YAMAHA YZF-R1 2016 Manual Online

Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R1, Model: YAMAHA YZF-R1 2016Pages: 128, PDF Size: 9.43 MB

Page 81 of 128

Periodic maintenance and adjustment

7-4

1

2

3

4

5

678

9

10

11

12

EAU1770M

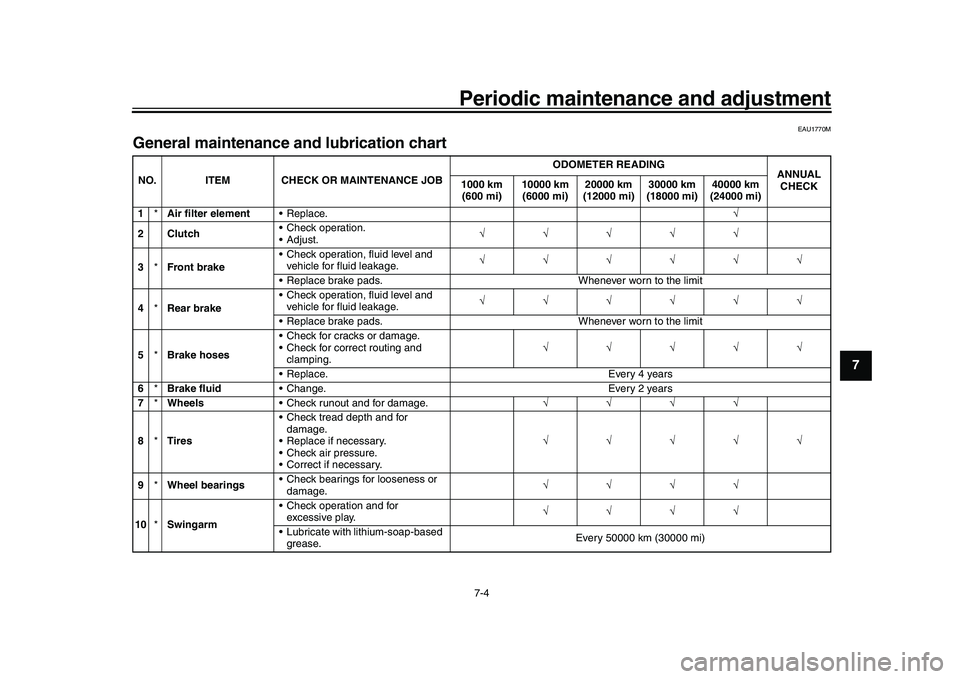

General maintenance an d lubrication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Air filter element Replace.

2Clutch Check operation.

Adjust.

3 *Front brake Check operation, fluid level and

vehicle for fluid leakage.

Replace brake pads. Whenever worn to the limit

4 *Rear brake Check operation, fluid level and

vehicle for fluid leakage.

Replace brake pads. Whenever worn to the limit

5 *Brake hoses Check for cracks or damage.

Check for correct routing and

clamping.

Replace. Every 4 years

6 *Brake fluid Change. Every 2 years

7 *Wheels Check runout and for damage.

8 *Tires Check tread depth and for

damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

9 *Wheel bearings Check bearings fo

r looseness or

damage.

10 *Swingarm Check operation and for

excessive play.

Lubricate with lithium-soap-based grease. Every 50000 km (30000 mi)

2CR-9-E1.book 4 ページ 2015年8月20日 木曜日 午後4時46分

Page 82 of 128

Periodic maintenance and adjustment

7-5

1

2

3

4

5

67

8

9

10

11

12

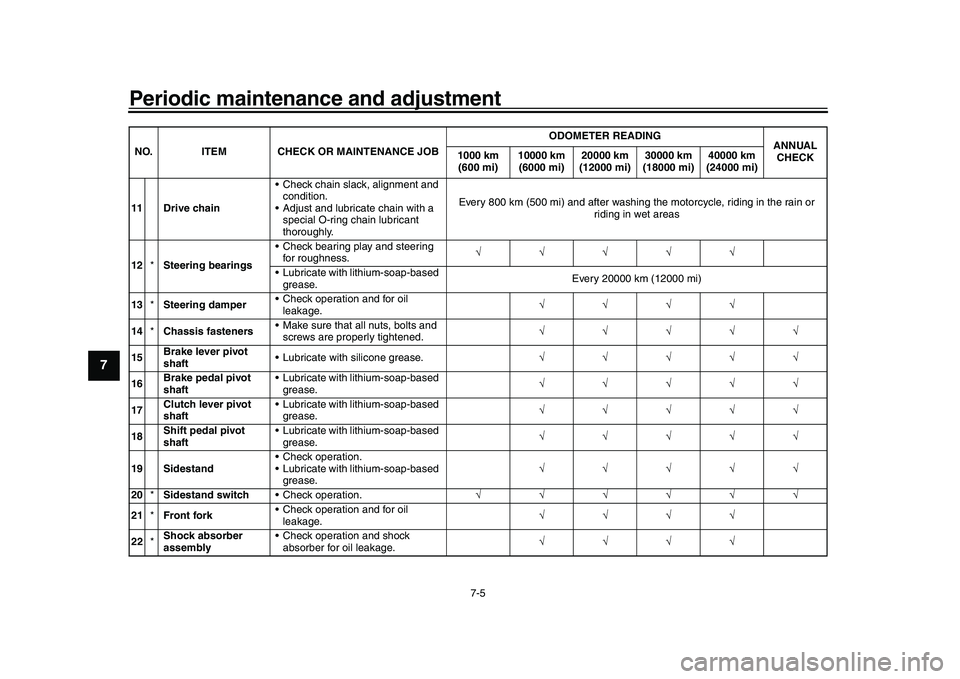

11 Drive chain Check chain slack, alignment and

condition.

Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 800 km (500 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

12 *Steering bearings Check bearing play and steering

for roughness.

Lubricate with lithium-soap-based grease. Every 20000 km (12000 mi)

13 *Steering damper Check operation and for oil

leakage.

14 *Chassis fasteners Make sure that all nuts, bolts and

screws are properly tightened.

15 Brake lever pivot

shaft Lubricate with silicone grease.

16 Brake pedal pivot

shaft Lubricate with lithium-soap-based

grease.

17 Clutch lever pivot

shaft Lubricate with lithium-soap-based

grease.

18 Shift pedal pivot

shaft Lubricate with lithium-soap-based

grease.

19 Sidestand Check operation.

Lubricate with lithium-soap-based

grease.

20 *Sidestand switch Check operation.

21 *Front fork Check operation and for oil

leakage.

22 *Shock absorber

assembly Check operation and shock

absorber for oil leakage.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)2CR-9-E1.book 5 ページ 2015年8月20日 木曜日 午後4時46分

Page 83 of 128

Periodic maintenance and adjustment

7-6

1

2

3

4

5

678

9

10

11

12

23 *Rear suspension

relay arm and

connecting arm

pivoting points Check operation.

24 Engine oil Change.

Check oil level and vehicle for oil

leakage.

25 Engine oil filter

cartridge Replace.

26 *Cooling system Check coolant level and vehicle

for coolant leakage.

Change coolant. Every 3 years

27 *EXUP system Check operation, cable free play

and pulley position.

28 *Front and rear brake

switches Check operation.

29 Moving parts and

cables Lubricate.

30 *Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing.

31 *Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

2CR-9-E1.book 6 ページ 2015年8月20日 木曜日 午後4時46分

Page 84 of 128

Periodic maintenance and adjustment

7-7

1

2

3

4

5

67

8

9

10

11

12

EAU70402

TIP

Air filter

This model’s air filter is equipped wi th a disposable oil-coated paper elemen t, which must not be cleaned with com-

pressed air to avoid damaging it.

The air filter element needs to be replaced more fr equently when riding in unusually wet or dusty areas.

Hydraulic brake service

After disassembling the front brake master cylinder and cali pers, always change the fluid. Regularly check the brake

fluid levels and fill the reservoirs as required.

Every two years replace the rear brake master cylinder, the internal components of the front brake master cylinder, the brake calipers, and change the brake fluid.

Replace the brake hoses every four years or sooner if cracked, damaged, or if any section of the stainless steel brakehose has turned black.

2CR-9-E1.book 7 ページ 2015年8月20日 木曜日 午後4時46分

Page 85 of 128

Periodic maintenance and adjustment

7-8

1

2

3

4

5

678

9

10

11

12

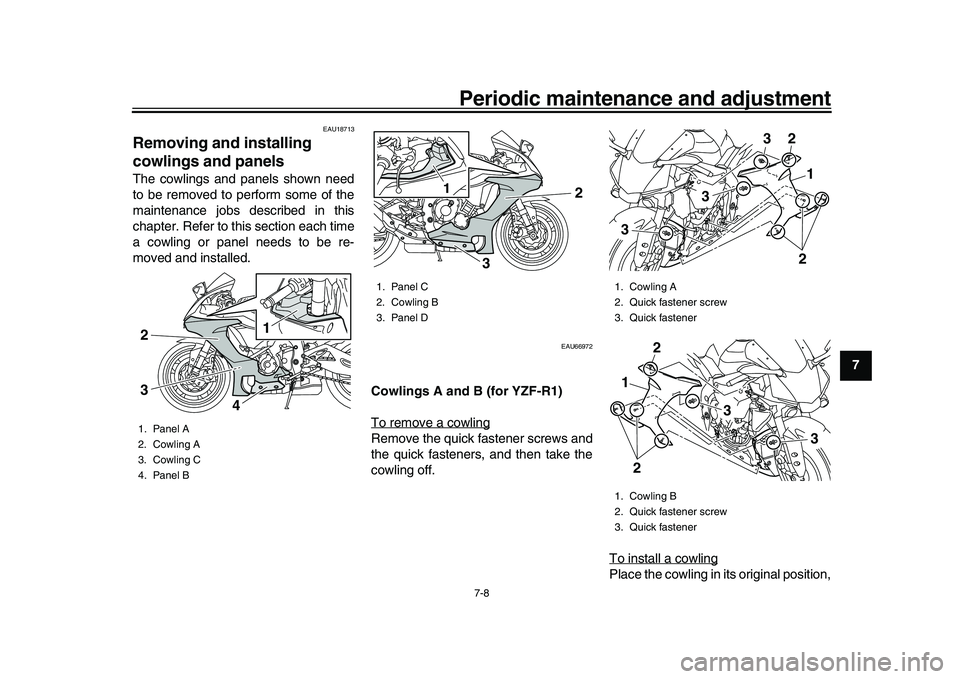

EAU18713

Removing and installing

cowlings and panelsThe cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU66972

Cowlings A and B (for YZF-R1)

To remove a cowlingRemove the quick fastener screws and

the quick fasteners, and then take the

cowling off.

To install a cowling

Place the cowling in its original position,

1. Panel A

2. Cowling A

3. Cowling C

4. Panel B

1

2

34

1. Panel C

2. Cowling B

3. Panel D

1

2

3

1. Cowling A

2. Quick fastener screw

3. Quick fastener

1. Cowling B

2. Quick fastener screw

3. Quick fastener

1

2

3 2

3

3

1

2

3

2

3

2CR-9-E1.book 8 ページ 2015年8月20日 木曜日 午後4時46分

Page 86 of 128

Periodic maintenance and adjustment

7-9

1

2

3

4

5

67

8

9

10

11

12 and then install the quick fasteners and

the quick fastener screws.

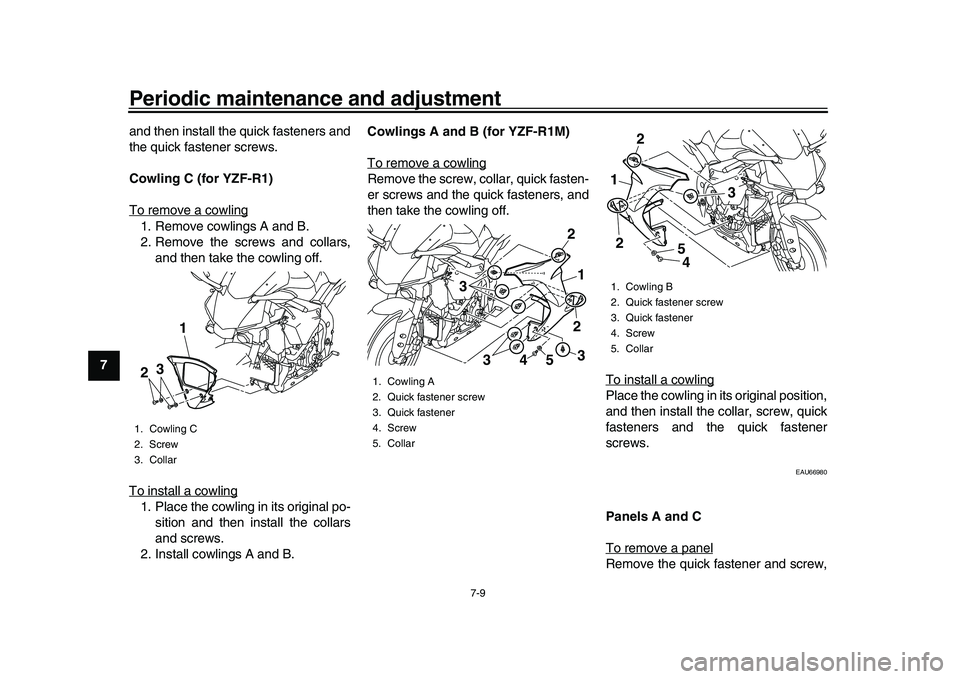

Cowling C (for YZF-R1)

To remove a cowling

1. Remove cowlings A and B.

2. Remove the screws and collars,

and then take the cowling off.

To install a cowling1. Place the cowling in its original po- sition and then install the collars

and screws.

2. Install cowlings A and B. Cowlings A and B (for YZF-R1M)

To remove a cowling

Remove the screw, collar, quick fasten-

er screws and the quick fasteners, and

then take the cowling off.

To install a cowling

Place the cowling in its original position,

and then install the collar, screw, quick

fasteners and the quick fastener

screws.

EAU66980

Panels A and C

To remove a panelRemove the quick fastener and screw,

1. Cowling C

2. Screw

3. Collar

3

2 1

1. Cowling A

2. Quick fastener screw

3. Quick fastener

4. Screw

5. Collar

2

3

2

3

3

45

1

1. Cowling B

2. Quick fastener screw

3. Quick fastener

4. Screw

5. Collar1 2

3

4

5

2

2CR-9-E1.book 9 ページ 2015年8月20日 木曜日 午後4時46分

Page 87 of 128

Periodic maintenance and adjustment7-10

1

2

3

4

5

678

9

10

11

12

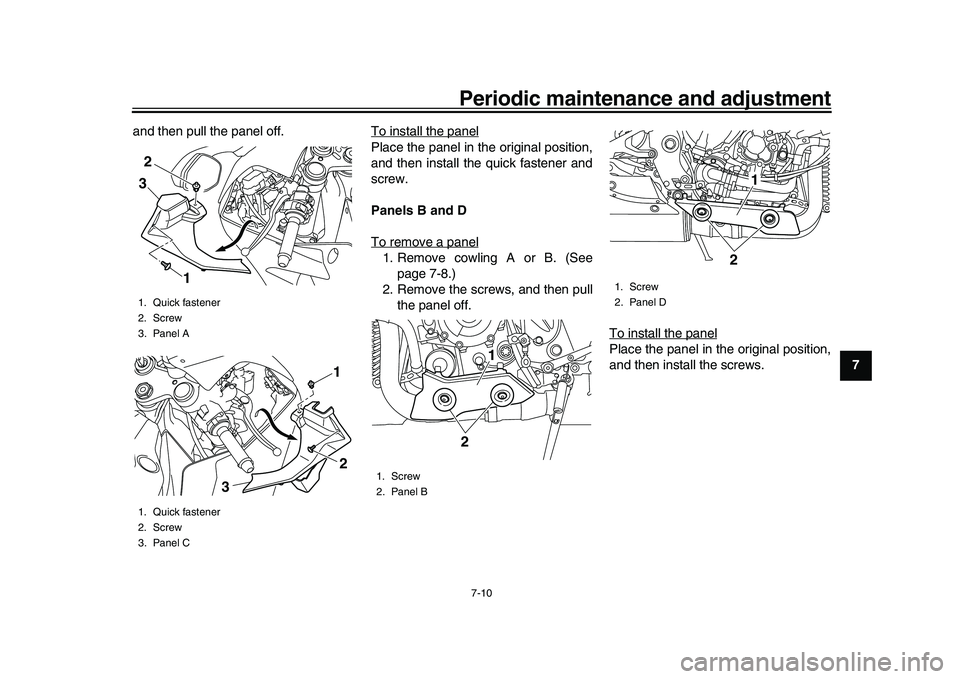

and then pull the panel off. To install the panel

Place the panel in the original position,

and then install the quick fastener and

screw.

Panels B and D

To remove a panel1. Remove cowling A or B. (See

page 7-8.)

2. Remove the screws, and then pull the panel off.

To install the panel

Place the panel in the original position,

and then install the screws.

1. Quick fastener

2. Screw

3. Panel A

1. Quick fastener

2. Screw

3. Panel C

1

2

3

1

2

3

1. Screw

2. Panel B

1

2

1. Screw

2. Panel D

1

2

2CR-9-E1.book 10 ページ 2015年8月20日 木曜日 午後4時46分

Page 88 of 128

Periodic maintenance and adjustment

7-11

1

2

3

4

5

67

8

9

10

11

12

EAU67110

Checking the spark plugsThe spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced. Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twistit back and forth while pushing it in.

Specified spark plug:

NGK/LMAR9E-J

1. Spark plug gapSpark plug gap: 0.6–0.7 mm (0.024–0.028 in)

Tightening torque: Spark plug (new):18 Nm (1.8 m·kgf, 13 ft·lbf)

Spark plug (after checking):

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1

1

2CR-9-E1.book 11 ページ 2015年8月20日 木曜日 午後4時46分

Page 89 of 128

Periodic maintenance and adjustment7-12

1

2

3

4

5

678

9

10

11

12

EAU66533

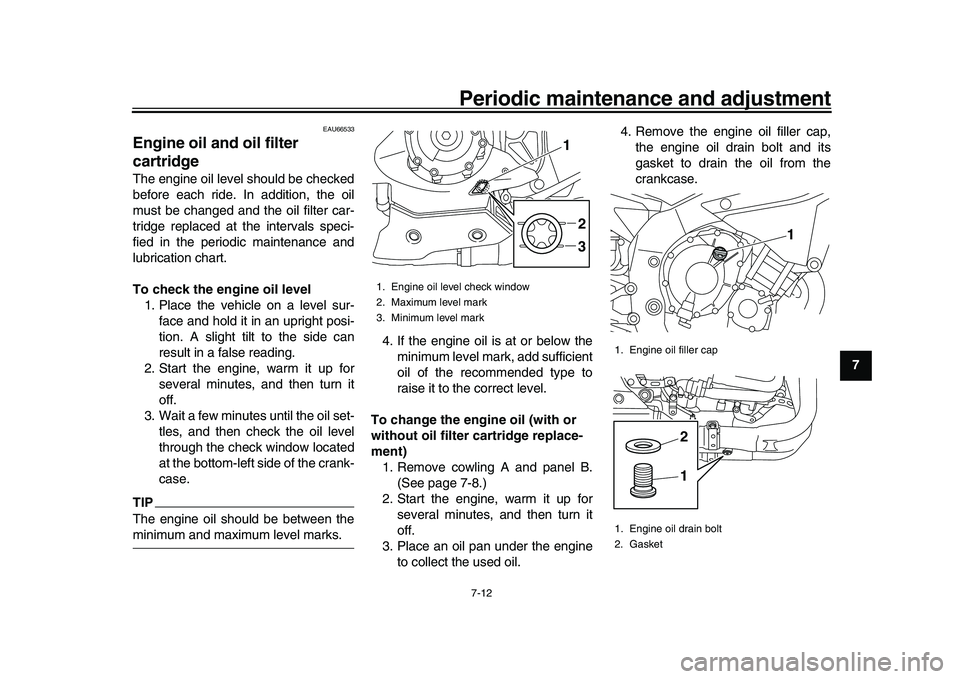

Engine oil and oil filter

cartridgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the check window located

at the bottom-left side of the crank-

case.TIPThe engine oil should be between theminimum and maximum level marks. 4. If the engine oil is at or below the

minimum level mark, add sufficient

oil of the recommended type to

raise it to the correct level.

To change the engine oil (with or

without oil filter cartridge replace-

ment) 1. Remove cowling A and panel B. (See page 7-8.)

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil. 4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

2

3

1

1. Engine oil filler cap

1. Engine oil drain bolt

2. Gasket

1

12

2CR-9-E1.book 12 ページ 2015年8月20日 木曜日 午後4時46分

Page 90 of 128

Periodic maintenance and adjustment

7-13

1

2

3

4

5

67

8

9

10

11

12

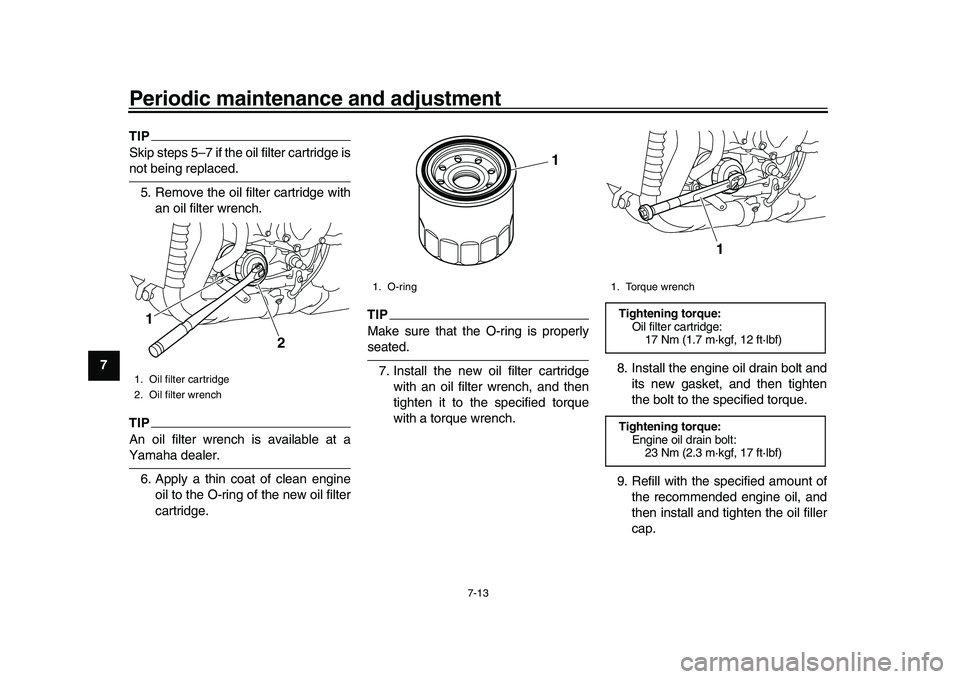

TIPSkip steps 5–7 if the oil filter cartridge isnot being replaced. 5. Remove the oil filter cartridge with an oil filter wrench.TIPAn oil filter wrench is available at aYamaha dealer.

6. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.

TIPMake sure that the O-ring is properlyseated.

7. Install the new oil filter cartridge with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

1. Oil filter cartridge

2. Oil filter wrench1

2

1. O-ring

1

1. Torque wrenchTightening torque:Oil filter cartridge:

17 Nm (1.7 m·kgf, 12 ft·lbf)

Tightening torque: Engine oil drain bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

1

2CR-9-E1.book 13 ページ 2015年8月20日 木曜日 午後4時46分