clock YAMAHA YZ85 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YZ85, Model: YAMAHA YZ85 2002Pages: 504, PDF Size: 40.45 MB

Page 130 of 504

3 - 5

INSP

ADJ

EC350000

ENGINE

COOLANT LEVEL INSPECTION

WARNING

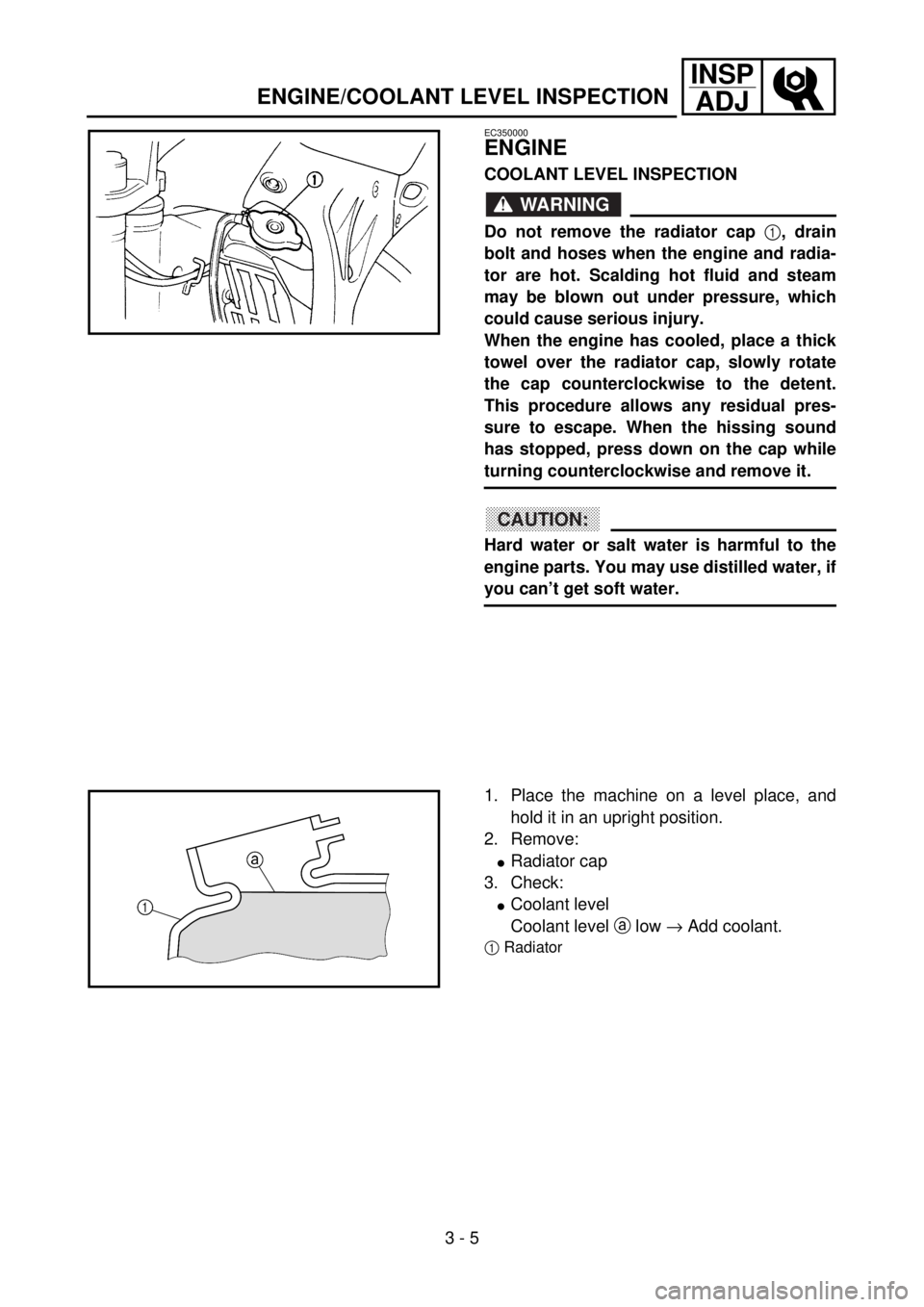

Do not remove the radiator cap

1, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

5PA30010

1. Place the machine on a level place, and

hold it in an upright position.

2. Remove:

lRadiator cap

3. Check:

lCoolant level

Coolant level a low ® Add coolant.

1Radiator

5PA30020

ENGINE/COOLANT LEVEL INSPECTION

Page 158 of 504

3 - 19

INSP

ADJ

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

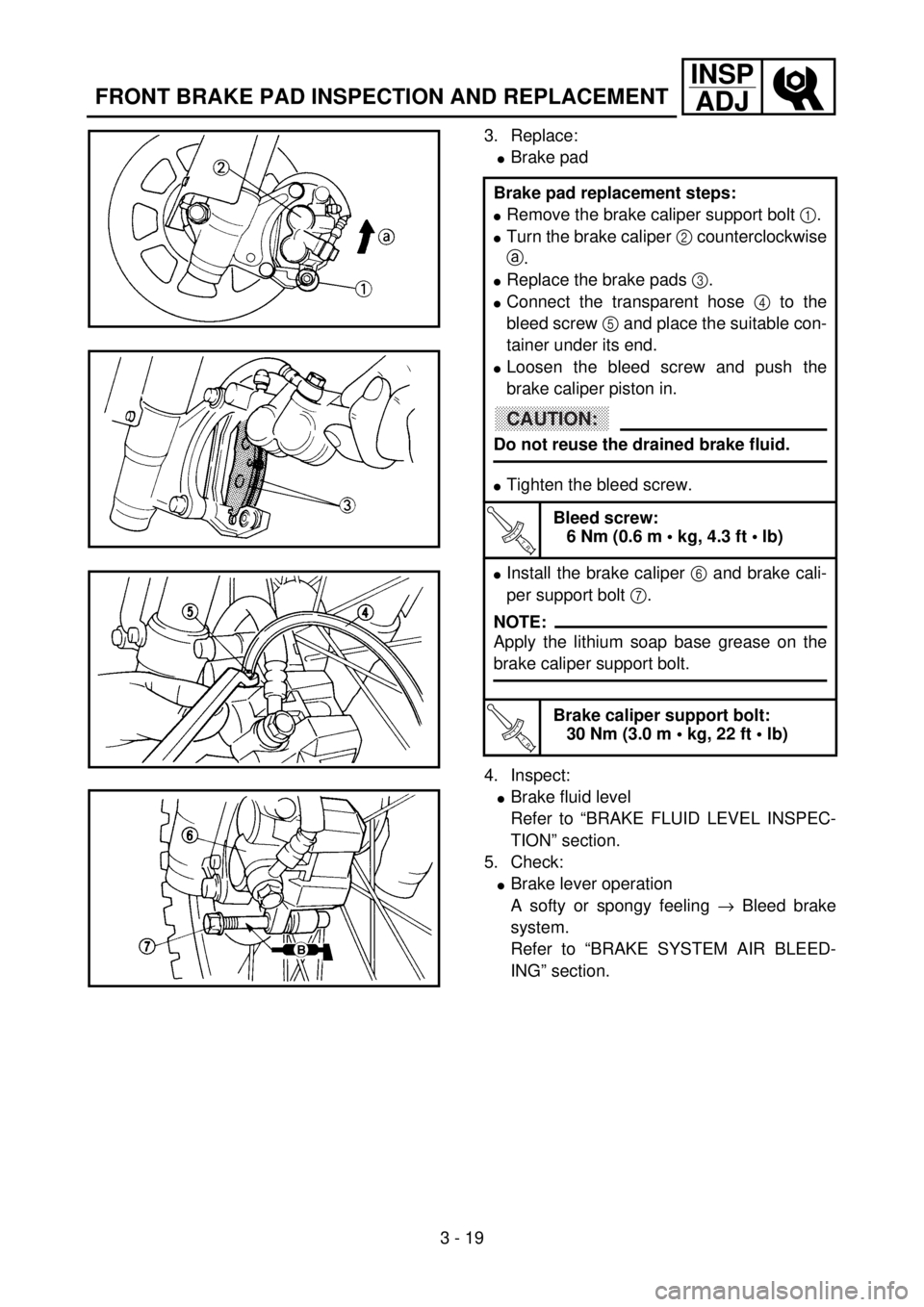

3. Replace:

lBrake pad

4. Inspect:

lBrake fluid level

Refer to “BRAKE FLUID LEVEL INSPEC-

TION” section.

5. Check:

lBrake lever operation

A softy or spongy feeling ® Bleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEED-

ING” section. Brake pad replacement steps:

lRemove the brake caliper support bolt 1.

lTurn the brake caliper 2 counterclockwise

a.

lReplace the brake pads 3.

lConnect the transparent hose 4 to the

bleed screw 5 and place the suitable con-

tainer under its end.

lLoosen the bleed screw and push the

brake caliper piston in.

CAUTION:

Do not reuse the drained brake fluid.

lTighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

lInstall the brake caliper 6 and brake cali-

per support bolt 7.

NOTE:

Apply the lithium soap base grease on the

brake caliper support bolt.

T R..

Brake caliper support bolt:

30 Nm (3.0 m • kg, 22 ft • lb)

5PA30370

5PA30380

5PA30390

5PA30400

Page 168 of 504

3 - 24

INSP

ADJFRONT FORK INSPECTION/

FRONT FORK OIL SEAL AND DUST SEAL CLEANING

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the axle nut 1 and locknuts 2.

lAdjust chain slack by turning the adjusters 3.

To tighten

® Turn adjuster

3 clockwise.

To loosen

® Turn adjuster

3 counter-

clockwise and push wheel forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

lTighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

110 Nm (11.0 m • kg, 80 ft • lb)

lTighten the locknuts.

5PA30560

EC36C000

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the front

fork.

Unsmooth action/oil leakage ® Repair or

replace.

5PA30570

EC36D001

FRONT FORK OIL SEAL AND DUST SEAL

CLEANING

1. Remove:

lProtector 1

lDust seal 2

NOTE:

Use a thin screw driver, and be careful not to

damage the inner fork tube and dust seal.5PA30580

Page 192 of 504

3 - 36

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lAir scoop

lSpark plug

lLeft crankcase cover

2. Attach:

lDial gauge 1

lDial gauge stand 2

Dial gauge and stand:

YU-3097/90890-01252

Stand:

YU-12565PA30870

3. Rotate the rotor 1 until the piston reaches

top dead center (TDC). When this hap-

pens, the needle on the dial gauge will stop

and reverse directions even though the

rotor is being turned in the same direction.

4. Set the dial gauge to zero at TDC.

5PA30880

5. From TDC, rotate the rotor clockwise until

the dial gauge indicates that the piston is at

a specified distance from TDC.

Ignition timing (B.T.D.C.):

0.9 mm (0.035 in)

6. Check:

lIgnition timing

Punch mark a on rotor should be aligned

with punch mark b on stator.

Not aligned ® Adjust.

5PA30890

Page 202 of 504

4 - 4

ENGRADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC454000

INSPECTION

Radiator

1. Inspect:

lRadiator core 1

Obstruction ® Blow out with compressed

air through rear of the radiator.

Bent fin ® Repair or replace.

5PA40040

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

lRadiator breather hose 1

To radiator 2.

5PA40050

2. Install:

lRadiator 1

lBolt (radiator) 2

5PA40060

Page 270 of 504

4 - 38

ENG

2. Install:

lSpring guide 1

NOTE:

Slide the spring guide into the kick shaft, make

sure the groove a in the spring guide fits on

the stopper of the torsion spring.

5PA41120

3. Install:

lKick shaft assembly 1

NOTE:

lApply the transmission oil on the kick shaft.

lApply the lithium soap base grease on the

kick shaft stopper.

lSlide the kick shaft assembly into the crank-

case, make sure the clip 2 and kick shaft

stopper a fit into their home positions b, c.5PA41130

4. Hook:

lTorsion spring 1

NOTE:

Turn the torsion spring clockwise and hook

into the proper hole a in the crankcase.

5PA41140

Kick idle gear

1. Install:

lWasher 1

lKick idle gear 2

lCirclip 3

NOTE:

lApply the transmission oil on the kick idle

gear inner circumference.

lInstall the kick idle gear with its groove a

facing the engine.

5PA41150

KICK SHAFT, SHIFT SHAFT AND PRIMARY DRIVE GEAR

Page 286 of 504

4 - 46

ENG

EC4L3000

REMOVAL POINTS

Rotor

1. Remove:

lNut (rotor) 1

lWasher 2

Use the rotor holding tool 3.

Rotor holding tool:

YU-1235/90890-01235

5PA41390

2. Remove:

lRotor 1

Use the flywheel puller 2.

NOTE:

When installing the flywheel puller, turn it

counterclockwise.

Flywheel puller:

YM-1189/90890-01189

5PA41400

EC4L4000

INSPECTION

EC4L4101

CDI magneto

1. Inspect:

lRotor inner surface a

lStator outer surface b

Damage ® Inspect the crankshaft runout

and crankshaft bearing.

If necessary, replace CDI magneto and/or

stator.

5PA41410

EC4L4200

Woodruff key

1. Inspect:

lWoodruff key 1

Damage ® Replace.

5PA41420

CDI MAGNETO

Page 348 of 504

![YAMAHA YZ85 2002 Owners Manual 5 - 13

CHAS

EC5A3000

REMOVAL POINTS

Brake fluid

1. Remove:

[Front]

lBrake master cylinder cap 1

[Rear]

lReservoir tank cap 1

NOTE:

Do not remove the diaphragm.

ÈFront

ÉRear

È

5PA50290

€

É

5PA5 YAMAHA YZ85 2002 Owners Manual 5 - 13

CHAS

EC5A3000

REMOVAL POINTS

Brake fluid

1. Remove:

[Front]

lBrake master cylinder cap 1

[Rear]

lReservoir tank cap 1

NOTE:

Do not remove the diaphragm.

ÈFront

ÉRear

È

5PA50290

€

É

5PA5](/img/51/54066/w960_54066-347.png)

5 - 13

CHAS

EC5A3000

REMOVAL POINTS

Brake fluid

1. Remove:

[Front]

lBrake master cylinder cap 1

[Rear]

lReservoir tank cap 1

NOTE:

Do not remove the diaphragm.

ÈFront

ÉRear

È

5PA50290

€

É

5PA50300

2. Connect the transparent hose 2 to the

bleed screw 1 and place a suitable con-

tainer under its end.

ÈFront

ÉRear

3. Loosen the bleed screw and drain the

brake fluid while pulling the lever in or

pushing down on the pedal.

CAUTION:

lDo not reuse the drained brake fluid.

lBrake fluid may erode painted surfaces or

plastic parts. Always clean up spilled

fluid immediately.

€

ÈÉ

5PA50310

Front brake caliper

1. Remove:

lBrake caliper 1

NOTE:

Turn the brake caliper counterclockwise and

pull out it from the guide pin 2 on the brake

caliper bracket.

€

5PA50320

FRONT BRAKE AND REAR BRAKE

Page 358 of 504

5 - 18

CHAS

2. Install:

lPin boot 1

On brake caliper 2.

NOTE:

Apply the lithium soap base grease on the pin

boot inner surface.

5PA50500

3. Install:

lBrake caliper bracket 1

lBolt (brake caliper bracket) 2

lBrake pad 3

5PA50510

T R..30 Nm (3.0 m · kg, 22 ft · lb)

4. Install:

lBrake caliper 1

NOTE:

lApply the lithium soap base grease on the

guide pin 2.

lInstall the brake caliper into the guide pin

and turn it clockwise.

5PA50520

5. Install:

lBrake caliper support bolt 1

NOTE:

Apply the lithium soap base grease on the

brake caliper support bolt.

Rear brake caliper

1. Install:

lPad support 1

lBrake pad 2

lPad pin 3

NOTE:

lInstall the brake pad fitted with brake pad

shim 4 on the brake caliper piston side.

lTemporarily tighten the pad pins at this point.

5PA50530

T R..23 Nm (2.3 m · kg, 17 ft · lb)

5PA50540

FRONT BRAKE AND REAR BRAKE

Page 498 of 504

7 - 18

TUNSETTING

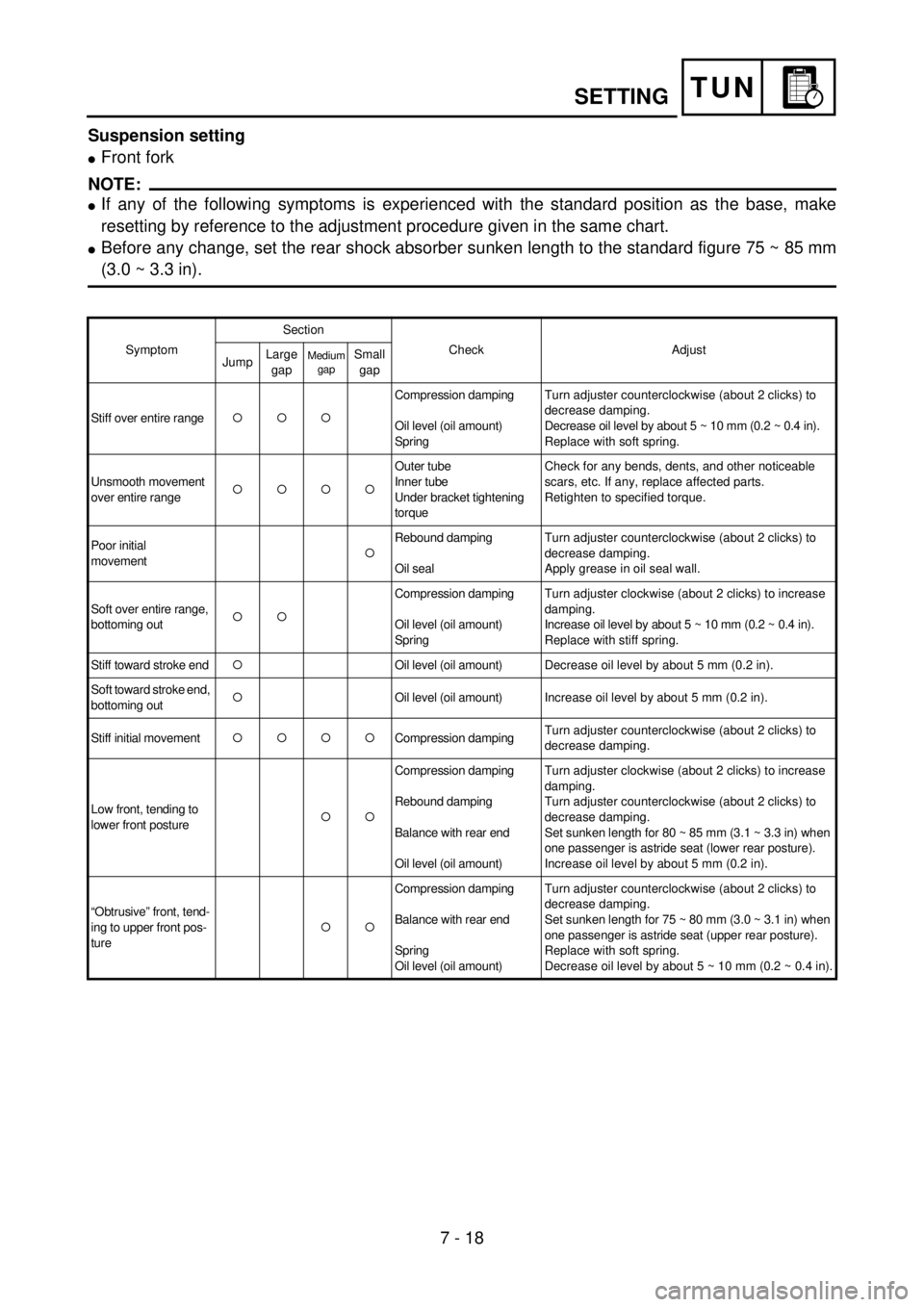

Suspension setting

lFront fork

NOTE:

lIf any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

lBefore any change, set the rear shock absorber sunken length to the standard figure 75 ~ 85 mm

(3.0 ~ 3.3 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire range

{{{Compression damping

Oil level (oil amount)

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with soft spring.

Unsmooth movement

over entire range{{{{Outer tube

Inner tube

Under bracket tightening

torqueCheck for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Retighten to specified torque.

Poor initial

movement{Rebound damping

Oil sealTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Apply grease in oil seal wall.

Soft over entire range,

bottoming out{{Compression damping

Oil level (oil amount)

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with stiff spring.

Stiff toward stroke end{Oil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke end,

bottoming out{Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement{{{{Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture{{Compression damping

Rebound damping

Balance with rear end

Oil level (oil amount)Turn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 80 ~ 85 mm (3.1 ~ 3.3 in) when

one passenger is astride seat (lower rear posture).

Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front, tend-

ing to upper front pos-

ture{{Compression damping

Balance with rear end

Spring

Oil level (oil amount)Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 75 ~ 80 mm (3.0 ~ 3.1 in) when

one passenger is astride seat (upper rear posture).

Replace with soft spring.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).