coolant temperature YAMAHA YZF-R7 1999 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 1999, Model line: YZF-R7, Model: YAMAHA YZF-R7 1999Pages: 381, PDF Size: 18.88 MB

Page 17 of 381

1 - 5

INSTRUMENT AND CONTROL FUNCTIONS

4 681012

14

x1000r/min

0

1 12

3 3

4

1. Warning light

2. Oil level symbol “ ”

3. Coolant temperature symbol “ ”

4. Engine trouble symbol “ ”

EAU01564

Warning light

This indicator light has three functions.

l

The light will come on and symbol

“ ” will flash if the engine oil

level is low.

If this symbol flashes, stop the en-

gine immediately and fill it with oil

to the specified level.

l

The light will come on and symbol

“ ” will flash if trouble occurs in

a monitoring circuit. In such a

case, take the motorcycle to a

Yamaha dealer to have the self-

diagnostic systems checked.

l

The light will come on and symbol

“ ” will flash if the coolant tem-

perature is too high. The following

chart shows the conditions of the

indicator light, symbol and tem-

perature display in accordance to

coolant temperature.

The light circuit can be checked by the

procedure on page 1-6.

EC000118

CAUTION:

l

Do not run the motorcycle until

you know it has sufficient en-

gine oil.

l

Do not run the motorcycle if the

engine is overheated.

NOTE:

Even if the oil is filled to the specified

level, the indicator light may flicker

when riding on a slope or during sud-

den acceleration or deceleration, but

this is normal.

CB-74ECB-74E

Coolant

temperatureDisplay Conditions What to do

~ 39 ˚CSymbol is on and “LO” is

displayed.OK. Go ahead with riding.

40 ËšC ~ 120 ËšCSymbol is on and temper-

ature is displayed.OK. Go ahead with riding.

121 ËšC ~ 139 ËšCSymbol and temperature

flash.

Warning light comes on.Stop the motorcycle and al-

low it to idle until coolant tem-

perature goes down.

If the temperature does not

go down, stop the engine.

140 ËšC ~ Symbol and message

“HI” flash.

Warning light comes on.Stop the engine and allow it

to cool. Seen page 1-19 if the

engine overheats.

—Symbol and message

“Err” flash.

Warning light comes on.Ask a Yamaha dealer to in-

spect the motorcycle.

C

C

C

C

C

Page 57 of 381

2 - 19

SPEC

Shift shaft cover Bolt M6 6 12 1.2 8.7

Oil baffle plate Bolt M6 5 10 1.0 7.2

LT

Timing mark accessing screw – M8 1 15 1.5 11

Starter clutch Bolt M6 3 12 1.2 8.7

LT

Clutch boss Nut M20 1 70 7.0 50Use a lock

washer.

Clutch spring Bolt M6 6 8 0.8 5.8

Drive sprocket Nut M18 1 70 7.0 50Use a lock

washer.

Main axle bearing housing Screw M6 3 12 1.2 8.7

LT

Shift drum retainer Bolt M6 2 10 1.0 7.2LT

Shift shaft spring stopper Bolt M8 1 22 2.2 16LT

Shift rod locknut Nut M6 2 7 0.7 5.1

Shift arm Bolt M6 1 10 1.0 7.2

Stator coil Bolt M6 3 10 1.0 7.2

LT

Neutral switch – M10 1 20 2.0 14

Pickup coil Screw M5 2 4 0.4 2.9

LT

Thermo switch – M16 1 23 2.3 17

Camshaft sensor Bolt M6 1 10 1.0 7.2

LT

Speed sensor Bolt M6 1 10 1.0 7.2LT

Coolant temperature sensor – M12 1 18 1.8 13

Intake air temperature sensor – M12 1 18 1.8 13

Intake air pressure sensor Screw M5 2 5 0.5 3.6

LT

Atmospheric pressure sensor Screw M5 2 5 0.5 3.6LT

Air funnel Bolt M6 8 10 1.0 7.2LT

Throttle body assembly Bolt M6 16 10 1.0 7.2

Injector 2 cover Bolt M5 8 8 0.8 5.8

LT

Fuel distributor Bolt M6 6 10 1.0 7.2LT

Injector fuel pipe 1,3 and 4 Union bolt M12 3 30 3.0 22

Injector fuel pipe 2 – M12 1 30 3.0 22

Fuel hose joint pipe Bolt M5 1 6 0.6 4.3

LT

Pressure sensor bracket Bolt M5 2 8 0.8 5.8LT

Item Fastener Thread size Q’tyTightening torque

Remarks

Nm m·kgf ft·lb

TIGHTENING TORQUES

Page 69 of 381

2 - 31

SPEC

KPickup coil lead

LStator coil lead

MSpeed sensor lead

NSidestand switch lead

OOil level switch lead

PCoolant reservoir breather hose

QWire harness

RWire harness lead (to fall detection

switch coupler)

SWire harness lead (to fuse box)

TStarter motor leadUNeutral switch lead

VGround lead

WCoolant temperature sensor coupler

XThrottle cable

Route the wire harness in front of the ignition coils.

õBe sure that there is no slack in the tail/brake light lead

and rear turn signal leads below the rear fender panel.

‚Align the portions of the wire harness, ground lead and

starter motor lead marked with white tape with the lead

holder.

CABLE ROUTING

Page 223 of 381

5 - 4

COOL

RADIATOR AND THERMOSTAT

Order Job/Part Q’ty Remarks

3 Thermostat assembly breather hose 1

4 Coolant temperature sensor 1

5 Copper washer 1

6 Plastic band 1

7 Thermostat assembly inlet pipe 1

For installation, reverse the removal

procedure.

Page 337 of 381

8 - 1

–+ELEC

ELECTRICAL COMPONENTS

EB800000

ELECTRICAL

ELECTRICAL COMPONENTS

1

Wire harness

2

Main switch

3

Front brake light switch

4

Ignition coils

5

Clutch switch

6

Throttle position sensor

7

Intake air temperature sensor

8

Intake air pressure sensor

9

Atmospheric pressure sensor

0

Turn signal relay

A

Relay unit

B

ECU

C

CDI unit

D

Fuse box

E

Fall detection switch

F

Starter relay

G

Main fuse

H

Main relay

I

Battery

J

Rectifier/regulator

K

Rear brake light switch

L

Neutral switch

M

Speed sensor

N

Sidestand switch

O

Stator coil assembly

P

Oil level switch

Q

Pickup coil

R

Radiator fan

S

Horn

T

Coolant temperature

sender

U

Thermo switch

V

Camshaft sensor

8

Page 361 of 381

8 - 25

–+ELECCOOLING SYSTEM

TROUBLESHOOTING

C0NTINUITYOK

C0NTINUITYOK

C0NTINUITYOK

C0NTINUITYOK

C0NTINUITYOK

NOTE:

• Before troubleshooting, remove the following part(-s):

1) bottom cowling

2) front cowling

3) rear cowling

• Troubleshoot with the following special tool(-s).

• The radiator fan motor fails to turn.

• The coolant temperature meter needle fails to move when the engine is warm.

Check the main and radiator fan

motor fuses for continuity.Replace.

Check the condition of the bat-

tery.Recharge or replace.

Check the main switch. Replace.

Check the radiator fan motor. Replace.

Check the thermo switch. Replace.

Check the entire cooling system’s

wiring.Repair or replace.

Pocket tester

90890-03112

No good

No good

No good

No good

No good

No good

Page 362 of 381

8 - 26

–+ELECCOOLING SYSTEM

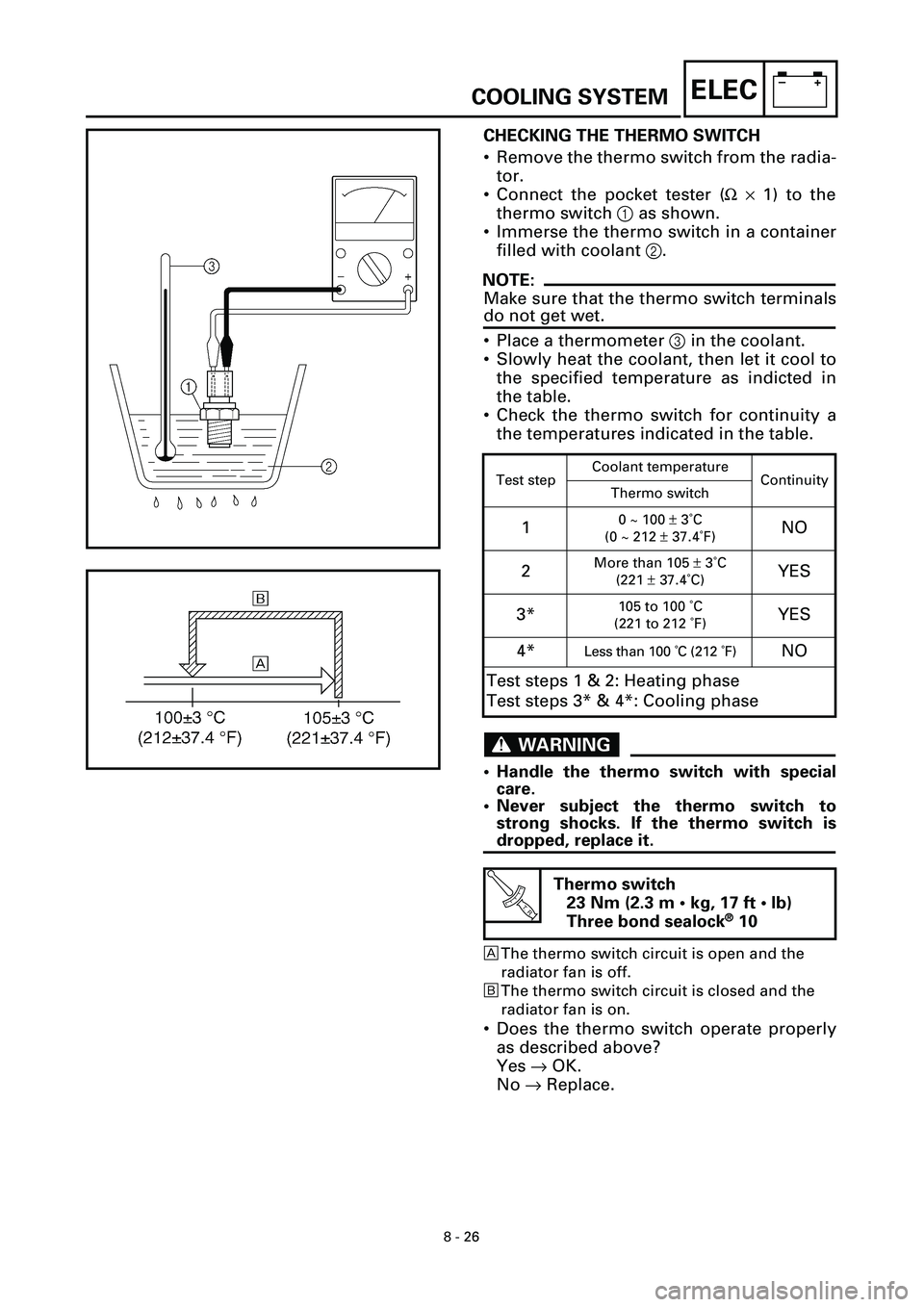

CHECKING THE THERMO SWITCH

• Remove the thermo switch from the radia-

tor.

• Connect the pocket tester (W ´ 1) to the

thermo switch 1 as shown.

• Immerse the thermo switch in a container

filled with coolant 2.

NOTE:

Make sure that the thermo switch terminals

do not get wet.

• Place a thermometer 3 in the coolant.

• Slowly heat the coolant, then let it cool to

the specified temperature as indicted in

the table.

• Check the thermo switch for continuity a

the temperatures indicated in the table.

WARNINGWARNING

• Handle the thermo switch with special

care.

• Never subject the thermo switch to

strong shocks. If the thermo switch is

dropped, replace it.

The thermo switch circuit is open and the

radiator fan is off.

õThe thermo switch circuit is closed and the

radiator fan is on.

• Does the thermo switch operate properly

as described above?

Yes ® OK.

No ® Replace.

Test stepCoolant temperature

Continuity

Thermo switch

10 ~ 100 ± 3˚C

(0 ~ 212 ± 37.4˚F)NO

2

More than 105 ± 3˚C

(221 ± 37.4˚C)YES

3*

105 to 100 ËšC

(221 to 212 ËšF)YES

4*

Less than 100 ËšC (212 ËšF)NO

Test steps 1 & 2: Heating phase

Test steps 3* & 4*: Cooling phase

T R..

Thermo switch

23 Nm (2.3 m • kg, 17 ft • lb)

Three bond sealock

® 10

Page 365 of 381

8 - 29

–+ELECELECTRONIC FUEL INJECTION SYSTEM

1Main switch

5Battery

6Main fuse

CCamshaft sensor

DThrottle position sensor

EIntake air pressure sensor

FAtmospheric pressure sensor

GIntake air temperature sensor

HCoolant temperature sensor

IPickup coil

JECU

KCylinder #1-injector 1

LCylinder #2-injector 1

MCylinder #3-injector 1

NCylinder #4-injector 1

OCylinder #1-injector 2

PCylinder #2-injector 2

QCylinder #3-injector 2

RCylinder #4-injector 2

XFall detection switch

YSpeed sensor

yFuel pump

zMain relay

}Engine stop switch

Ĺ’Electronic fuel injection system fuse

ÂŁECU fuse

TROUBLESHOOTING

NOTE:

• Before troubleshooting, remove the following part(-s):

1) bottom cowling

2) front cowling

• Troubleshoot with the following special tool(-s).

The condition code is displayed by the tachometer.

Check the condition code list to

identify the faulty part. Refer to

“ELECTRICAL CONTROL SYS-

TEM”.

In diagnosis mode, select the

appropriate diagnosis code to

check the operation of the faulty

part.Check the

wiring.Replace.

Co, diagnosis switch box

90890-03171

Test coupler adapter

90890-03149

Out of specifi-

cationNo good

Page 368 of 381

8 - 32

–+ELECELECTRICAL CONTROL SYSTEM

Condition code list

NOTE:

* This condition code is also displayed in the following cases:

- when the starter switch is held down for more than 4 seconds, causing the warning

light to flash

- when the ignition circuit cut-off system stops the engine or prevents it from starting

** This condition code is also displayed when the engine is operated at 5,000 r/min for at

least 30 seconds with the rear wheel at standstill.

*** This condition code is also displayed when the engine stop switch is turned to “ ”

while riding with the transmission in gear. Condition

codeCircuit Defect(s) System response

11 Camshaft sensor • No incoming sig-

nalThe ECU pairs the ignition of cyl-

inders #1 and #4 and cylinders #2

and #3. The motorcycle can be

ridden.

12* Pickup coil • No incoming sig-

nalThe motorcycle cannot be ridden.

13 Intake air pressure

sensor• Disconnected

• Short-circuitThe ECU stays set to an intake air

pressure of 760 mm Hg (29.9 in Hg).

The motorcycle can be ridden.

14 Intake air pressure

sensor hose and

negative pressure

hose• Improper connec-

tion

• Bending

15 Throttle position

sensor• Disconnected

• Short-circuitThe ECU stays set to a wide throt-

tle opening.

The motorcycle can be ridden.

16 Throttle position

sensor• Locked

21 Coolant tempera-

ture sensor• Disconnected

• Short-circuitThe ECU stays set to a coolant

temperature of 80ËšC (176ËšF).

The motorcycle can be ridden.

22 Intake air tempera-

ture sensor• Disconnected

• Short-circuitThe ECU stays set to an intake air

temperature of 40ËšC (104ËšF).

The motorcycle can be ridden.

23 Atmospheric pres-

sure sensor• Disconnected

• Short-circuitThe ECU stays set to an atmo-

spheric pressure of 760 mm Hg

(29.9 in Hg).

The motorcycle can be ridden.

41 Fall detection

switch• Disconnected The main relay stays switched off.

The motorcycle cannot be ridden.

42** Speed sensor • Incorrect signal The ECU stays set to 6th gear.

The motorcycle can be ridden.

43*** Monitored voltage • Incorrect The ECU stays set to a monitored

voltage of 12 V.

The motorcycle can be ridden.

44 ROM operation • CO emission

adjustment errorThe CO emission adjustment is

set to 0.

Page 372 of 381

8 - 36

–+ELECELECTRICAL CONTROL SYSTEM

Diagnosis code list

Diagnosis

codeInspected item System responseTachometer display

(0 ~ 10,000 r/min)

00 — — —

01 Voltage The tachometer displays the volt-

age ´ 500.

Example:

If the voltage is 12.5 V, the tachome-

ter displays 12.5 ´ 500 = 6,250 r/min.0 r/min (0 V) –

10,000 r/min (20 V)

02 Atmospheric

pressureThe tachometer displays the atmo-

spheric pressure sensor signal.

Example:

If the atmospheric pressure is 760

mm Hg (29.9 in Hg), the tachometer

displays 8,000 r/min.

03 Intake air pres-

sureThe tachometer displays the differ-

ence between the minimum intake

air pressure sensor signal and the

atmospheric pressure sensor signal

after the main switch is turned to

“ON” in the diagnosis mode.0 r/min (0 mm Hg)

– 1,000 r/min

(100 mm Hg)

04 Throttle position

sensorThe tachometer displays the throttle

position sensor signal.1,300 r/min (0.68 V) –

5,900 r/min (2.93 V)

05 Throttle position

sensorThe tachometer displays the mini-

mum throttle position sensor signal.5,500 r/min (0.68 V) –

10,000 r/min (1.25 V)

06 Intake air temper-

atureThe tachometer displays the intake

air temperature signal.4,800 r/min (20˚C) –

5,700 r/min (30ËšC)

07 Coolant tempera-

tureThe tachometer displays the coolant

temperature sensor signal.4,900 r/min (20˚C) –

9,200 r/min (100ËšC)

08 Speed sensor The tachometer displays the speed

sensor signal when the rear wheel is

rotated by hand.0 –

09 Fall detection

switchThe tachometer displays whether

the fall detection switch is on or

whether it is off or disconnected.0 r/min (on), 8,000 r/

min (off) or 10,000 r/

min (disconnected)

10 Sidestand switch The tachometer displays whether

the sidestand switch is on or off.

The tachometer displays 0 r/min

when the sidestand is down (switch

on) and 10,000 r/min when the side-

stand is up (switch off).0 r/min (on) or

10,000 r/min (off)

11 — — —