maintenance YAMAHA YZF-R6 2016 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R6, Model: YAMAHA YZF-R6 2016Pages: 112, PDF Size: 2.57 MB

Page 88 of 112

Periodic maintenance an d a djustment

6-37

6 6. Install the headlight bulb cover by

turning it clockwise.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU44941

Auxiliary li ghtThis model is equipped with an LED-

type auxiliary light.

If the auxiliary light does not come on,

have a Yamaha dealer check it.

EAU70540

Brake/tail li ghtThis model is equipped with an LED-

type brake/tail light.

If the brake/tail light does not come on,

have a Yamaha dealer check it.

1. Auxiliary light

U2CXE2E0.book Page 37 Tuesday, June 9, 2015 5:04 PM

Page 89 of 112

Periodic maintenance an d a djustment

6-38

6

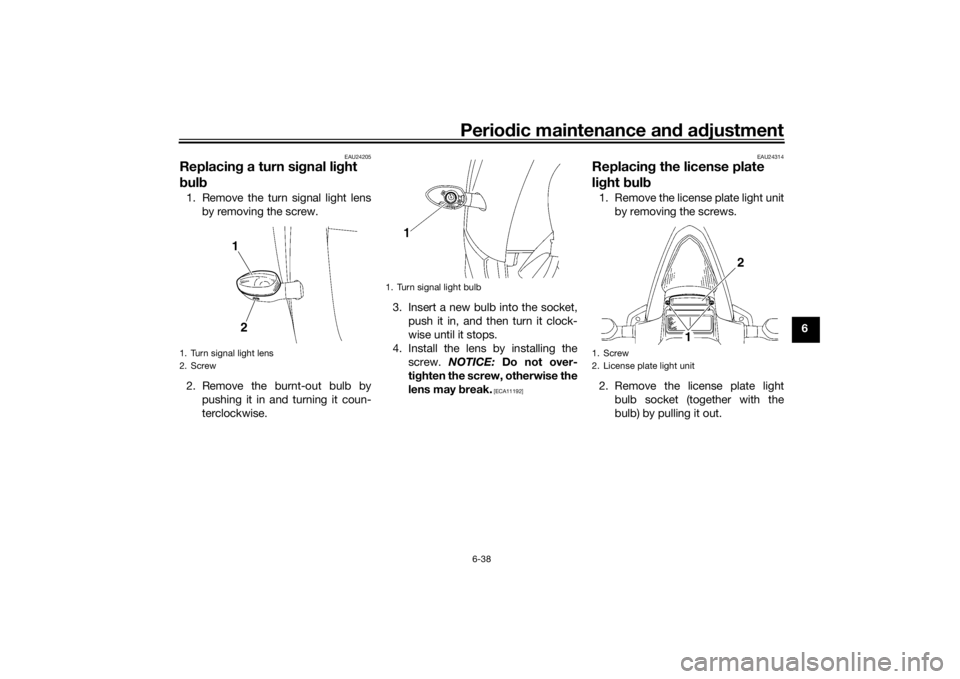

EAU24205

Replacin g a turn sig nal light

b ul b1. Remove the turn signal light lens

by removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it coun-

terclockwise. 3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

ti g hten the screw, otherwise the

lens may break.

[ECA11192] EAU24314

Replacin

g the license plate

lig ht bul b1. Remove the license plate light unit

by removing the screws.

2. Remove the license plate light bulb socket (together with the

bulb) by pulling it out.

1. Turn signal light lens

2. Screw

21

1. Turn signal light bulb

1. Screw

2. License plate light unit

1

2

U2CXE2E0.book Page 38 Tuesday, June 9, 2015 5:04 PM

Page 90 of 112

Periodic maintenance an d a djustment

6-39

6 3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the screws.

EAU24351

Supportin g the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

1. License plate light bulb

2. License plate light bulb socket

1

2

U2CXE2E0.book Page 39 Tuesday, June 9, 2015 5:04 PM

Page 91 of 112

Periodic maintenance an d a djustment

6-40

6

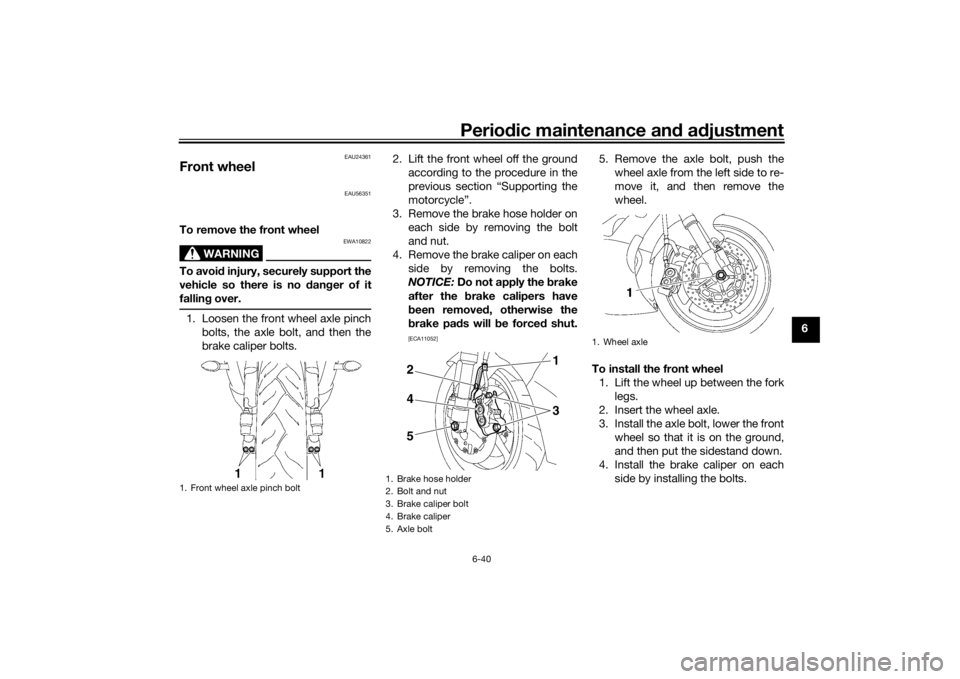

EAU24361

Front wheel

EAU56351

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolts, the axle bolt, and then the

brake caliper bolts. 2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake hose holder on each side by removing the bolt

and nut.

4. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the b rake

after the b rake calipers have

b een removed , otherwise the

b rake pad s will be forced shut.

[ECA11052]

5. Remove the axle bolt, push the

wheel axle from the left side to re-

move it, and then remove the

wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the axle bolt, lower the front wheel so that it is on the ground,

and then put the sidestand down.

4. Install the brake caliper on each side by installing the bolts.

1. Front wheel axle pinch bolt

1. Brake hose holder

2. Bolt and nut

3. Brake caliper bolt

4. Brake caliper

5. Axle bolt

31

2

4

5

1. Wheel axle

U2CXE2E0.book Page 40 Tuesday, June 9, 2015 5:04 PM

Page 92 of 112

Periodic maintenance an d a djustment

6-41

6

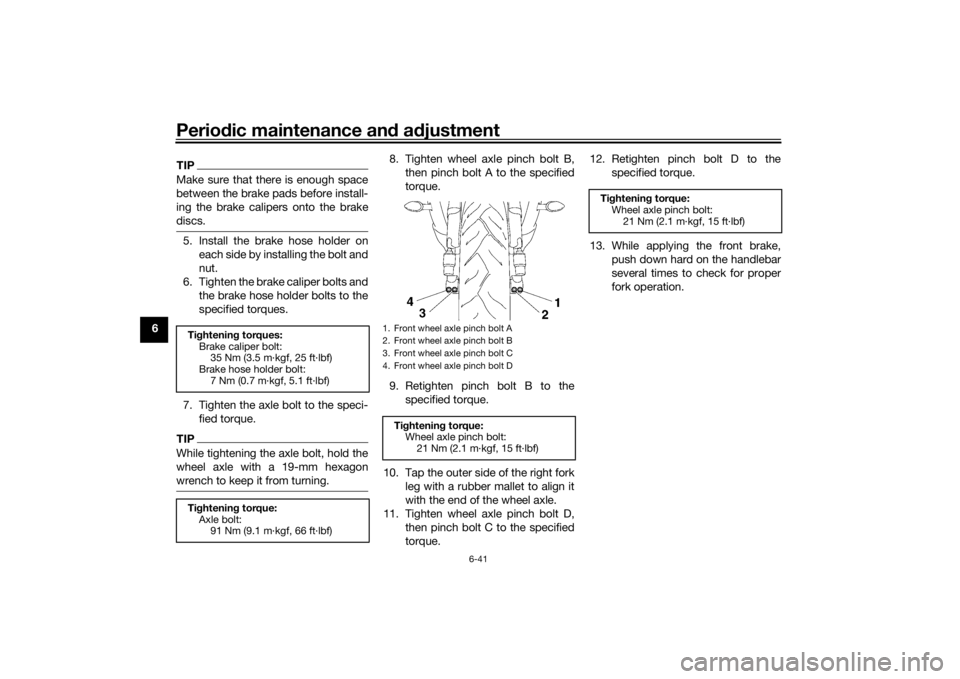

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.5. Install the brake hose holder on

each side by installing the bolt and

nut.

6. Tighten the brake caliper bolts and the brake hose holder bolts to the

specified torques.

7. Tighten the axle bolt to the speci- fied torque.TIPWhile tightening the axle bolt, hold the

wheel axle with a 19-mm hexagon

wrench to keep it from turning.

8. Tighten wheel axle pinch bolt B,then pinch bolt A to the specified

torque.

9. Retighten pinch bolt B to the specified torque.

10. Tap the outer side of the right fork leg with a rubber mallet to align it

with the end of the wheel axle.

11. Tighten wheel axle pinch bolt D, then pinch bolt C to the specified

torque. 12. Retighten pinch bolt D to the

specified torque.

13. While applying the front brake, push down hard on the handlebar

several times to check for proper

fork operation.

Tightenin g torques:

Brake caliper bolt: 35 Nm (3.5 m·kgf, 25 ft·lbf)

Brake hose holder bolt:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Ti ghtenin g torque:

Axle bolt: 91 Nm (9.1 m·kgf, 66 ft·lbf)

1. Front wheel axle pinch bolt A

2. Front wheel axle pinch bolt B

3. Front wheel axle pinch bolt C

4. Front wheel axle pinch bolt DTightenin g torque:

Wheel axle pinch bolt: 21 Nm (2.1 m·kgf, 15 ft·lbf)

Tightenin g torque:

Wheel axle pinch bolt: 21 Nm (2.1 m·kgf, 15 ft·lbf)

U2CXE2E0.book Page 41 Tuesday, June 9, 2015 5:04 PM

Page 93 of 112

Periodic maintenance an d a djustment

6-42

6

EAU25081

Rear wheel

EAU56721

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut.

2. Lift the rear wheel off the ground

according to the procedure on

page 6-39. 3. Remove the axle nut.

4. Fully loosen the locknut on each

side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts in direction (a) to loosen

the drive chain enough so it can

be removed from the rear sprock-

et, and then push the wheel for-

ward.

6. Remove the drive chain from the rear sprocket.

TIPIf the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disas-

sembled.7. While supporting the brake caliper

bracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the b rake

after the wheel an d b rake disc

have been removed , otherwise

the brake pad s will be forced

shut.

[ECA11073]

1. Axle nut

2. Brake caliper

3. Brake caliper bracket

1

2

3

1. Drive chain slack adjusting bolt

2. Locknut

(a)

12

U2CXE2E0.book Page 42 Tuesday, June 9, 2015 5:04 PM

Page 94 of 112

Periodic maintenance an d a djustment

6-43

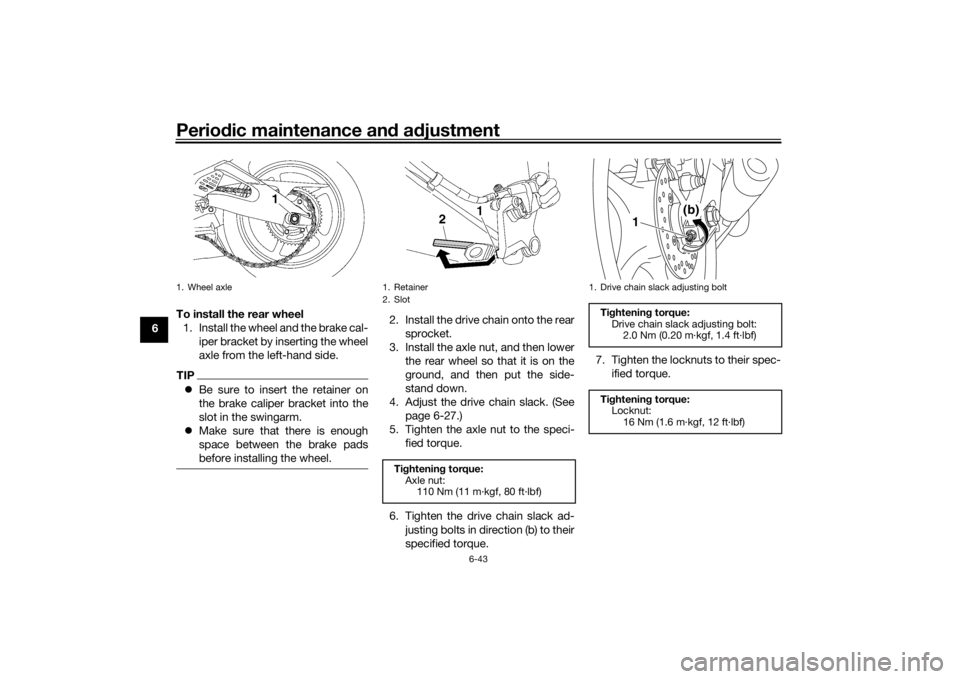

6 To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.

TIPBe sure to insert the retainer on

the brake caliper bracket into the

slot in the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.

2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut, and then lower the rear wheel so that it is on the

ground, and then put the side-

stand down.

4. Adjust the drive chain slack. (See page 6-27.)

5. Tighten the axle nut to the speci- fied torque.

6. Tighten the drive chain slack ad- justing bolts in direction (b) to their

specified torque. 7. Tighten the locknuts to their spec-

ified torque.

1. Wheel axle

1. Retainer

2. SlotTightenin g torque:

Axle nut: 110 Nm (11 m·kgf, 80 ft·lbf)

1. Drive chain slack adjusting boltTightenin g torque:

Drive chain slack adjusting bolt: 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Ti ghtenin g torque:

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

(b)

1

U2CXE2E0.book Page 43 Tuesday, June 9, 2015 5:04 PM

Page 95 of 112

Periodic maintenance an d a djustment

6-44

6

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water heaters or furnaces. Gasoline or

g

asoline vapors can i gnite or ex-

plo de, causin g severe injury or prop-

erty damag e.

U2CXE2E0.book Page 44 Tuesday, June 9, 2015 5:04 PM

Page 96 of 112

Periodic maintenance an d a djustment

6-45

6

EAU42505

Trou bleshootin g chartsStartin g pro blems or poor en gine performance

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.

There is no fuel.

Check the battery.

Supply fuel.

The engine does not start.

Check the battery.

Remove the spark plugs

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gaps, or replace the spark plugs.

Have a Yamaha dealer check the vehicle.

Operate the electric starter.4. Compression

There is compression.

There is no compression.

The engine does not start.

Have a Yamaha dealer check the vehicle.Have a Yamaha dealer check the vehicle.

The engine does not start.

Check the compression.

Operate the electric starter.2. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The engine does not start.

Check the ignition.

The battery is good.Check the battery lead connections,

and have a Yamaha dealer charge

the battery if necessary.

DryWet

Operate the electric starter.

U2CXE2E0.book Page 45 Tuesday, June 9, 2015 5:04 PM

Page 97 of 112

Periodic maintenance an d a djustment

6-46

6

En

gine overheatin g

WARNING

EWAT1041

Do not remove the ra diator cap when the en gine an d ra diator are hot. Scal din g hot flui d an d steam may be

b lown out un der pressure, which coul d cause serious injury. Be sure to wait until the en gine has coole d.

Place a thick rag , like a towel, over the ra diator cap, an d then slowly rotate the cap counterclockwise to the

d etent to allow any resi dual pressure to escape. When the hissin g soun d has stopped , press down on the cap

while turnin g it counterclockwise, an d then remove the cap.TIPIf coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended cool-

ant as soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

U2CXE2E0.book Page 46 Tuesday, June 9, 2015 5:04 PM