check oil YAMAHA YZ85 2002 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 452 of 504

6 - 2

–+ELECIGNITION SYSTEM

EC620000

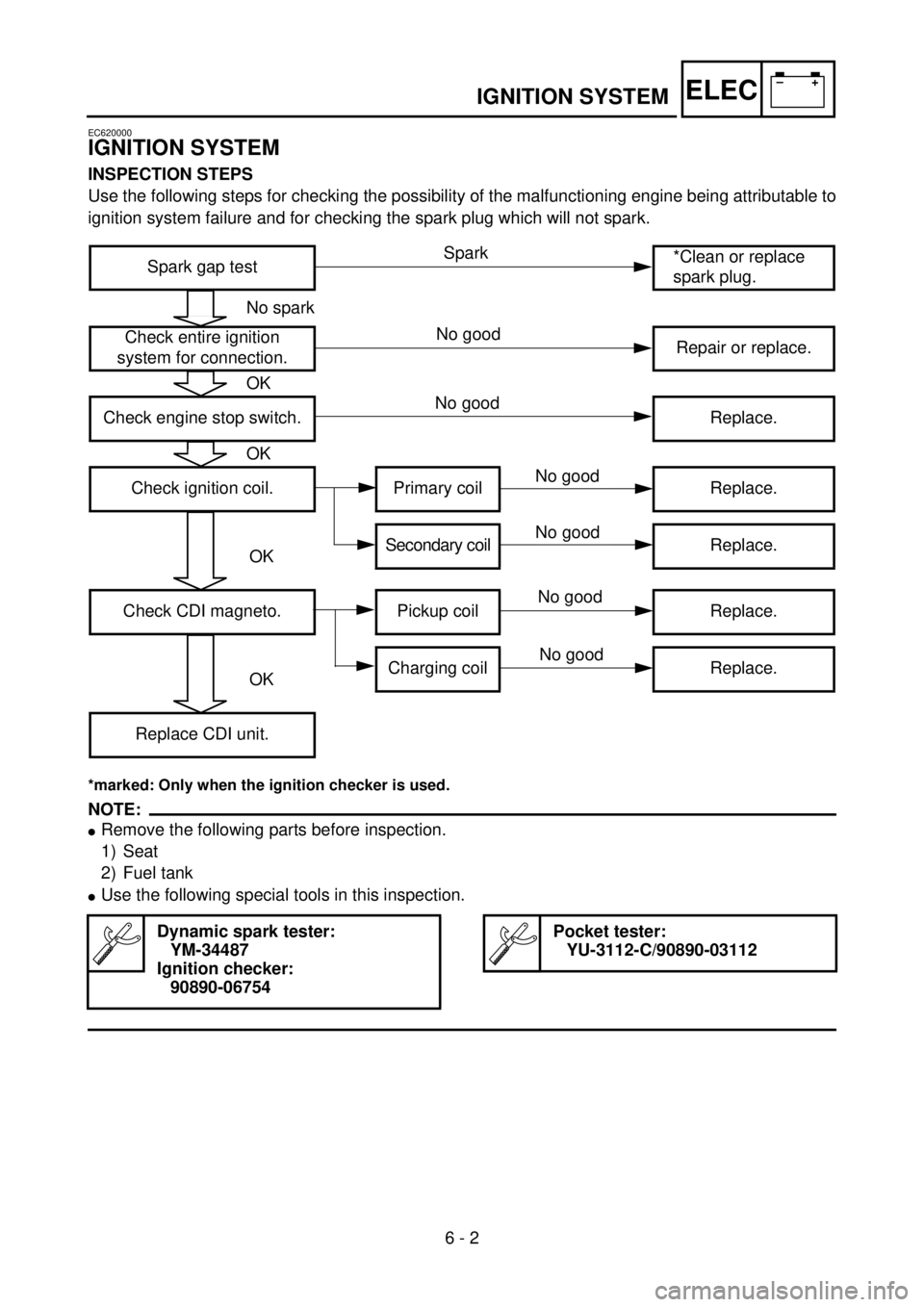

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*marked: Only when the ignition checker is used.

NOTE:

lRemove the following parts before inspection.

1) Seat

2) Fuel tank

lUse the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

Spark gap test*Clean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check engine stop switch. Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check CDI magneto. Pickup coil Replace.

Charging coil Replace.

Replace CDI unit.

No spark

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

Page 460 of 504

6 - 5

–+ELECIGNITION SYSTEM

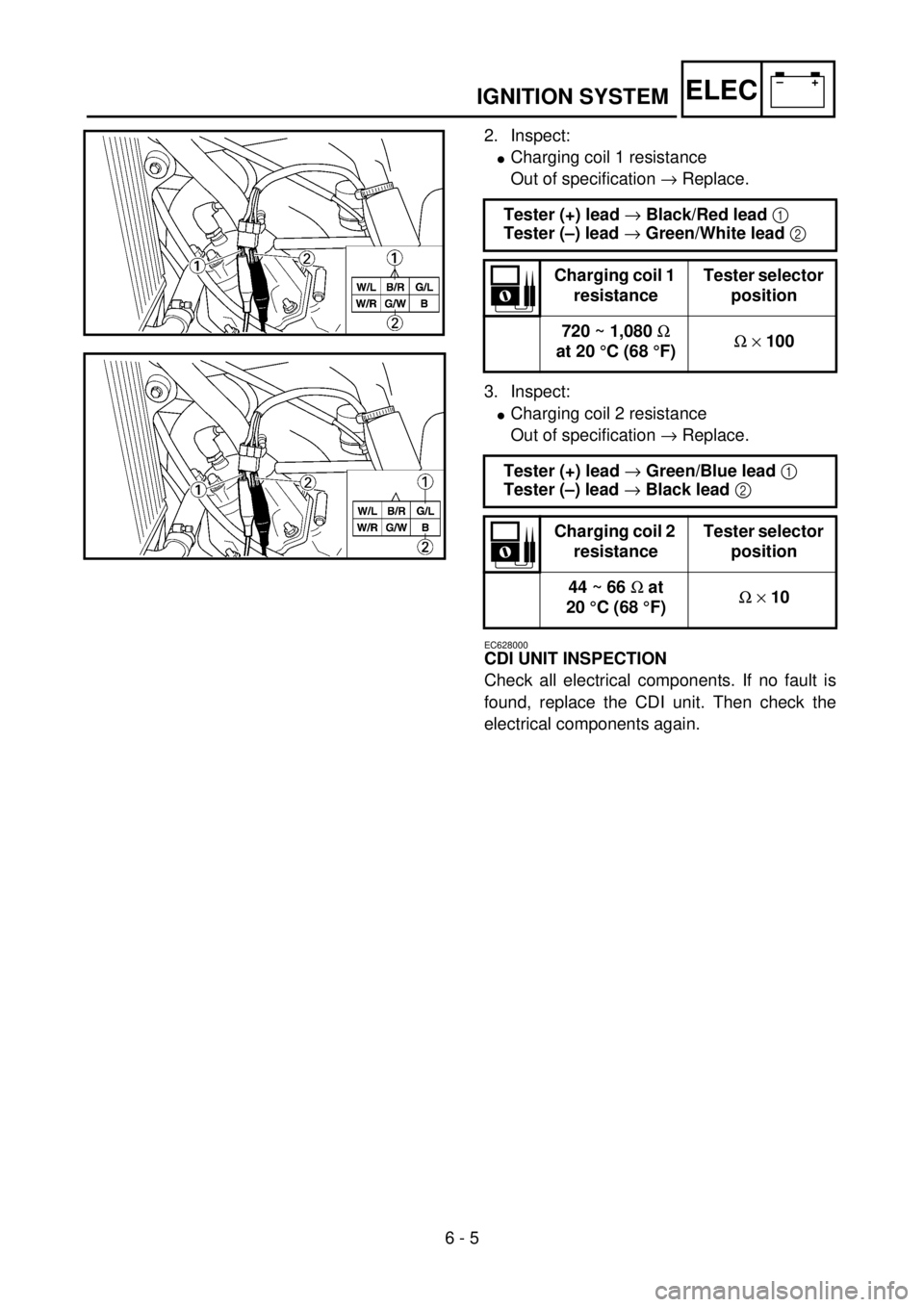

2. Inspect:

lCharging coil 1 resistance

Out of specification ® Replace.

3. Inspect:

lCharging coil 2 resistance

Out of specification ® Replace.

EC628000

CDI UNIT INSPECTION

Check all electrical components. If no fault is

found, replace the CDI unit. Then check the

electrical components again.Tester (+) lead

® Black/Red lead

1

Tester (–) lead

® Green/White lead

2

Charging coil 1

resistanceTester selector

position

720 ~ 1,080

W

at 20 °C (68 °F)W

´ 100

Tester (+) lead

® Green/Blue lead

1

Tester (–) lead

® Black lead

2

Charging coil 2

resistanceTester selector

position

44 ~ 66

W at

20 °C (68 °F)W

´ 10

5PA60090

5PA60100

Page 462 of 504

7 - 1

TUN

EC700000

TUNING

EC710000

ENGINE

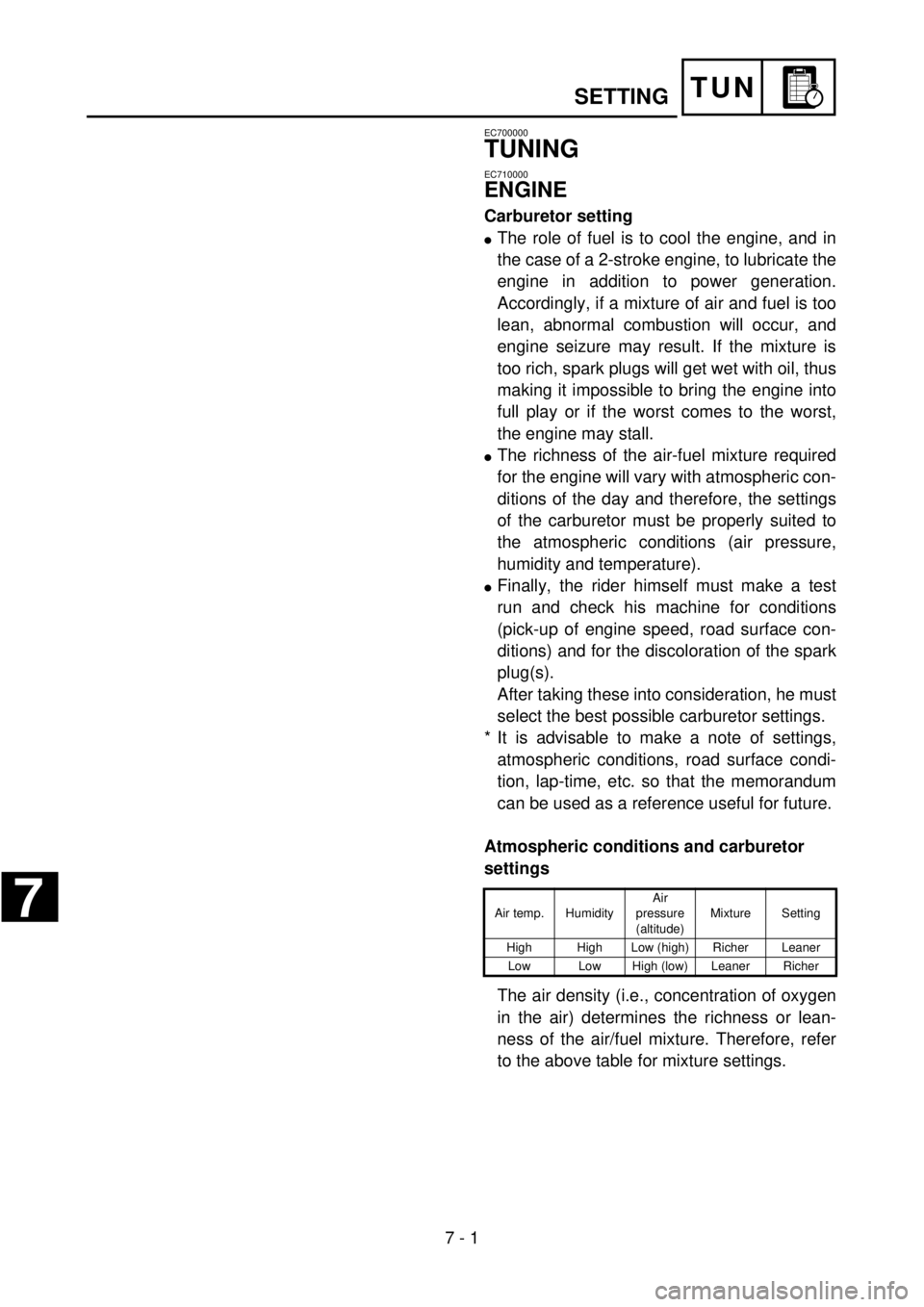

Carburetor setting

lThe role of fuel is to cool the engine, and in

the case of a 2-stroke engine, to lubricate the

engine in addition to power generation.

Accordingly, if a mixture of air and fuel is too

lean, abnormal combustion will occur, and

engine seizure may result. If the mixture is

too rich, spark plugs will get wet with oil, thus

making it impossible to bring the engine into

full play or if the worst comes to the worst,

the engine may stall.

lThe richness of the air-fuel mixture required

for the engine will vary with atmospheric con-

ditions of the day and therefore, the settings

of the carburetor must be properly suited to

the atmospheric conditions (air pressure,

humidity and temperature).

lFinally, the rider himself must make a test

run and check his machine for conditions

(pick-up of engine speed, road surface con-

ditions) and for the discoloration of the spark

plug(s).

After taking these into consideration, he must

select the best possible carburetor settings.

* It is advisable to make a note of settings,

atmospheric conditions, road surface condi-

tion, lap-time, etc. so that the memorandum

can be used as a reference useful for future.

Atmospheric conditions and carburetor

settings

The air density (i.e., concentration of oxygen

in the air) determines the richness or lean-

ness of the air/fuel mixture. Therefore, refer

to the above table for mixture settings.

Air temp. HumidityAir

pressure

(altitude)Mixture Setting

High High Low (high) Richer Leaner

Low Low High (low) Leaner Richer

SETTING

7

Page 464 of 504

7 - 2

TUN

That is:

lHigher temperature expands the air with its

resultant reduced density.

lHigher humidity reduces the amount of oxy-

gen in the air by so much of the water vapor

in the same air.

lLower atmospheric pressure (at a high alti-

tude) reduces the density of the air.

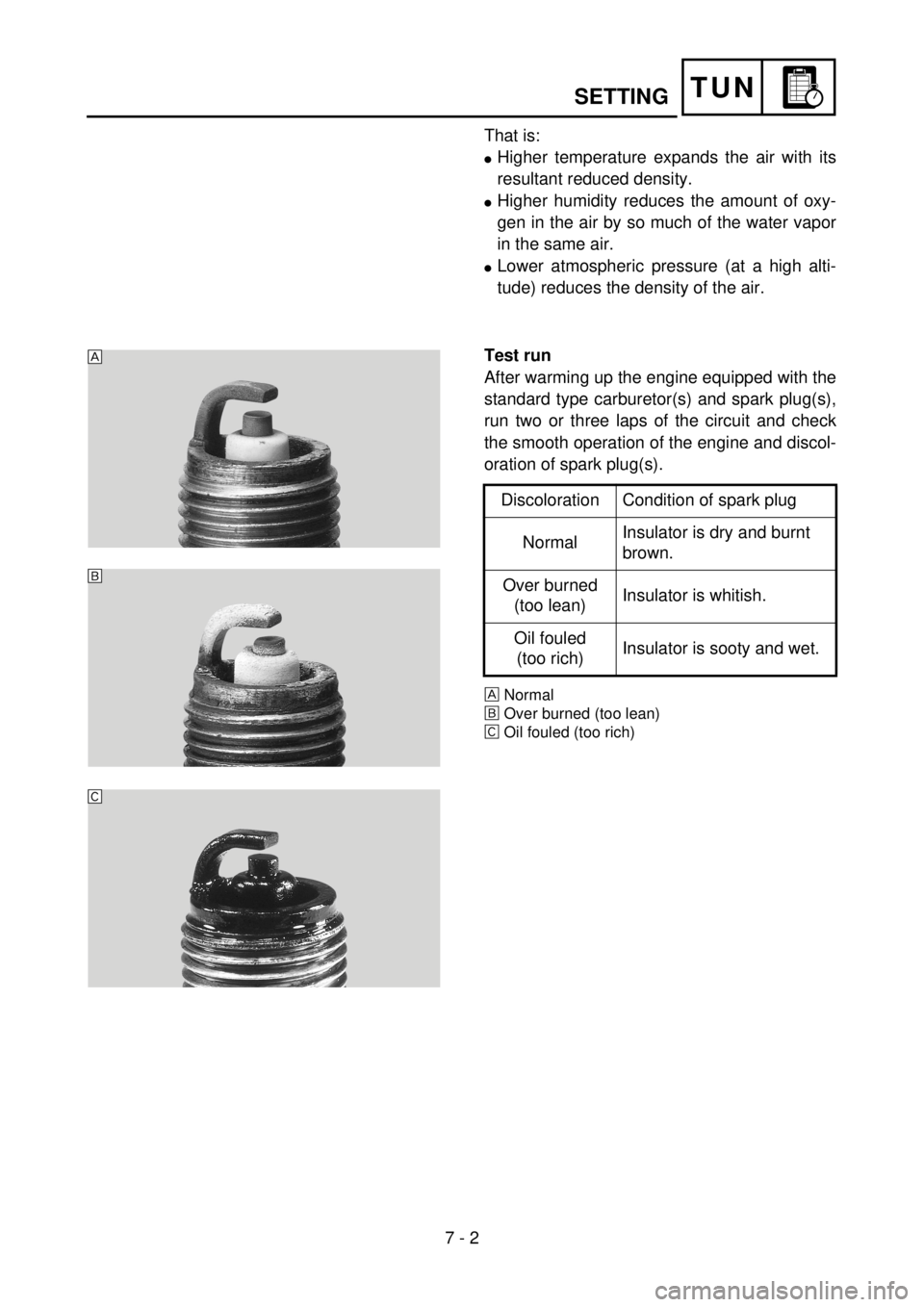

Test run

After warming up the engine equipped with the

standard type carburetor(s) and spark plug(s),

run two or three laps of the circuit and check

the smooth operation of the engine and discol-

oration of spark plug(s).

ÈNormal

ÉOver burned (too lean)

ÊOil fouled (too rich)

Discoloration Condition of spark plug

NormalInsulator is dry and burnt

brown.

Over burned

(too lean)Insulator is whitish.

Oil fouled

(too rich)Insulator is sooty and wet.

5PA70010

È

É

Ê

SETTING

Page 480 of 504

7 - 9

TUNSETTING

Change of the heat range of spark plugs

Judging from the discoloration of spark plugs,

if they are found improper, it can be corrected

by the following two methods; changing carbu-

retor settings and changing the heat range of

spark plug.

lIn principle, it is advisable to first use spark

plugs of standard heat range, and judging

from the discoloration of spark plugs, adjust

carburetor settings.

lIf the calibration No. of the main jet must be

changed by ±30, it is advisable to change the

heat range of spark plugs and newly select

the proper main jet.

NOTE:

lWhen checking the discoloration of spark

plugs, be sure to stop the engine immedi-

ately after a run and check.

lAvoid racing.

lWhen changing the heat range of spark

plugs, never attempt to change it more than

±1 rank.

lWhen using spark plugs other than standard,

make sure of the difference in heat range

and find the equivalent to the standard.

lNote that even if the discoloration seems

proper, it may slightly vary with the spark

plug maker and oil in use.Standard spark plug BR10EG/NGK

5PA70110

Page 498 of 504

7 - 18

TUNSETTING

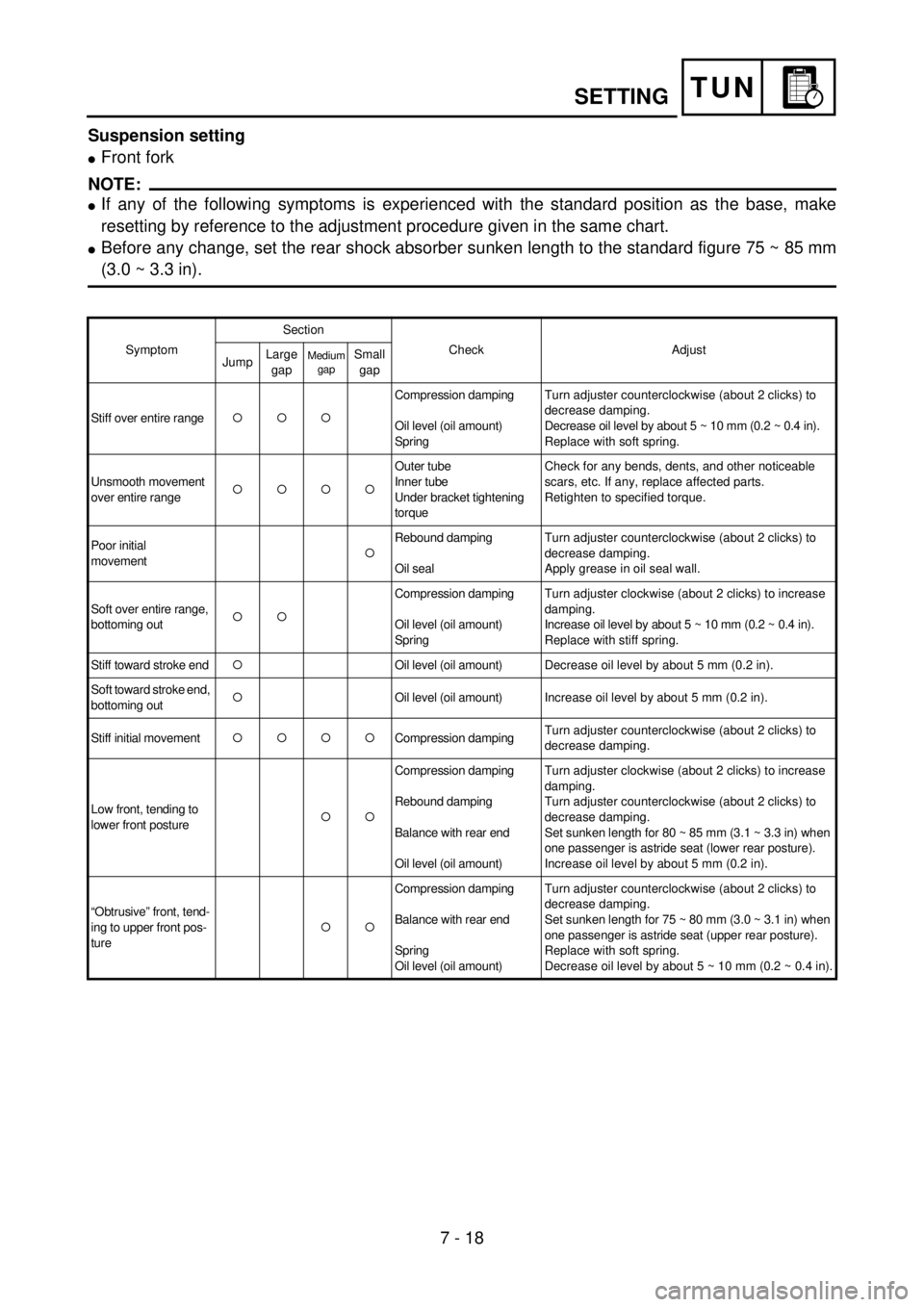

Suspension setting

lFront fork

NOTE:

lIf any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

lBefore any change, set the rear shock absorber sunken length to the standard figure 75 ~ 85 mm

(3.0 ~ 3.3 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire range

{{{Compression damping

Oil level (oil amount)

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with soft spring.

Unsmooth movement

over entire range{{{{Outer tube

Inner tube

Under bracket tightening

torqueCheck for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Retighten to specified torque.

Poor initial

movement{Rebound damping

Oil sealTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Apply grease in oil seal wall.

Soft over entire range,

bottoming out{{Compression damping

Oil level (oil amount)

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with stiff spring.

Stiff toward stroke end{Oil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke end,

bottoming out{Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement{{{{Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture{{Compression damping

Rebound damping

Balance with rear end

Oil level (oil amount)Turn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 80 ~ 85 mm (3.1 ~ 3.3 in) when

one passenger is astride seat (lower rear posture).

Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front, tend-

ing to upper front pos-

ture{{Compression damping

Balance with rear end

Spring

Oil level (oil amount)Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 75 ~ 80 mm (3.0 ~ 3.1 in) when

one passenger is astride seat (upper rear posture).

Replace with soft spring.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).