lock YAMAHA YZF-R1 2018 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: YZF-R1, Model: YAMAHA YZF-R1 2018Pages: 130, PDF Size: 10.29 MB

Page 37 of 130

Instrument and control functions

4-15

1

2

345

6

7

8

9

10

11

12

MENU access and operation

The following wheel switch operations

are common operations for accessing,

selecting, and moving within the MENU

screen and its modules.

Long push - press and hold the wheel

switch for one second to access the

MENU screen or exit MENU entirely.

Select - rotate the wheel switch up or

down to highlight the desired module or

setting item and then short push the

wheel switch (briefly press the wheel

switch inward) to confirm the selection.

Triangle mark

- certain setting screens have an upward pointing triangle mark

item. Select the triangle mark to exit

that screen and move back one screen

(or long push the wheel switch to exit

MENU entirely).

TIPShould vehicle motion be detected, the

screen will automat

ically exit MENUand change to the main screen.

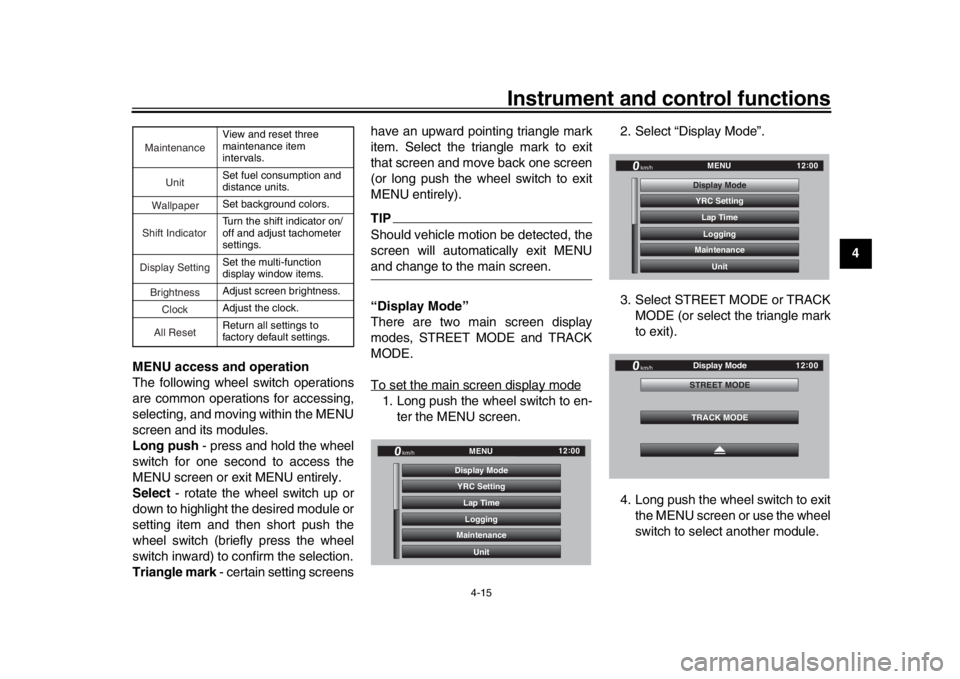

“Display Mode”

There are two main screen display

modes, STREET MODE and TRACK

MODE.

To set the main screen display mode1. Long push the wheel switch to en-

ter the MENU screen. 2. Select “Display Mode”.

3. Select STREET MODE or TRACK

MODE (or select the triangle mark

to exit).

4. Long push the wheel switch to exit the MENU screen or use the wheel

switch to select another module.

View and reset three

maintenance item

intervals.

Set fuel consumption and

distance units.

Set background colors.

Turn the shift indicator on/

off and adjust tachometer

settings.

Set the multi-function

display window items.

Adjust screen brightness.

Adjust the clock.

Return all settings to

factory default settings.

Maintenance

Unit

WallpaperShift IndicatorDisplay SettingBrightnessCloc

k

All Reset

YRC Setting

Lap TimeLogging

Maintenance

Unit

Display ModeMENU

km/h

GPS

12

:

00

YRC Setting

Lap TimeLogging

Maintenance

Unit

Display ModeMENU

km/h

GPS

12

:

00

km/h

12 :

00

TRACK MODE

STREET MODE

Display Mode

BX4-9-E1_1.book 15 ページ 2018年4月27日 金曜日 午後4時3分

Page 51 of 130

Instrument and control functions

4-29

1

2

345

6

7

8

9

10

11

12

4. Select STREET MODE 1-1.

5. Select the desired information dis-

play item with the wheel switch.

TIPThe information display items which

can be selected are:

A.TEMP: air temperature

C.TEMP: coolant temperature

TRIP-1: tripmeter 1 TRIP-2: tripmeter 2

ODO: odometer

FUEL CON: the amount of fuel con-

sumed

FUEL AVG: average fuel consumption

CRNT FUEL: current fuel consumption

6. Select STREET MODE 1-2 or TRACK MODE to set the remain-

ing DISPLAY-1 group items.

7. Select the triangle symbol to exit. To set the other display groups, re-

peat from step 3.

“Brightness”

This module allows you to adjust the

general brightness level of the display

screen. To set the brightness

1. Select “Brightness”.

2. Select the desired brightness level

by rotating the wheel switch, and

then short push the wheel switch

to fix the setting.

“Clock”

This module allows you to set the clock.

STREET MODE 1 - 1

A.TEMP

C.TEMP

C.TEMP

Display Setting DISPLAY-1

km/h

GPS

12 :

00

TRACK MODE STREET MODE 1 - 2 STREET MODE 1 - 1

A.TEMP

C.TEMP

C.TEMP

Display Setting

DISPLAY-1

km/h

GPS

12 :

00

TRACK MODE STREET MODE 1 - 2

STREET MODE 1 - 1

A.TEMP

C.TEMP

C.TEMP

Display Setting

DISPLAY-1

km/h

GPS

12 :

00

TRACK MODE STREET MODE 1 - 2

GPGPS

Wallpaper Unit

Shift Indicator

Display Setting MENU

Maintenance

Brightness

km/h

12 :

00

Brightness

km/h

GPS

12 :

00

2

BX4-9-E1_1.book 29 ページ 2018年4月27日 金曜日 午後4時3分

Page 52 of 130

Instrument and control functions

4-30

1

2

34

5

6

7

8

9

10

11

12 To set the clock

1. From the MENU screen, select

“Clock”.

2. When “Clock” is selected, the hours figure will be highlighted.

3. Set the hour by rotating and then short push the wheel switch. 4. The minutes figure will become

highlighted.

5. Set the minutes figure by rotating and then short push the wheel

switch. 6. Short push the wheel switch again

to exit and go back to the MENU

screen.

“All Reset”

This module resets everything, except

the odometer and clock, to its factory

preset or default setting.

Select YES to reset all items. After se-

lecting YES, all items will be reset and

the screen will automatically return to

the MENU screen.

GPGPS

Shift Indicator Wallpaper

Display Setting Brightness MENU

Unit

Clock

km/h

12 :

00

Clock

km/h

12 :

00

11 :

34

Clock

km/h

12 :

00

12 :

34

Clock

km/h

12 :

00

12 34

:

Clock

km/h

12 :

00

12 :

58

BX4-9-E1_1.book 30 ページ 2018年4月27日 金曜日 午後4時3分

Page 55 of 130

Instrument and control functions

4-33

1

2

345

6

7

8

9

10

11

12

EAU67041

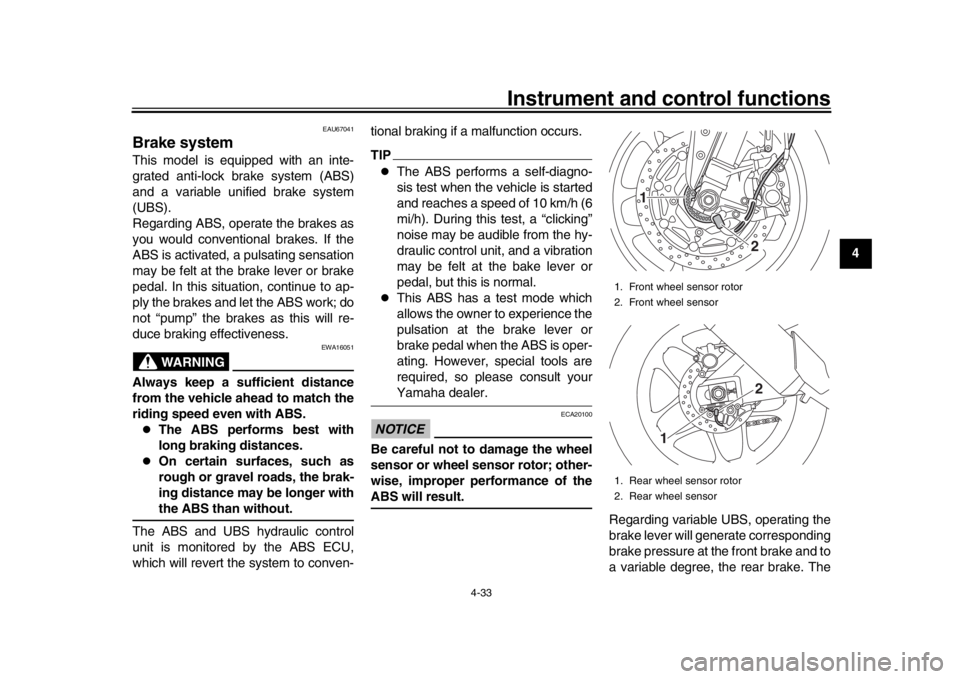

Brake systemThis model is equipped with an inte-

grated anti-lock brake system (ABS)

and a variable unified brake system

(UBS).

Regarding ABS, operate the brakes as

you would conventional brakes. If the

ABS is activated, a pulsating sensation

may be felt at the brake lever or brake

pedal. In this situation, continue to ap-

ply the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahead to match the

riding speed even with ABS.

The ABS performs best with

long braking distances.

On certain surfaces, such as

rough or gravel roads, the brak-

ing distance may be longer withthe ABS than without.

The ABS and UBS hydraulic control

unit is monitored by the ABS ECU,

which will revert the system to conven- tional braking if a malfunction occurs.

TIP

The ABS performs a self-diagno-

sis test when the vehicle is started

and reaches a speed of 10 km/h (6

mi/h). During this test, a “clicking”

noise may be audible from the hy-

draulic control unit, and a vibration

may be felt at the bake lever or

pedal, but this is normal.

This ABS has a test mode which

allows the owner to experience the

pulsation at the brake lever or

brake pedal when the ABS is oper-

ating. However, special tools are

required, so please consult yourYamaha dealer.

NOTICE

ECA20100

Be careful not to damage the wheel

sensor or wheel sensor rotor; other-

wise, improper performance of theABS will result.

Regarding variable UBS, operating the

brake lever will generate corresponding

brake pressure at the front brake and to

a variable degree, the rear brake. The

1. Front wheel sensor rotor

2. Front wheel sensor

1. Rear wheel sensor rotor

2. Rear wheel sensor

1

22

1

BX4-9-E1_1.book 33 ページ 2018年4月27日 金曜日 午後4時3分

Page 56 of 130

Instrument and control functions

4-34

1

2

34

5

6

7

8

9

10

11

12 amount of rear wheel braking force to

be applied by the UBS is based on ve-

hicle attitude and lean angle. However,

operating only the brake pedal will not

generate any brake pressure at the

front brake.

For full braking performance, apply

both the brake lever and brake pedal si-

multaneously.

When both the brake lever and the

brake pedal are applied simultaneous-

ly, the UBS will control the distribution

of braking force between the two

wheels.

TIP

The UBS does not function until

the vehicle starts moving.

After coming to a stop while apply-

ing the brake lever, the UBS is still

enabled. As further squeezing of

the brake lever will not increase

the braking power of the rear

brake, apply the rear brake should

further braking power be neces-

sary (such as when parking on a

slope).

The UBS disables after the brake

lever is released. When the vehicle starts moving,

the UBS is re-enabled.

EAU13076

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be re-

leased and the fuel tank cap can be

opened.

To close the fuel tank cap

With the key still inserted in the lock,

push down the fuel tank cap. Turn the

key 1/4 turn counterclockwise, remove

it, and then close the lock cover.TIPThe fuel tank cap cannot be closed un-1. Fuel tank cap lock cover

2. Unlock.

1

2

BX4-9-E1_1.book 34 ページ 2018年4月27日 金曜日 午後4時3分

Page 57 of 130

Instrument and control functions

4-35

1

2

345

6

7

8

9

10

11

12

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly closed after filling fuel.Leaking fuel is a fire hazard.

EAU13222

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, followthese instructions.

1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters and

clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank. 3. Wipe up any spilled fuel immedi-

ately. NOTICE: Immediately wipe

off spilled fuel with a clean, dry,

soft cloth, since fuel may deteri-

orate painted surfaces or plastic

parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous and can

cause injury or death. Handle gaso-

line with care. Never siphon gaso-

line by mouth. If you should swallow

some gasoline or inhale a lot of gas-

oline vapor, or get some gasoline in1. Fuel tank filler tube

2. Maximum fuel level

1

2

BX4-9-E1_1.book 35 ページ 2018年4月27日 金曜日 午後4時3分

Page 59 of 130

Instrument and control functions

4-37

1

2

345

6

7

8

9

10

11

12

EAU80200

Fuel tank overflow hoseBefore operating the vehicle:

Check the fuel tank overflow hose

connection.

Check the fuel tank overflow hose

for cracks or damage, and replace

it if necessary.

Make sure that the end of the fuel

tank overflow hose is not blocked,

and clean it if necessary.

Make sure that the end of the fuel

tank overflow hos e is positioned as

shown.

TIPSee page 7-12 for canister information.

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up ofheat.

NOTICE

ECA10702

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

1. Clamp

2. Paint mark

3. Fuel tank overflow hose

1

2

3

BX4-9-E1_1.book 37 ページ 2018年4月27日 金曜日 午後4時3分

Page 60 of 130

Instrument and control functions

4-38

1

2

34

5

6

7

8

9

10

11

12 pairable damage to the catalytic

converter.

EAU66570

SeatsPassenger seat

To remove the passenger seat1. Insert the key into the seat lock,

and then turn it clockwise.

2. Lift the front of the passenger seat and pull it forward.

To install the passenger seat1. Insert the projection on the rear of the passenger seat into the seat

holder as shown, and then push

the front of the seat down to lock it

in place. 2. Remove the key.

Rider seat

To remove the rider seat

1. Remove the passenger seat.

2. Pull up the corners on the rear of the rider seat as shown, remove

the bolts with the hexagon wrench

located under the passenger seat,

and then pull the seat off.

1. Seat lock

2. Unlock.

12

1. Projection

2. Seat holder

1

2

BX4-9-E1_1.book 38 ページ 2018年4月27日 金曜日 午後4時3分

Page 66 of 130

Instrument and control functions

4-44

1

2

34

5

6

7

8

9

10

11

12

EAU66493

Adjusting th e shock absorber

assembly

WARNING

EWA10222

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.

Do not tamper with or attempt to

open the cylinder assembly.

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

Do not dispose of a damaged or

worn-out shock absorber as-

sembly yourself. Take the shock

absorber assembly to a Yamahadealer for any service.

NOTICE

ECA10102

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

For YZF-R1:

This model is equipped with adjustable

suspension. The spring preload, re-

bound damping force, fast compres-

sion damping force, and slow

compression damping force can be ad-

justed.

Spring preload

1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspension,

turn the adjusting ring in direction

(a). To decrease the spring pre-

load and thereby soften the sus-

pension, turn the adjusting ring in

direction (b).

The spring preload setting is deter-

mined by measuring distance A.

The longer distance A is, the high-

er the spring preload; the shorter

distance A is, the lower the spring preload.

Use the special wrench includ-

ed in the owner’s tool kit to

make the adjustment.

1. Spring preload adjusting ring

2. Locknut

1. Distance A

(a)

(b)1

2

1

BX4-9-E1_1.book 44 ページ 2018年4月27日 金曜日 午後4時3分

Page 67 of 130

Instrument and control functions

4-45

1

2

345

6

7

8

9

10

11

12

3. Tighten the locknut to the specified

torque. NOTICE: Always tighten

the locknut against the adjust-

ing ring, and then tighten the

locknut to the specified

torque.

[ECA22760]

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting screw in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b). Compression damping force

Fast compression damping force

To increase the compression damping

force and thereby harden the fast com-

pression damping, turn the adjusting

bolt in direction (a). To decrease the

compression damping force and there-by soften the compression damping,

turn the adjusting bolt in direction (b).

Slow compression damping force

To increase the compression damping

force and thereby harden the slow

compression damping, turn the adjust-

ing screw in direction (a). To decrease

Spring preload:

Minimum (soft): Distance A = 77.5 mm (3.05 in)

Standard:

Distance A = 79.0 mm (3.11 in)

Maximum (hard): Distance A = 85.5 mm (3.37 in)

Tightening torque: Locknut: 25 N·m (2.5 kgf·m, 18 lb·ft)

1. Rebound damping force adjusting screwRebound damping setting:Minimum (soft):

23 click(s) in direction (b)*

Standard: 12 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)(a) (b)

1

1. Fast compression damping force

adjusting boltFast compression damping settingMinimum (soft):

5.5 turn(s) in direction (b)*

Standard: 3 turn(s) in direction (b)*

Maximum (hard): 0 turn(s) in direction (b)*

* With the adjusting bolt fully turned in

direction (a)

(a) (b)

1

BX4-9-E1_1.book 45 ページ 2018年4月27日 金曜日 午後4時3分