light YAMAHA YZF-R6 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZF-R6, Model: YAMAHA YZF-R6 2000Pages: 111, PDF Size: 11.91 MB

Page 42 of 111

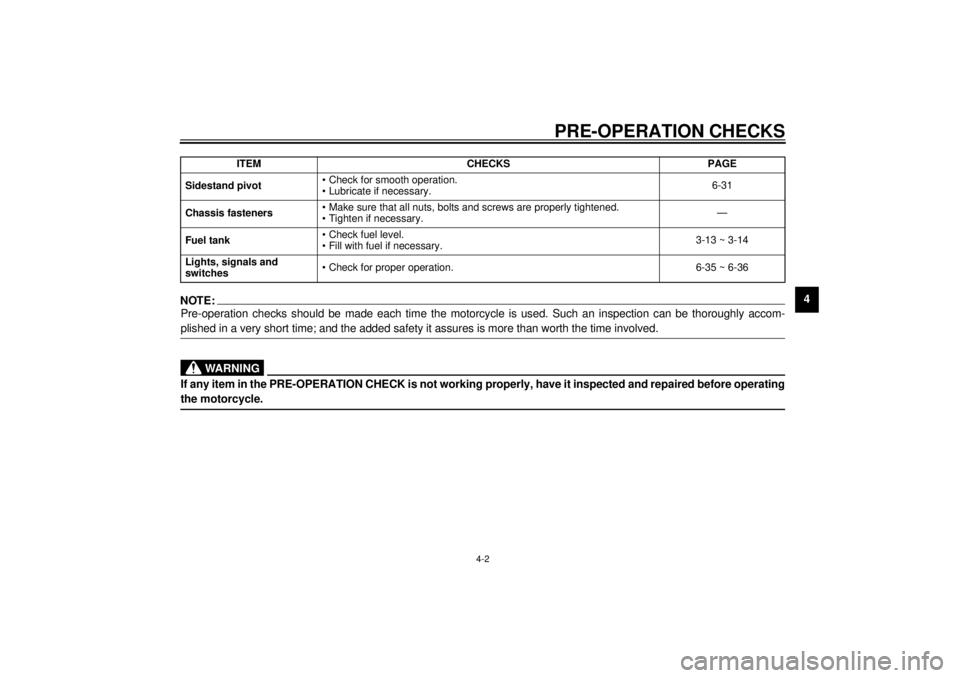

PRE-OPERATION CHECKS

4-2

4

NOTE:Pre-operation checks should be made each time the motorcycle is used. Such an inspection can be thoroughly accom-

plished in a very short time; and the added safety it assures is more than worth the time involved.

WARNING

If any item in the PRE-OPERATION CHECK is not working properly, have it inspected and repaired before operating

the motorcycle.Sidestand pivot• Check for smooth operation.

• Lubricate if necessary.6-31

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary.—

Fuel tank• Check fuel level.

• Fill with fuel if necessary.3-13 ~ 3-14

Lights, signals and

switches• Check for proper operation. 6-35 ~ 6-36 ITEM CHECKS PAGE

E_5eb_Preop.fm Page 2 Thursday, November 18, 1999 4:05 PM

Page 47 of 111

OPERATION AND IMPORTANT RIDING POINTS

5-3

51. Turn the main switch to “ON” and

the engine stop switch to “ ”.

ECA00005

CAUTION:@ The oil level/coolant temperature in-

dicator light and fuel indicator light

should come on for a few seconds

and then go off. If an indicator light

does not go off, refer to the corre-

sponding indicator light circuit

check in the “INSTRUMENT AND

CONTROL FUNCTIONS” section. @2. Shift the transmission into neutral.NOTE:@ When the transmission is in neutral, the

neutral indicator light should be on. If

the light does not come on, ask a

Yamaha dealer to inspect it. @3. Turn on the starter (choke) and

completely close the throttle grip.

4. Start the engine by pushing the

start switch.

NOTE:@ If the engine fails to start, release the

start switch, wait a few seconds, then

try again. Each attempt should be as

short as possible to preserve the bat-

tery. Do not crank the engine more

than 10 seconds on any one attempt. @5. After starting the engine, move the

starter (choke) to the halfway posi-

tion.NOTE:@ For maximum engine life, never accel-

erate hard with a cold engine! @6. After the engine is warm, turn off

the starter (choke) completely.NOTE:@ The engine is warm when it responds

normally to the throttle with the starter

(choke) turned off. @

EAU01258

Starting a warm engineThe starter (choke) is not required

when the engine is warm.

EC000046

CAUTION:@ See the “Engine break-in” section

prior to operating the motorcycle for

the first time. @

E_5eb_Operation.fm Page 3 Thursday, November 18, 1999 4:05 PM

Page 48 of 111

OPERATION AND IMPORTANT RIDING POINTS

5-4

5

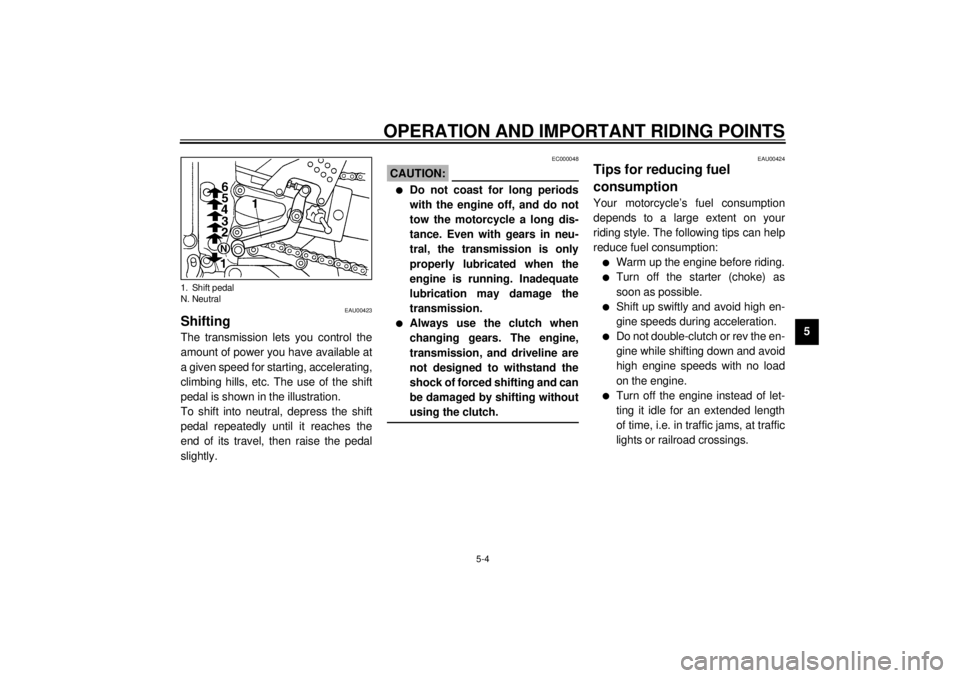

EAU00423

ShiftingThe transmission lets you control the

amount of power you have available at

a given speed for starting, accelerating,

climbing hills, etc. The use of the shift

pedal is shown in the illustration.

To shift into neutral, depress the shift

pedal repeatedly until it reaches the

end of its travel, then raise the pedal

slightly.

EC000048

CAUTION:@ l

Do not coast for long periods

with the engine off, and do not

tow the motorcycle a long dis-

tance. Even with gears in neu-

tral, the transmission is only

properly lubricated when the

engine is running. Inadequate

lubrication may damage the

transmission.

l

Always use the clutch when

changing gears. The engine,

transmission, and driveline are

not designed to withstand the

shock of forced shifting and can

be damaged by shifting without

using the clutch.

@

EAU00424

Tips for reducing fuel

consumptionYour motorcycle’s fuel consumption

depends to a large extent on your

riding style. The following tips can help

reduce fuel consumption:l

Warm up the engine before riding.

l

Turn off the starter (choke) as

soon as possible.

l

Shift up swiftly and avoid high en-

gine speeds during acceleration.

l

Do not double-clutch or rev the en-

gine while shifting down and avoid

high engine speeds with no load

on the engine.

l

Turn off the engine instead of let-

ting it idle for an extended length

of time, i.e. in traffic jams, at traffic

lights or railroad crossings.

1. Shift pedal

N. Neutral

E_5eb_Operation.fm Page 4 Thursday, November 18, 1999 4:05 PM

Page 50 of 111

6

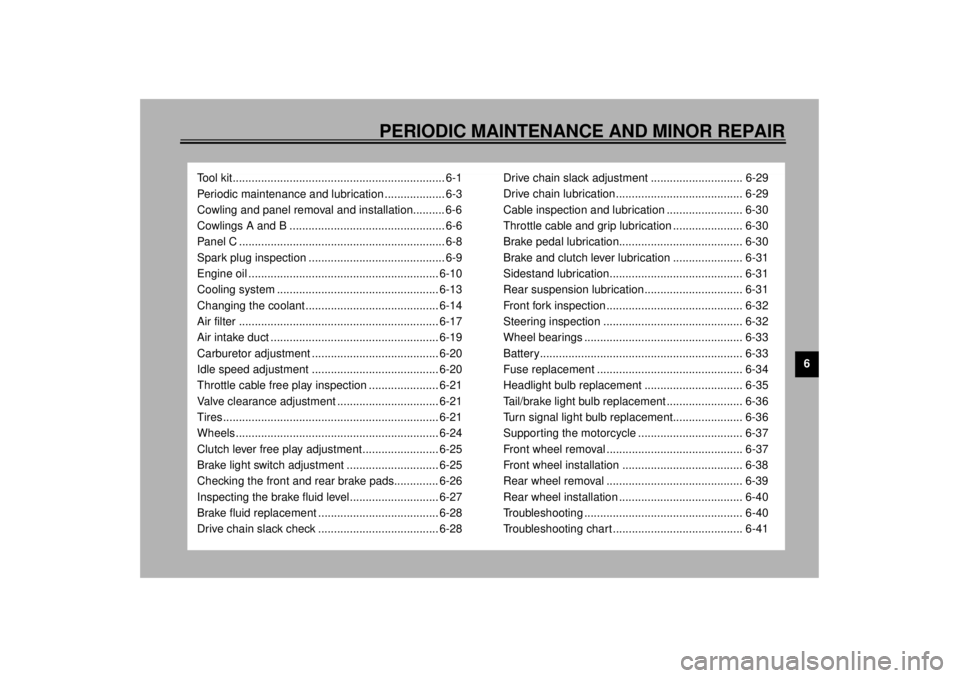

PERIODIC MAINTENANCE AND MINOR REPAIR

Tool kit................................................................... 6-1

Periodic maintenance and lubrication ................... 6-3

Cowling and panel removal and installation.......... 6-6

Cowlings A and B ................................................. 6-6

Panel C ................................................................. 6-8

Spark plug inspection ........................................... 6-9

Engine oil ............................................................ 6-10

Cooling system ................................................... 6-13

Changing the coolant .......................................... 6-14

Air filter ............................................................... 6-17

Air intake duct ..................................................... 6-19

Carburetor adjustment ........................................ 6-20

Idle speed adjustment ........................................ 6-20

Throttle cable free play inspection ...................... 6-21

Valve clearance adjustment ................................ 6-21

Tires .................................................................... 6-21

Wheels ................................................................ 6-24

Clutch lever free play adjustment........................ 6-25

Brake light switch adjustment ............................. 6-25

Checking the front and rear brake pads.............. 6-26

Inspecting the brake fluid level............................ 6-27

Brake fluid replacement ...................................... 6-28

Drive chain slack check ...................................... 6-28Drive chain slack adjustment ............................. 6-29

Drive chain lubrication........................................ 6-29

Cable inspection and lubrication ........................ 6-30

Throttle cable and grip lubrication ...................... 6-30

Brake pedal lubrication....................................... 6-30

Brake and clutch lever lubrication ...................... 6-31

Sidestand lubrication.......................................... 6-31

Rear suspension lubrication............................... 6-31

Front fork inspection ........................................... 6-32

Steering inspection ............................................ 6-32

Wheel bearings .................................................. 6-33

Battery................................................................ 6-33

Fuse replacement .............................................. 6-34

Headlight bulb replacement ............................... 6-35

Tail/brake light bulb replacement ........................ 6-36

Turn signal light bulb replacement...................... 6-36

Supporting the motorcycle ................................. 6-37

Front wheel removal ........................................... 6-37

Front wheel installation ...................................... 6-38

Rear wheel removal ........................................... 6-39

Rear wheel installation ....................................... 6-40

Troubleshooting .................................................. 6-40

Troubleshooting chart ......................................... 6-41

E_5eb_PeriodicTOC.fm Page 1 Thursday, November 18, 1999 4:06 PM

Page 59 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-9

6

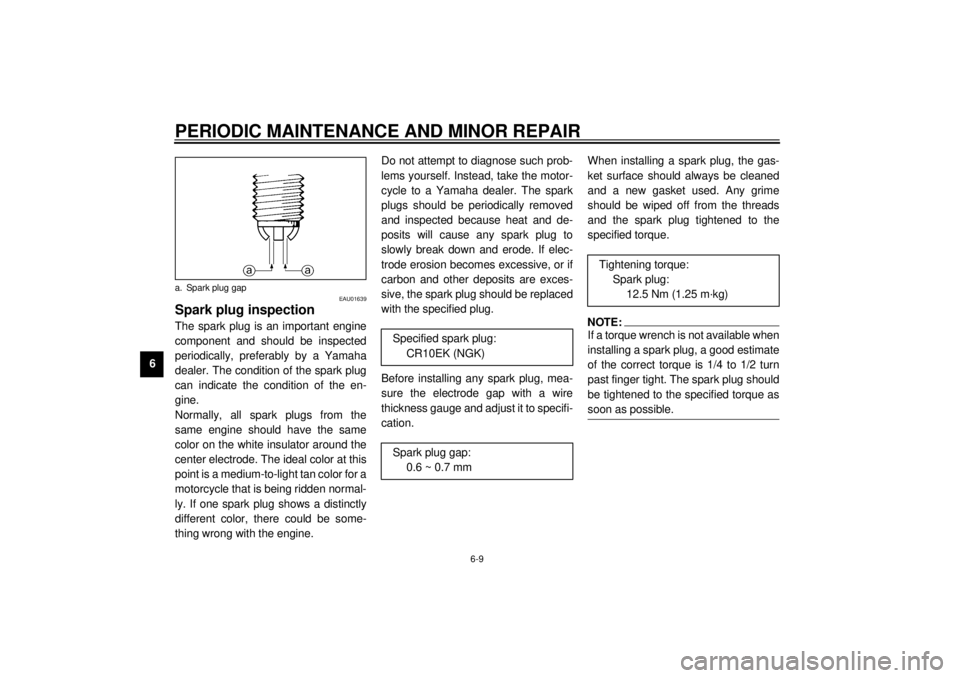

EAU01639

Spark plug inspectionThe spark plug is an important engine

component and should be inspected

periodically, preferably by a Yamaha

dealer. The condition of the spark plug

can indicate the condition of the en-

gine.

Normally, all spark plugs from the

same engine should have the same

color on the white insulator around the

center electrode. The ideal color at this

point is a medium-to-light tan color for a

motorcycle that is being ridden normal-

ly. If one spark plug shows a distinctly

different color, there could be some-

thing wrong with the engine.Do not attempt to diagnose such prob-

lems yourself. Instead, take the motor-

cycle to a Yamaha dealer. The spark

plugs should be periodically removed

and inspected because heat and de-

posits will cause any spark plug to

slowly break down and erode. If elec-

trode erosion becomes excessive, or if

carbon and other deposits are exces-

sive, the spark plug should be replaced

with the specified plug.

Before installing any spark plug, mea-

sure the electrode gap with a wire

thickness gauge and adjust it to specifi-

cation.When installing a spark plug, the gas-

ket surface should always be cleaned

and a new gasket used. Any grime

should be wiped off from the threads

and the spark plug tightened to the

specified torque.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4 to 1/2 turn

past finger tight. The spark plug should

be tightened to the specified torque as

soon as possible. @

a. Spark plug gap

Specified spark plug:

CR10EK (NGK)

Spark plug gap:

0.6 ~ 0.7 mm

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kg)

E_5eb_Periodic.fm Page 9 Thursday, November 18, 1999 4:06 PM

Page 60 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-10

6

ECA00021

CAUTION:@ Do not use any type of tools to re-

move or install the cap as the igni-

tion coil coupler may get damaged.

The spark plug cap may be difficult

to remove because a rubber seal on

the end of the cap is tightly fit into

the cylinder bore. To remove the

cap, simply twist it back and forth

while pulling it upward; when install-

ing the cap, twist it back and forth

while pushing it downward. @

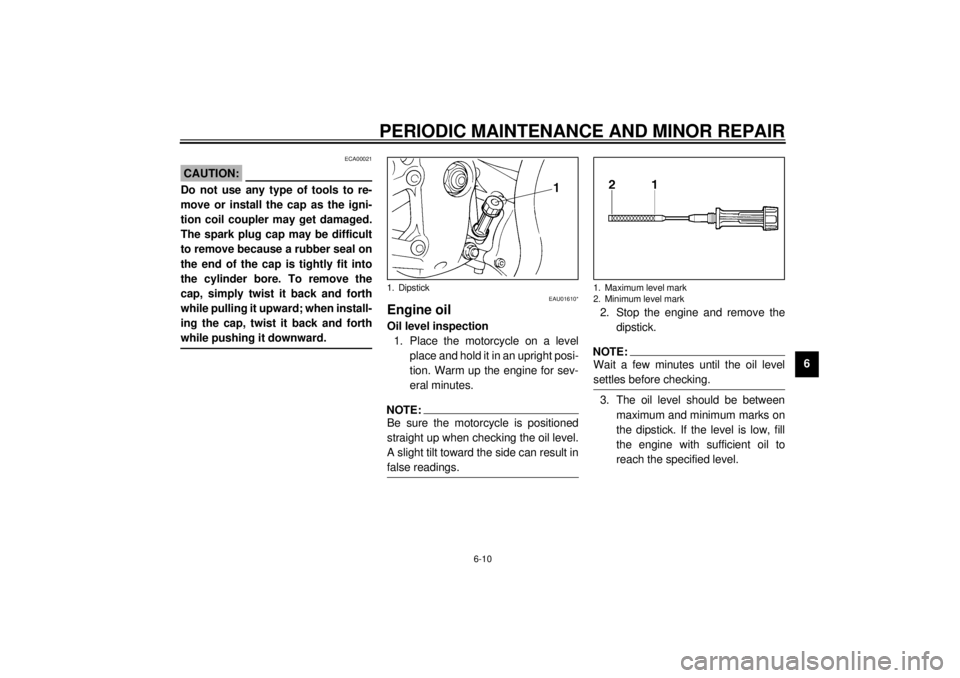

EAU01610*

Engine oilOil level inspection

1. Place the motorcycle on a level

place and hold it in an upright posi-

tion. Warm up the engine for sev-

eral minutes.NOTE:@ Be sure the motorcycle is positioned

straight up when checking the oil level.

A slight tilt toward the side can result in

false readings. @

2. Stop the engine and remove the

dipstick.NOTE:@ Wait a few minutes until the oil level

settles before checking. @3. The oil level should be between

maximum and minimum marks on

the dipstick. If the level is low, fill

the engine with sufficient oil to

reach the specified level.

1. Dipstick

1. Maximum level mark

2. Minimum level mark

E_5eb_Periodic.fm Page 10 Thursday, November 18, 1999 4:06 PM

Page 62 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-12

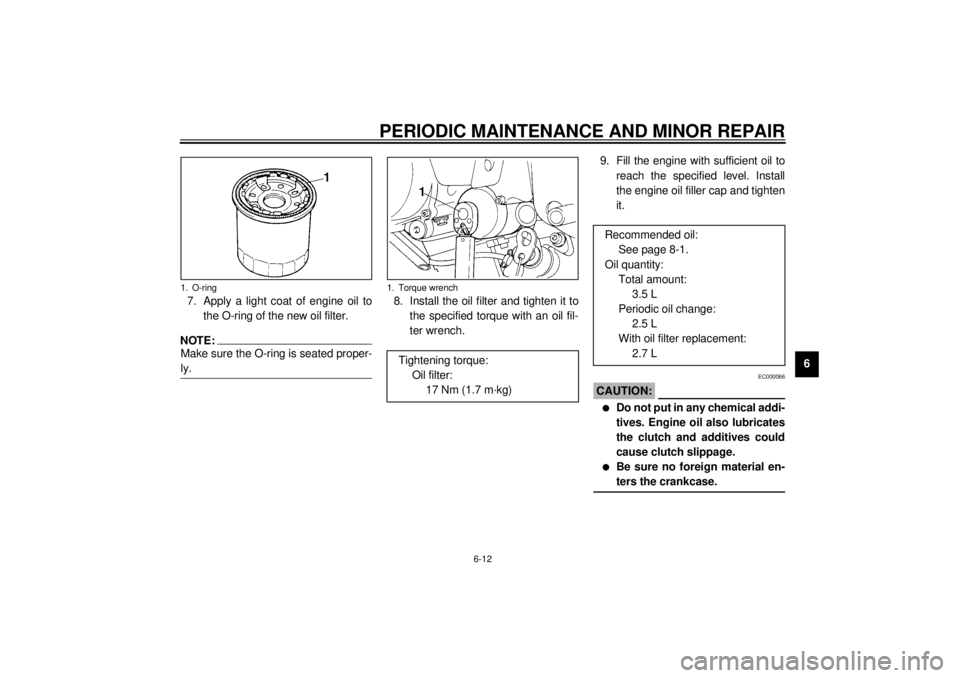

6 7. Apply a light coat of engine oil to

the O-ring of the new oil filter.

NOTE:@ Make sure the O-ring is seated proper-

ly. @

8. Install the oil filter and tighten it to

the specified torque with an oil fil-

ter wrench.9. Fill the engine with sufficient oil to

reach the specified level. Install

the engine oil filler cap and tighten

it.

EC000066

CAUTION:@ l

Do not put in any chemical addi-

tives. Engine oil also lubricates

the clutch and additives could

cause clutch slippage.

l

Be sure no foreign material en-

ters the crankcase.

@

1. O-ring

1. Torque wrenchTightening torque:

Oil filter:

17 Nm (1.7 m·kg)

Recommended oil:

See page 8-1.

Oil quantity:

Total amount:

3.5 L

Periodic oil change:

2.5 L

With oil filter replacement:

2.7 L

E_5eb_Periodic.fm Page 12 Thursday, November 18, 1999 4:06 PM

Page 63 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-13

610. Start the engine and warm it up for

several minutes. While warming

up, check for oil leakage. If oil

leakage is found, stop the engine

immediately and check for the

cause.

11. After the engine is started, the oil

level indicator light should go off if

the oil is at the specified level.

EC000067

CAUTION:@ If the indicator light flickers or re-

mains on, immediately stop the en-

gine and consult with a Yamaha

dealer. @12. Install the cowling.

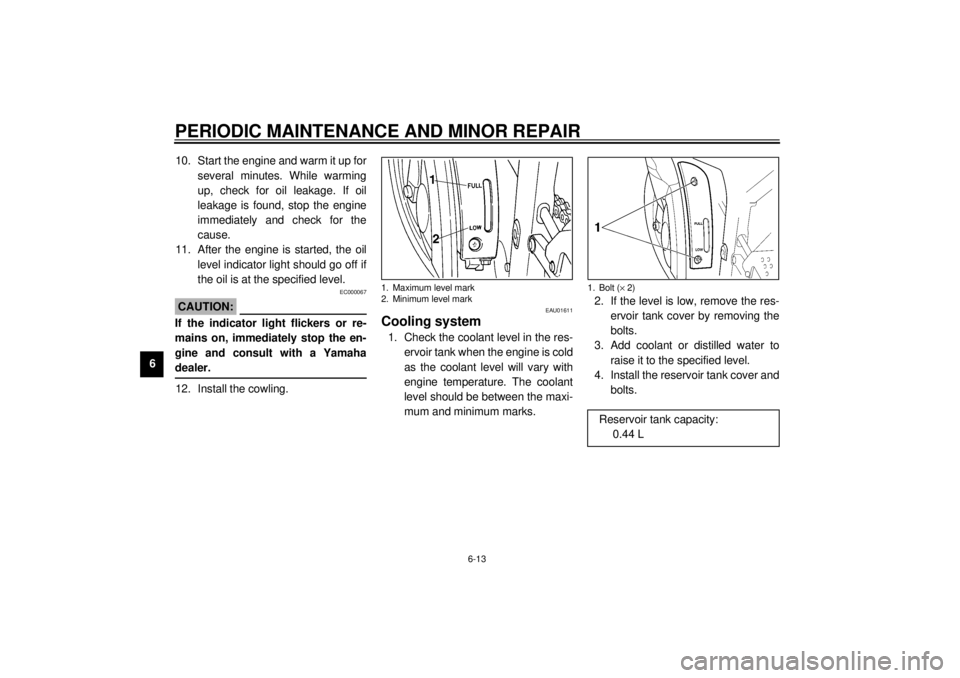

EAU01611

Cooling system1. Check the coolant level in the res-

ervoir tank when the engine is cold

as the coolant level will vary with

engine temperature. The coolant

level should be between the maxi-

mum and minimum marks.2. If the level is low, remove the res-

ervoir tank cover by removing the

bolts.

3. Add coolant or distilled water to

raise it to the specified level.

4. Install the reservoir tank cover and

bolts.1. Maximum level mark

2. Minimum level mark

1. Bolt (´ 2)

Reservoir tank capacity:

0.44 L

E_5eb_Periodic.fm Page 13 Thursday, November 18, 1999 4:06 PM

Page 74 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-24

6

EAU00684

WARNING

@ This motorcycle is fitted with super

high-speed running tires. The fol-

lowing points must be observed in

order for you to make fully effective

use of these tires.l

Never fail to use the specified

tires in tire replacement. Other

tires may have a danger of

bursting at super high-speeds.

l

New tires have a relatively low

grip on the road surface until

they have been slightly worn.

Therefore, approximately

100 km should be traveled at

normal speed before any high-

speed riding is done.

l

Before any high-speed runs, the

tires should be warmed-up suf-

ficiently.

l

Always inflate to the correct tire

pressure according to the oper-

ating conditions.

@

EAU00687

WheelsTo ensure maximum performance,

long service, and safe operation, note

the following:l

Always inspect the wheels before

a ride. Check for cracks, bends, or

warpage of the wheels. If any ab-

normal condition exists in a wheel,

consult a Yamaha dealer. Do not

attempt even small repairs to the

wheel. If a wheel is deformed or

cracked, it must be replaced.

l

Tires and wheels should be bal-

anced whenever either one is

changed or replaced. Failure to

have a wheel balanced can result

in poor performance, adverse han-

dling characteristics, and short-

ened tire life.

l

Ride at moderate speeds after

changing a tire since the tire sur-

face must first be broken in for it to

develop its optimal characteristics.

E_5eb_Periodic.fm Page 24 Thursday, November 18, 1999 4:06 PM

Page 75 of 111

PERIODIC MAINTENANCE AND MINOR REPAIR

6-25

6

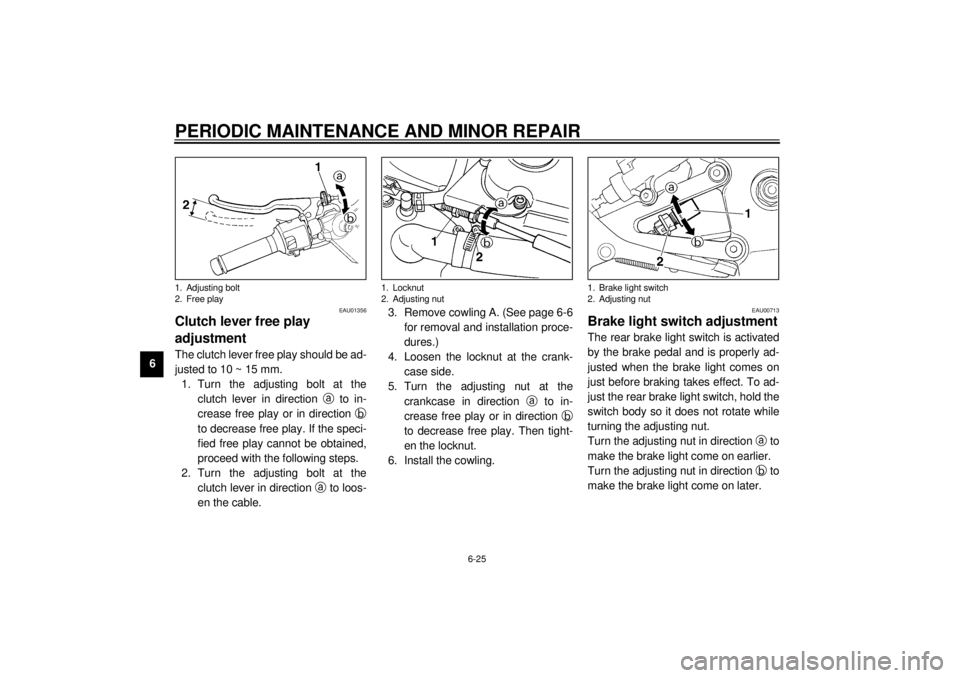

EAU01356

Clutch lever free play

adjustmentThe clutch lever free play should be ad-

justed to 10 ~ 15 mm.

1. Turn the adjusting bolt at the

clutch lever in direction

a to in-

crease free play or in direction

b

to decrease free play. If the speci-

fied free play cannot be obtained,

proceed with the following steps.

2. Turn the adjusting bolt at the

clutch lever in direction

a to loos-

en the cable.3. Remove cowling A. (See page 6-6

for removal and installation proce-

dures.)

4. Loosen the locknut at the crank-

case side.

5. Turn the adjusting nut at the

crankcase in direction

a to in-

crease free play or in direction

b

to decrease free play. Then tight-

en the locknut.

6. Install the cowling.

EAU00713

Brake light switch adjustmentThe rear brake light switch is activated

by the brake pedal and is properly ad-

justed when the brake light comes on

just before braking takes effect. To ad-

just the rear brake light switch, hold the

switch body so it does not rotate while

turning the adjusting nut.

Turn the adjusting nut in direction

a to

make the brake light come on earlier.

Turn the adjusting nut in direction

b to

make the brake light come on later.

1. Adjusting bolt

2. Free play

1. Locknut

2. Adjusting nut

1. Brake light switch

2. Adjusting nut

E_5eb_Periodic.fm Page 25 Thursday, November 18, 1999 4:06 PM