light YAMAHA YZF-R125 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZF-R125, Model: YAMAHA YZF-R125 2014Pages: 98, PDF Size: 6.92 MB

Page 50 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

6

EAU18732

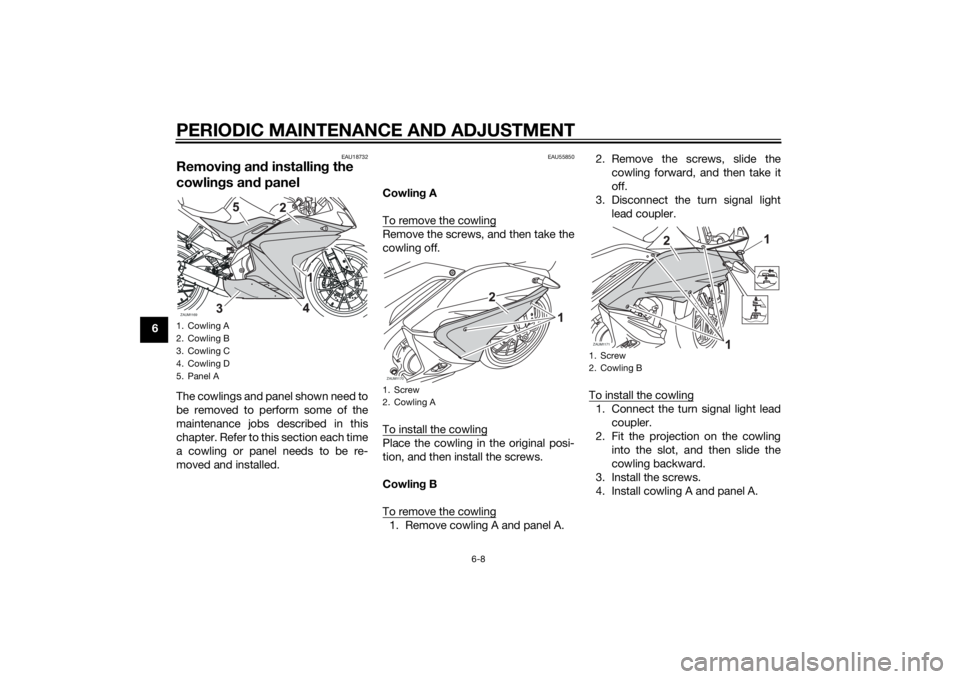

Removing and installing the

cowlings and panelThe cowlings and panel shown need to

be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU55850

Cowling A

To remove the cowlingRemove the screws, and then take the

cowling off.

To install the cowlingPlace the cowling in the original posi-

tion, and then install the screws.

Cowling B

To remove the cowling1. Remove cowling A and panel A.2. Remove the screws, slide the

cowling forward, and then take it

off.

3. Disconnect the turn signal light

lead coupler.

To install the cowling

1. Connect the turn signal light lead

coupler.

2. Fit the projection on the cowling

into the slot, and then slide the

cowling backward.

3. Install the screws.

4. Install cowling A and panel A.

1. Cowling A

2. Cowling B

3. Cowling C

4. Cowling D

5. Panel AZAUM1169

1. Screw

2. Cowling AZAUM1170

1. Screw

2. Cowling BZAUM1171

U5D7E5E0.book Page 8 Thursday, August 21, 2014 9:30 AM

Page 52 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

6To install the panel

1. Place the panel in the original po-

sition, and then install the screws.

2. Install the rider seat.

EAU19633

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plug

1. Remove cowling A. (See page

6-8.)

2. Remove the spark plug cap.3. Remove the spark plug as shown,

with the spark plug wrench includ-

ed in the owner’s tool kit.

To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

1. Screw

2. Panel A

1. Spark plug cap

1. Spark plug wrench

U5D7E5E0.book Page 10 Thursday, August 21, 2014 9:30 AM

Page 53 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6 2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.4. Install the spark plug cap.

5. Install the cowling.

EAUM3490

Engine oil and oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.

NOTICE: Do not operate the ve-

hicle until you know that the en-

gine oil level is sufficient.

[ECA10012]

Specified spark plug:

NGK/CR9E1. Spark plug gapSpark plug gap:

0.7–0.8 mm (0.028–0.031 in)

1

ZAUM0037

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kgf, 9.04 ft·lbf)

U5D7E5E0.book Page 11 Thursday, August 21, 2014 9:30 AM

Page 56 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

611. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-

rial enters the crankcase.

12. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

13. Turn the engine off, and then

check the oil level and correct it if

necessary.

14. Reset the oil change indicator.

(See page 3-10.)

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU20095

To check the coolant level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:

0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement:

1.00 L (1.06 US qt, 0.88 Imp.qt)

U5D7E5E0.book Page 14 Thursday, August 21, 2014 9:30 AM

Page 64 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

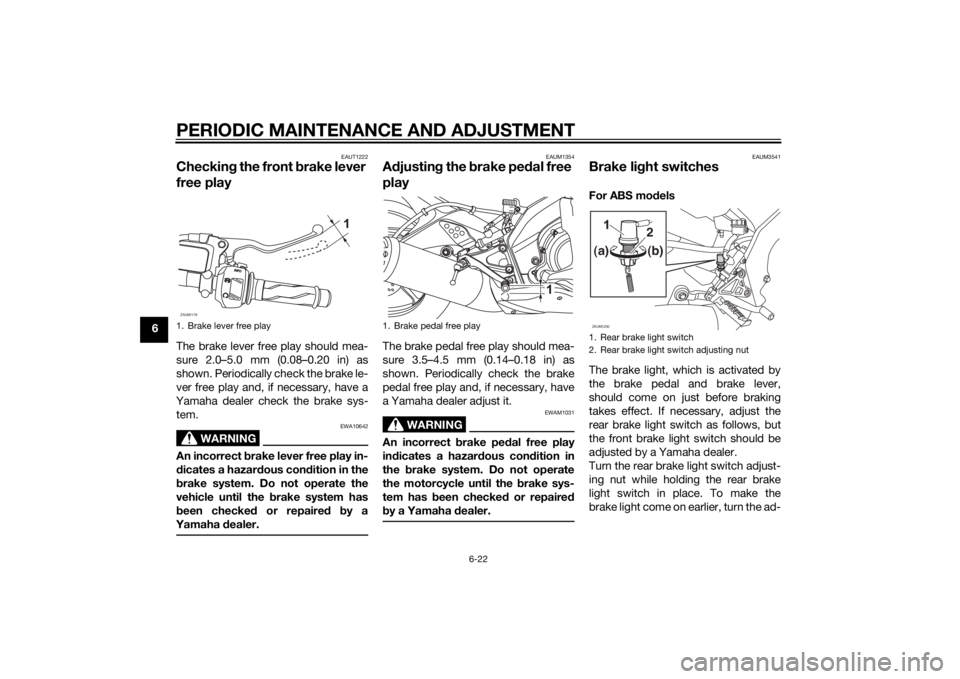

EAUT1222

Checking the front brake lever

free playThe brake lever free play should mea-

sure 2.0–5.0 mm (0.08–0.20 in) as

shown. Periodically check the brake le-

ver free play and, if necessary, have a

Yamaha dealer check the brake sys-

tem.

WARNING

EWA10642

An incorrect brake lever free play in-

dicates a hazardous condition in the

brake system. Do not operate the

vehicle until the brake system has

been checked or repaired by a

Yamaha dealer.

EAUM1354

Adjusting the brake pedal free

playThe brake pedal free play should mea-

sure 3.5–4.5 mm (0.14–0.18 in) as

shown. Periodically check the brake

pedal free play and, if necessary, have

a Yamaha dealer adjust it.

WARNING

EWAM1031

An incorrect brake pedal free play

indicates a hazardous condition in

the brake system. Do not operate

the motorcycle until the brake sys-

tem has been checked or repaired

by a Yamaha dealer.

EAUM3541

Brake light switchesFor ABS models

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

1. Brake lever free playZAUM1179

INFOINFO

1. Brake pedal free play

1. Rear brake light switch

2. Rear brake light switch adjusting nutZAUM1230

2

(a)(b)

U5D7E5E0.book Page 22 Thursday, August 21, 2014 9:30 AM

Page 65 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6 justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For non-ABS models

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer check the brake light

switches.

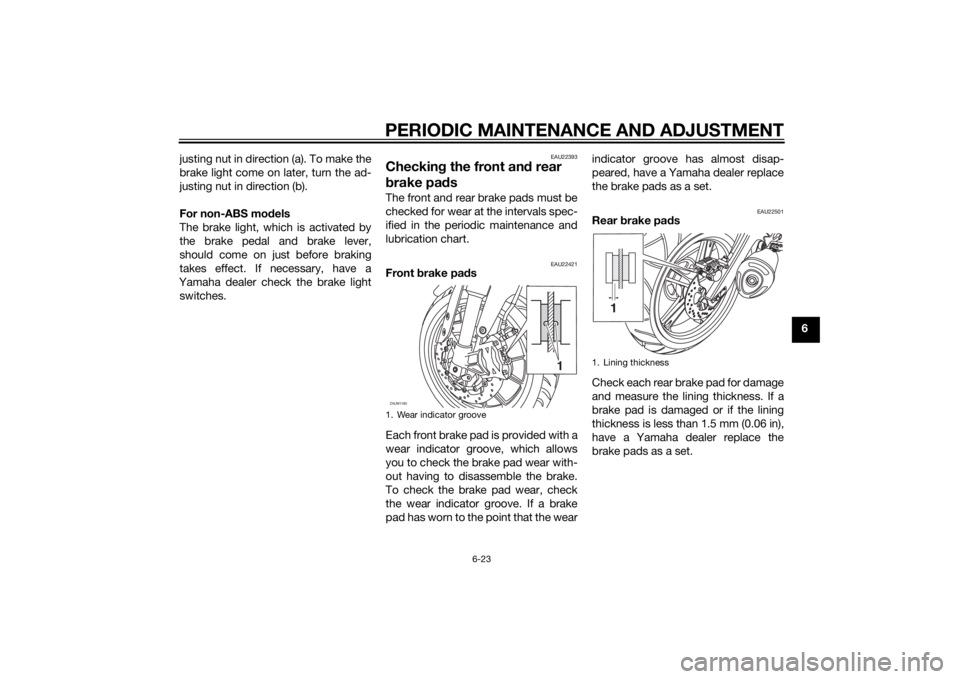

EAU22393

Checking the front and rear

brake padsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU22421

Front brake pads

Each front brake pad is provided with a

wear indicator groove, which allows

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator groove. If a brake

pad has worn to the point that the wearindicator groove has almost disap-

peared, have a Yamaha dealer replace

the brake pads as a set.

EAU22501

Rear brake pads

Check each rear brake pad for damage

and measure the lining thickness. If a

brake pad is damaged or if the lining

thickness is less than 1.5 mm (0.06 in),

have a Yamaha dealer replace the

brake pads as a set.

1. Wear indicator grooveZAUM1180

1

1. Lining thickness

U5D7E5E0.book Page 23 Thursday, August 21, 2014 9:30 AM

Page 75 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6 If the breather hose is posi-

tioned in such a way that the

frame is exposed to electrolyte

or gas expelled from the bat-

tery, the frame could suffer

structural and external damag-

es.

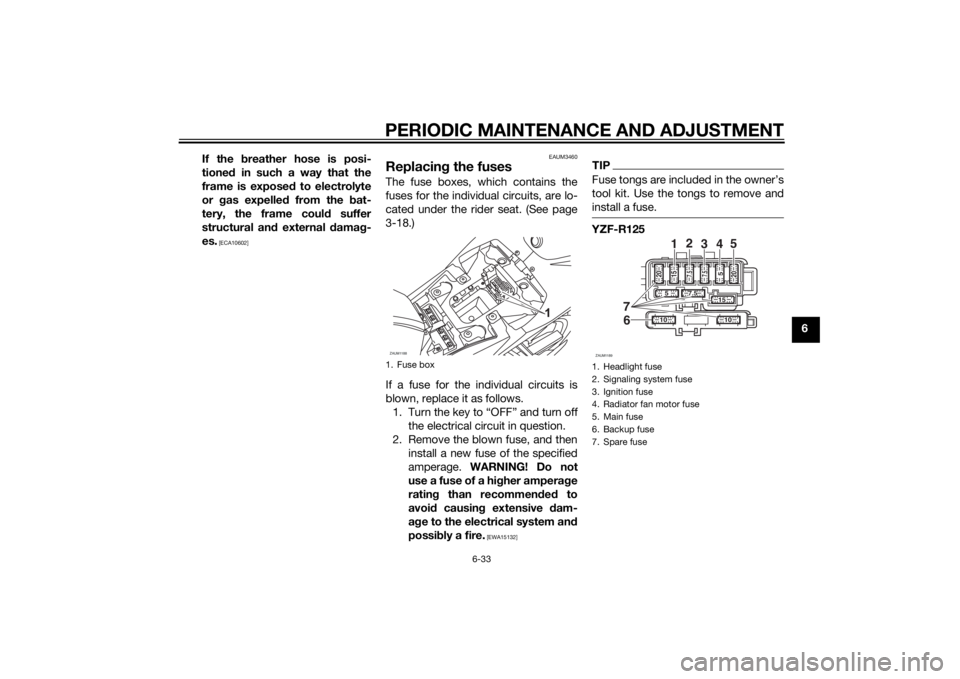

[ECA10602]EAUM3460

Replacing the fusesThe fuse boxes, which contains the

fuses for the individual circuits, are lo-

cated under the rider seat. (See page

3-18.)

If a fuse for the individual circuits is

blown, replace it as follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

TIP

tool kit. Use the tongs to remove and

install a fuse.YZF-R125

1. Fuse boxZAUM1188

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Radiator fan motor fuse

5. Main fuse

6. Backup fuse

7. Spare fuseZAUM1189

10

10

15

7.5

5

20

7.5 7.5

15 20

5

7

1

2

3

45

6

U5D7E5E0.book Page 33 Thursday, August 21, 2014 9:30 AM

Page 76 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

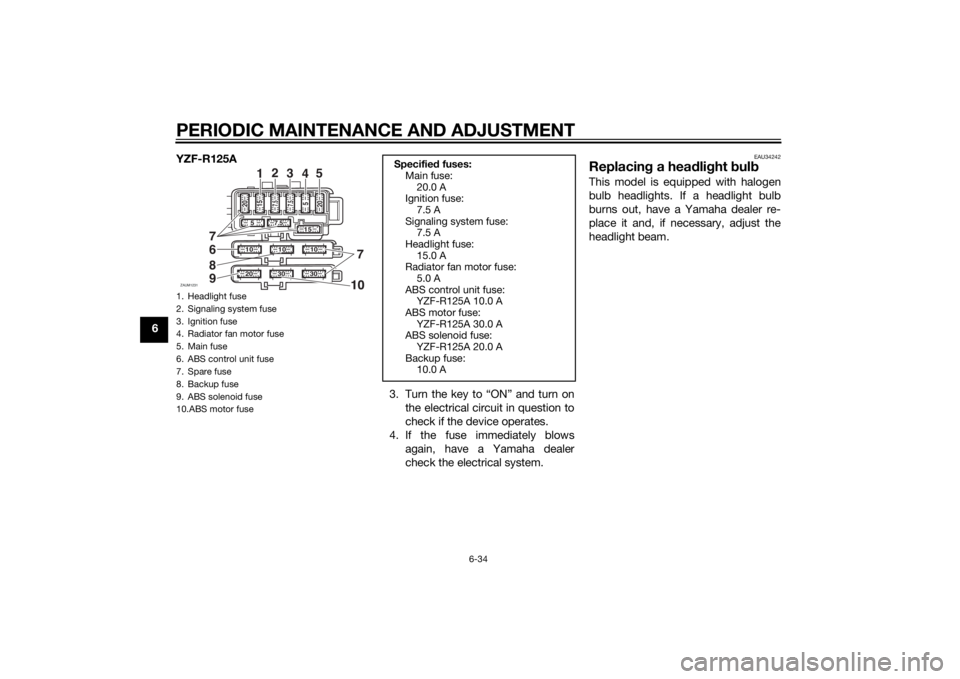

6YZF-R125A

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EAU34242

Replacing a headlight bulbThis model is equipped with halogen

bulb headlights. If a headlight bulb

burns out, have a Yamaha dealer re-

place it and, if necessary, adjust the

headlight beam.

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Radiator fan motor fuse

5. Main fuse

6. ABS control unit fuse

7. Spare fuse

8. Backup fuse

9. ABS solenoid fuse

10.ABS motor fuseZAUM1231

1030

30

20

7

8

9

10

10

15

7.5

20

7.5 7.5

15

5 20

5

7

1

2

3

45

6

Specified fuses:

Main fuse:

20.0 A

Ignition fuse:

7.5 A

Signaling system fuse:

7.5 A

Headlight fuse:

15.0 A

Radiator fan motor fuse:

5.0 A

ABS control unit fuse:

YZF-R125A 10.0 A

ABS motor fuse:

YZF-R125A 30.0 A

ABS solenoid fuse:

YZF-R125A 20.0 A

Backup fuse:

10.0 A

U5D7E5E0.book Page 34 Thursday, August 21, 2014 9:30 AM

Page 77 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

6

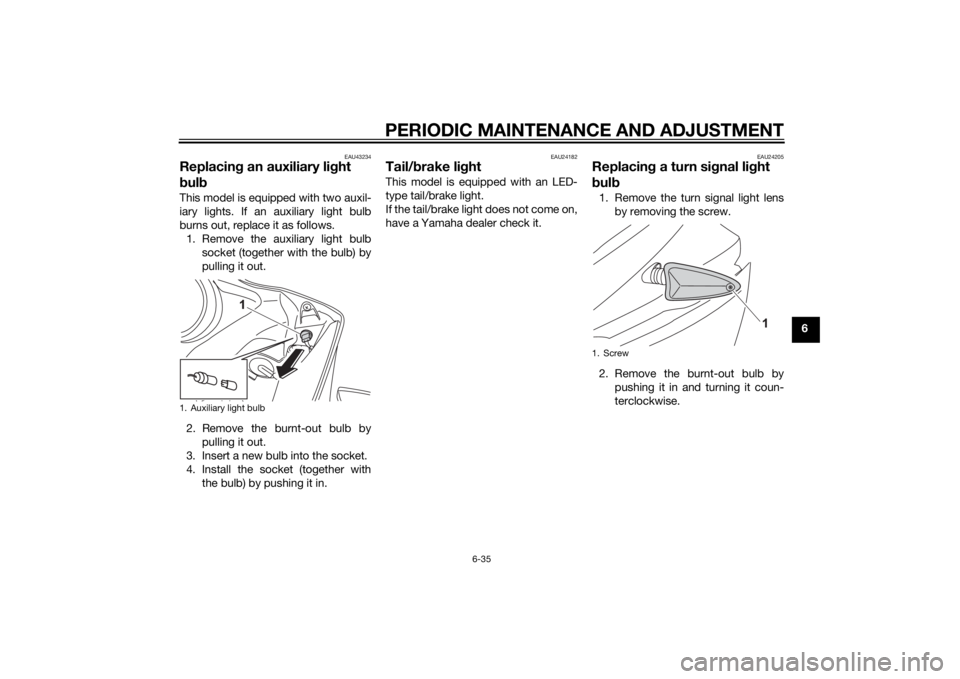

EAU43234

Replacing an auxiliary light

bulbThis model is equipped with two auxil-

iary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove the auxiliary light bulb

socket (together with the bulb) by

pulling it out.

2. Remove the burnt-out bulb by

pulling it out.

3. Insert a new bulb into the socket.

4. Install the socket (together with

the bulb) by pushing it in.

EAU24182

Tail/brake lightThis model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU24205

Replacing a turn signal light

bulb1. Remove the turn signal light lens

by removing the screw.

2. Remove the burnt-out bulb by

pushing it in and turning it coun-

terclockwise.

1. Auxiliary light bulb

1. Screw

U5D7E5E0.book Page 35 Thursday, August 21, 2014 9:30 AM

Page 78 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

63. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

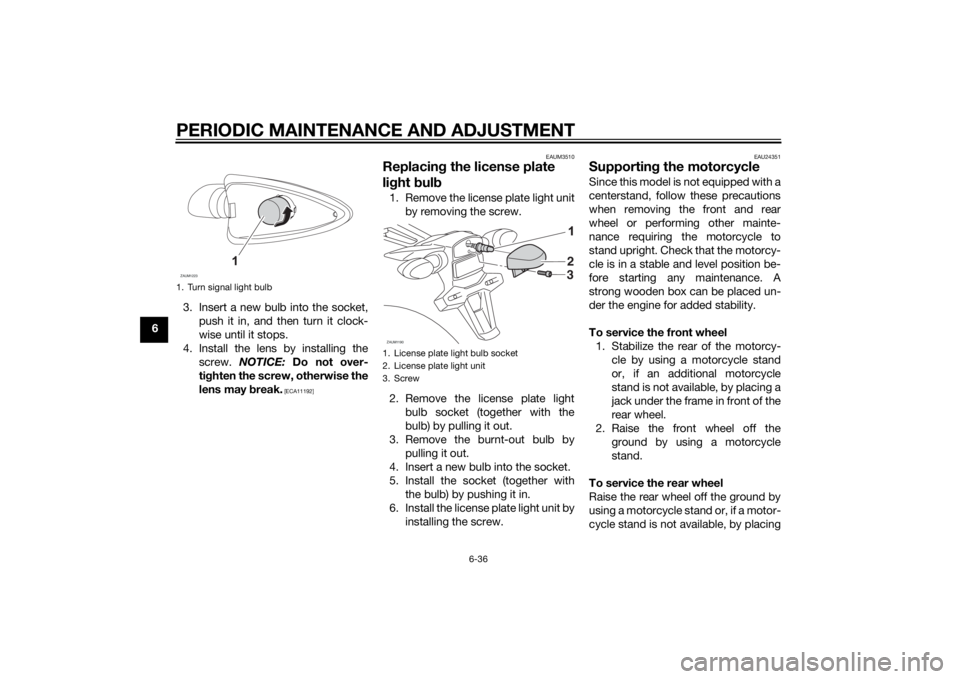

[ECA11192]EAUM3510

Replacing the license plate

light bulb1. Remove the license plate light unit

by removing the screw.

2. Remove the license plate light

bulb socket (together with the

bulb) by pulling it out.

3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by pushing it in.

6. Install the license plate light unit by

installing the screw.

EAU24351

Supporting the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy-

cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

1. Turn signal light bulbZAUM1223

1. License plate light bulb socket

2. License plate light unit

3. ScrewZAUM1190

2

3

U5D7E5E0.book Page 36 Thursday, August 21, 2014 9:30 AM