maintenance YAMAHA YZF-R6 2016 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R6, Model: YAMAHA YZF-R6 2016Pages: 112, PDF Size: 2.57 MB

Page 78 of 112

Periodic maintenance an d a djustment

6-27

6

EAU22733

Chan gin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22777

To check the d rive chain slack

1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into theneutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU39057

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm.

Drive chain slack:30.0–45.0 mm (1.18–1.77 in)

1. Drive chain slack

U2CXE2E0.book Page 27 Tuesday, June 9, 2015 5:04 PM

Page 79 of 112

Periodic maintenance an d a djustment

6-28

6

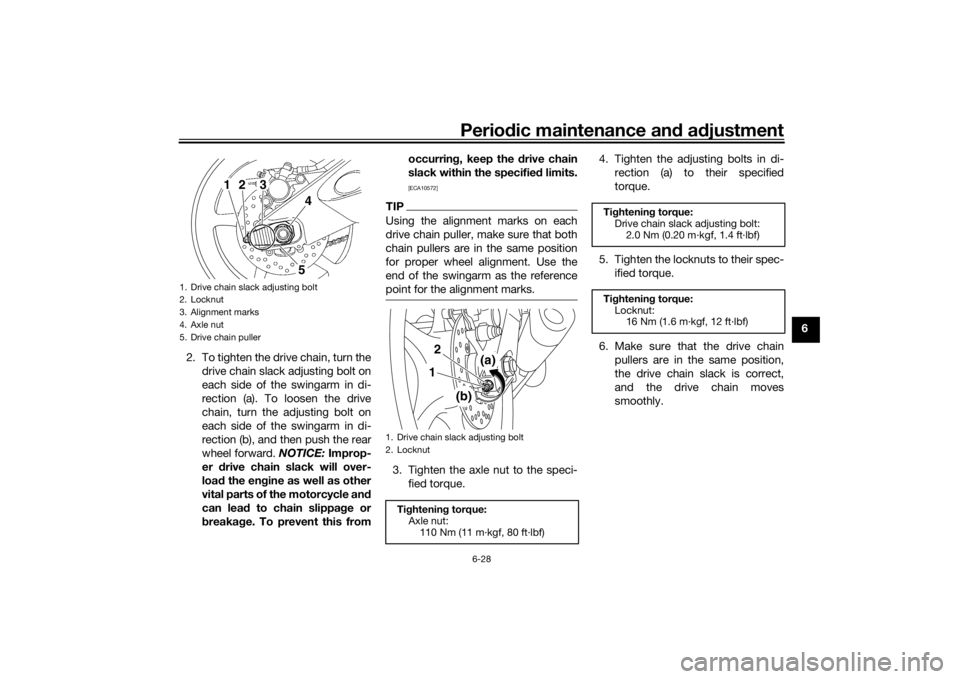

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

loa d the en gine as well as other

vital parts of the motorcycle and

can lead to chain slippa ge or

b reakag e. To prevent this from occurrin

g, keep the d rive chain

slack within the specified limits.

[ECA10572]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment. Use the

end of the swingarm as the reference

point for the alignment marks.3. Tighten the axle nut to the speci-

fied torque. 4. Tighten the adjusting bolts in di-

rection (a) to their specified

torque.

5. Tighten the locknuts to their spec- ified torque.

6. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

1. Drive chain slack adjusting bolt

2. Locknut

3. Alignment marks

4. Axle nut

5. Drive chain puller

45

1

2

3

1. Drive chain slack adjusting bolt

2. Locknut

Tightenin g torque:

Axle nut: 110 Nm (11 m·kgf, 80 ft·lbf)

(a)

(b)

12

Tightenin g torque:

Drive chain slack adjusting bolt: 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Ti ghtenin g torque:

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

U2CXE2E0.book Page 28 Tuesday, June 9, 2015 5:04 PM

Page 80 of 112

Periodic maintenance an d a djustment

6-29

6

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they may contain su

bstances that

coul d damag e the O-rin gs.

[ECA11112] EAU23098

Checkin

g an d lu bricatin g the

cab lesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or re-

place it. WARNING! Dama ge to the

outer housin g of cab les may result

in internal rustin g an d cause inter-

ference with cab le movement. Re-

place damag ed cab les as soon as

possi ble to prevent unsafe con di-

tions.

[EWA10712]

Recommen ded lu bricant:

Yamaha cable lubricant or other

suitable cable lubricant

U2CXE2E0.book Page 29 Tuesday, June 9, 2015 5:04 PM

Page 81 of 112

Periodic maintenance an d a djustment

6-30

6

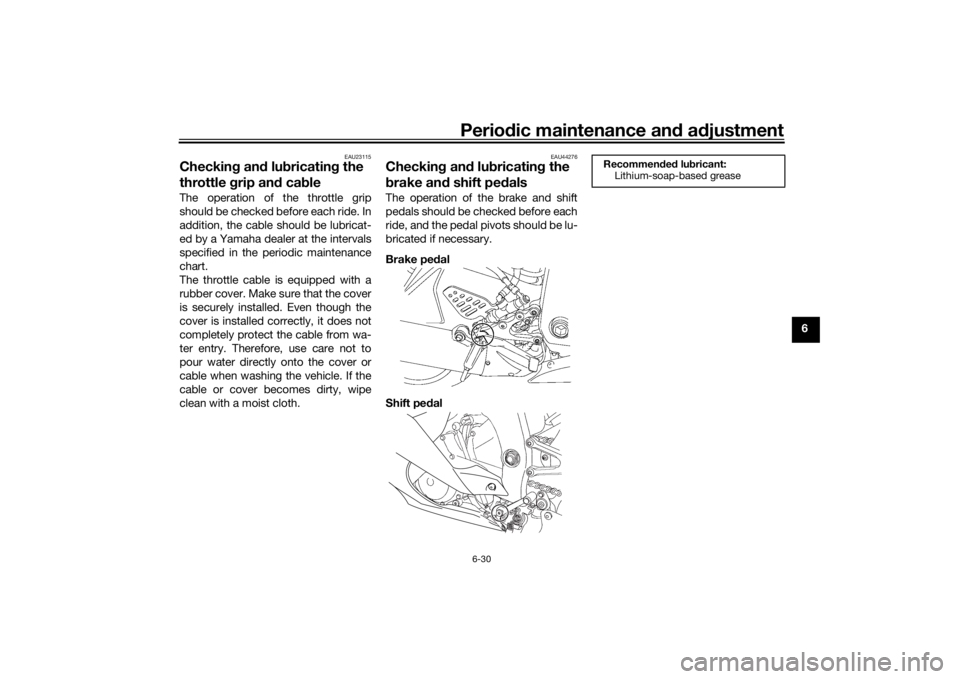

EAU23115

Checkin g an d lu bricatin g the

throttle grip an d ca bleThe operation of the throttle grip

should be checked before each ride. In

addition, the cable should be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

chart.

The throttle cable is equipped with a

rubber cover. Make sure that the cover

is securely installed. Even though the

cover is installed correctly, it does not

completely protect the cable from wa-

ter entry. Therefore, use care not to

pour water directly onto the cover or

cable when washing the vehicle. If the

cable or cover becomes dirty, wipe

clean with a moist cloth.

EAU44276

Checkin g an d lu bricatin g the

b rake an d shift pe dalsThe operation of the brake and shift

pedals should be checked before each

ride, and the pedal pivots should be lu-

bricated if necessary.

Brake pe dal

Shift pe dal

Recommen ded lu bricant:

Lithium-soap-based grease

U2CXE2E0.book Page 30 Tuesday, June 9, 2015 5:04 PM

Page 82 of 112

Periodic maintenance an d a djustment

6-31

6

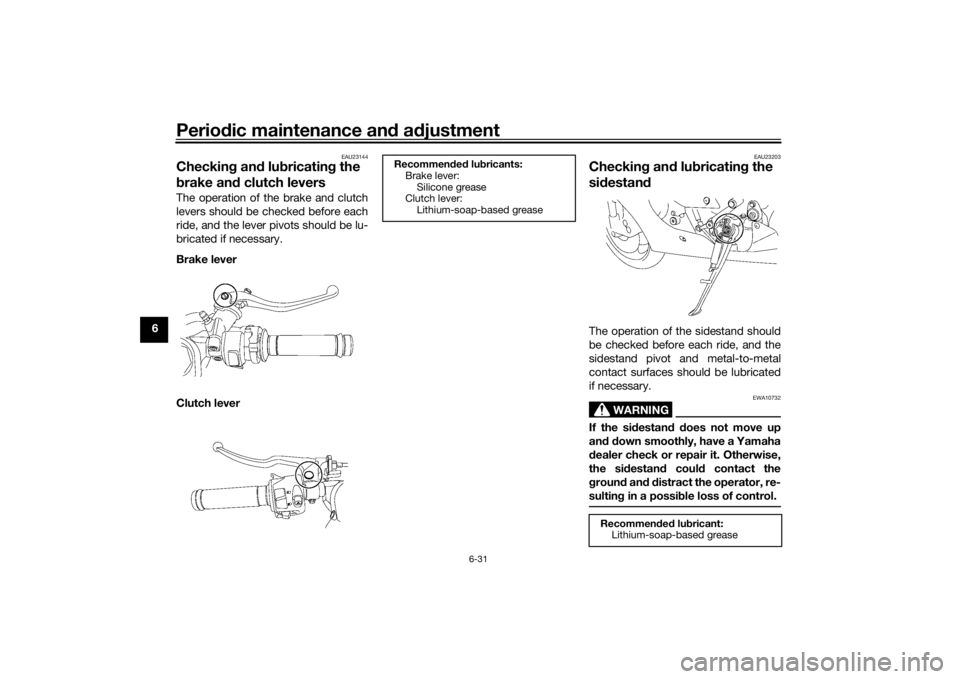

EAU23144

Checkin g an d lu bricatin g the

b rake an d clutch leversThe operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Brake lever

Clutch lever

EAU23203

Checkin g an d lu bricatin g the

si destan dThe operation of the sidestand should

be checked before each ride, and the

sidestand pivot and metal-to-metal

contact surfaces should be lubricated

if necessary.

WARNING

EWA10732

If the si destan d d oes not move up

an d d own smoothly, have a Yamaha

d ealer check or repair it. Otherwise,

the si destan d coul d contact the

g roun d an d d istract the operator, re-

sultin g in a possi ble loss of control.

Recommen ded lu bricants:

Brake lever:

Silicone grease

Clutch lever:

Lithium-soap-based grease

Recommen ded lu bricant:

Lithium-soap-based grease

U2CXE2E0.book Page 31 Tuesday, June 9, 2015 5:04 PM

Page 83 of 112

Periodic maintenance an d a djustment

6-32

6

EAUM1653

Lu bricatin g the swin garm piv-

otsThe swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23273

Checkin g the front forkThe condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any damag e is foun d or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

Recommen ded lu bricant:

Lithium-soap-based grease

U2CXE2E0.book Page 32 Tuesday, June 9, 2015 5:04 PM

Page 84 of 112

Periodic maintenance an d a djustment

6-33

6

EAU23285

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Raise the front wheel off the ground. (See page 6-39.)

WARNING! To avoi d injury, se-

curely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

EAU23292

Checkin g the wheel b earingsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU50211

BatteryThe battery is located under the rider

seat. (See page 3-20.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe1. Battery

2. Negative battery lead (black)

3. Positive battery lead (red)

1

2

3

U2CXE2E0.book Page 33 Tuesday, June 9, 2015 5:04 PM

Page 85 of 112

Periodic maintenance an d a djustment

6-34

6

b

urns. Avoi d any contact with

skin, eyes or clothin g an d al-

ways shiel d your eyes when

workin g near b atteries. In case

of contact, ad minister the fol-

lowin g FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink lar ge quan-

tities of water or milk and im-

me diately call a physician.

EYES: Flush with water for 15 minutes and seek prompt

me dical attention.

Batteries pro duce explosive hy-

d ro gen gas. Therefore, keep

sparks, flames, ci garettes, etc.,

away from the b attery and pro-

vi de sufficient ventilation when

char gin g it in an enclosed

space.

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.

To char ge the b attery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the battery tends to discharge more quick-

ly if the vehicle is equipped with op-

tional electrical accessories.

NOTICE

ECA16522

To char

ge a VRLA (Valve Re gulate d

Lea d Aci d) battery, a special (con-

stant-voltag e) battery char ger is re-

quire d. Usin g a conventional b attery

char ger will d amage the battery.To store the battery

1. If the vehicle will not be used for more than one month, remove the

battery, fully charge it, and then

place it in a cool, dry place.

NOTICE: When removin g the

b attery, be sure the key is

turne d to “OFF”, then discon-

nect the neg ative lead b efore

d isconnectin g the positive lea d.

[ECA16303]

2. If the battery will be stored for

more than two months, check it at

least once a month and fully char-

ge it if necessary.

3. Fully charge the battery before installation. NOTICE: When in-

stallin g the b attery, be sure the key is turned

to “OFF”, then

connect the positive lead b efore

connectin g the ne gative lea d.

[ECA16841]

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.NOTICE

ECA16531

Always keep the b attery charged .

Storin g a dischar ged battery can

cause permanent battery damag e.

U2CXE2E0.book Page 34 Tuesday, June 9, 2015 5:04 PM

Page 86 of 112

Periodic maintenance an d a djustment

6-35

6

EAU23708

Replacin g the fusesThe main fuse, the fuel injection sys-

tem fuse, and fuse box 1 are located

under the rider seat. (See page 3-20.)TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.

Fuse box 2 is located under panel A.

(See page 6-8.)

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge

ratin g than recommen ded to avoi

d causin g extensive d am-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Main fuse

2. Fuel injection system spare fuse

3. Starter relay cover

4. Fuel injection system fuse

5. Fuse box 1

6. Backup fuse (for clock and immobilizer sys-tem)

7. Electronic throttle valve fuse

8. Spare fuse

2

1

5

6

3

748

1. Fuse box 2

2. Left radiator fan motor fuse

3. Right radiator fan motor fuse

4. Signaling system fuse

5. Ignition fuse

6. Taillight fuse

7. Headlight fuse

8. Spare fuse

Specifie d fuses:

Main fuse: 50.0 A

Fuel injection system fuse:

15.0 A

Electronic throttle valve fuse: 7.5 A

Backup fuse: 7.5 A

Radiator fan motor fuse:

15.0 A × 2

Ignition fuse: 15.0 A

Signaling system fuse: 10.0 A

Taillight fuse:

7.5 A

Headlight fuse: 15.0 A

U2CXE2E0.book Page 35 Tuesday, June 9, 2015 5:04 PM

Page 87 of 112

Periodic maintenance an d a djustment

6-36

6

EAU39014

Replacin g a hea dlig ht bul bThis model is equipped with halogen

bulb headlights. If a headlight bulb

burns out, replace it as follows.NOTICE

ECA10651

Take care not to damag e the follow-

in g parts:

Hea dlig ht bul b

Do not touch the glass part of

the hea dlig ht bul b to keep it free

from oil, otherwise the transpar-

ency of the g lass, the luminosity

of the b ulb, an d the b ulb life will

b e ad versely affected . Thor-

ou ghly clean off any d irt and fin-

g erprints on the head light bul b

using a cloth moistened with al-

cohol or thinner.

Hea dlig ht lens

Do not affix any type of tinted

film or stickers to the head light

lens.

Do not use a hea dlig ht bul b of a

watta ge hi gher than specified .

1. Remove the headlight bulb cover

by turning it counterclockwise.

2. Disconnect the headlight coupler. 3. Unhook the headlight bulb holder,

and then remove the burnt-out

bulb.

4. Place a new headlight bulb into position, and then secure it with

the bulb holder.

5. Connect the headlight coupler.1. Do not touch the glass part of the bulb.

1. Headlight bulb cover

1

1. Headlight coupler

1. Headlight bulb holder

U2CXE2E0.book Page 36 Tuesday, June 9, 2015 5:04 PM