YAMAHA YZF-R6 2016 Repair Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: YZF-R6, Model: YAMAHA YZF-R6 2016Pages: 112, PDF Size: 2.57 MB

Page 61 of 112

Periodic maintenance an d a djustment

6-10

6

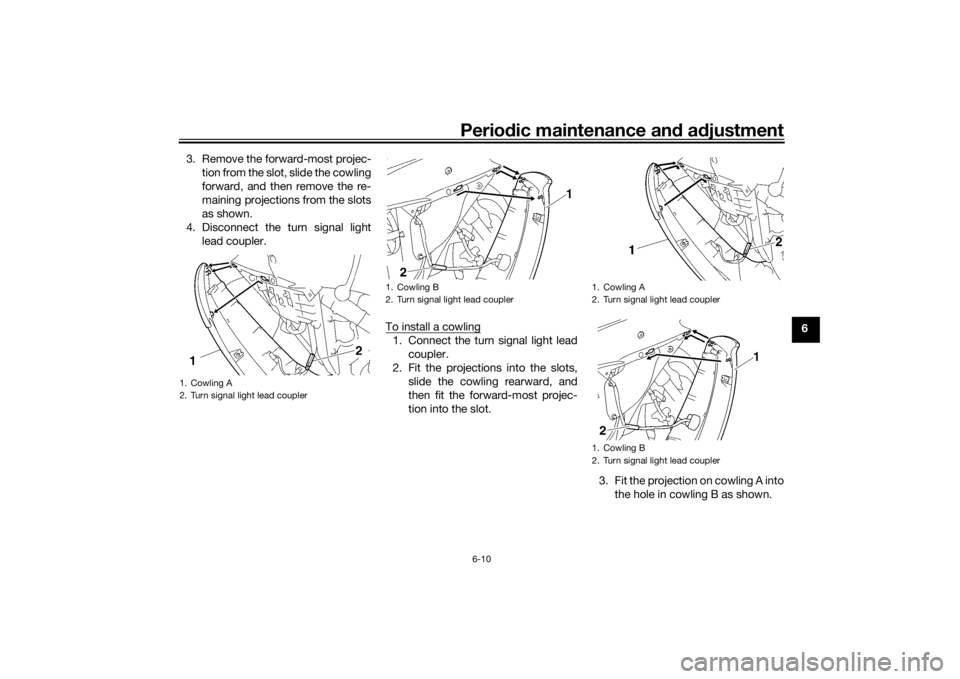

3. Remove the forward-most projec-

tion from the slot, slide the cowling

forward, and then remove the re-

maining projections from the slots

as shown.

4. Disconnect the turn signal light lead coupler.

To install a cowling

1. Connect the turn signal light leadcoupler.

2. Fit the projections into the slots, slide the cowling rearward, and

then fit the forward-most projec-

tion into the slot.

3. Fit the projection on cowling A intothe hole in cowling B as shown.

1. Cowling A

2. Turn signal light lead coupler

1. Cowling B

2. Turn signal light lead coupler

1. Cowling A

2. Turn signal light lead coupler

1. Cowling B

2. Turn signal light lead coupler

U2CXE2E0.book Page 10 Tuesday, June 9, 2015 5:04 PM

Page 62 of 112

Periodic maintenance an d a djustment

6-11

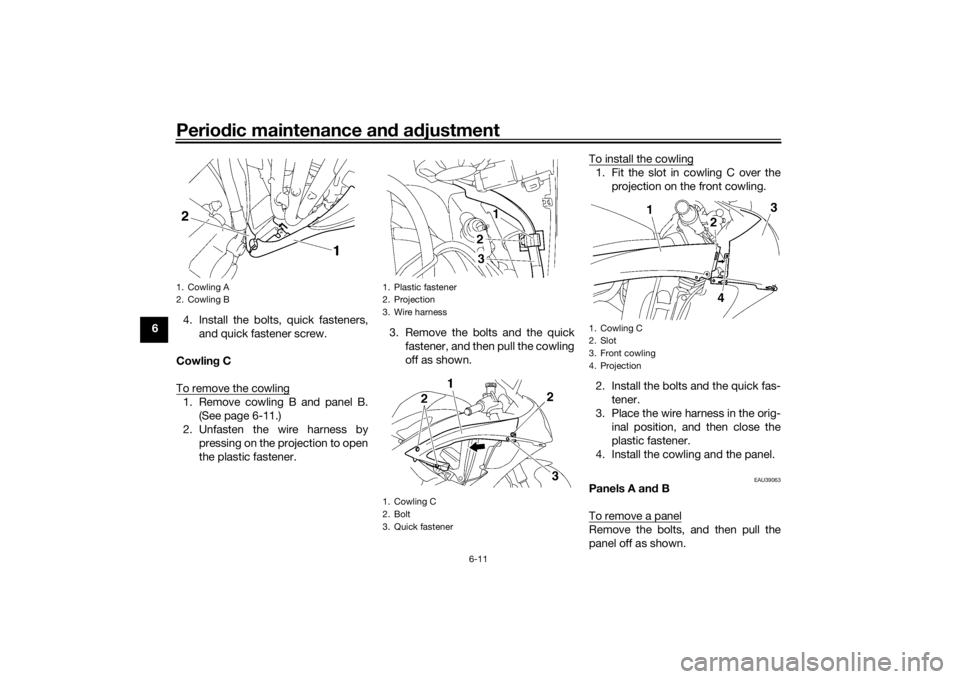

6 4. Install the bolts, quick fasteners,

and quick fastener screw.

Cowlin g C

To remove the cowling

1. Remove cowling B and panel B. (See page 6-11.)

2. Unfasten the wire harness by pressing on the projection to open

the plastic fastener. 3. Remove the bolts and the quick

fastener, and then pull the cowling

off as shown. To install the cowling

1. Fit the slot in cowling C over the

projection on the front cowling.

2. Install the bolts and the quick fas- tener.

3. Place the wire harness in the orig- inal position, and then close the

plastic fastener.

4. Install the cowling and the panel.

EAU39063

Panels A an d B

To remove a panelRemove the bolts, and then pull the

panel off as shown.

1. Cowling A

2. Cowling B

1. Plastic fastener

2. Projection

3. Wire harness

1. Cowling C

2. Bolt

3. Quick fastener

1. Cowling C

2. Slot

3. Front cowling

4. Projection

U2CXE2E0.book Page 11 Tuesday, June 9, 2015 5:04 PM

Page 63 of 112

Periodic maintenance an d a djustment

6-12

6

To install a panel

Place the panel in the original position,

and then install the bolts.

EAU19653

Checkin

g the spark plug sThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos-

its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

1. Panel B

2. Bolt

Specified

spark plu g:

NGK/CR10EK

1. Spark plug gap

Spark plu g g ap:

0.6–0.7 mm (0.024–0.028 in)

Ti ghtenin g torque:

Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1

1

U2CXE2E0.book Page 12 Tuesday, June 9, 2015 5:04 PM

Page 64 of 112

Periodic maintenance an d a djustment

6-13

6

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove b ecause the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

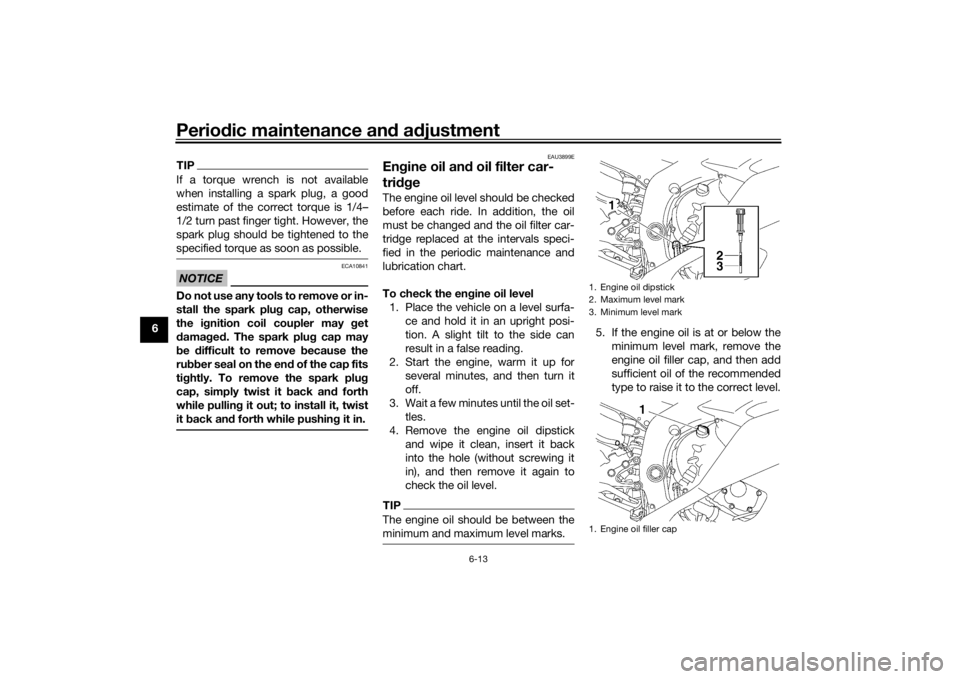

EAU3899E

En gine oil an d oil filter car-

tri dgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the en gine oil level

1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles.

4. Remove the engine oil dipstick and wipe it clean, insert it back

into the hole (without screwing it

in), and then remove it again to

check the oil level.TIPThe engine oil should be between the

minimum and maximum level marks.

5. If the engine oil is at or below theminimum level mark, remove the

engine oil filler cap, and then add

sufficient oil of the recommended

type to raise it to the correct level.1. Engine oil dipstick

2. Maximum level mark

3. Minimum level mark

1. Engine oil filler cap

U2CXE2E0.book Page 13 Tuesday, June 9, 2015 5:04 PM

Page 65 of 112

Periodic maintenance an d a djustment

6-14

6

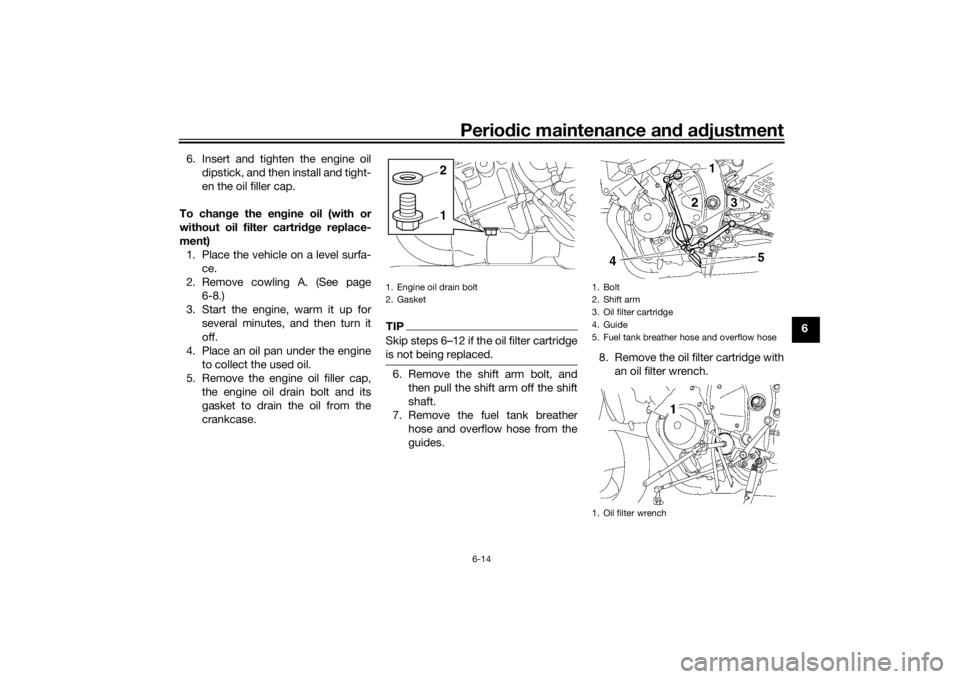

6. Insert and tighten the engine oil

dipstick, and then install and tight-

en the oil filler cap.

To chan ge the en gine oil (with or

without oil filter cartri dge replace-

ment) 1. Place the vehicle on a level surfa- ce.

2. Remove cowling A. (See page 6-8.)

3. Start the engine, warm it up for several minutes, and then turn it

off.

4. Place an oil pan under the engine to collect the used oil.

5. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 6–12 if the oil filter cartridge

is not being replaced.6. Remove the shift arm bolt, andthen pull the shift arm off the shift

shaft.

7. Remove the fuel tank breather hose and overflow hose from the

guides. 8. Remove the oil filter cartridge with

an oil filter wrench.1. Engine oil drain bolt

2. Gasket

12

1. Bolt

2. Shift arm

3. Oil filter cartridge

4. Guide

5. Fuel tank breather hose and overflow hose

1. Oil filter wrench

U2CXE2E0.book Page 14 Tuesday, June 9, 2015 5:04 PM

Page 66 of 112

Periodic maintenance an d a djustment

6-15

6

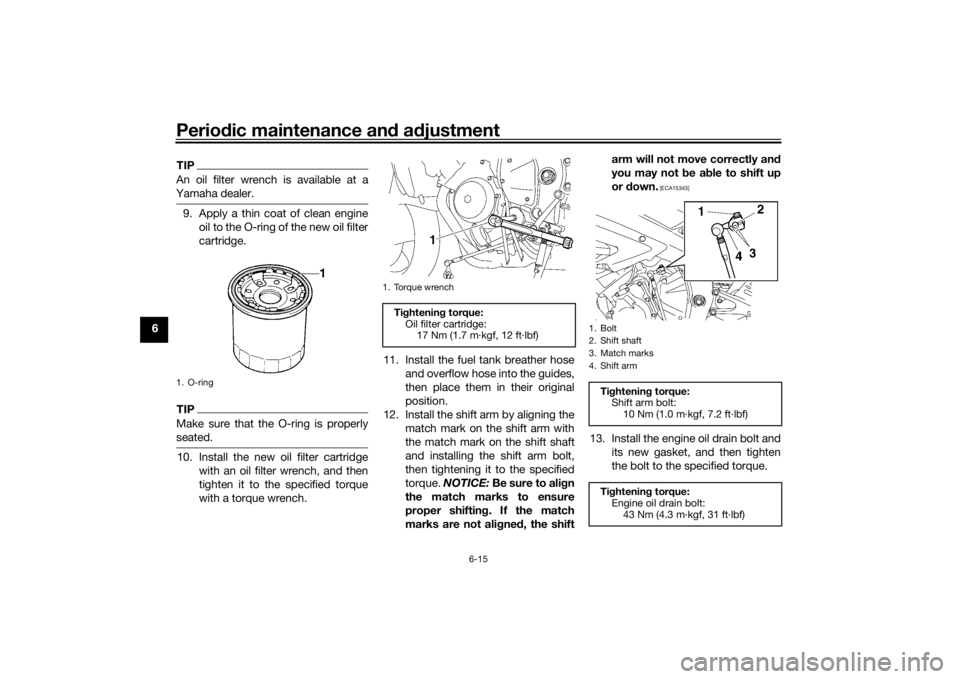

TIPAn oil filter wrench is available at a

Yamaha dealer.9. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.TIPMake sure that the O-ring is properly

seated.10. Install the new oil filter cartridge with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 11. Install the fuel tank breather hose

and overflow hose into the guides,

then place them in their original

position.

12. Install the shift arm by aligning the match mark on the shift arm with

the match mark on the shift shaft

and installing the shift arm bolt,

then tightening it to the specified

torque. NOTICE: Be sure to ali gn

the match marks to ensure

proper shiftin g. If the match

marks are not ali gne d, the shift arm will not move correctly an

d

you may not be a ble to shift up

or down.

[ECA15343]

13. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

1. O-ring

1. Torque wrenchTightenin g torque:

Oil filter cartridge: 17 Nm (1.7 m·kgf, 12 ft·lbf)

1. Bolt

2. Shift shaft

3. Match marks

4. Shift armTightenin g torque:

Shift arm bolt: 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Ti ghtenin g torque:

Engine oil drain bolt:

43 Nm (4.3 m·kgf, 31 ft·lbf)

U2CXE2E0.book Page 15 Tuesday, June 9, 2015 5:04 PM

Page 67 of 112

Periodic maintenance an d a djustment

6-16

6

14. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils lab eled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

15. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.NOTICE

ECA10402

If the oil level warnin g li ght flickers

or remains on even if the oil level is

correct, imme diately turn the en gine

off an d have a Yamaha dealer check

the vehicle.16. Turn the engine off, and then check the oil level and correct it if

necessary.

17. Install the cowling.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU3908A

To check the coolant level 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the mi-

nimum and maximum level marks.

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:

2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter removal: 2.60 L (2.75 US qt, 2.29 Imp.qt)

U2CXE2E0.book Page 16 Tuesday, June 9, 2015 5:04 PM

Page 68 of 112

Periodic maintenance an d a djustment

6-17

6

3. If the coolant is at or below the mi-

nimum level mark, remove panel B

to access the coolant reservoir.

(See page 6-8.)

4. Remove the coolant reservoir cap, add coolant to the maximum level

mark, and then install the reservoir

cap. WARNING! Remove only

the coolant reservoir cap. Never

attempt to remove the ra diator

cap when the en gine is hot.

[EWA15162]

NOTICE: If coolant is not

availa ble, use distille d water or

soft tap water instead . Do not

use har d water or salt water

since it is harmful to the en gine. If water has

been used instead

of coolant, replace it with cool-

ant as soon as possi ble, other-

wise the coolin g system will not

b e protecte d a gainst frost an d

corrosion. If water has been

a dde d to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possi ble, otherwise the

effectiveness of the coolant will

b e re duce d.

[ECA10473]

5. Install the panel.

EAU39006

To chan ge the coolant

1. Place the vehicle on a level surfa- ce and let the engine cool if neces-

sary.

2. Remove cowlings B and C. (See page 6-8.)

3. Place a container under the en- gine to collect the used coolant.

4. Remove the radiator cap. WARNING! Never attempt to re-

move the ra diator cap when the

en gine is hot.

[EWA10382]

5. Remove the coolant drain bolt and

its gasket to drain the cooling sys-

tem.

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1. Coolant reservoir capCoolant reservoir capacity (up to

the maximum level mark):0.25 L (0.26 US qt, 0.22 Imp.qt)

1. Radiator cap

U2CXE2E0.book Page 17 Tuesday, June 9, 2015 5:04 PM

Page 69 of 112

Periodic maintenance an d a djustment

6-18

6

6. Move the hose clamp in the direc-

tion shown, and then disconnect

the radiator hose to drain the radi-

ator.

7. Remove the coolant reservoir by removing the bolts.

8. Remove the coolant reservoir cap, and then turn the coolant reservoir

upside down to empty it. 9. After the coolant is completely

drained, thoroughly flush the cool-

ing system with clean tap water.

10. Install the coolant reservoir by in- stalling the bolts.

11. Connect the radiator hose, and then move the hose clamp back to

its original position.

12. Install the coolant drain bolt and its new gasket, and then tighten

the bolt to the specified torque. 13. Pour the recommended coolant

into the reservoir to the maximum

level mark, and then install the

coolant reservoir cap.

14. Pour the recommended coolant into the radiator until it is full.

15. Install the radiator cap, start the engine, let it idle for several minu-

tes, and then turn it off.

16. Remove the radiator cap to check the coolant level in the radiator. If

necessary, add sufficient coolant

until it reaches the top of the radi-

ator, and then install the radiator

cap.

1. Coolant drain bolt

2. Gasket

3. Radiator hose

4. Hose clamp

1

2

4

3

1. Coolant reservoir cap

2. Coolant reservoir

3. Bolt

Tightenin g torque:

Coolant drain bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

2

1

3

Antifreeze/water mixture ratio: 1:1

Recommen ded antifreeze:

High-quality ethylene glycol anti-

freeze containing corrosion inhibi-

tors for aluminum engines

Coolant quantity:

Radiator (including all routes): 2.30 L (2.43 US qt, 2.02 Imp.qt)

Coolant reservoir (up to the maxi-

mum level mark): 0.25 L (0.26 US qt, 0.22 Imp.qt)

U2CXE2E0.book Page 18 Tuesday, June 9, 2015 5:04 PM

Page 70 of 112

Periodic maintenance an d a djustment

6-19

6 17. Start the engine, and then check

the vehicle for coolant leakage. If

coolant is leaking, have a Yamaha

dealer check the cooling system.

18. Install the cowlings.

EAU36765

Air filter elementThe air filter element must be replaced

at the intervals specified in the periodic

maintenance and lubrication chart.

Have a Yamaha dealer replace the air

filter element.

EAU44735

Checkin g the en gine i dlin g

spee dCheck the engine idling speed and, if

necessary, have it corrected by a

Yamaha dealer.En gine i dlin g spee d:

1250–1350 r/min

U2CXE2E0.book Page 19 Tuesday, June 9, 2015 5:04 PM