YAMAHA YZF600 2001 Manual PDF

Manufacturer: YAMAHA, Model Year: 2001, Model line: YZF600, Model: YAMAHA YZF600 2001Pages: 114, PDF Size: 12.39 MB

Page 71 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

l

Securely pack the heaviest

items close to the center of the

motorcycle and distribute the

weight evenly on both sides.

l

Adjust the suspension and tire

air pressure with regard to the

load.

l

Check the tire condition and air

pressure before each ride.

_

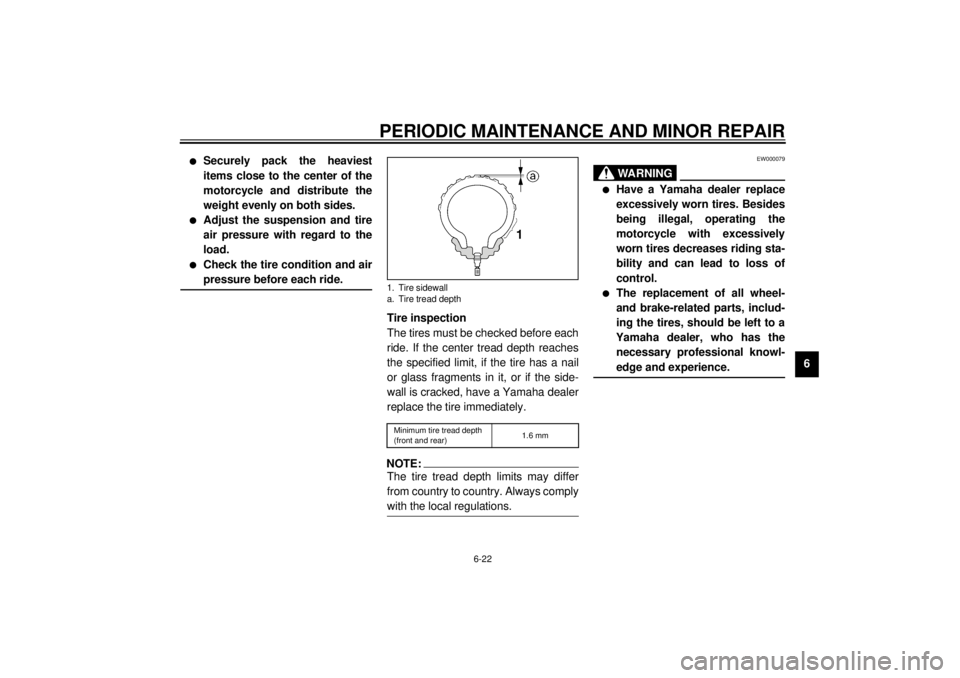

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.CE-08ENOTE:_ The tire tread depth limits may differ

from country to country. Always comply

with the local regulations. _

EW000079

WARNING

_ l

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the

motorcycle with excessively

worn tires decreases riding sta-

bility and can lead to loss of

control.

l

The replacement of all wheel-

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the

necessary professional knowl-

edge and experience.

_

1. Tire sidewall

a. Tire tread depthMinimum tire tread depth

(front and rear)1.6 mm

E_4tv.book Page 22 Wednesday, October 4, 2000 2:15 PM

Page 72 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

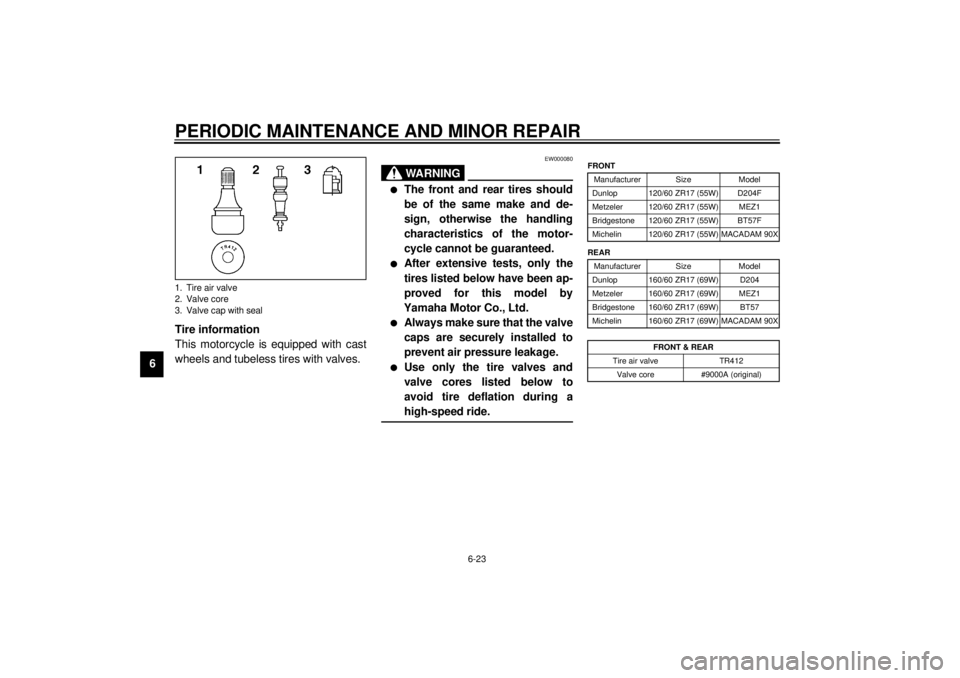

6Tire information

This motorcycle is equipped with cast

wheels and tubeless tires with valves.

EW000080

WARNING

_ l

The front and rear tires should

be of the same make and de-

sign, otherwise the handling

characteristics of the motor-

cycle cannot be guaranteed.

l

After extensive tests, only the

tires listed below have been ap-

proved for this model by

Yamaha Motor Co., Ltd.

l

Always make sure that the valve

caps are securely installed to

prevent air pressure leakage.

l

Use only the tire valves and

valve cores listed below to

avoid tire deflation during a

high-speed ride.

_

CE-10E

CE-14E

1. Tire air valve

2. Valve core

3. Valve cap with seal

FRONT

Manufacturer Size Model

Dunlop 120/60 ZR17 (55W) D204F

Metzeler 120/60 ZR17 (55W) MEZ1

Bridgestone 120/60 ZR17 (55W) BT57F

Michelin 120/60 ZR17 (55W) MACADAM 90X

REAR

Manufacturer Size Model

Dunlop 160/60 ZR17 (69W) D204

Metzeler 160/60 ZR17 (69W) MEZ1

Bridgestone 160/60 ZR17 (69W) BT57

Michelin 160/60 ZR17 (69W) MACADAM 90X

FRONT & REAR

Tire air valve TR412

Valve core #9000A (original)

E_4tv.book Page 23 Wednesday, October 4, 2000 2:15 PM

Page 73 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-24

6

EAU00684

WARNING

_ This motorcycle is fitted with su-

per-high-speed tires. Note the fol-

lowing points in order to make the

most efficient use of these tires.l

Use only the specified replace-

ment tires. Other tires may run

the danger of bursting at super

high speeds.

l

Brand-new tires can have a rela-

tively poor grip on certain road

surfaces until they have been

“broken in”. Therefore, it is ad-

visable before doing any

high-speed riding to ride con-

servatively for approximately

100 km after installing a new

tire.

l

The tires must be warmed up

before a high-speed run.

l

Always adjust the tire air pres-

sure according to the operating

conditions.

_

EAU03773

Cast wheels To maximize the performance, durabil-

ity, and safe operation of your motor-

cycle, note the following points

regarding the specified wheels.l

The wheel rims should be checked

for cracks, bends or warpage be-

fore each ride. If any damage is

found, have a Yamaha dealer re-

place the wheel. Do not attempt

even the smallest repair to the

wheel. A deformed or cracked

wheel must be replaced.

l

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

l

Ride at moderate speeds after

changing a tire since the tire sur-

face must first be “broken in” for it

to develop its optimal characteris-

tics.

E_4tv.book Page 24 Wednesday, October 4, 2000 2:15 PM

Page 74 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-25

6

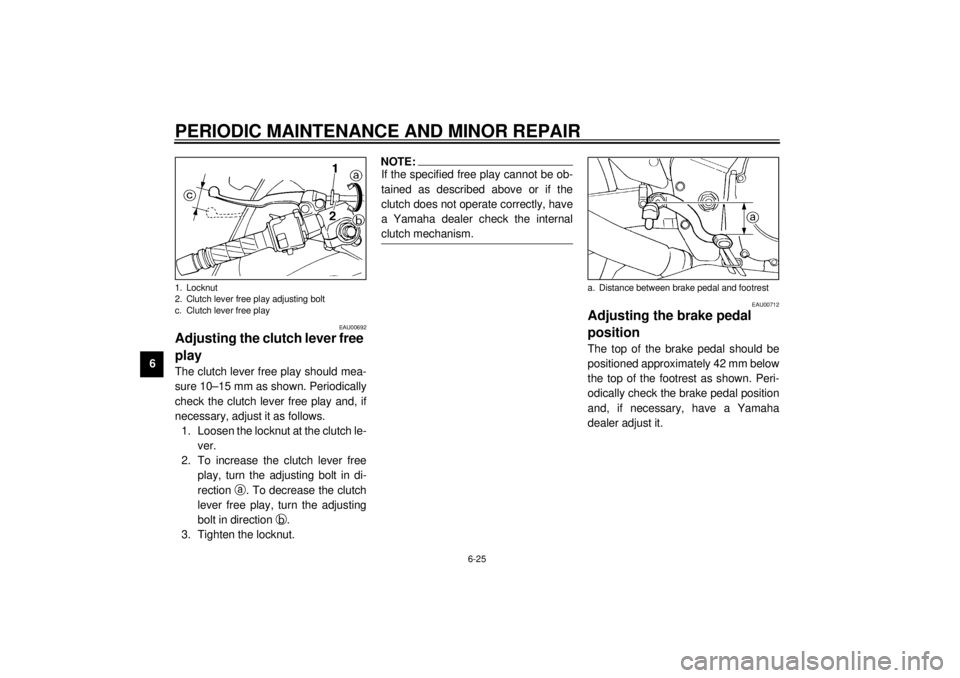

EAU00692

Adjusting the clutch lever free

play The clutch lever free play should mea-

sure 10–15 mm as shown. Periodically

check the clutch lever free play and, if

necessary, adjust it as follows.

1. Loosen the locknut at the clutch le-

ver.

2. To increase the clutch lever free

play, turn the adjusting bolt in di-

rection

a. To decrease the clutch

lever free play, turn the adjusting

bolt in direction

b.

3. Tighten the locknut.

NOTE:_ If the specified free play cannot be ob-

tained as described above or if the

clutch does not operate correctly, have

a Yamaha dealer check the internal

clutch mechanism. _

EAU00712

Adjusting the brake pedal

position The top of the brake pedal should be

positioned approximately 42 mm below

the top of the footrest as shown. Peri-

odically check the brake pedal position

and, if necessary, have a Yamaha

dealer adjust it.

1. Locknut

2. Clutch lever free play adjusting bolt

c. Clutch lever free play

a. Distance between brake pedal and footrest

E_4tv.book Page 25 Wednesday, October 4, 2000 2:15 PM

Page 75 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-26

6

EW000109

WARNING

_ A soft or spongy feeling in the brake

pedal can indicate the presence of

air in the hydraulic system. If there

is air in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the motorcycle. Air in

the hydraulic system will diminish

the braking performance, which

may result in loss of control and an

accident. _

EAU00713

Adjusting the rear brake light

switch The rear brake light switch, which is ac-

tivated by the brake pedal, is properly

adjusted when the brake light comes

on just before braking takes effect. If

necessary, adjust the brake light switch

as follows.

Turn the adjusting nut while holding the

rear brake light switch in place. To

make the brake light come on earlier,

turn the adjusting nut in direction

a. To

make the brake light come on later,

turn the adjusting nut in direction

b. 1. Rear brake light switch

2. Rear brake light switch adjusting nut

E_4tv.book Page 26 Wednesday, October 4, 2000 2:15 PM

Page 76 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

6

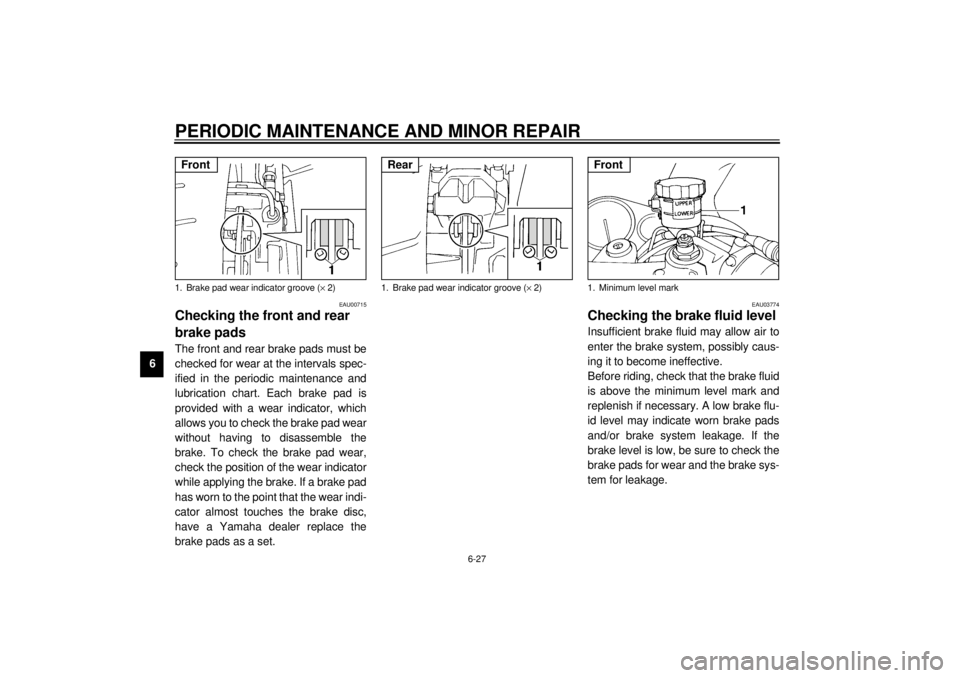

EAU00715

Checking the front and rear

brake pads The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart. Each brake pad is

provided with a wear indicator, which

allows you to check the brake pad wear

without having to disassemble the

brake. To check the brake pad wear,

check the position of the wear indicator

while applying the brake. If a brake pad

has worn to the point that the wear indi-

cator almost touches the brake disc,

have a Yamaha dealer replace the

brake pads as a set.

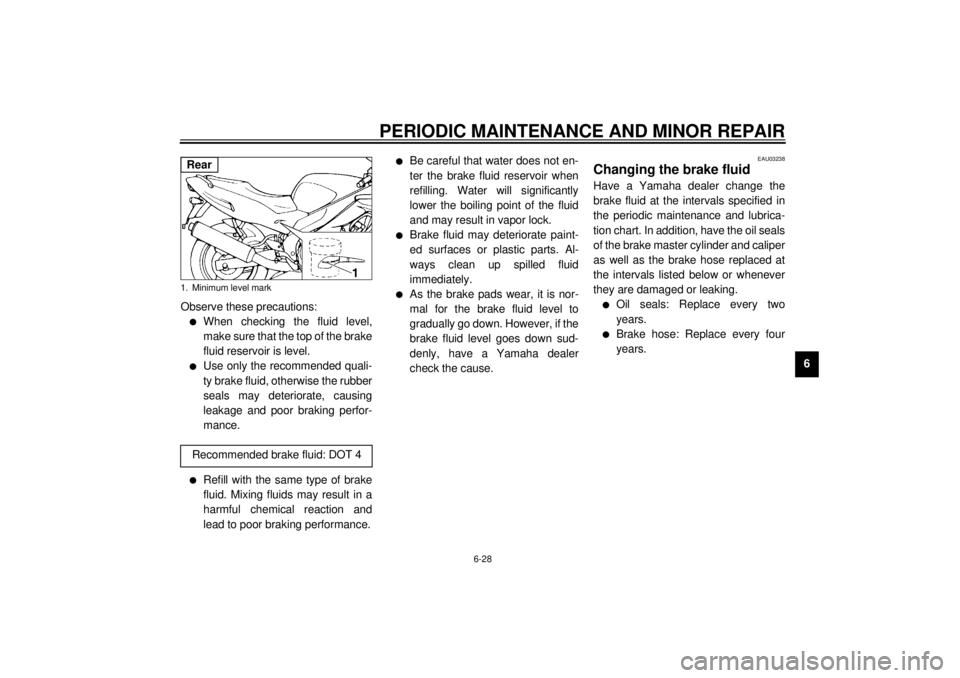

EAU03774

Checking the brake fluid level Insufficient brake fluid may allow air to

enter the brake system, possibly caus-

ing it to become ineffective.

Before riding, check that the brake fluid

is above the minimum level mark and

replenish if necessary. A low brake flu-

id level may indicate worn brake pads

and/or brake system leakage. If the

brake level is low, be sure to check the

brake pads for wear and the brake sys-

tem for leakage.

1. Brake pad wear indicator groove (´ 2)Front

1. Brake pad wear indicator groove (´ 2)Rear

1. Minimum level markFront

E_4tv.book Page 27 Wednesday, October 4, 2000 2:15 PM

Page 77 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

6 Observe these precautions:

l

When checking the fluid level,

make sure that the top of the brake

fluid reservoir is level.

l

Use only the recommended quali-

ty brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

l

Be careful that water does not en-

ter the brake fluid reservoir when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer

check the cause.

EAU03238

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake master cylinder and caliper

as well as the brake hose replaced at

the intervals listed below or whenever

they are damaged or leaking.l

Oil seals: Replace every two

years.

l

Brake hose: Replace every four

years.

1. Minimum level mark

Recommended brake fluid: DOT 4Rear

E_4tv.book Page 28 Wednesday, October 4, 2000 2:15 PM

Page 78 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-29

6

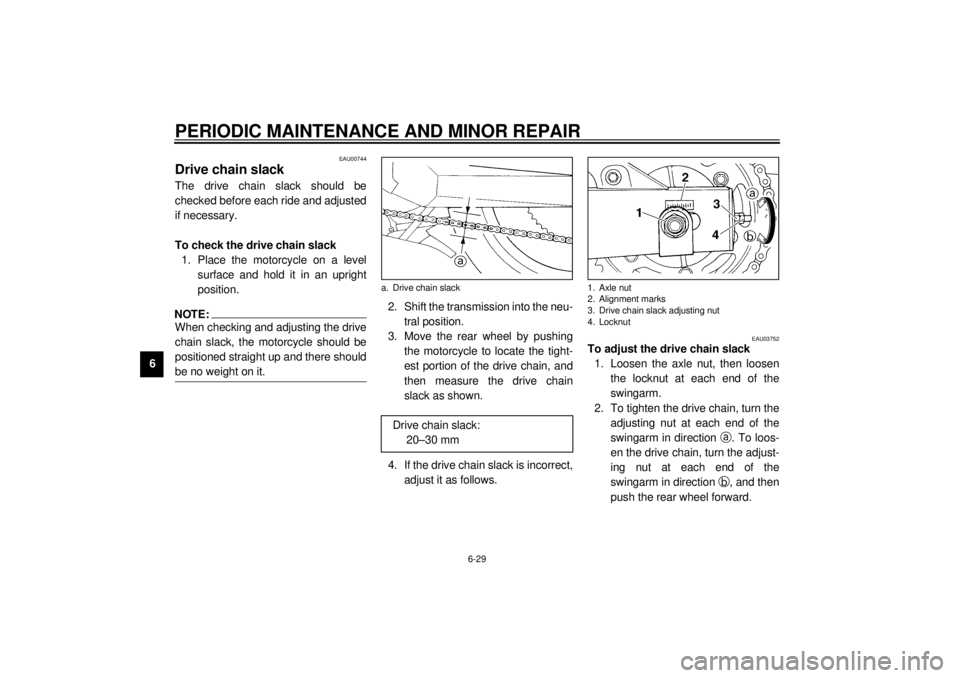

EAU00744

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

To check the drive chain slack

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:_ When checking and adjusting the drive

chain slack, the motorcycle should be

positioned straight up and there should

be no weight on it. _

2. Shift the transmission into the neu-

tral position.

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain, and

then measure the drive chain

slack as shown.

4. If the drive chain slack is incorrect,

adjust it as follows.

EAU03752

To adjust the drive chain slack

1. Loosen the axle nut, then loosen

the locknut at each end of the

swingarm.

2. To tighten the drive chain, turn the

adjusting nut at each end of the

swingarm in direction

a. To loos-

en the drive chain, turn the adjust-

ing nut at each end of the

swingarm in direction

b, and then

push the rear wheel forward.

a. Drive chain slack

Drive chain slack:

20–30 mm

1. Axle nut

2. Alignment marks

3. Drive chain slack adjusting nut

4. Locknut

E_4tv.book Page 29 Wednesday, October 4, 2000 2:15 PM

Page 79 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-30

6

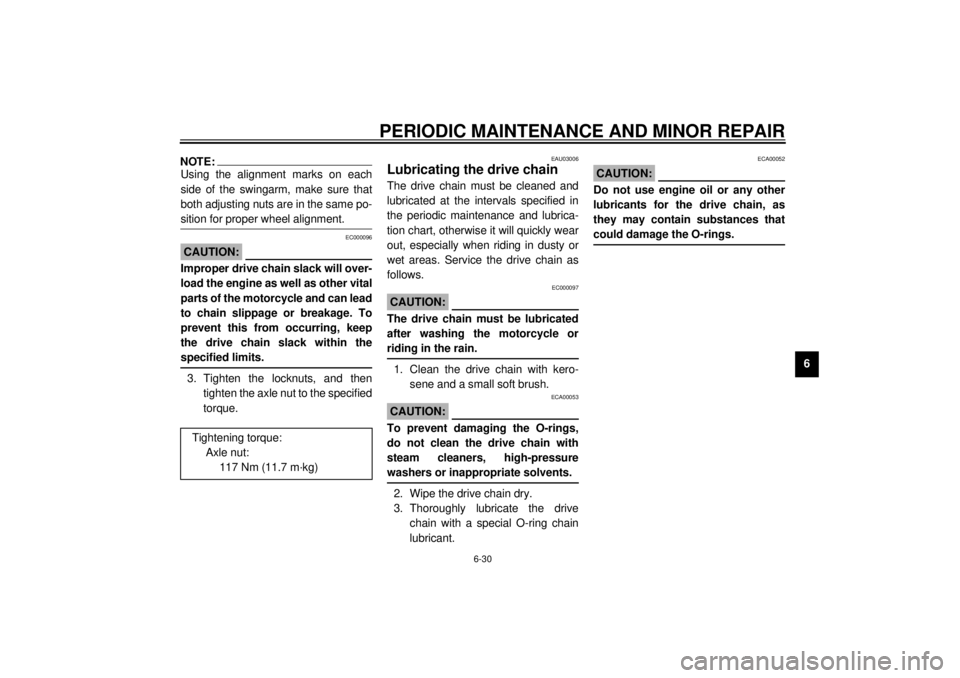

NOTE:_ Using the alignment marks on each

side of the swingarm, make sure that

both adjusting nuts are in the same po-

sition for proper wheel alignment. _

EC000096

CAUTION:_ Improper drive chain slack will over-

load the engine as well as other vital

parts of the motorcycle and can lead

to chain slippage or breakage. To

prevent this from occurring, keep

the drive chain slack within the

specified limits. _3. Tighten the locknuts, and then

tighten the axle nut to the specified

torque.

EAU03006

Lubricating the drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

EC000097

CAUTION:_ The drive chain must be lubricated

after washing the motorcycle or

riding in the rain. _1. Clean the drive chain with kero-

sene and a small soft brush.

ECA00053

CAUTION:_ To prevent damaging the O-rings,

do not clean the drive chain with

steam cleaners, high-pressure

washers or inappropriate solvents. _2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

ECA00052

CAUTION:_ Do not use engine oil or any other

lubricants for the drive chain, as

they may contain substances that

could damage the O-rings. _

Tightening torque:

Axle nut:

117 Nm (11.7 m·kg)

E_4tv.book Page 30 Wednesday, October 4, 2000 2:15 PM

Page 80 of 114

PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

6

EAU02962

Checking and lubricating the

cables The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubricat-

ed if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

EW000112

WARNING

_ Damage to the outer sheath may in-

terfere with proper cable operation

and will cause the inner cable to

rust. Replace a damaged cable as

soon as possible to prevent unsafe

conditions. _

EAU03209

Checking and lubricating the

throttle grip and cable The operation of the throttle grip and

the condition of the throttle cable

should be checked before each ride,

and the cable should be lubricated or

replaced if necessary.NOTE:_ Since the throttle grip must be removed

to access the throttle cable end, the

throttle grip and the cable should al-

ways be lubricated at the same time. _1. Remove the throttle grip by remov-

ing the screws.

2. Disconnect the throttle cable, hold

it up, and then apply several drops

of oil to the cable end, allowing it to

trickle into the sheath.

3. Connect the throttle cable, and

then grease the inside of the throt-

tle grip housing.

4. Grease the metal-to-metal contact

surface of the throttle grip, and

then install the grip by installing

the screws. Recommended lubricant:

Engine oil

Recommended lubricant:

Throttle cable:

Engine oil

Throttle grip housing and grip:

Lithium-soap-based grease

(all-purpose grease)

E_4tv.book Page 31 Wednesday, October 4, 2000 2:15 PM