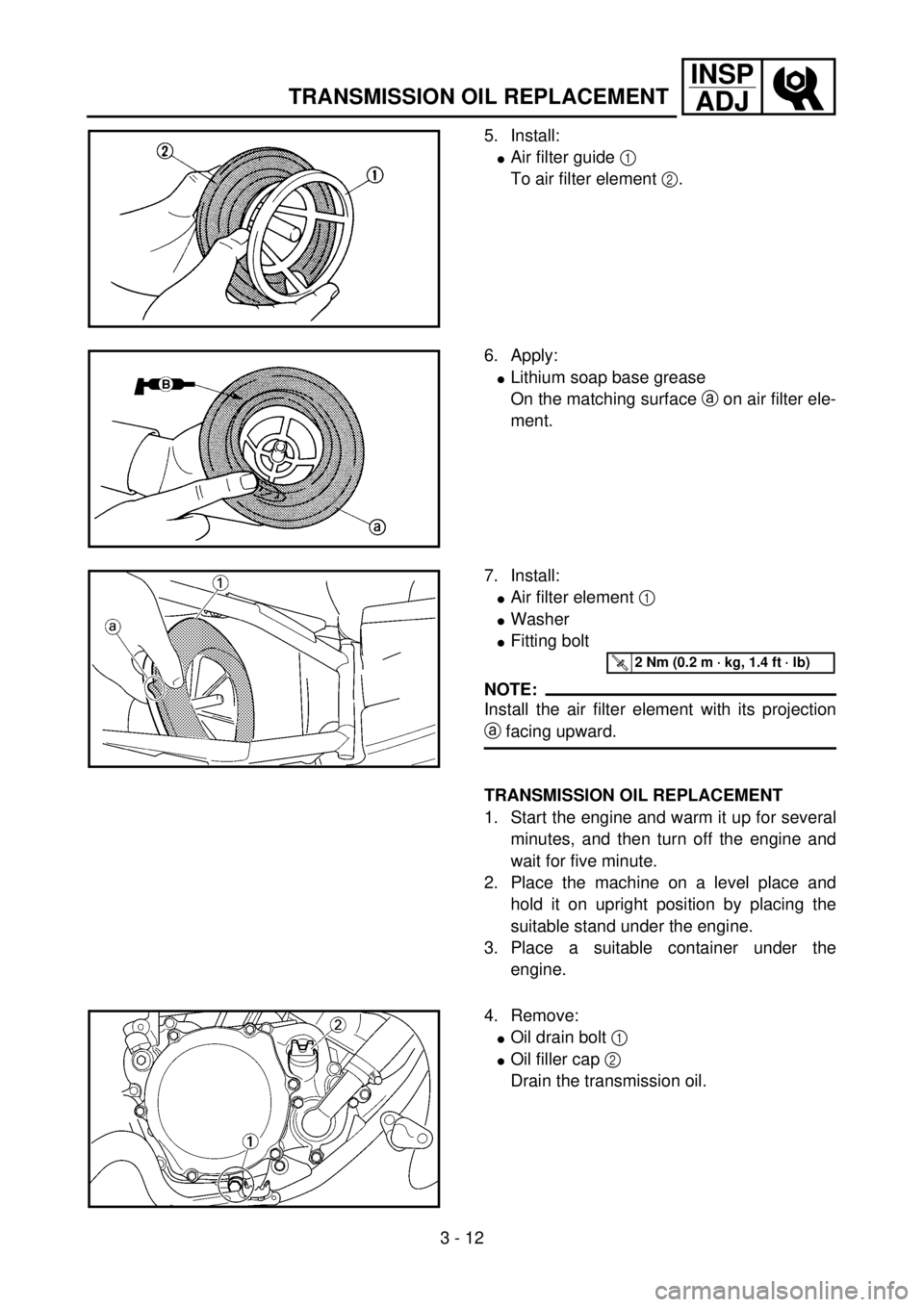

5. Install:

lAir filter guide 1

To air filter element 2.

5PA30170

6. Apply:

lLithium soap base grease

On the matching surface a on air filter ele-

ment.

5PA30180

7. Install:

lAir filter element 1

lWasher

lFitting bolt

NOTE:

Install the air filter element with its projection

a facing upward.

5PA30190

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

TRANSMISSION OIL REPLACEMENT

1. Start the engine and warm it up for several

minutes, and then turn off the engine and

wait for five minute.

2. Place the machine on a level place and

hold it on upright position by placing the

suitable stand under the engine.

3. Place a suitable container under the

engine.

4. Remove:

lOil drain bolt 1

lOil filler cap 2

Drain the transmission oil.

5PA30200

Page 148 of 504

3 - 14

INSP

ADJ

PILOT AIR SCREW ADJUSTMENT

1. Adjust:

lPilot air screw 1

Adjustment steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot air screw has

been individually set at the factry. Before

adjusting the pilot air screw, turn it in fully and

count the number of turns. Record this num-

ber as the factry-set number of turns out.

lTurn in the pilot air screw until it is lightly

seated.

lTurn out the pilot air screw by the speci-

fied number of turns.

Pilot air screw:

2 turns out (example)

5PA30230

ENGINE IDLING SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

lEngine idling speed

Adjustment steps:

lTurn the throttle stop screw 1 until the

engine runs at the lowest possible speed.

To increase idle speed ® Turn the throt-

tle stop screw 1 in a.

To decrease idle speed ® Turn the throt-

tle stop screw 1 out b.

5PA30240

EXHAUST PIPE INSPECTION

1. Inspect:

lO-ring 1

Damage ® Replace.

NOTE:

Install the O-rings with their depressed a fac-

ing inward.

5PA30250

PILOT AIR SCREW ADJUSTMENT/ENGINE IDLING

SPEED ADJUSTMENT/EXHAUST PIPE INSPECTION

Page 166 of 504

3 - 23

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

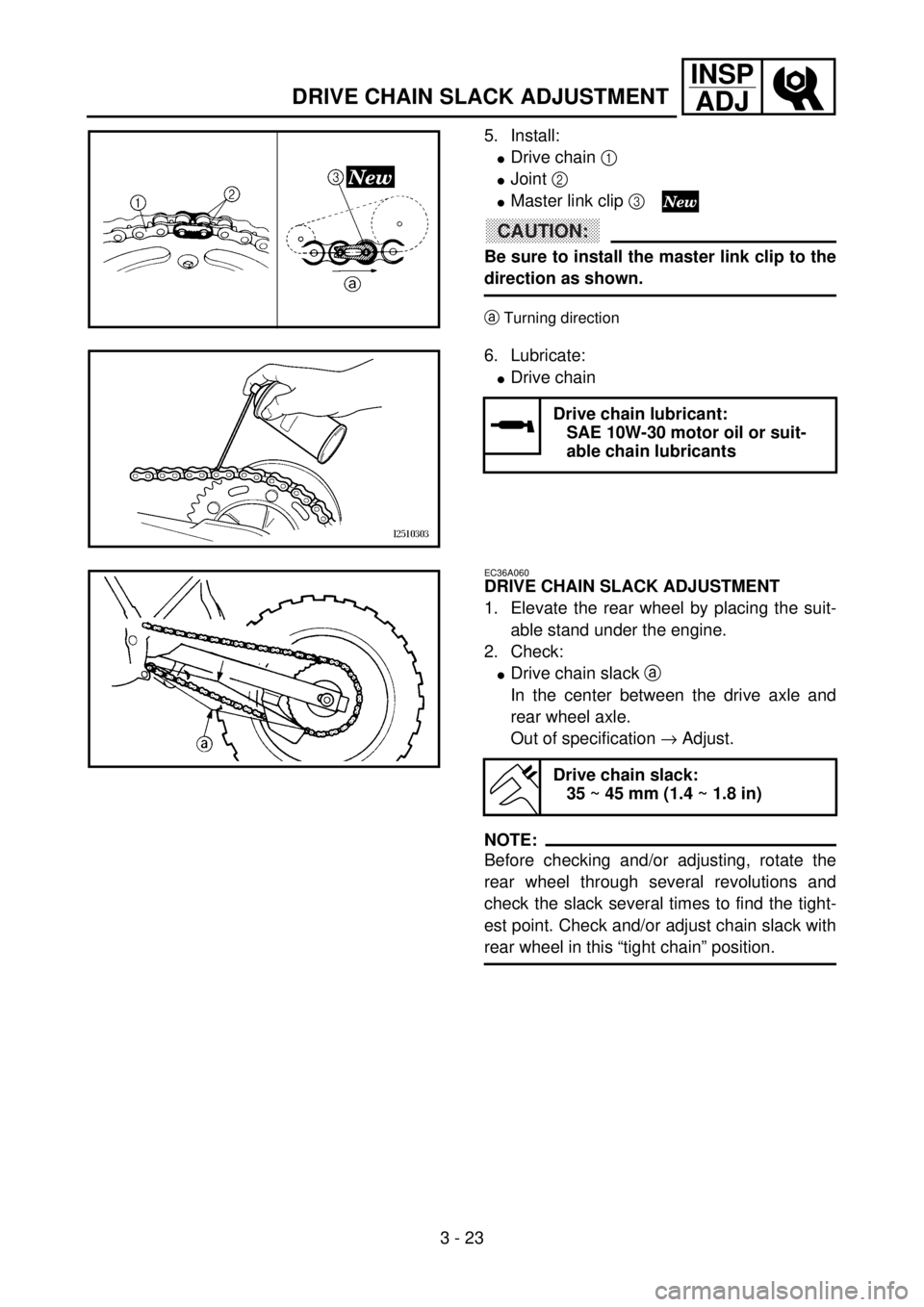

5. Install:

lDrive chain 1

lJoint 2

lMaster link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction5PA30530

6. Lubricate:

lDrive chain

Drive chain lubricant:

SAE 10W-30 motor oil or suit-

able chain lubricants

5PA30540

EC36A060

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

lDrive chain slack

a

In the center between the drive axle and

rear wheel axle.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

35 ~ 45 mm (1.4 ~ 1.8 in)

5PA30550

Page 168 of 504

3 - 24

INSP

ADJFRONT FORK INSPECTION/

FRONT FORK OIL SEAL AND DUST SEAL CLEANING

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the axle nut 1 and locknuts 2.

lAdjust chain slack by turning the adjusters 3.

To tighten

® Turn adjuster

3 clockwise.

To loosen

® Turn adjuster

3 counter-

clockwise and push wheel forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

lTighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

110 Nm (11.0 m • kg, 80 ft • lb)

lTighten the locknuts.

5PA30560

EC36C000

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the front

fork.

Unsmooth action/oil leakage ® Repair or

replace.

5PA30570

EC36D001

FRONT FORK OIL SEAL AND DUST SEAL

CLEANING

1. Remove:

lProtector 1

lDust seal 2

NOTE:

Use a thin screw driver, and be careful not to

damage the inner fork tube and dust seal.5PA30580

Page 170 of 504

3 - 25

INSP

ADJFRONT FORK INTERNAL PRESSURE BLEEDING/FRONT

FORK REBOUND DAMPING FORCE ADJUSTMENT

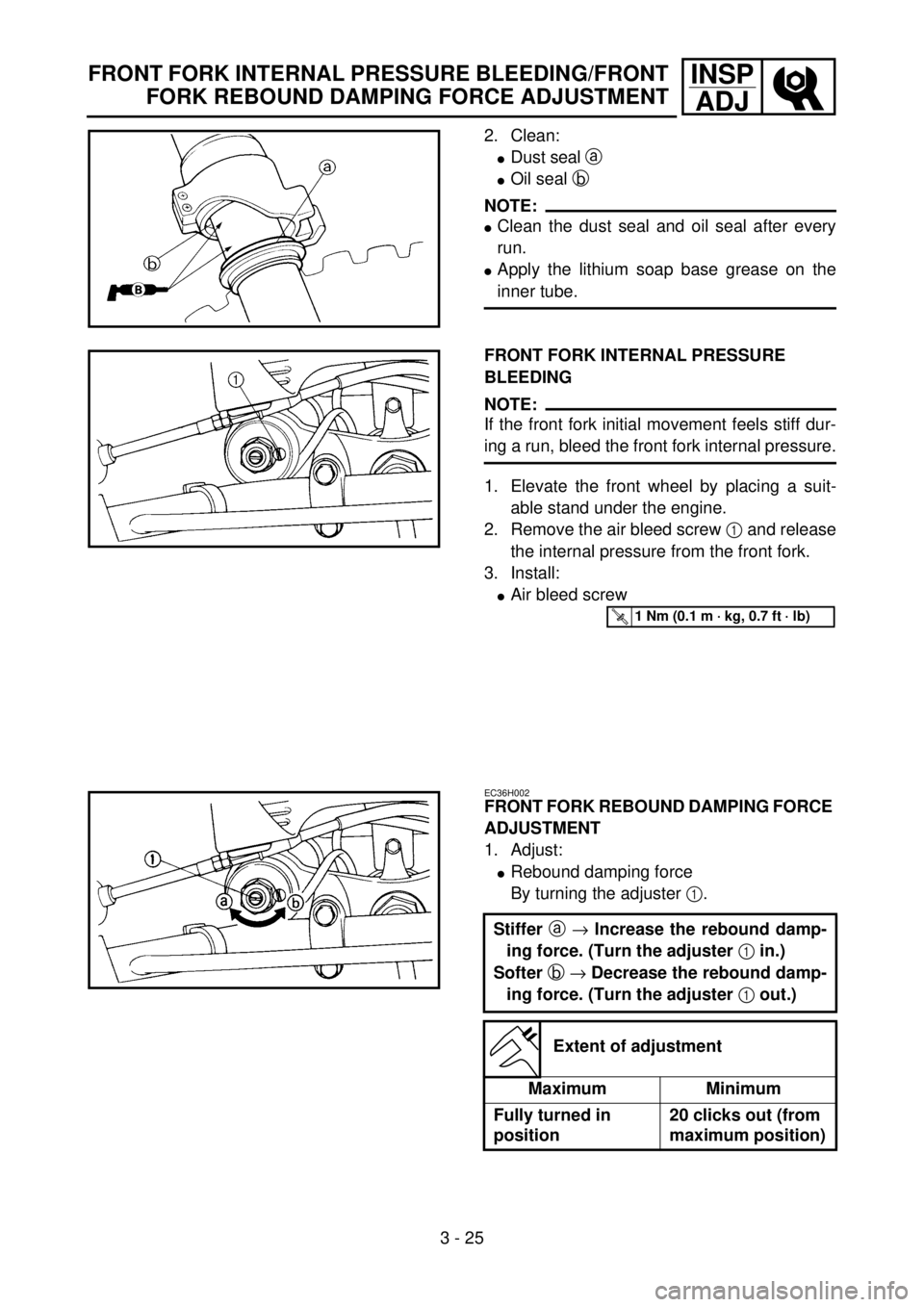

2. Clean:

lDust seal a

lOil seal b

NOTE:

lClean the dust seal and oil seal after every

run.

lApply the lithium soap base grease on the

inner tube.

5PA30590

FRONT FORK INTERNAL PRESSURE

BLEEDING

NOTE:

If the front fork initial movement feels stiff dur-

ing a run, bleed the front fork internal pressure.

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Remove the air bleed screw 1 and release

the internal pressure from the front fork.

3. Install:

lAir bleed screw

5PA30590

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

EC36H002

FRONT FORK REBOUND DAMPING FORCE

ADJUSTMENT

1. Adjust:

lRebound damping force

By turning the adjuster 1.

Stiffer

a

® Increase the rebound damp-

ing force. (Turn the adjuster

1 in.)

Softer

b

® Decrease the rebound damp-

ing force. (Turn the adjuster

1 out.)

Extent of adjustment

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum position)

5PA30600

Page 176 of 504

3 - 28

INSP

ADJREAR SHOCK ABSORBER SPRING PRELOAD

ADJUSTMENT

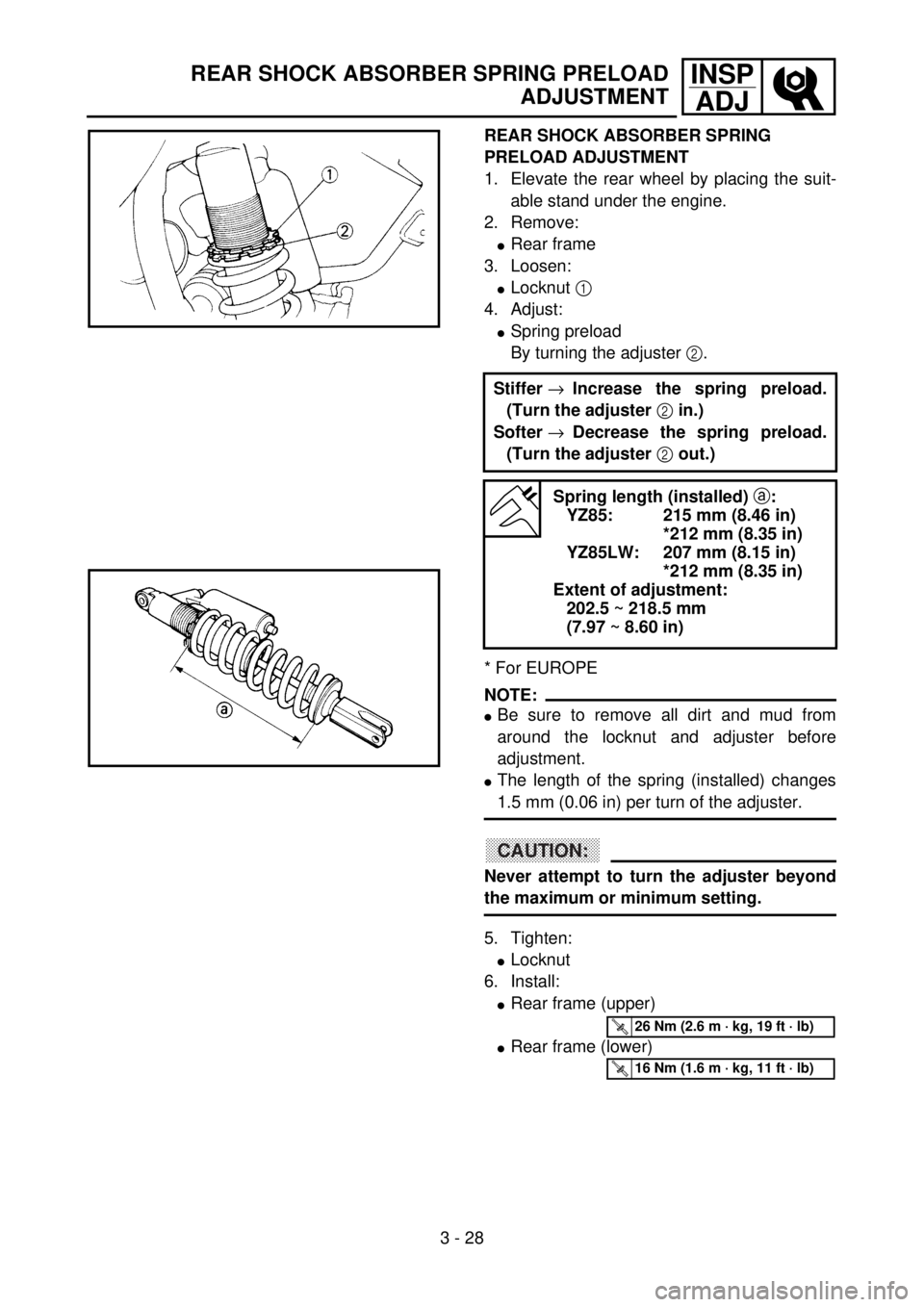

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Remove:

lRear frame

3. Loosen:

lLocknut 1

4. Adjust:

lSpring preload

By turning the adjuster 2.

* For EUROPE

NOTE:

lBe sure to remove all dirt and mud from

around the locknut and adjuster before

adjustment.

lThe length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjuster.

CAUTION:

Never attempt to turn the adjuster beyond

the maximum or minimum setting.

5. Tighten:

lLocknut

6. Install:

lRear frame (upper)

lRear frame (lower) Stiffer

®Increase the spring preload.

(Turn the adjuster

2 in.)

Softer

®Decrease the spring preload.

(Turn the adjuster

2 out.)

Spring length (installed)

a:

YZ85: 215 mm (8.46 in)

*212 mm (8.35 in)

YZ85LW: 207 mm (8.15 in)

*212 mm (8.35 in)

Extent of adjustment:

202.5 ~ 218.5 mm

(7.97 ~ 8.60 in)

5PA30630

5PA30640

T R..26 Nm (2.6 m · kg, 19 ft · lb)

T R..16 Nm (1.6 m · kg, 11 ft · lb)

Page 184 of 504

3 - 32

INSP

ADJ

2. Inspect:

lBearing free play

Exist play ® Replace.

5PA30710

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering stem

Grasp the bottom of the forks and gently

rock the fork assembly back and forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

5PA30720

5PA30730

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the number plate.

lRemove the handlebar and handlebar

upper bracket.

lLoosen the steering ring nut 1 using the

steering nut wrench 2.

Steering nut wrench:

YU-33975/90890-01403

5PA30740

STEERING HEAD INSPECTION AND ADJUSTMENT

Page 190 of 504

3 - 35

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

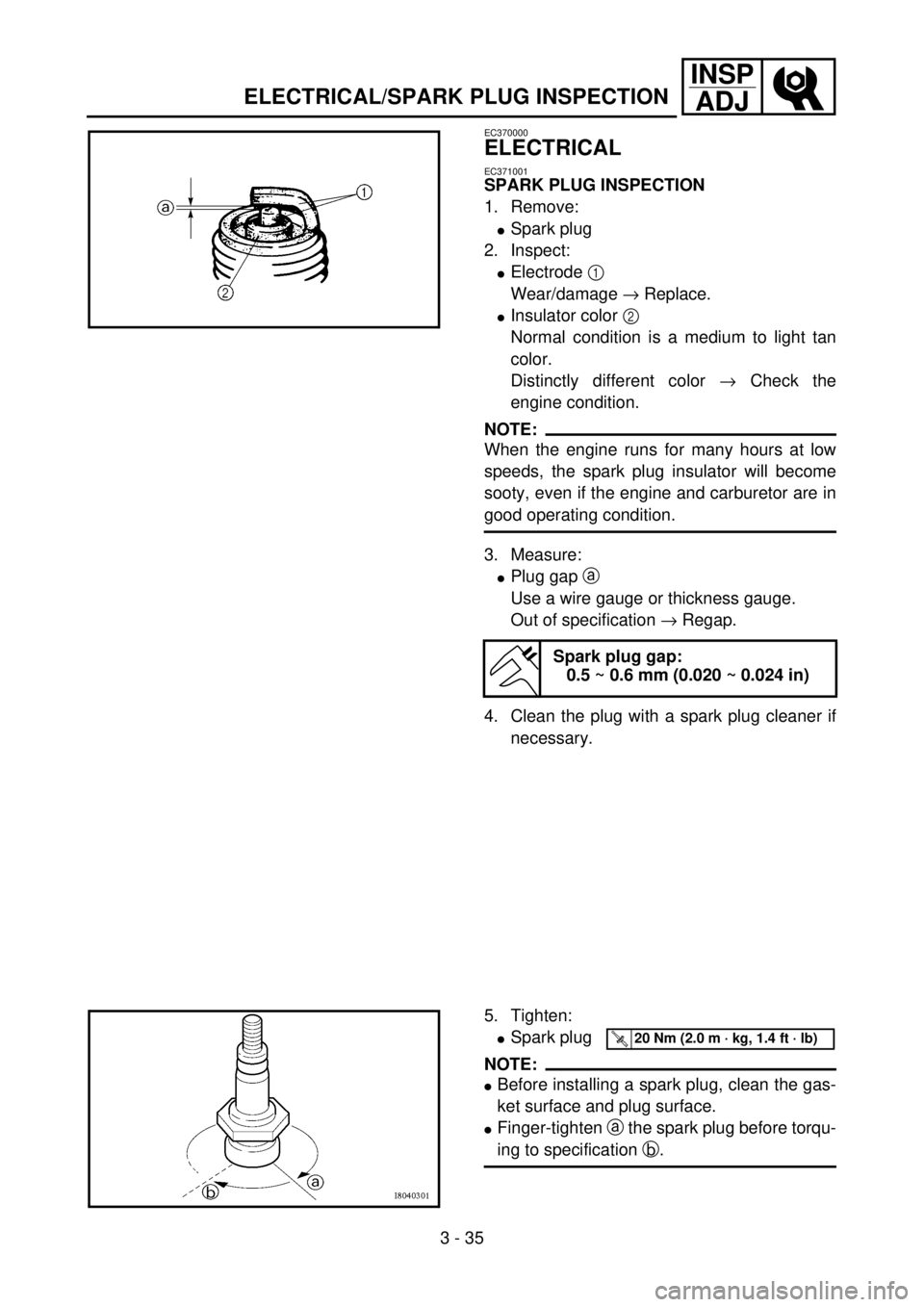

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Regap.

4. Clean the plug with a spark plug cleaner if

necessary.

Spark plug gap:

0.5 ~ 0.6 mm (0.020 ~ 0.024 in)

5PA30850

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before torqu-

ing to specification b.

5PA30860

T R..20 Nm (2.0 m · kg, 1.4 ft · lb)