check engine YAMAHA YZ85 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 6 of 504

IMPORTANT NOTICE

THIS MACHINE IS DESIGNED STRICTLY

FOR COMPETITION USE, ONLY ON A

CLOSED COURSE. It is illegal for this

machine to be operated on any public street,

road, or highway. Off-road use on public lands

may also be illegal. Please check local regula-

tions before riding.

1. THIS MACHINE IS TO BE OPERATED

BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this

machine at maximum power until you

are totally familiar with its character-

istics.

2. THIS MACHINE IS DESIGNED TO BE

RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this

machine.

3. ALWAYS WEAR PROTECTIVE

APPAREL.

When operating this machine, always

wear an approved helmet with gog-

gles or a face shield. Also wear heavy

boots, gloves, and protective cloth-

ing. Always wear proper fitting cloth-

ing that will not be caught in any of

the moving parts or controls of the

machine.

4. ALWAYS MAINTAIN YOUR MACHINE

IN PROPER WORKING ORDER.

For safety and reliability, the machine

must be properly maintained. Always

perform the pre-operation checks

indicated in this manual. Correcting a

mechanical problem before you ride

may prevent an accident.

5. GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refu-

eling. Take care to not spill any gaso-

line on the engine or exhaust system.

Never refuel in the vicinity of an open

flame, or while smoking.

SAFETY INFORMATION

Page 20 of 504

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

DESCRIPTION

........................................... 1-1

MACHINE IDENTIFICATION

..................... 1-2

IMPORTANT INFORMATION

.................... 1-3

CHECKING OF CONNECTION

................. 1-6

SPECIAL TOOLS

...................................... 1-7

CONTROL FUNCTIONS

............................ 1-9

FUEL AND ENGINE MIXING OIL

............ 1-12

STARTING AND BREAK-IN

.................... 1-13

TORQUE-CHECK POINTS

...................... 1-16

CLEANING AND STORAGE

................... 1-17

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS

................... 2-1

MAINTENANCE SPECIFICATIONS

.......... 2-4

ENGINE

................................................... 2-4

CHASSIS

................................................. 2-8

YZ85

..................................................... 2-8

YZ85LW

.............................................. 2-10

ELECTRICAL

........................................ 2-14

GENERAL TORQUE

SPECIFICATIONS

................................... 2-15

DEFINITION OF UNITS

........................... 2-15

CABLE ROUTING DIAGRAM

................. 2-16

Page 52 of 504

1 - 13

GEN

INFO

STARTING AND BREAK-IN

STARTING AND BREAK-IN

CAUTION:

Before starting the machine, perform the

checks in the pre-operation check list.

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

STARTING A COLD ENGINE

1. Shift the transmission into neutral.

2. Turn the fuel cock to “ON” and full open the

starter knob (CHOKE).

3. With the throttle completely closed start the

engine by kicking the kickstarter crank

forthly with firm stroke.

4. Run the engine at idle or slightly higher

until it warms up: this usually takes about

one or two minutes.

5. The engine is warmed up when it responds

normally to the throttle with the starter knob

(CHOKE) turned off.

CAUTION:

Do not warm up the engine for extended

periods.

STARTING A WARM ENGINE

Do not operate the starter knob (CHOKE).

Open the throttle slightly and start the engine

by kicking the kickstarter crank forcefully with

firm stroke.

CAUTION:

Observe the following break-in procedures

during initial operation to ensure optimum

performance and avoid engine damage.

Page 54 of 504

1 - 14

GEN

INFO

STARTING AND BREAK-IN

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with a break-in oil-fuel mixture as follows.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the engine stop switch.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes. Stop and check the spark plug

condition; it will show a rich condition dur-

ing break-in.

5. Allow the engine to cool. Restart the

engine and operate the machine as in the

step above for five minutes. Then, very

briefly shift to the higher gears and check

full-throttle response. Stop and check the

spark plug.

6. After again allowing the engine to cool,

restart and run the machine for five more

minutes. Full throttle and the higher gears

may be used, but sustained full-throttle

operation should be avoided. Check the

spark plug condition.

7. Allow the engine to cool, remove the top

end, and inspect the piston and cylinder.

Remove any high spots on the piston with

#600 grit wet sandpaper. Clean all compo-

nents and carefully reassemble the top

end.

8. Drain the break-in oil-fuel mixture from the

fuel tank and refill with the specified mix.

9. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Stop and check the spark plug

condition. Restart the machine and operate

it for about 10 to 15 more minutes. The

machine will now be ready to race.

Mixing oil:

Yamalube “2-R”

Mixing ratio:

15 : 1

Page 56 of 504

1 - 15

GEN

INFO

STARTING AND BREAK-IN

CAUTION:

lAfter the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

lWhen any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

Page 58 of 504

GEN

INFO

1 - 16

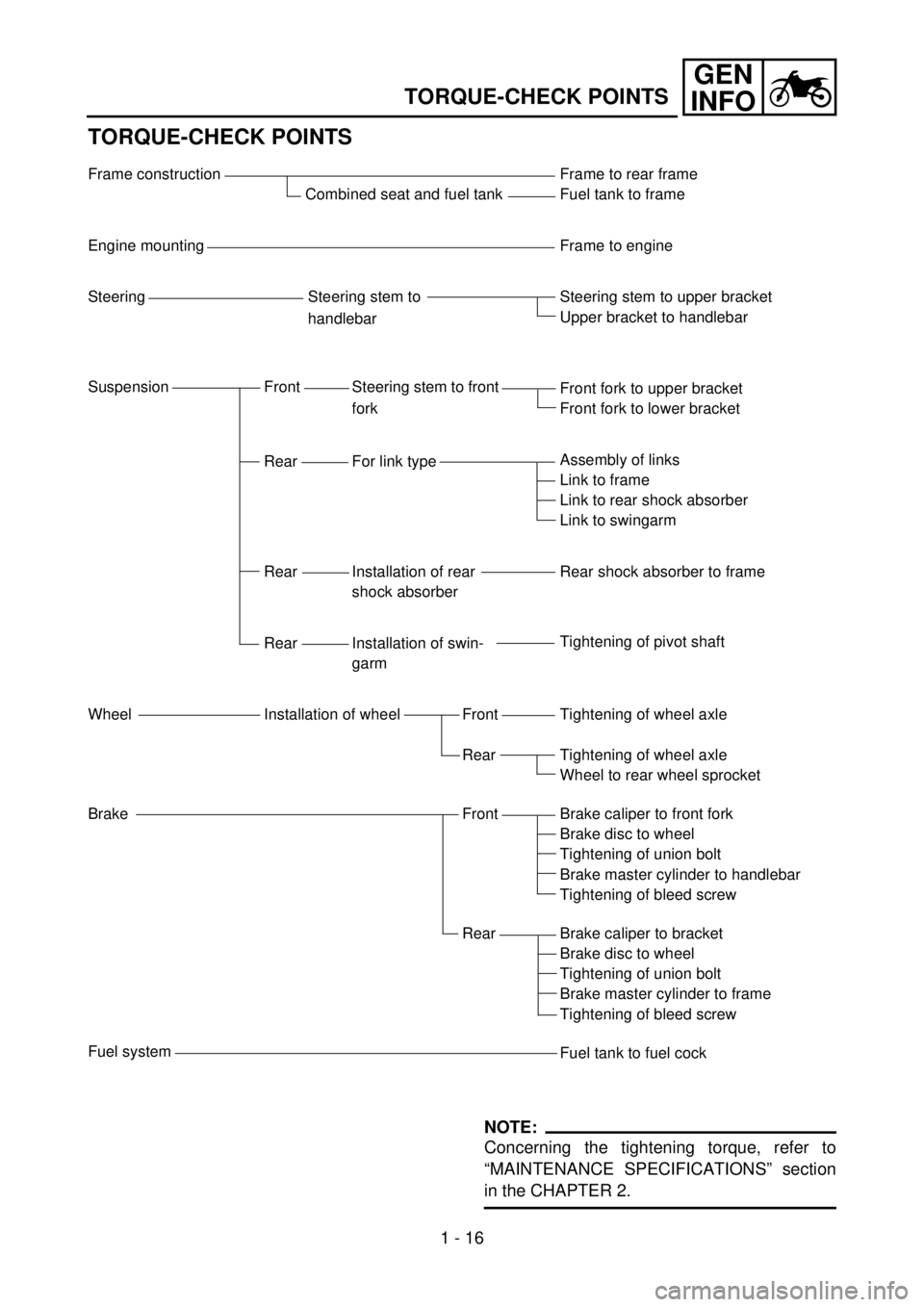

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Frame construction

Combined seat and fuel tank

Engine mounting

Steering Steering stem to

handlebar

Suspension Front Steering stem to front

fork

Rear For link type

Rear Installation of rear

shock absorber

Rear Installation of swin-

garm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel systemFrame to rear frame

Fuel tank to frame

Frame to engine

Steering stem to upper bracket

Upper bracket to handlebar

Front fork to upper bracket

Front fork to lower bracket

Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear shock absorber to frame

Tightening of pivot shaft

Tightening of wheel axle

Tightening of wheel axle

Wheel to rear wheel sprocket

Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Brake caliper to bracket

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Fuel tank to fuel cock

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Page 78 of 504

SPEC

2 - 13

MAINTENANCE SPECIFICATIONS

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke) — 64 3 0.3 2.2

Rear wheel sprocket M8 ´ 1.25 4 42 4.2 30

Rear brake caliper protector M6 ´ 1.0 1 10 1.0 7.2

Engine mounting:

Engine and frame (front) M10 ´ 1.25 1 69 6.9 50

Engine and frame (lower) M10 ´ 1.25 1 69 6.9 50

Pivot shaft and nut M12 ´ 1.25 1 63 6.3 45

Relay arm and frame M10 ´ 1.25 1 54 5.4 39

Relay arm and connecting rod M12 ´ 1.25 1 53 5.3 38

Connecting rod and swingarm M12 ´ 1.25 1 53 5.3 38

Rear shock absorber and frame M10 ´ 1.25 1 36 3.6 25

Rear shock absorber and relay arm M10 ´ 1.25 1 36 3.6 25

Rear frame (upper) M8 ´ 1.25 1 26 2.6 19

Rear frame (lower) M8 ´ 1.25 2 16 1.6 11

Swingarm and brake hose holder M5 ´ — 4 4 0.4 2.9

Drive chain tensioner (upper) M8 ´ 1.25 1 23 2.3 17

Drive chain tensioner (lower) M6 ´ 1.0 1 10 1.0 7.2

Drive chain case M8 ´ 1.25 2 11 1.1 8

Seal guard and swingarm M6 ´ 1.0 2 10 1.0 7.2

Fuel tank M6 ´ 1.0 2 7 0.7 5.1

Fuel cock M6 ´ 1.0 2 4 0.4 2.9

Fuel tank bracket and fuel tank M6 ´ 1.0 4 7 0.7 5.1

Seat set bracket and fuel tank M6 ´ 1.0 1 7 0.7 5.1

Radiator cover M6 ´ 1.0 3 4 0.4 2.9

Front fender M6 ´ 1.0 4 7 0.7 5.1

Rear fender M6 ´ 1.0 4 7 0.7 5.1

Flap guard M6 ´ 1.0 2 7 0.7 5.1

Side cover M6 ´ 1.0 2 7 0.7 5.1

Seat M6 ´ 1.0 2 7 0.7 5.1

Number plate M6 ´ 1.0 1 7 0.7 5.1

Page 127 of 504

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh mixture of oil and gasoline is filled in the fuel

tank. Check the fuel line for leakage.P.1-12

Transmission oilCheck that the oil level is correct. Check the crankcase for leak-

age.P.3-12 ~ 13

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10

Brakes Check the play of front brake and effect of front and rear brake. P.3-16 ~ 21

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-22 ~ 24

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-31 ~ 32

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-32 ~ 33

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-24 ~ 30

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipe and silencerCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-2

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-34

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-16

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 19

Page 130 of 504

3 - 5

INSP

ADJ

EC350000

ENGINE

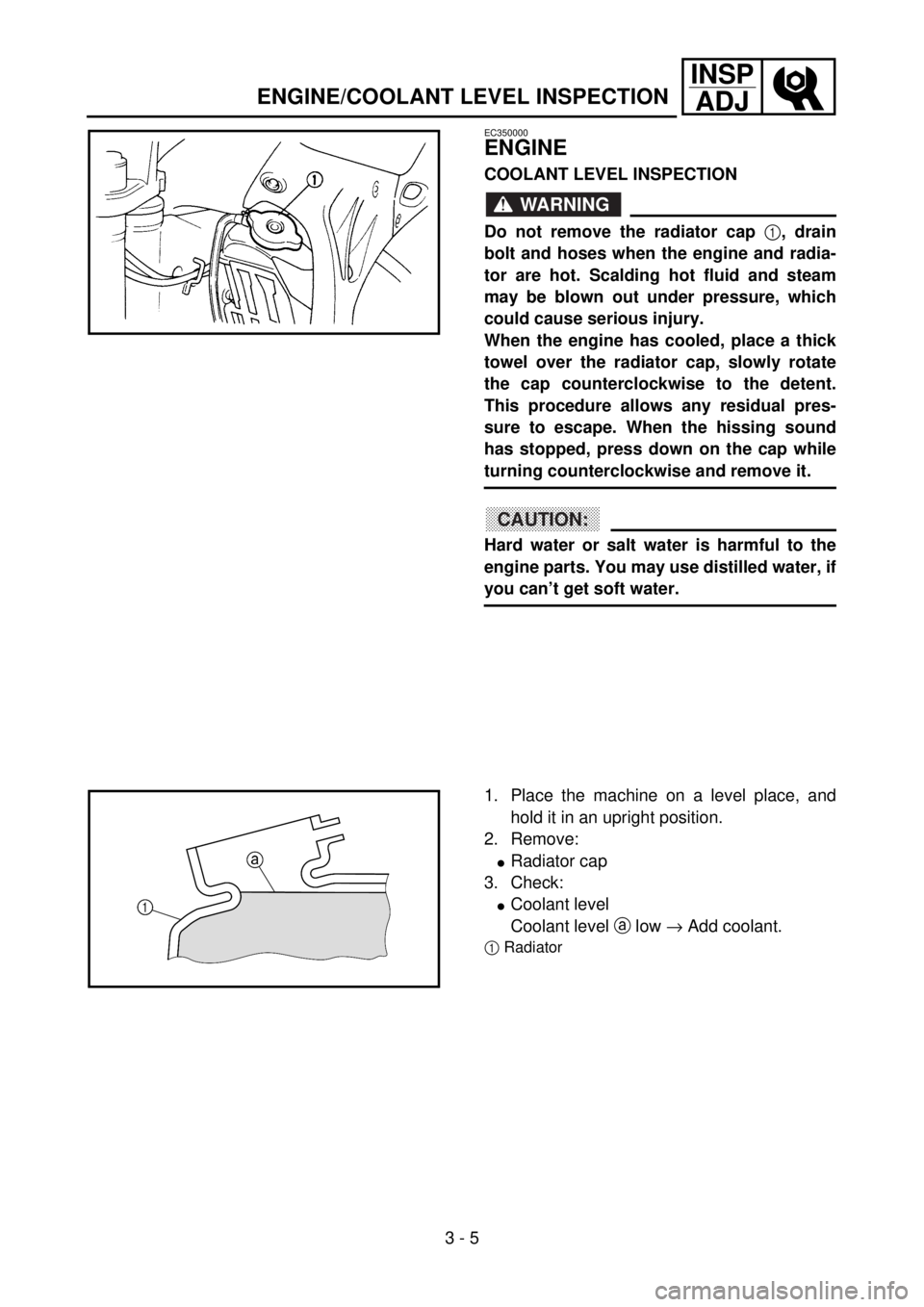

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap

1, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

5PA30010

1. Place the machine on a level place, and

hold it in an upright position.

2. Remove:

lRadiator cap

3. Check:

lCoolant level

Coolant level a low ® Add coolant.

1Radiator

5PA30020

ENGINE/COOLANT LEVEL INSPECTION

Page 134 of 504

3 - 7

INSP

ADJ

RADIATOR CAP INSPECTION

CAUTION:

lDo not mix more than one type of ethyl-

ene glycol antifreeze containing corro-

sion inhibitors for aluminum engine.

lDo not use water containing impurities or

oil.

7. Install:

lRadiator cap

Start the engine and warm it up for a sev-

eral minutes.

8. Check:

lCoolant level

Coolant level low ® Add coolant. Handling notes of coolant:

The coolant is harmful so it should be han-

dled with special care.

WARNING

lWhen coolant splashes to your eye.

Thoroughly wash your eye with water

and see your doctor.

lWhen coolant splashes to your clothes.

Quickly wash it away with water and

then with soap.

lWhen coolant is swallowed.

Quickly make him vomit and take him

to a doctor.

EC355000

RADIATOR CAP INSPECTION

1. Inspect:

lSeal (radiator cap) 1

lValve and valve seat 2

Crack/damage ® Replace.

Exist fur deposits 3 ® Clean or replace.

5PA30050