warning YAMAHA YZ85 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ85, Model: YAMAHA YZ85 2013Pages: 88, PDF Size: 1.74 MB

Page 37 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-11

4

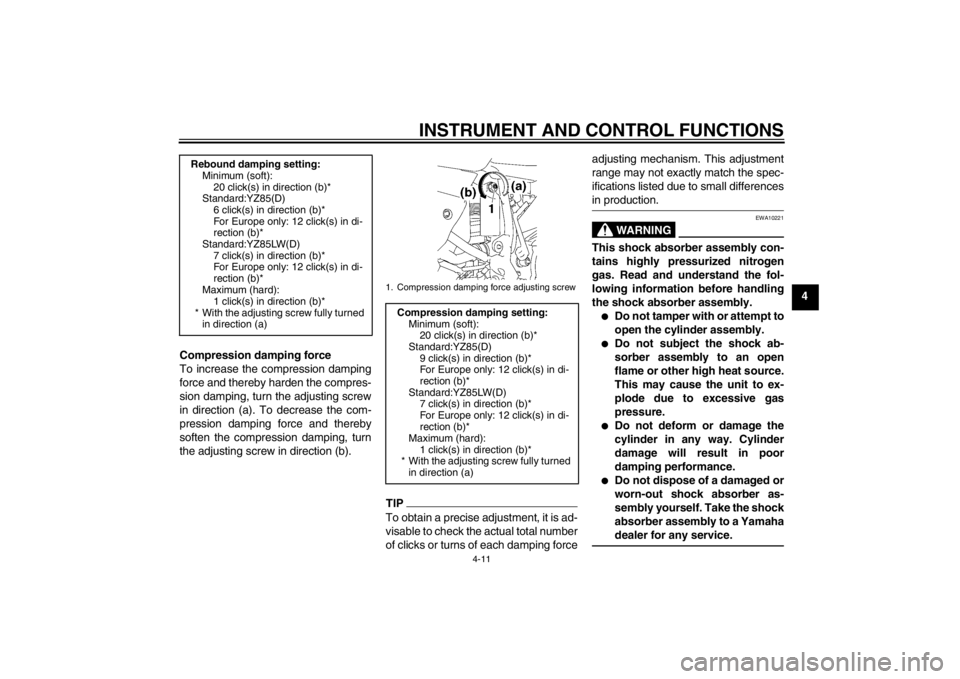

Compression damping force

To increase the compression damping

force and thereby harden the compres-

sion damping, turn the adjusting screw

in direction (a). To decrease the com-

pression damping force and thereby

soften the compression damping, turn

the adjusting screw in direction (b).

TIPTo obtain a precise adjustment, it is ad-

visable to check the actual total number

of clicks or turns of each damping force adjusting mechanism. This adjustment

range may not exactly match the spec-

ifications listed due to small differences

in production.

WARNING

EWA10221

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.●

Do not tamper with or attempt to

open the cylinder assembly.

●

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

●

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

●

Do not dispose of a damaged or

worn-out shock absorber as-

sembly yourself. Take the shock

absorber assembly to a Yamaha

dealer for any service.

Rebound damping setting:

Minimum (soft):

20 click(s) in direction (b)*

Standard:YZ85(D)

6 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Standard:YZ85LW(D) 7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1. Compression damping force adjusting screw

Compression damping setting: Minimum (soft):20 click(s) in direction (b)*

Standard:YZ85(D) 9 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Standard:YZ85LW(D) 7 click(s) in direction (b)*

For Europe only: 12 click(s) in di-

rection (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U1SN81E0.book Page 11 Tuesday, June 12, 2012 3:17 PM

Page 38 of 88

INSTRUMENT AND CONTROL FUNCTIONS

4-12

4

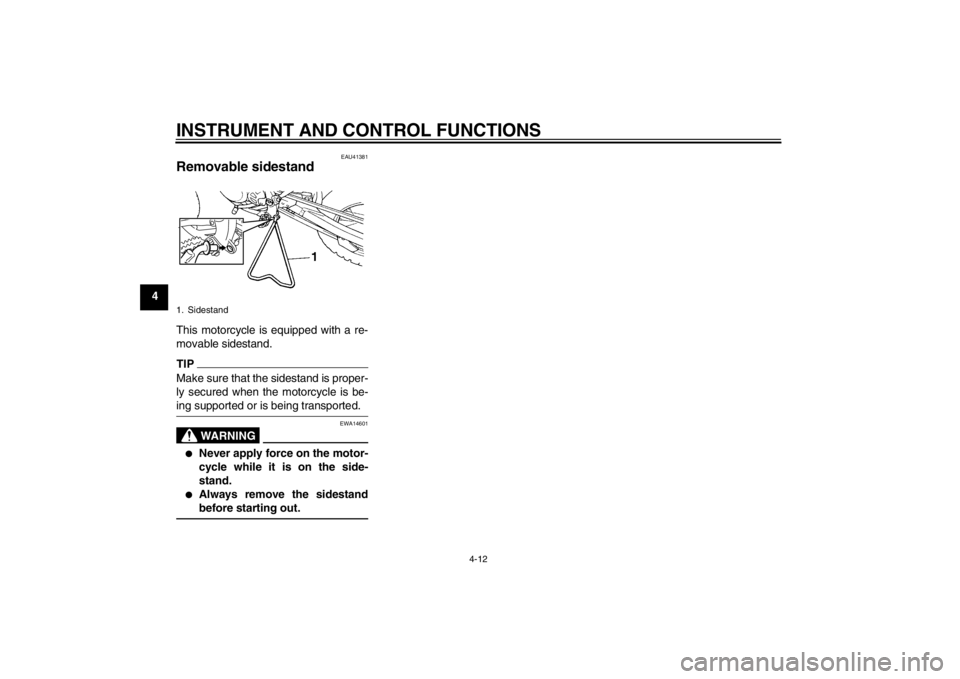

EAU41381

Removable sidestand This motorcycle is equipped with a re-

movable sidestand.TIPMake sure that the sidestand is proper-

ly secured when the motorcycle is be-

ing supported or is being transported.

WARNING

EWA14601

●

Never apply force on the motor-

cycle while it is on the side-

stand.

●

Always remove the sidestand

before starting out.

1. SidestandU1SN81E0.book Page 12 Tuesday, June 12, 2012 3:17 PM

Page 39 of 88

FOR YOUR SAFETY – PRE-OPERATION CHECKS

5-1

5

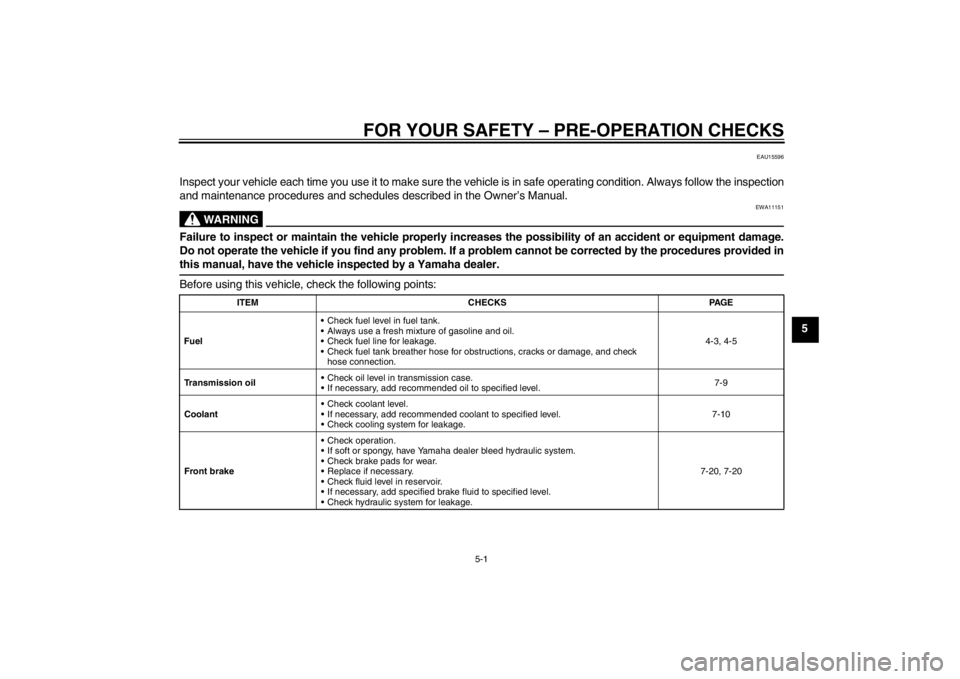

EAU15596

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11151

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment damage.

Do not operate the vehicle if you find any problem. If a problem cannot be corrected by the procedures provided in

this manual, have the vehicle inspected by a Yamaha dealer.Before using this vehicle, check the following points:

ITEMCHECKS PAGE

Fuel Check fuel level in fuel tank.

Always use a fresh mixture of gasoline and oil.

Check fuel line for leakage.

Check fuel tank breather hose for ob

structions, cracks or damage, and check

hose connection. 4-3, 4-5

Transmission oil Check oil level in transmission case.

If necessary, add recommended oil to specified level. 7-9

Coolant Check coolant level.

If necessary, add recommended coolant to specified level.

Check cooling system for leakage. 7-10

Front brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 7-20, 7-20

U1SN81E0.book Page 1 Tuesday, June 12, 2012 3:17 PM

Page 42 of 88

OPERATION AND IMPORTANT RIDING POINTS

6-1

6

EAU15951

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10271

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which could cause an accident

or injury.

EAU41307

Starting and warming up a

cold engine 1. Turn the fuel cock lever to “ON”.

2. Shift the transmission into the neu-tral position.

3. Turn the starter (choke) on and completely close the throttle. (See

page 4-6.)

4. Start the engine by pushing the kickstarter lever down.

5. When the engine is warm, turn the starter (choke) off.TIPThe engine is warm when it responds

quickly to the throttle with the starter

(choke) turned off.NOTICE

ECA11042

For maximum engine life, never ac-

celerate hard when the engine is

cold!

EAU16660

Starting a warm engine Follow the same procedure as for start-

ing a cold engine with the exception

that the starter (choke) is not required

when the engine is warm. Instead, start

the engine with the throttle slightly

open.TIPIf the engine does not start after several

kicks, try again with the throttle 1/4 to

1/2 open.

U1SN81E0.book Page 1 Tuesday, June 12, 2012 3:17 PM

Page 44 of 88

OPERATION AND IMPORTANT RIDING POINTS

6-3

6

EAU41503

Engine break-in

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer perform

service.1. Before starting the engine, fill thefuel tank with a break-in oil-fuel

mixture as follows.

2. Start and warm up the engine. Check the operation of the controls

and the engine stop button. (See

page 4-1.)

3. Operate the motorcycle in the low- er gears at moderate throttle open-

ings for five to eight minutes. Stop

the engine and check the spark plug condition (see page 7-8); it

will show a rich condition during

break-in.

4. Allow the engine to cool. Restart the engine and operate the motor-

cycle as in the step above for five

minutes. Then, very briefly shift to

the higher gears and check the

full-throttle response. Stop the en-

gine and check the spark plug.

5. After again allowing the engine to cool, restart and run the motorcy-

cle for five more minutes. Full

throttle and the higher gears may

be used, but sustained full-throttle

operation should be avoided. Stop

the engine and check the spark

plug again.

6. Allow the engine to cool, remove the cylinder head and cylinder, and

inspect the piston and cylinder.

Remove any high spots on the pis-

ton with #600-grit wet sandpaper.

Clean all components and careful-

ly reassemble the cylinder head

and cylinder.

7. Drain the break-in oil-fuel mixture from the fuel tank and refill with the

specified mix. (See page 4-3.) 8. Start the engine and check the op-

eration of the motorcycle through-

out its entire operating range. Stop

the engine and check the spark

plug condition. Restart the motor-

cycle and ride it for about 10 to 15

more minutes. The motorcycle will

now be ready to ride normally.

After the engine break-in period, thor-

oughly check the motorcycle for loose

parts, oil leakage and any other prob-

lems. Be sure to inspect and make ad-

justments thoroughly, especially cable

and drive chain slack and loose

spokes. In addition, check all fittings

and fasteners for looseness, and tight-

en if necessary.

NOTICE

ECA15560

●

When any of the following parts

have been replaced, they must

be broken in.

Cylinder or crankshaft:

About one hour of break-in op-

eration is necessary.

Piston, rings or transmission

gears:

Recommended 2-stroke engine oil: See page 9-1.

Mixing ratio (gasoline to oil): 15:1

U1SN81E0.book Page 3 Tuesday, June 12, 2012 3:17 PM

Page 45 of 88

OPERATION AND IMPORTANT RIDING POINTS

6-4

6

These parts require about 30

minutes of break-in operation at

half-throttle or less. Observe the

condition of the engine carefully

during operation.

●

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi- cle.

EAU17191

Parking When parking, stop the engine, and

then turn the fuel cock lever to “OFF”.

WARNING

EWA10311

●

Since the engine and exhaust

system can become very hot,

park in a place where pedestri-

ans or children are not likely to

touch them and be burned.

●

Do not park on a slope or on soft

ground, otherwise the vehicle

may overturn, increasing the

risk of a fuel leak and fire.

●

Do not park near grass or other

flammable materials which

might catch fire.

U1SN81E0.book Page 4 Tuesday, June 12, 2012 3:17 PM

Page 46 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-1

7

EAU42073

Periodic inspection, adjustment, and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. Safety is an obligation of the vehi-

cle owner/operator. The most important

points of vehicle inspection, adjust-

ment, and lubrication are explained on

the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, depending on the

weather, terrain, geographical location,

and individual use, the maintenance in-

tervals may need to be shortened.

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer perform

service.

WARNING

EWA15122

Turn off the engine when performing

maintenance unless otherwise

specified.●

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

●

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 2-2 for more in-

formation about carbon monox-

ide.WARNING

EWA15460

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool before

touching them.

U1SN81E0.book Page 1 Tuesday, June 12, 2012 3:17 PM

Page 55 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-10

7

NOTICE

ECA10452

●

In order to prevent clutch slip-

page (since the transmission oil

also lubricates the clutch), do

not mix any chemical additives.

Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

●

Make sure that no foreign mate-

rial enters the transmission.

7. Start the engine, and then let it idlefor several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

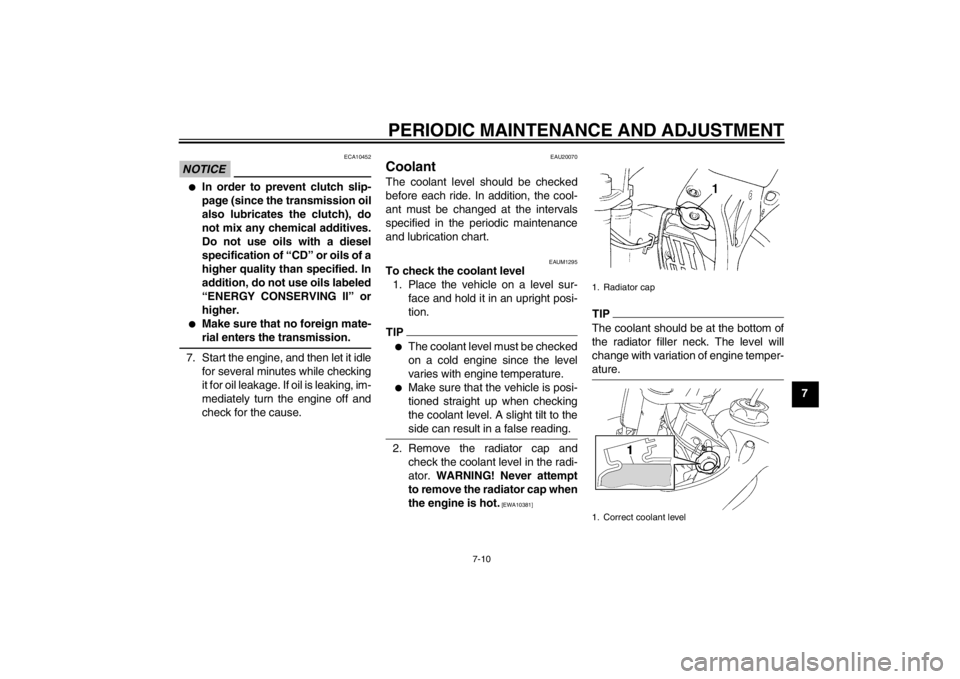

EAU20070

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM1295

To check the coolant level1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIP●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Remove the radiator cap andcheck the coolant level in the radi-

ator. WARNING! Never attempt

to remove the radiator cap when

the engine is hot.

[EWA10381]

TIPThe coolant should be at the bottom of

the radiator filler neck. The level will

change with variation of engine temper-

ature.1. Radiator cap

1. Correct coolant level

U1SN81E0.book Page 10 Tuesday, June 12, 2012 3:17 PM

Page 56 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-11

73. If the coolant is below the correct

coolant level, add coolant, and

then install the radiator cap.

NOTICE: If coolant is not avail-

able, use distilled water or soft

tap water instead. Do not use

hard water or salt water since it

is harmful to the engine. If water

has been used instead of cool-

ant, replace it with coolant as

soon as possible, otherwise the

cooling system will not be pro-

tected against frost and corro-

sion. If water has been added to

the coolant, have a Yamaha

dealer check the antifreeze con-

tent of the coolant as soon as

possible, otherwise the effec-

tiveness of the coolant will be

reduced.

[ECA10472]

EAUM1315

To change the coolant1. Place the vehicle on a level sur- face and let the engine cool if nec-

essary.

2. Place a container under the engine to collect the used coolant. 3. Remove the coolant drain bolt and

its gasket, and then the radiator

cap to drain the cooling system.

WARNING! Never attempt to re-

move the radiator cap when the

engine is hot.

[EWA10381]

4. After the coolant is completelydrained, thoroughly flush the cool-

ing system with clean tap water.

5. Install the coolant drain bolt and its new gasket, and then tighten the

bolt to the specified torque.

6. Pour the recommended coolant into the radiator until it is full.

7. Install the radiator cap, start the engine, let it idle for several min-

utes, and then turn it off.

8. Remove the radiator cap to check the coolant level in the radiator. If

necessary, add sufficient coolant

1. Coolant drain bolt

2. Gasket

1. Radiator cap

1

2

Tightening torque:Coolant drain bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Antifreeze/water mixture ratio: 1:1

Recommended antifreeze:

High-quality ethylene glycol anti-

freeze containing corrosion inhibi-

tors for aluminum engines

Coolant quantity: Radiator capacity (including all

routes):

0.54 L (0.57 US qt, 0.48 Imp.qt)

U1SN81E0.book Page 11 Tuesday, June 12, 2012 3:17 PM

Page 60 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-15

7

EAU48432

Adjusting the throttle grip free

play The throttle grip free play should mea-

sure 3.0–5.0 mm (0.12–0.20 in) at the

inner edge of the throttle grip. Periodi-

cally check the throttle grip free play

and, if necessary, adjust it as follows.TIPThe engine idling speed must be cor-

rectly adjusted before checking and ad-

justing the throttle grip free play.1. Slide the rubber cover back.

2. Loosen the locknut.3. To increase the throttle grip free

play, turn the adjusting nut in direc-

tion (a). To decrease the throttle

grip free play, turn the adjusting

nut in direction (b).

4. Tighten the locknut and then slide the rubber cover to its original po-

sition.

EAU41822

Tires Tires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be checked

and, if necessary, adjusted before each

ride.

WARNING

EWA14381

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control.●

The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the temperature

of the tires equals the ambient

temperature).

1. Throttle grip free play

1. Locknut

2. Throttle grip free play adjusting nut

3. Rubber cover

2

3

(a)

(b)

1

U1SN81E0.book Page 15 Tuesday, June 12, 2012 3:17 PM