check oil YAMAHA YZ85 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 166 of 504

3 - 23

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

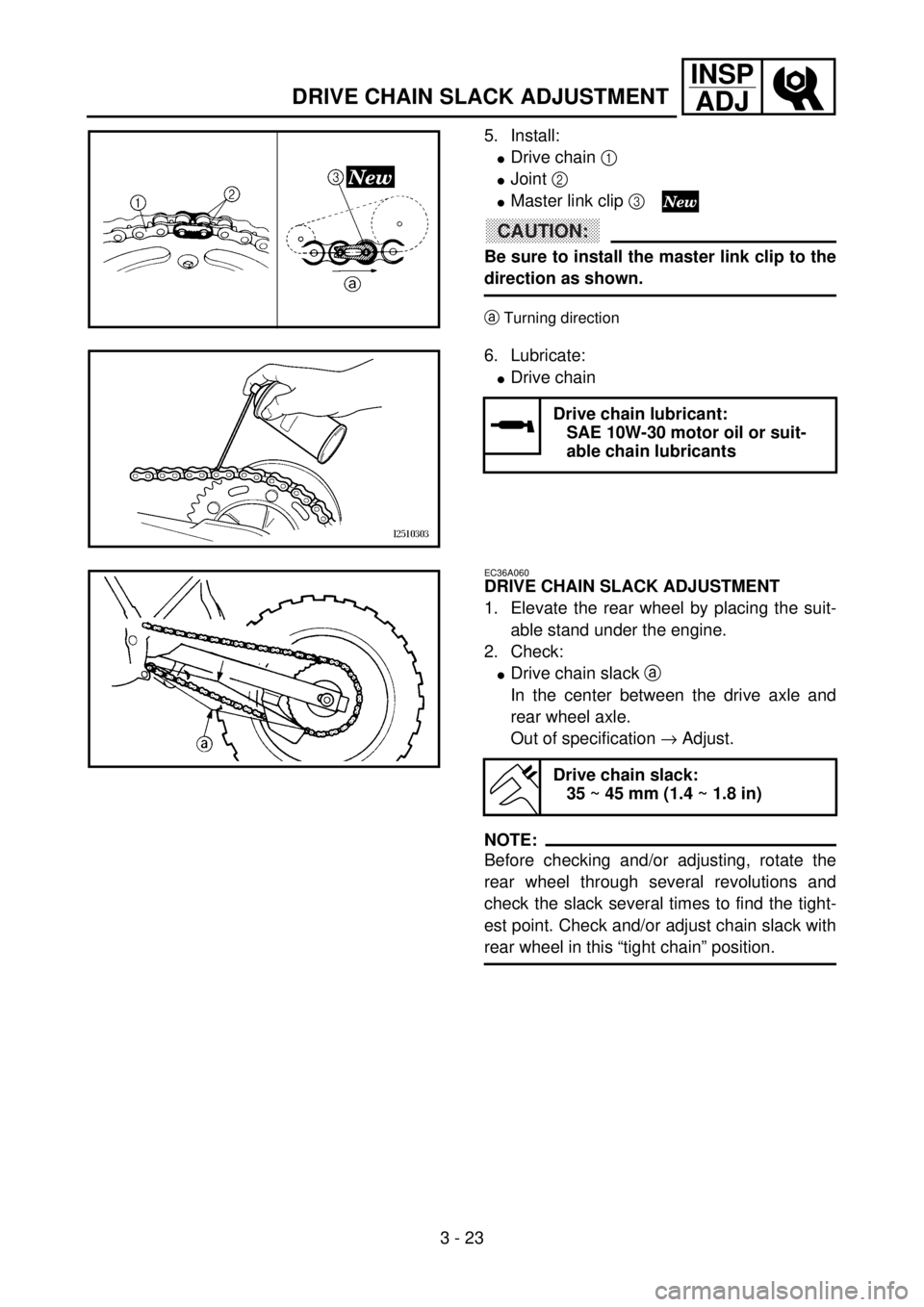

5. Install:

lDrive chain 1

lJoint 2

lMaster link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction5PA30530

6. Lubricate:

lDrive chain

Drive chain lubricant:

SAE 10W-30 motor oil or suit-

able chain lubricants

5PA30540

EC36A060

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

lDrive chain slack

a

In the center between the drive axle and

rear wheel axle.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

35 ~ 45 mm (1.4 ~ 1.8 in)

5PA30550

Page 240 of 504

4 - 23

ENG

NOTE:

When you purchase a cylinder, you cannot

designate its size. Choose the piston that

matches the above chart.

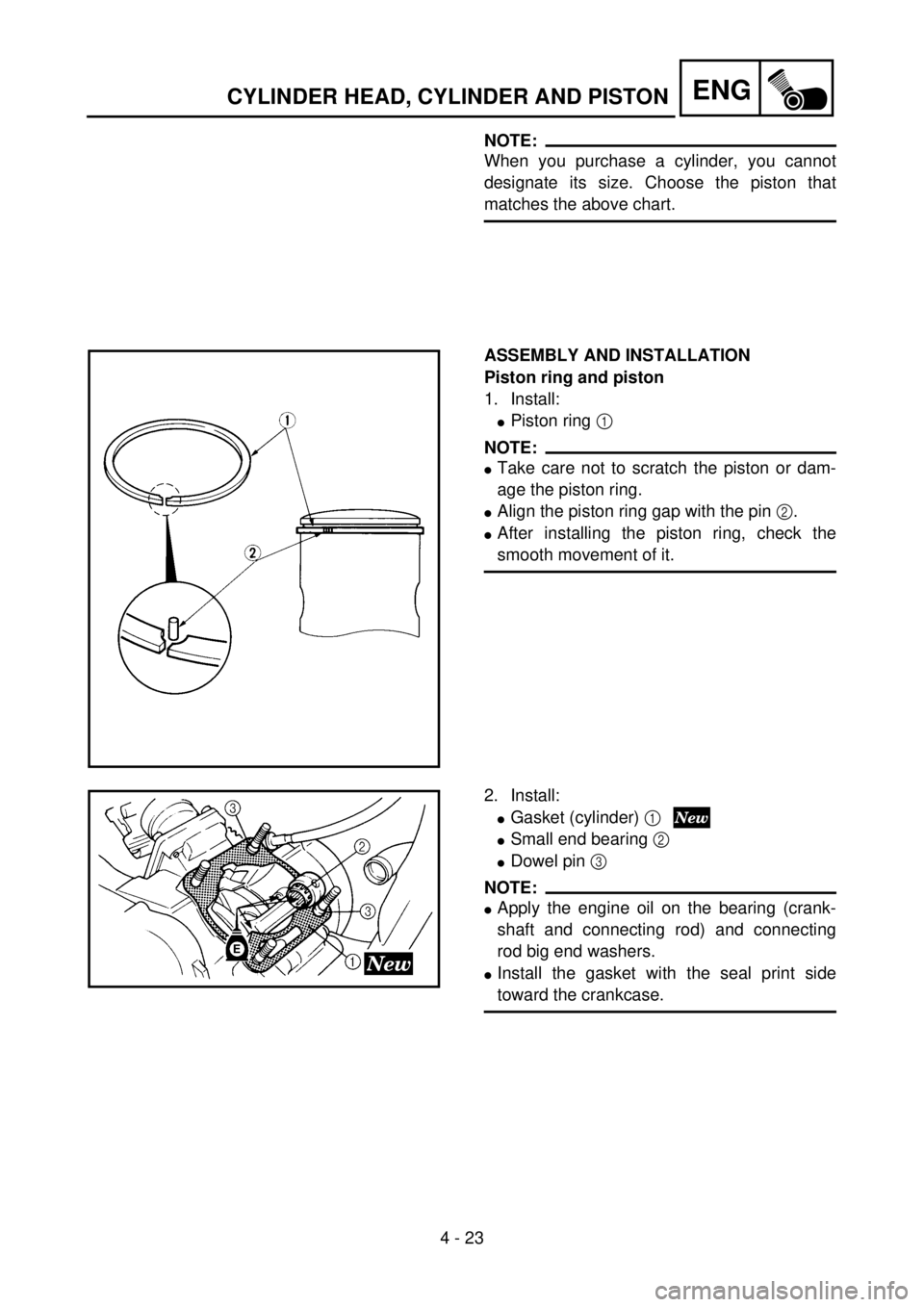

ASSEMBLY AND INSTALLATION

Piston ring and piston

1. Install:

lPiston ring 1

NOTE:

lTake care not to scratch the piston or dam-

age the piston ring.

lAlign the piston ring gap with the pin 2.

lAfter installing the piston ring, check the

smooth movement of it.

5PA40620

2. Install:

lGasket (cylinder) 1

lSmall end bearing 2

lDowel pin 3

NOTE:

lApply the engine oil on the bearing (crank-

shaft and connecting rod) and connecting

rod big end washers.

lInstall the gasket with the seal print side

toward the crankcase.

5PA40630

CYLINDER HEAD, CYLINDER AND PISTON

Page 242 of 504

4 - 24

ENG

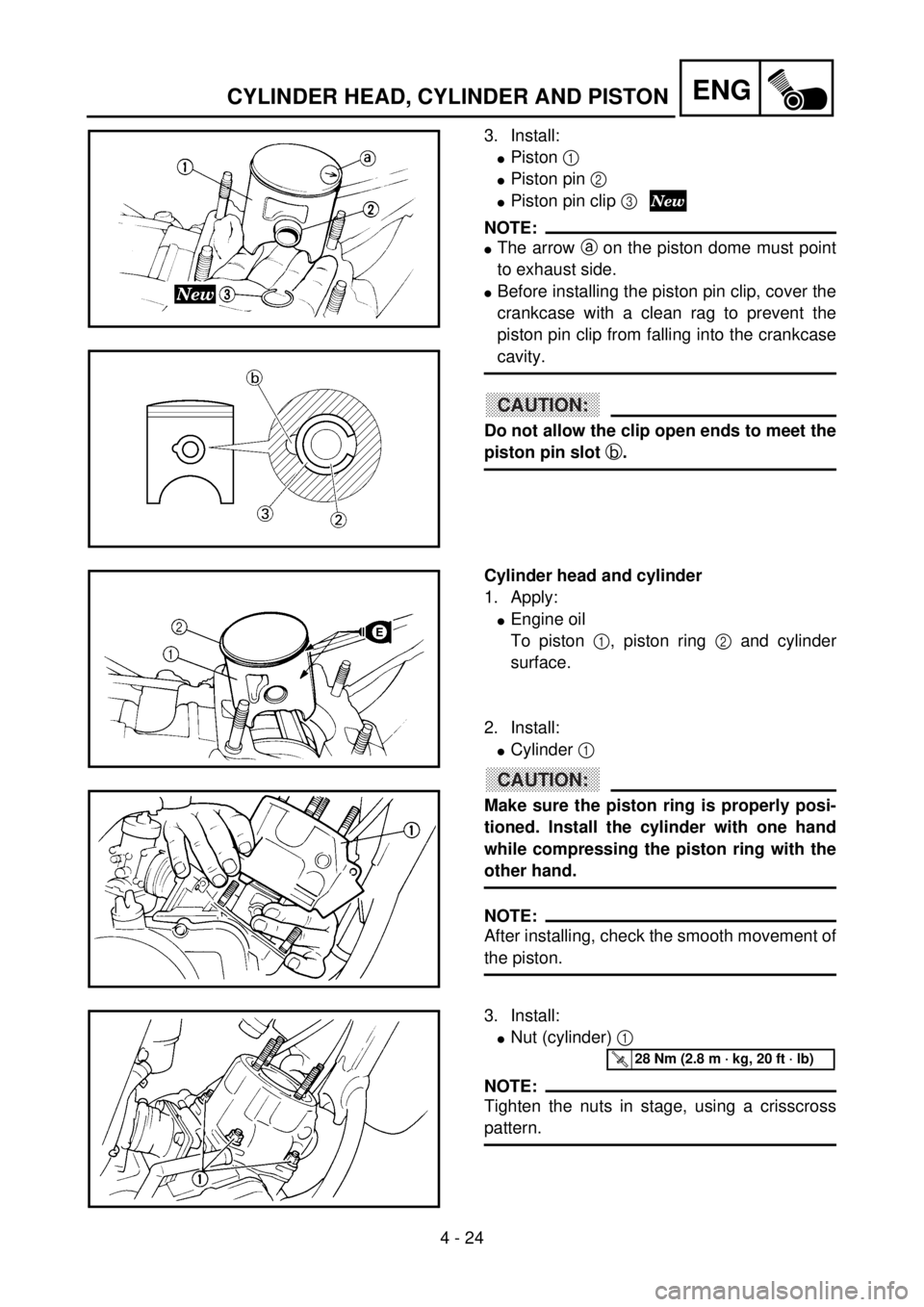

3. Install:

lPiston 1

lPiston pin 2

lPiston pin clip 3

NOTE:

lThe arrow a on the piston dome must point

to exhaust side.

lBefore installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase

cavity.

CAUTION:

Do not allow the clip open ends to meet the

piston pin slot b.

5PA40640

5PA40650

Cylinder head and cylinder

1. Apply:

lEngine oil

To piston 1, piston ring 2 and cylinder

surface.

2. Install:

lCylinder 1

CAUTION:

Make sure the piston ring is properly posi-

tioned. Install the cylinder with one hand

while compressing the piston ring with the

other hand.

NOTE:

After installing, check the smooth movement of

the piston.

5PA40660

5PA40670

3. Install:

lNut (cylinder) 1

NOTE:

Tighten the nuts in stage, using a crisscross

pattern.

5PA40680

T R..28 Nm (2.8 m · kg, 20 ft · lb)

CYLINDER HEAD, CYLINDER AND PISTON

Page 268 of 504

4 - 37

ENG

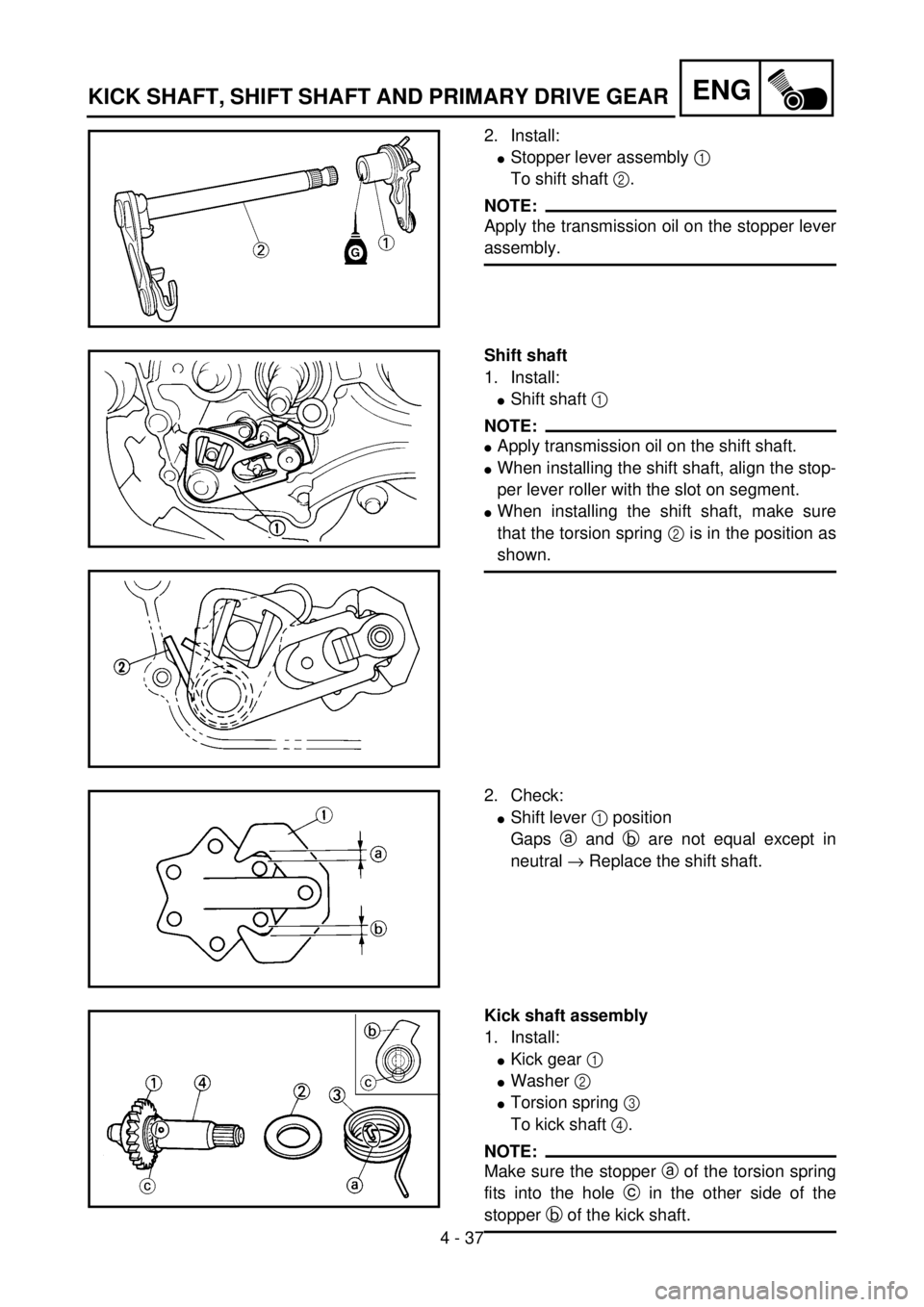

2. Install:

lStopper lever assembly 1

To shift shaft 2.

NOTE:

Apply the transmission oil on the stopper lever

assembly.

5PA41070

Shift shaft

1. Install:

lShift shaft 1

NOTE:

lApply transmission oil on the shift shaft.

lWhen installing the shift shaft, align the stop-

per lever roller with the slot on segment.

lWhen installing the shift shaft, make sure

that the torsion spring 2 is in the position as

shown.

5PA41080

5PA41090

2. Check:

lShift lever 1 position

Gaps a and b are not equal except in

neutral ® Replace the shift shaft.

5PA41100

Kick shaft assembly

1. Install:

lKick gear 1

lWasher 2

lTorsion spring 3

To kick shaft 4.

NOTE:

Make sure the stopper a of the torsion spring

fits into the hole c in the other side of the

stopper b of the kick shaft.

5PA41110

KICK SHAFT, SHIFT SHAFT AND PRIMARY DRIVE GEAR

Page 308 of 504

4 - 57

ENG

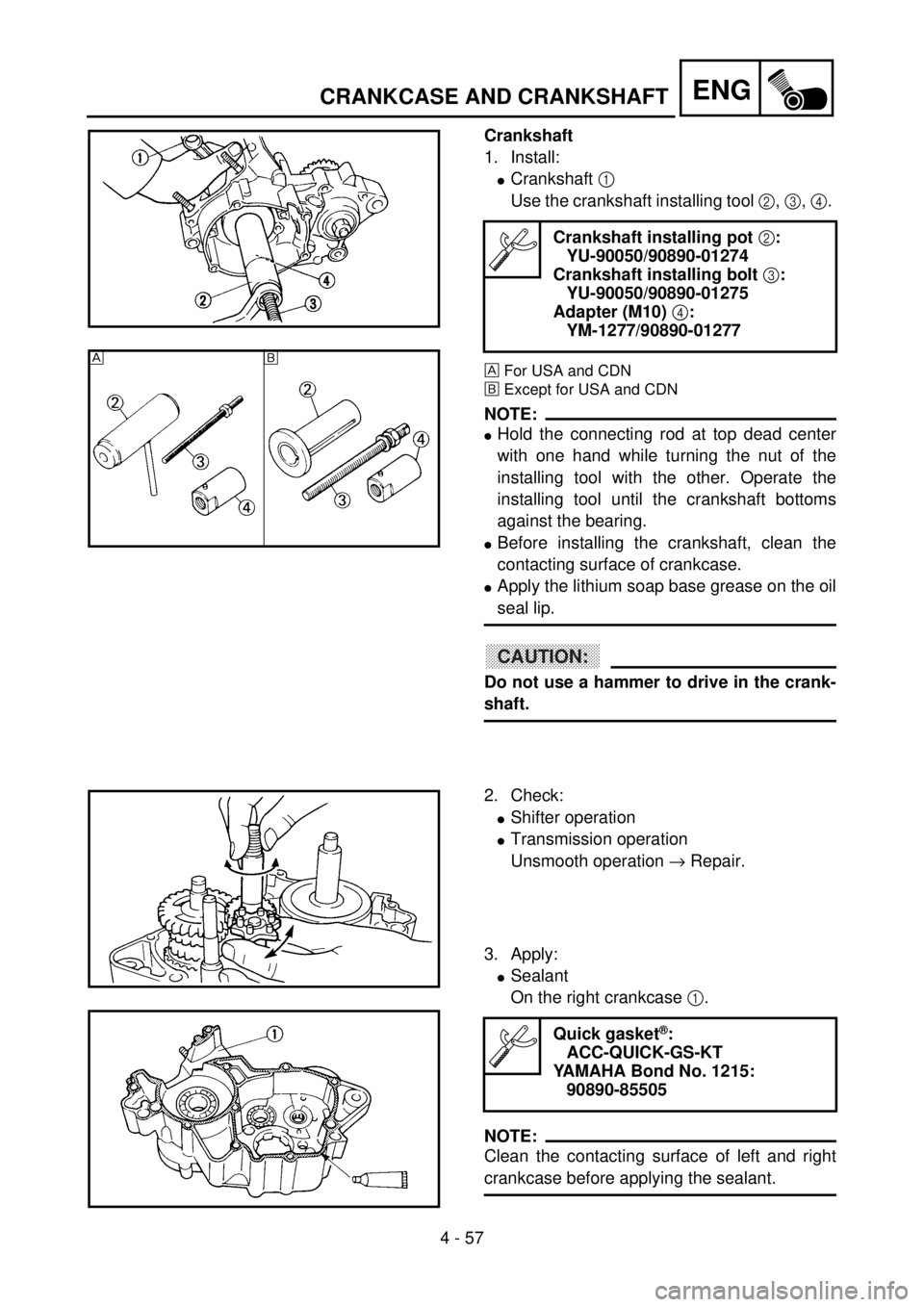

Crankshaft

1. Install:

lCrankshaft 1

Use the crankshaft installing tool 2, 3, 4.

ÈFor USA and CDN

ÉExcept for USA and CDN

NOTE:

lHold the connecting rod at top dead center

with one hand while turning the nut of the

installing tool with the other. Operate the

installing tool until the crankshaft bottoms

against the bearing.

lBefore installing the crankshaft, clean the

contacting surface of crankcase.

lApply the lithium soap base grease on the oil

seal lip.

CAUTION:

Do not use a hammer to drive in the crank-

shaft.

Crankshaft installing pot 2:

YU-90050/90890-01274

Crankshaft installing bolt 3:

YU-90050/90890-01275

Adapter (M10) 4:

YM-1277/90890-01277

5PA41720

È€É

5PA41730

2. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

3. Apply:

lSealant

On the right crankcase 1.

NOTE:

Clean the contacting surface of left and right

crankcase before applying the sealant.

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

5PA41740

5PA41750

CRANKCASE AND CRANKSHAFT

Page 310 of 504

4 - 58

ENG

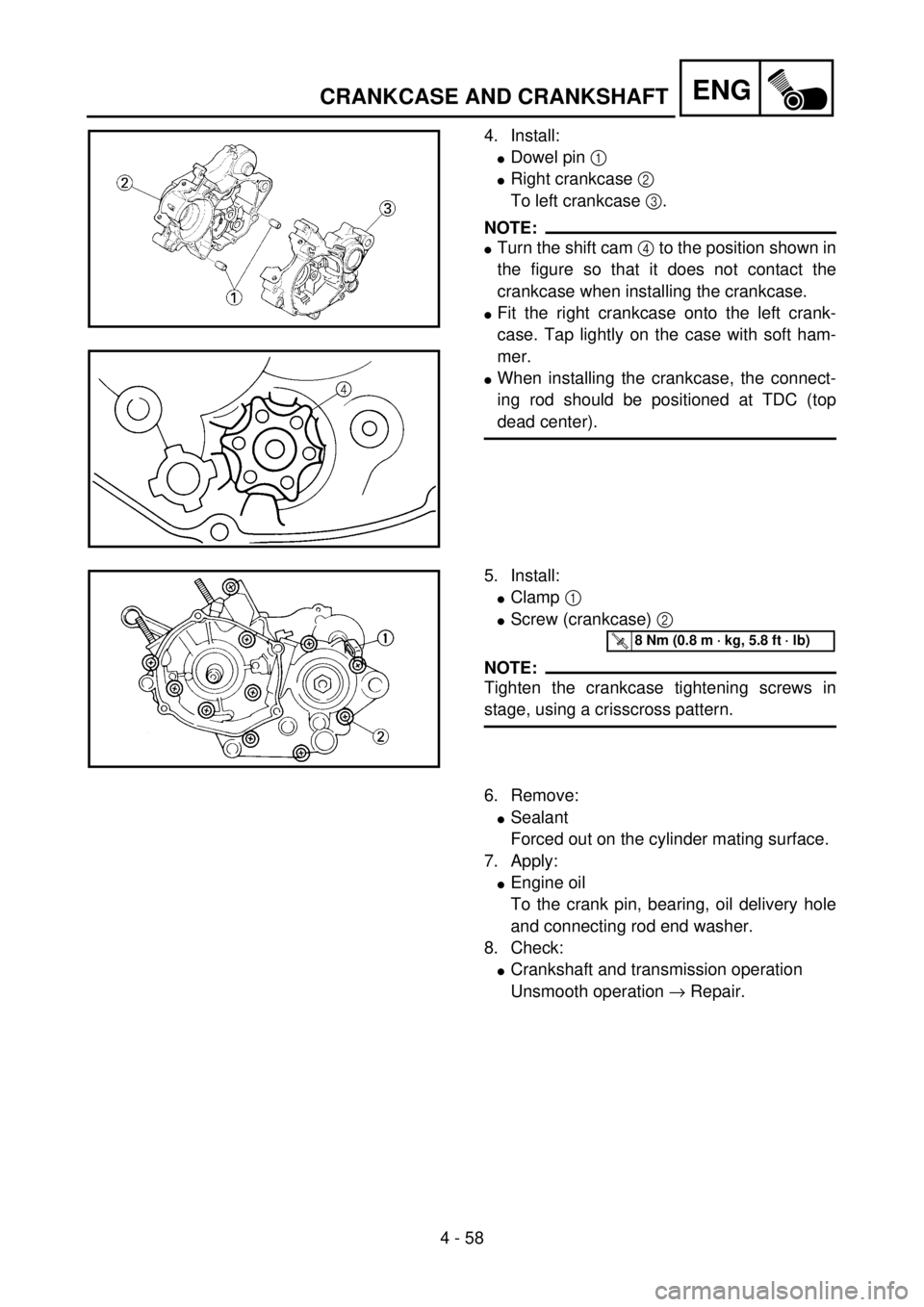

4. Install:

lDowel pin 1

lRight crankcase 2

To left crankcase 3.

NOTE:

lTurn the shift cam 4 to the position shown in

the figure so that it does not contact the

crankcase when installing the crankcase.

lFit the right crankcase onto the left crank-

case. Tap lightly on the case with soft ham-

mer.

lWhen installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

5PA41760

5PA41770

5. Install:

lClamp 1

lScrew (crankcase) 2

NOTE:

Tighten the crankcase tightening screws in

stage, using a crisscross pattern.

5PA41780

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

6. Remove:

lSealant

Forced out on the cylinder mating surface.

7. Apply:

lEngine oil

To the crank pin, bearing, oil delivery hole

and connecting rod end washer.

8. Check:

lCrankshaft and transmission operation

Unsmooth operation ® Repair.

CRANKCASE AND CRANKSHAFT

Page 316 of 504

4 - 61

ENG

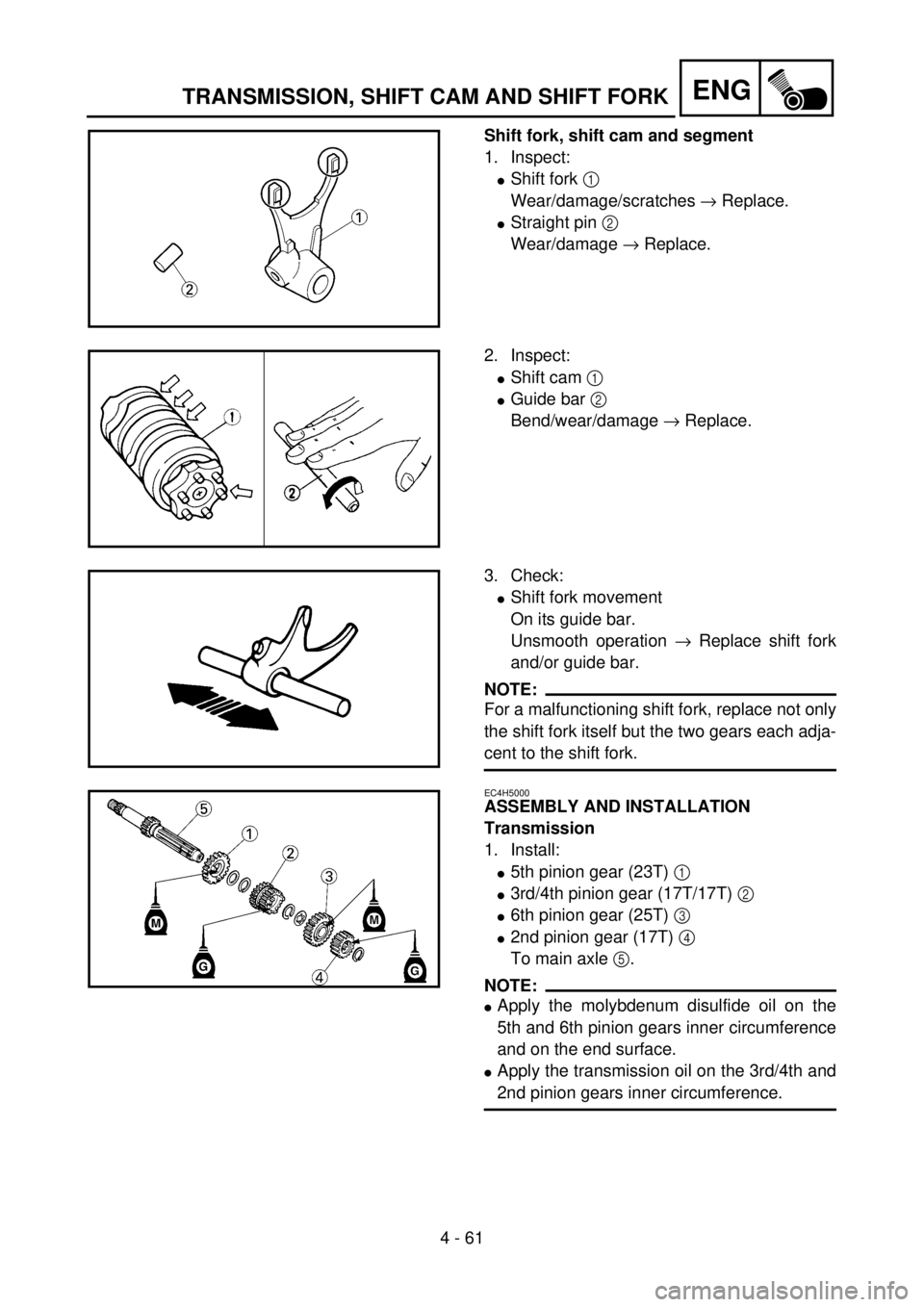

Shift fork, shift cam and segment

1. Inspect:

lShift fork 1

Wear/damage/scratches ® Replace.

lStraight pin 2

Wear/damage ® Replace.

5PA41840

2. Inspect:

lShift cam 1

lGuide bar 2

Bend/wear/damage ® Replace.

5PA41850

3. Check:

lShift fork movement

On its guide bar.

Unsmooth operation ® Replace shift fork

and/or guide bar.

NOTE:

For a malfunctioning shift fork, replace not only

the shift fork itself but the two gears each adja-

cent to the shift fork.5PA41860

EC4H5000

ASSEMBLY AND INSTALLATION

Transmission

1. Install:

l5th pinion gear (23T) 1

l3rd/4th pinion gear (17T/17T) 2

l6th pinion gear (25T) 3

l2nd pinion gear (17T) 4

To main axle 5.

NOTE:

lApply the molybdenum disulfide oil on the

5th and 6th pinion gears inner circumference

and on the end surface.

lApply the transmission oil on the 3rd/4th and

2nd pinion gears inner circumference.

5PA41870

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Page 322 of 504

4 - 64

ENG

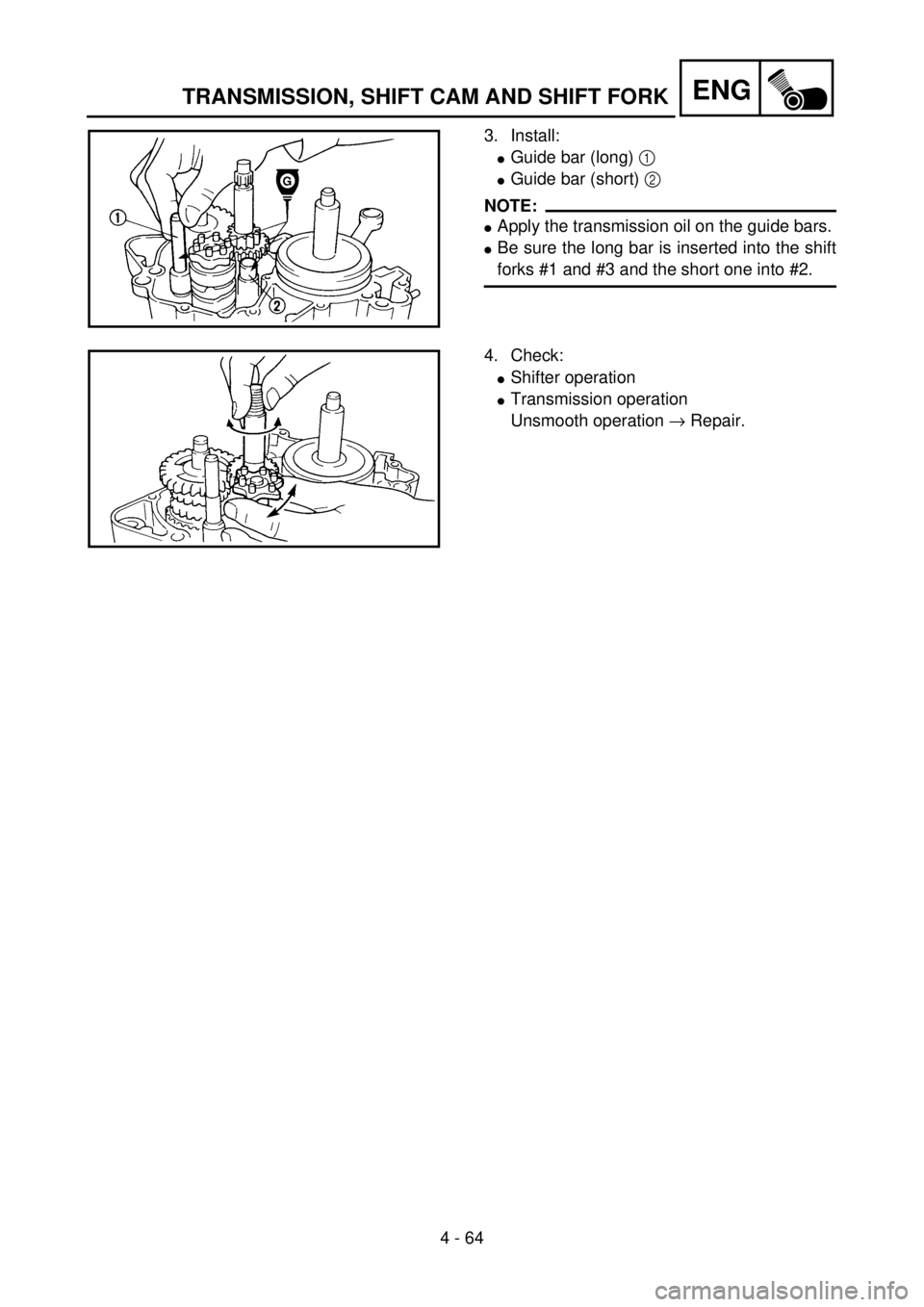

3. Install:

lGuide bar (long) 1

lGuide bar (short) 2

NOTE:

lApply the transmission oil on the guide bars.

lBe sure the long bar is inserted into the shift

forks #1 and #3 and the short one into #2.

5PA41960

4. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

5PA41970

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Page 392 of 504

5 - 35

CHAS

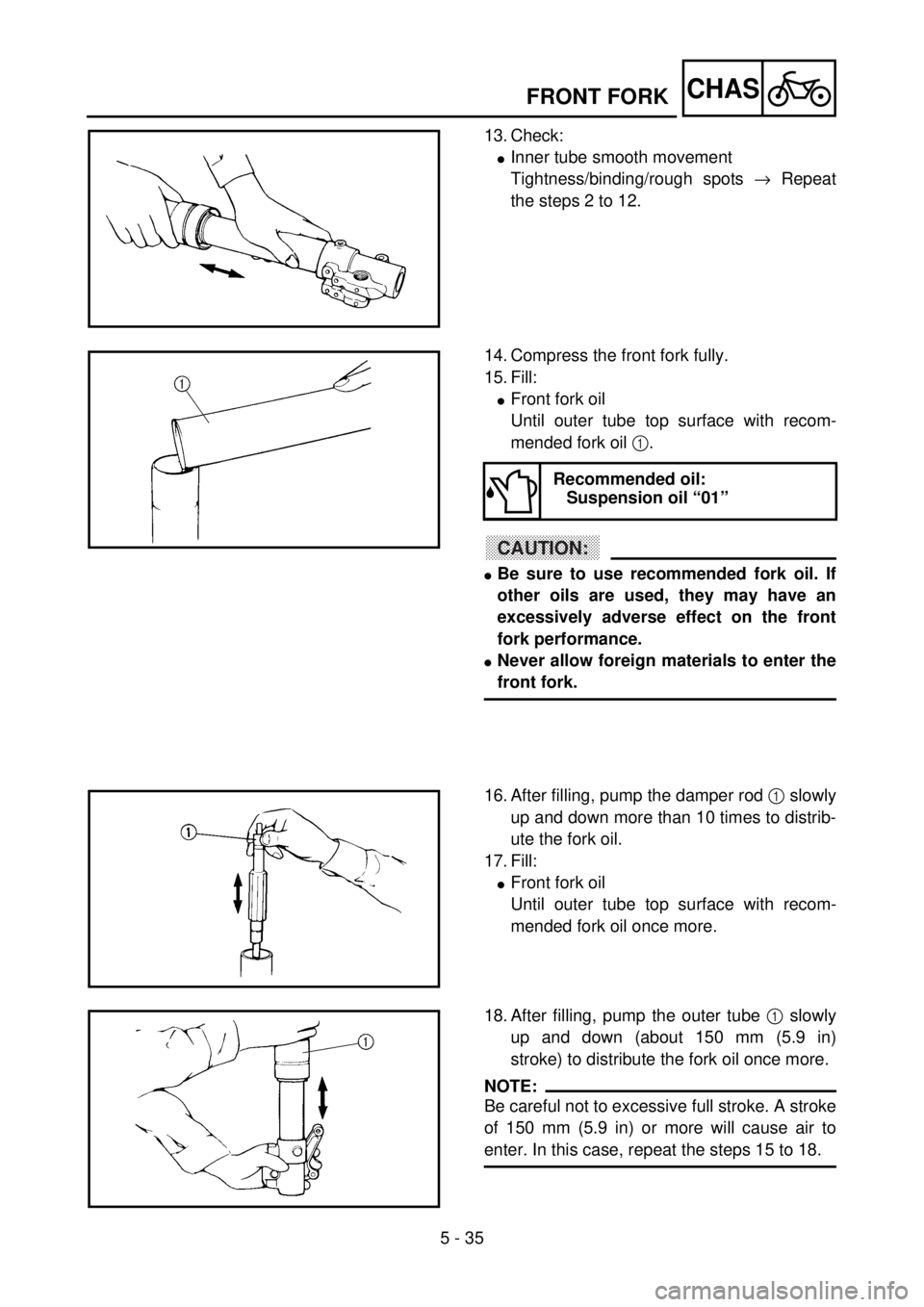

13. Check:

lInner tube smooth movement

Tightness/binding/rough spots ® Repeat

the steps 2 to 12.

5PA51080

14. Compress the front fork fully.

15. Fill:

lFront fork oil

Until outer tube top surface with recom-

mended fork oil 1.

CAUTION:

lBe sure to use recommended fork oil. If

other oils are used, they may have an

excessively adverse effect on the front

fork performance.

lNever allow foreign materials to enter the

front fork.

Recommended oil:

Suspension oil “01”

5PA51090

16. After filling, pump the damper rod 1 slowly

up and down more than 10 times to distrib-

ute the fork oil.

17. Fill:

lFront fork oil

Until outer tube top surface with recom-

mended fork oil once more.

5PA51100

18. After filling, pump the outer tube 1 slowly

up and down (about 150 mm (5.9 in)

stroke) to distribute the fork oil once more.

NOTE:

Be careful not to excessive full stroke. A stroke

of 150 mm (5.9 in) or more will cause air to

enter. In this case, repeat the steps 15 to 18.

5PA51110

FRONT FORK

Page 394 of 504

5 - 36

CHAS

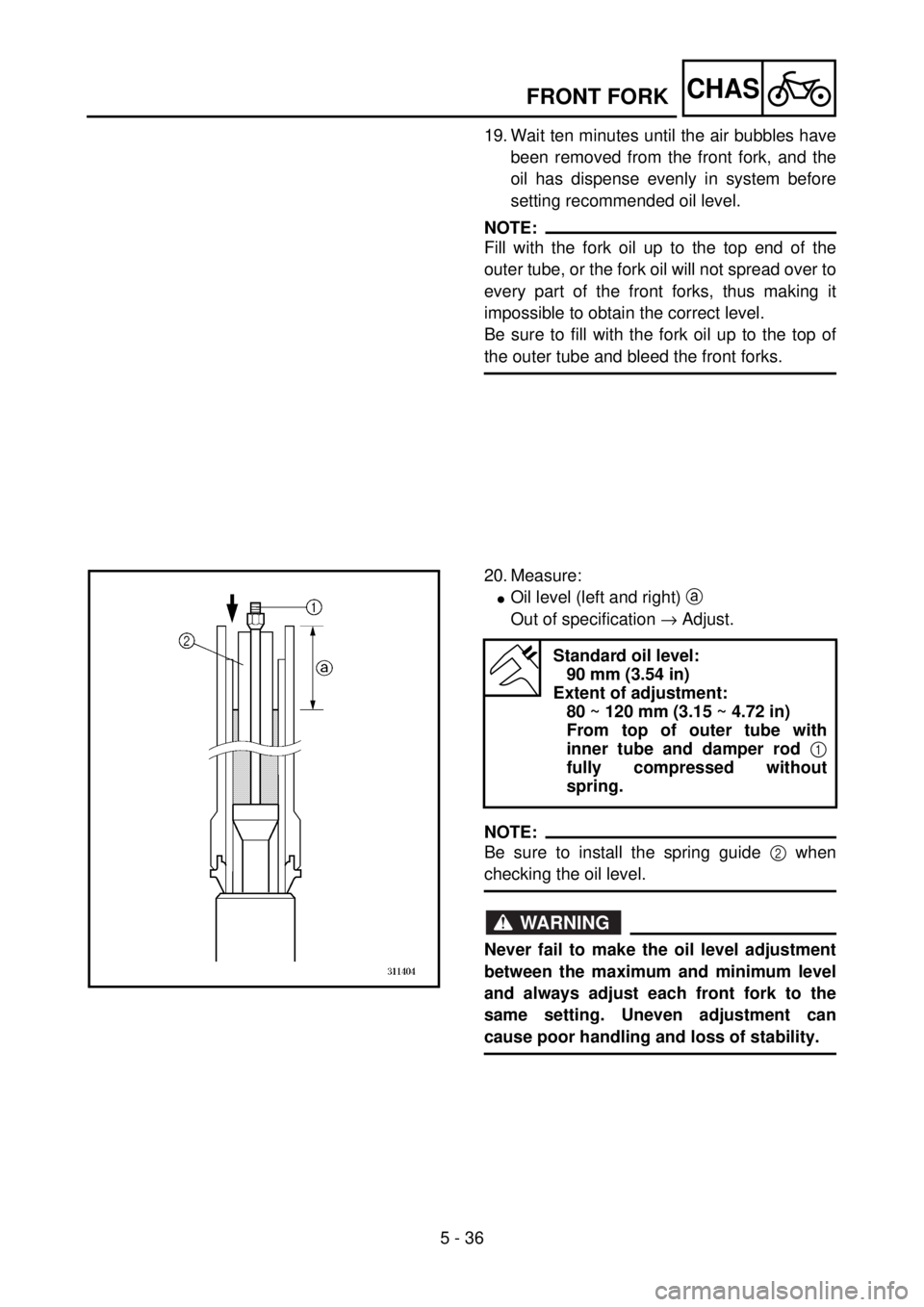

19. Wait ten minutes until the air bubbles have

been removed from the front fork, and the

oil has dispense evenly in system before

setting recommended oil level.

NOTE:

Fill with the fork oil up to the top end of the

outer tube, or the fork oil will not spread over to

every part of the front forks, thus making it

impossible to obtain the correct level.

Be sure to fill with the fork oil up to the top of

the outer tube and bleed the front forks.

20. Measure:

lOil level (left and right) a

Out of specification ® Adjust.

NOTE:

Be sure to install the spring guide 2 when

checking the oil level.

WARNING

Never fail to make the oil level adjustment

between the maximum and minimum level

and always adjust each front fork to the

same setting. Uneven adjustment can

cause poor handling and loss of stability.

Standard oil level:

90 mm (3.54 in)

Extent of adjustment:

80 ~ 120 mm (3.15 ~ 4.72 in)

From top of outer tube with

inner tube and damper rod 1

fully compressed without

spring.

5PA51120

FRONT FORK