Front YAMAHA YZF-R1 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZF-R1, Model: YAMAHA YZF-R1 2014Pages: 114, PDF Size: 2.87 MB

Page 38 of 114

INSTRUMENT AND CONTROL FUNCTIONS

3-23

3

“TCS” modes 2 through 6 provide

for more traction control system

assist. Mode 6 provides the most

traction control system assist.

“TCS OFF” mode turns the trac-

tion control system off. The sys-

tem may also be automatically

disabled in some riding conditions

(see “Resetting” on page 3-23).

When the key is turned to “ON”, the

traction control system is enabled and

the last mode selected displays in the

multi-function meter.

All traction control system modes can

be selected when the key is in the “ON”

position. Modes 1 through 6 can also

be selected when the vehicle is mov-

ing, however the throttle grip must be

completely closed. The traction control

system cannot be turned on or off

while the vehicle is moving.

NOTICE

ECA16801

Use only the specified tires. (See

pa ge 6-18.) Usin g different size d

tires will prevent the traction control

system from controllin g tire rotation

accurately.

Setting the traction control system

WARNING

EWA16071

Changin g settin gs while ri din g can

d istract the operator. Therefore,

take extra precaution when chan g-

in g mo des while rid ing.When the vehicle is stopped, push the

upper side of the traction control sys-

tem switch for at least two seconds to

turn the traction control system off.

Push the lower side of the switch to

turn the traction control system on.

When the vehicle is stopped or while

riding, close the throttle and push the

lower side of the switch to change from

modes 1 to 6. Close the throttle and

push the upper side of the switch to

change from modes 6 to 1.TIPThe vehicle was set to “TCS” mode 6

at the time of manufacture.

Resettin g

The traction control system may be

disabled in the following conditions: Either the front wheel or rear wheel

comes off the ground while riding

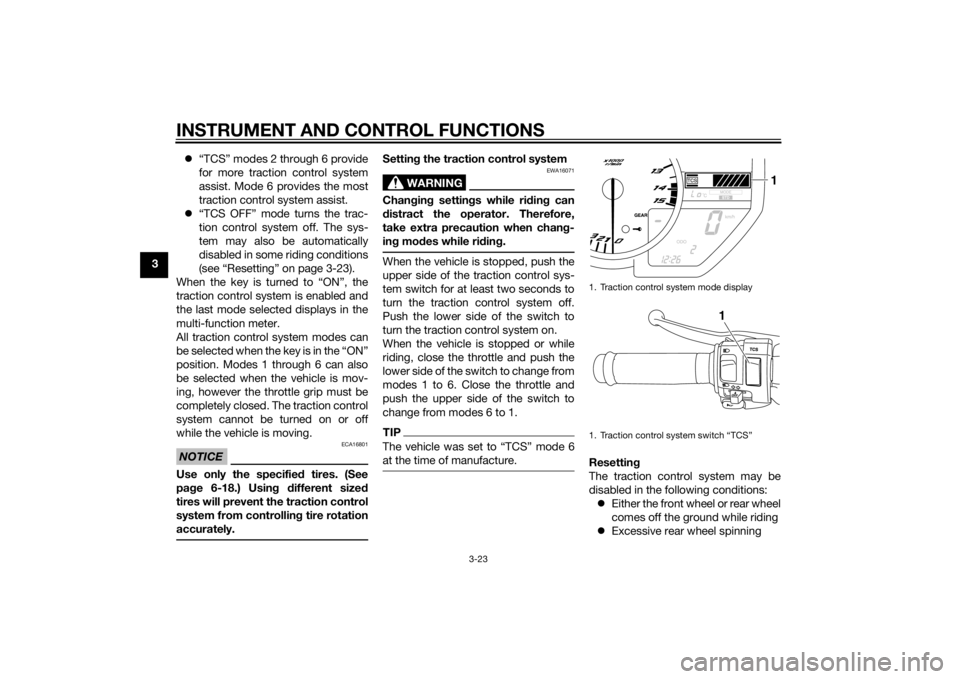

Excessive rear wheel spinning1. Traction control system mode display

1. Traction control system switch “TCS”

1

1

U2SGE0E0.book Page 23 Wednesday, June 12, 2013 1:15 PM

Page 39 of 114

INSTRUMENT AND CONTROL FUNCTIONS

3-24

3

If the traction control system has been

disabled, both the traction control sys-

tem indicator/warning light and the en-

gine trouble warning light come on.

To reset the traction control system:

Turn the key to “OFF”. Wait at least one

second, then turn the key back to

“ON”. The traction control system indi-

cator/warning light should go off and

the system will be enabled. The engine

trouble warning light should go off after

the motorcycle reaches at least 20

km/h (12 mi/h). If the traction control

system indicator/warning light and/or

engine trouble warning light still remain

on after resetting, the motorcycle may

still be ridden; however, have a

Yamaha dealer check the motorcycle as soon as possible.NOTICE

ECA17732

Keep any type of mag nets (in-

clu din g ma gnetic pick-up tools,

ma gnetic screw drivers, etc.)

away from the front wheel sen-

sor or rotor; otherwise, the sen-

sor or rotor may be damag ed , resultin

g in improper perfor-

mance of the traction control

system.

Be careful not to d amage the

sensor or rotor.

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap 1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

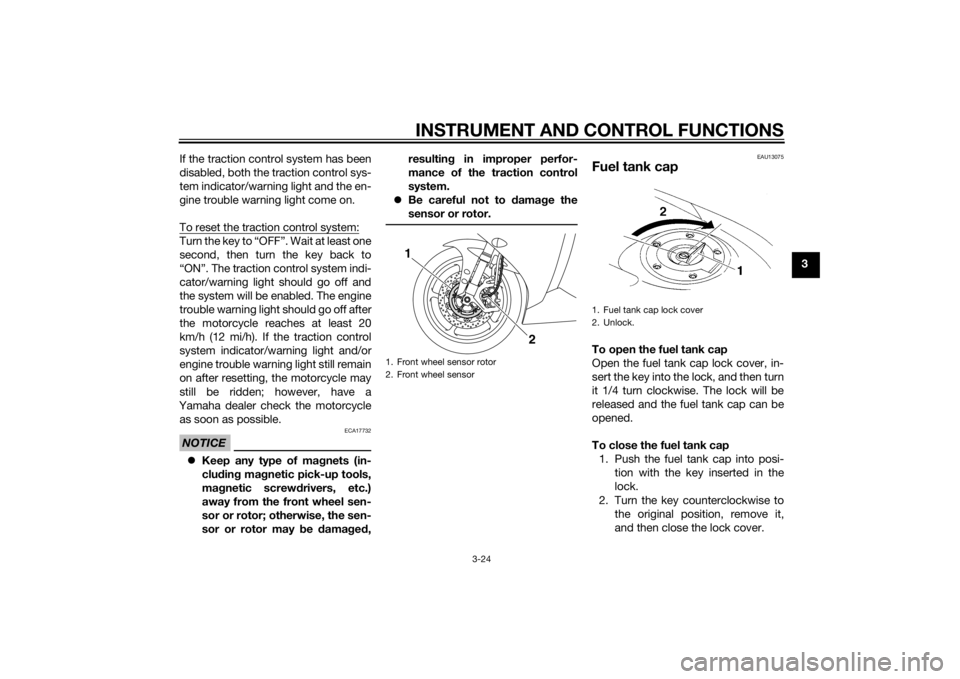

1. Front wheel sensor rotor

2. Front wheel sensor

2

1

1. Fuel tank cap lock cover

2. Unlock.

U2SGE0E0.book Page 24 Wednesday, June 12, 2013 1:15 PM

Page 42 of 114

INSTRUMENT AND CONTROL FUNCTIONS

3-27

3

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

b urns:

Do not park the vehicle near

possi ble fire hazard s such as

g rass or other materials that

easily burn.

Park the vehicle in a place

where ped estrians or chil dren

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has cooled down before

d oin g any maintenance work.

Do not allow the en gine to i dle

more than a few minutes. Lon g

i d lin g can cause a b uild-up of

heat.

NOTICE

ECA10702

Use only unlea ded g asoline. The use

of lead ed g asoline will cause unre-

pairab le dama ge to the catalytic

converter.

EAU47272

SeatsPassen ger seat

To remove the passenger seat1. Insert the key into the seat lock, and then turn it clockwise.

2. Lift the front of the passenger seat and pull it forward.

To install the passenger seat1. Insert the projection on the rear of the passenger seat into the seat

holder as shown, and then push

the front of the seat down to lock

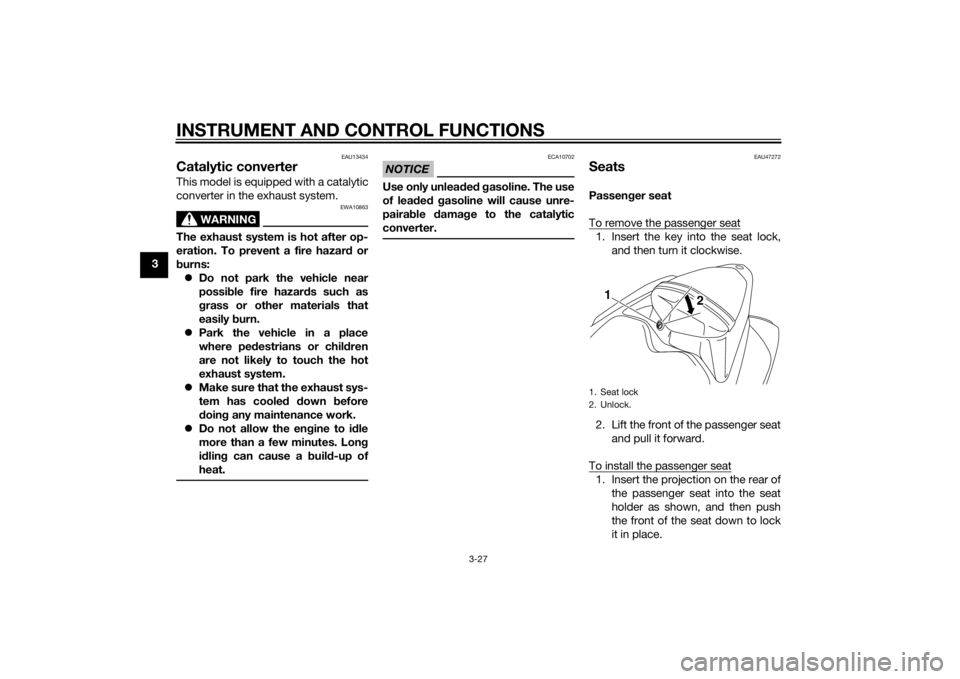

it in place.1. Seat lock

2. Unlock.

1 2

U2SGE0E0.book Page 27 Wednesday, June 12, 2013 1:15 PM

Page 46 of 114

INSTRUMENT AND CONTROL FUNCTIONS

3-31

3

EAU47622

Adjustin g the front fork

WARNING

EWA14671

Always a djust the sprin g preloa d on

b oth fork le gs equally, otherwise

poor han dlin g an d loss of sta bility

may result.Each front fork leg is equipped with a

spring preload adjusting bolt, the right

front fork leg is equipped with a re-

bound damping force adjusting screw

and the left front fork leg with a com-

pression damping force adjusting

screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

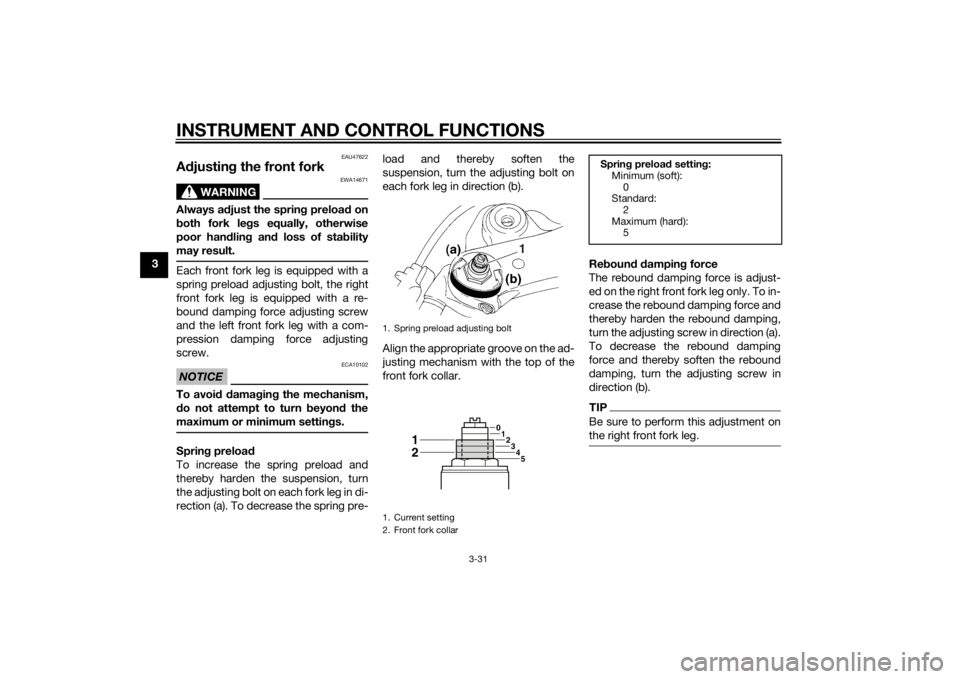

maximum or minimum setting s.Spring preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre- load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b).

Align the appropriate groove on the ad-

justing mechanism with the top of the

front fork collar.

Re

boun d d ampin g force

The rebound damping force is adjust-

ed on the right front fork leg only. To in-

crease the rebound damping force and

thereby harden the rebound damping,

turn the adjusting screw in direction (a).

To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in

direction (b).

TIPBe sure to perform this adjustment on

the right front fork leg.

1. Spring preload adjusting bolt

1. Current setting

2. Front fork collar

1

0 123

45

12

Sprin g preloa d setting :

Minimum (soft):

0

Standard:

2

Maximum (hard): 5

U2SGE0E0.book Page 31 Wednesday, June 12, 2013 1:15 PM

Page 47 of 114

INSTRUMENT AND CONTROL FUNCTIONS

3-32

3

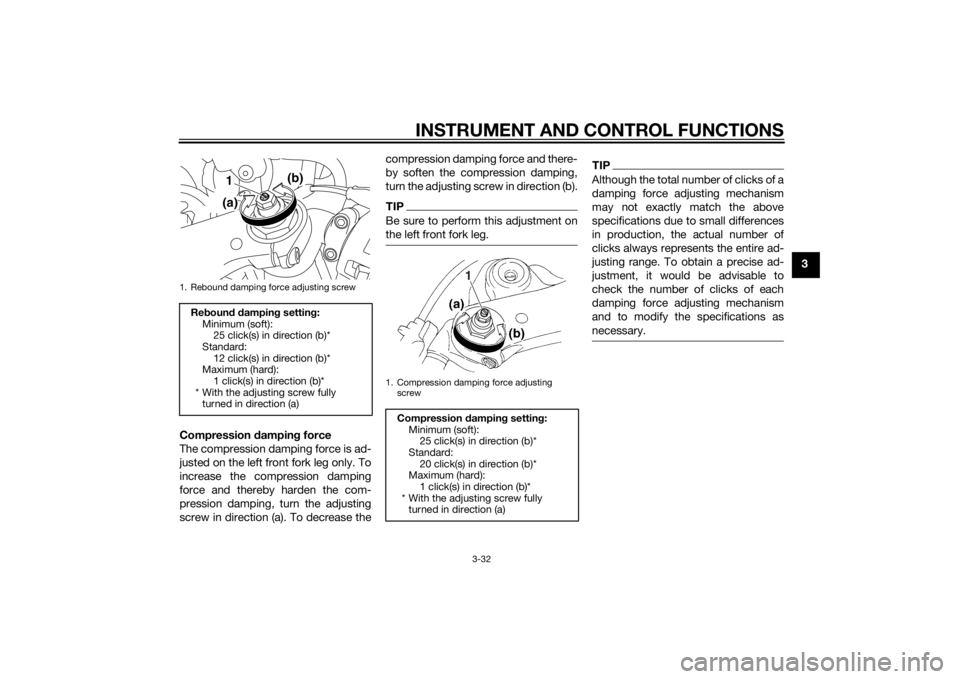

Compression dampin g force

The compression damping force is ad-

justed on the left front fork leg only. To

increase the compression damping

force and thereby harden the com-

pression damping, turn the adjusting

screw in direction (a). To decrease the compression damping force and there-

by soften the compression damping,

turn the adjusting screw in direction (b).

TIPBe sure to perform this adjustment on

the left front fork leg.

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-

justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

1. Rebound damping force adjusting screwRe

boun d d ampin g settin g:

Minimum (soft): 25 click(s) in direction (b)*

Standard: 12 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

(b)

1

(a)

1. Compression damping force adjusting screw

Compression dampin g setting :

Minimum (soft): 25 click(s) in direction (b)*

Standard: 20 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1

U2SGE0E0.book Page 32 Wednesday, June 12, 2013 1:15 PM

Page 53 of 114

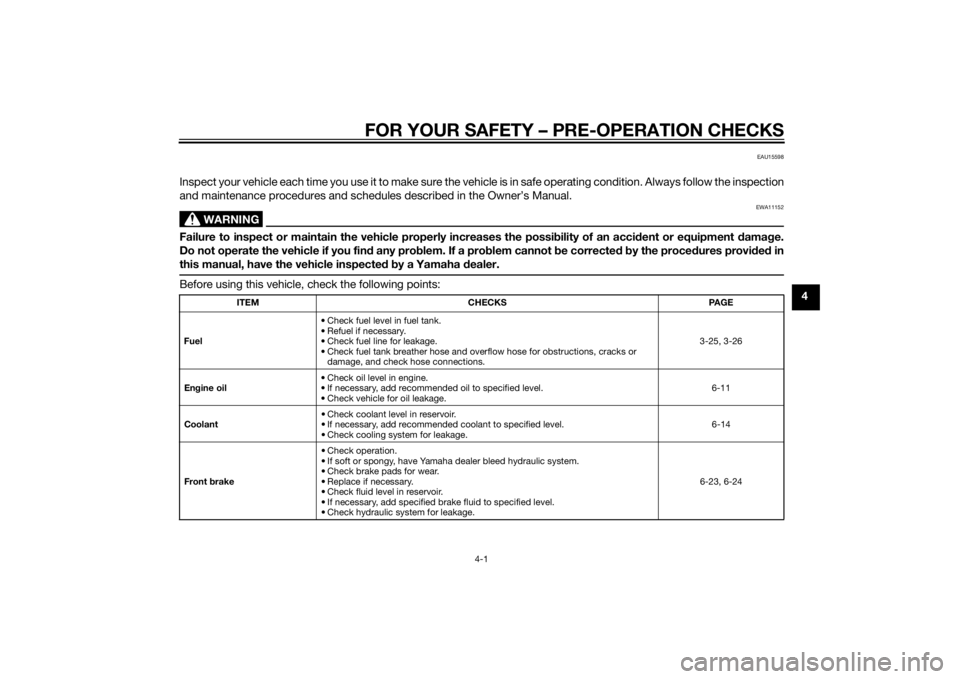

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-1

4

EAU15598

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an acci dent or equipment damag e.

Do not operate the vehicle if you fin d any pro blem. If a pro blem cannot be corrected b y the proce dures provi ded in

this manual, have the vehicle inspecte d b y a Yamaha dealer.Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel • Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank breather hose and overflow hose for obstructions, cracks or

damage, and check hose connections. 3-25, 3-26

En gine oil • Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage. 6-11

Coolant • Check coolant level in reservoir.

• If necessary, add recommended coolant to specified level.

• Check cooling system for leakage. 6-14

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-23, 6-24

U2SGE0E0.book Page 1 Wednesday, June 12, 2013 1:15 PM

Page 63 of 114

PERIODIC MAINTENANCE AND ADJUSTMENT

6-4

6

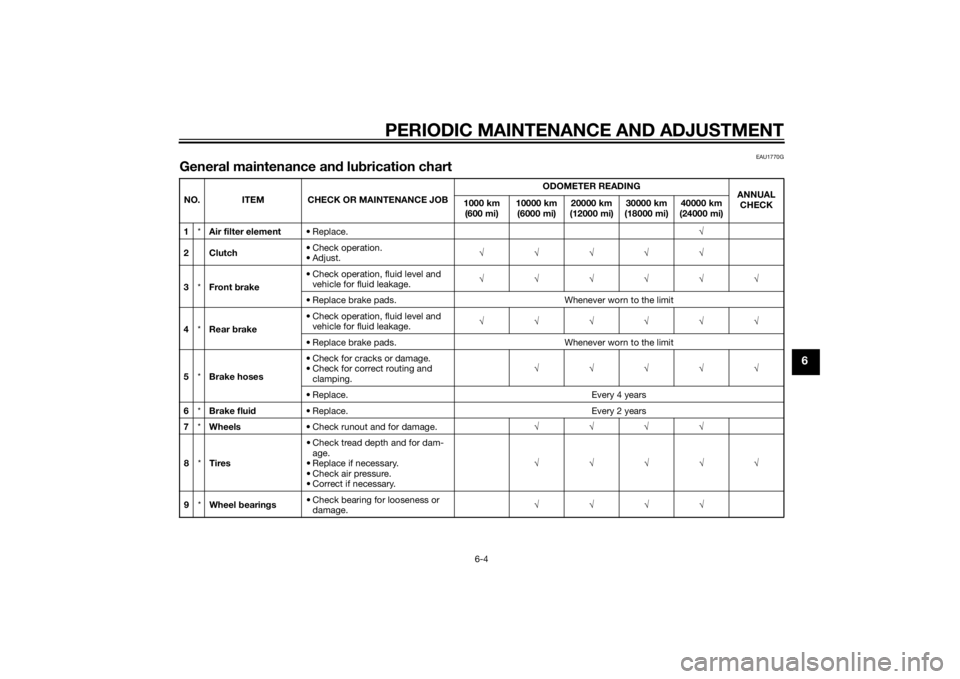

EAU1770G

General maintenance and lu brication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Air filter element •Replace. √

2Clutch • Check operation.

•Adjust.

√√√√√

3 *Front brake • Check operation, fluid level and

vehicle for fluid leakage. √√√√√√

• Replace brake pads. Whenever worn to the limit

4 *Rear brake • Check operation, fluid level and

vehicle for fluid leakage. √√√√√√

• Replace brake pads. Whenever worn to the limit

5 *Brake hoses • Check for cracks or damage.

• Check for correct routing and

clamping. √√√√√

• Replace. Every 4 years

6 *Brake flui d • Replace. Every 2 years

7 *Wheels • Check runout and for damage. √√√√

8 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary. √√√√√

9 *Wheel bearin gs • Check bearing for looseness or

damage. √√√√

U2SGE0E0.book Page 4 Wednesday, June 12, 2013 1:15 PM

Page 65 of 114

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

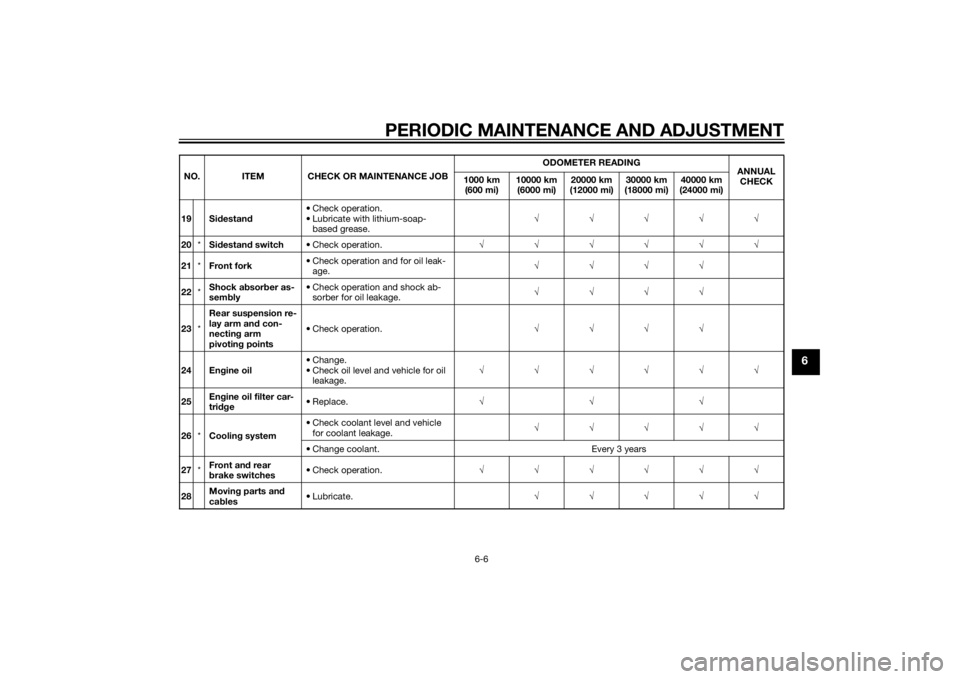

19 Sidestan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

20 *Sidestan d switch • Check operation. √√√√√√

21 *Front fork • Check operation and for oil leak-

age. √√√√

22 *Shock a

bsor ber as-

sem bly • Check operation and shock ab-

sorber for oil leakage. √√√√

23 *Rear suspension re-

lay arm an

d con-

nectin g arm

pivotin g points • Check operation.

√√√√

24 En gine oil • Change.

• Check oil level and vehicle for oil

leakage. √√√√√√

25 En

gine oil filter car-

tri dg e •Replace.

√√√

26 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change coolant. Every 3 years

27 *Front an

d rear

b rake switches • Check operation.

√√√√√√

28 Movin

g parts an d

ca bles • Lubricate.

√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 k

m

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

U2SGE0E0.book Page 6 Wednesday, June 12, 2013 1:15 PM

Page 78 of 114

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

6wei

ght of ri der, passen ger, car-

g o, an d accessories approve d

for this mo del.

WARNING

EWA10512

Never overloa d your vehicle. Opera-

tion of an overloa ded vehicle coul d

cause an acci dent.

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.TIPThe tire tread depth limits may differ

from country to country. Always com-

ply with the local regulations.

WARNING

EWA10472

Have a Yamaha dealer replace

excessively worn tires. Besi des

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases rid ing sta bility an d

can lead to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dge an d experience to do so.

Ride at mo derate speed s after

chan gin g a tire since the tire

surface must first be “ broken

in” for it to develop its optimal

characteristics.

Tire air pressure (measure d on col d

tires): 0–90 k g (0–198 l b):

Front:

250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

90–189 k g (198–417 l b):

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Hi gh-spee d ri din g:

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear:

290 kPa (2.90 kgf/cm², 42 psi)

Maximum loa d*:

189 kg (417 lb)

* Total weight of rider, passenger, car- go and accessories

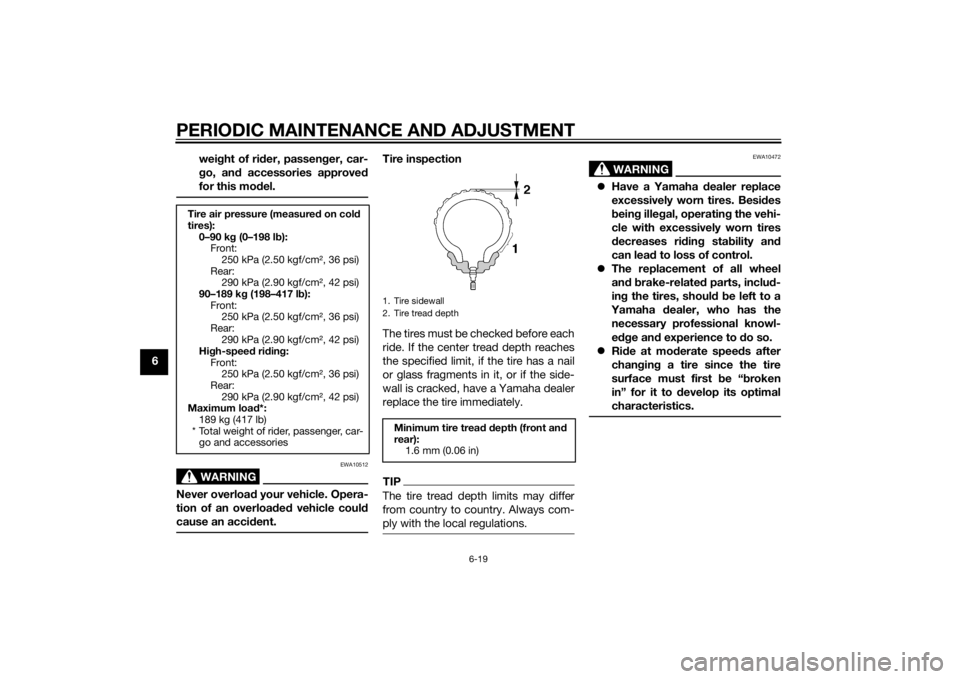

1. Tire sidewall

2. Tire tread depthMinimum tire trea d d epth (front an d

rear): 1.6 mm (0.06 in)

U2SGE0E0.book Page 19 Wednesday, June 12, 2013 1:15 PM

Page 79 of 114

PERIODIC MAINTENANCE AND ADJUSTMENT

6-20

6

Tire information

This motorcycle is equipped with tube-

less tires, tire air valves and cast

wheels.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10482

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g

characteristics of the motorcy-

cle may b e different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installe d to

prevent air pressure leaka ge.

Use only the tire valves an d

valve cores liste d below to

avoi d tire deflation during a

hi gh-spee d ri de.After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

WARNING

EWA10601

This motorcycle is fitte d with super-

hi gh-spee d tires. Note the followin g

points in or der to make the most ef-

ficient use of these tires. Use only the specified replace-

ment tires. Other tires may run

the dan ger of bursting at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor grip on certain roa d

surfaces until they have been

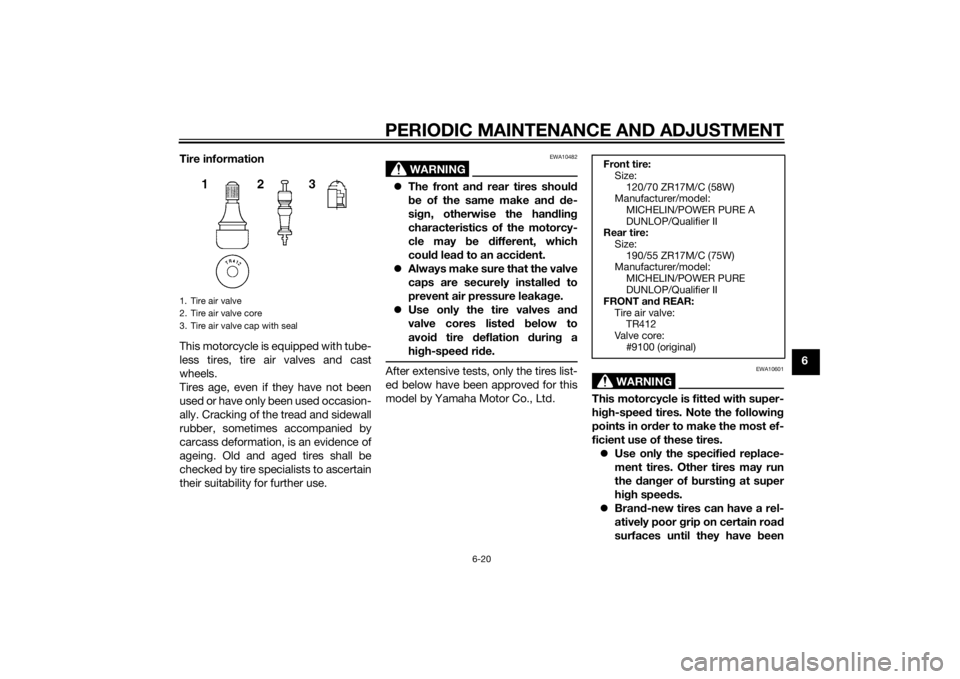

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

Front tire:

Size:

120/70 ZR17M/C (58W)

Manufacturer/model:

MICHELIN/POWER PURE A

DUNLOP/Qualifier II

Rear tire:

Size: 190/55 ZR17M/C (75W)

Manufacturer/model:

MICHELIN/POWER PURE

DUNLOP/Qualifier II

FRONT and REAR:

Tire air valve: TR412

Valve core:

#9100 (original)

U2SGE0E0.book Page 20 Wednesday, June 12, 2013 1:15 PM