Abarth 124 Spider 2020 Owner handbook (in English)

Manufacturer: ABARTH, Model Year: 2020, Model line: 124 Spider, Model: Abarth 124 Spider 2020Pages: 224, PDF Size: 3.9 MB

Page 161 of 224

IMPORTANT

3)Dispose of the bottle and the sealant

liquid properly. Have them disposed of in

compliance with national and local

regulations.

JUMP STARTING

PREPARATIONS FOR

JUMP STARTING

181) 182) 183) 184) 185) 186) 187) 188) 189) 190)

34)

Jump-starting is dangerous if done

incorrectly. So follow the procedure

carefully fig. 145. If you feel unsure

about jump-starting, we strongly

recommend that you have a competent

service technician do the work.

IMPORTANT When using booster

battery is used, comply with the

utilisation and precaution instructions

specified by the producer.

IMPORTANT Do not use the booster

battery or any other source of external

supply with a voltage above 12 V: the

battery, the starter, the alternator and

the electrical system of the vehicle

could be damaged. You can damage a

12 V starter, ignition system, and other

electrical parts beyond repair with a

24 V power supply (two 12 V batteries

in series or a 24 V motor generator set).

14508030100-121-001-1AB

159

Page 162 of 224

IMPORTANT Do not attempt jump

starting if the battery is wet. The battery

could break and explode!

JUMP-STARTING

PROCEDURE

IMPORTANT If the procedure below is

carried out incorrectly can cause severe

injuries to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Proceed as follows to carry out a jump

starting:

remove the battery cover fig. 146;

make sure the booster battery is

12 V and that its negative terminal is

grounded;

if the booster battery is in another

vehicle, do not allow both vehicles to

touch. Turn off the engine of the vehicle

with the booster battery and all

unnecessary electrical loads in both

vehicles;

connect the jumper leads in the

exact sequence as in “Preparations for

jump starting” paragraph:

– connect one end of a lead to the

positive terminal on the discharged

battery;

– attach the other end to the positive

terminal on the booster battery;

– connect one end of the other lead

to the negative terminal of the

booster battery;

– connect the other end to the

ground point indicated in the

illustration away from the

discharged battery.

start the engine of the booster

vehicle and run it a few minutes. Then

start the engine of the other vehicle;

when finished, carefully disconnect

the leads in the reverse order as

previously described;

if the battery cover has been

removed, install it in the reverse order of

removal.

IMPORTANT Verify that the covers are

securely installed.

IMPORTANT Perform the phonic wheel

learning procedure described in the

“Battery maintenance” section (see the

“Maintenance and care” chapter).

WARNING

181)Before opening the bonnet, make

sure that the engine is off and that the

ignition switch is in OFF position. During

refuelling, make sure that the engine is off

(and that the ignition switch is in OFF

position).

182)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Pay attention to scarves,

ties and other loose clothing which might

be pulled by moving parts.

183)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

184)Batteries contain acid which may

burn skin and eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Thus keep away flames or

devices which may cause sparks.

14608030100-122-001AB

160

IN CASE OF EMERGENCY

Page 163 of 224

185)Do not allow the positive (+) terminal

to contact any other metal object that

could cause sparks. Flames and sparks

near open battery cells are dangerous.

Hydrogen gas, produced during normal

battery operation, could ignite and cause

the battery to explode. An exploding

battery can cause serious burns and

injuries. When working near a battery, do

not allow metal tools to contact the positive

(+) or negative (–) terminal of the battery.

186)Keep all flames, including cigarettes,

and sparks away from open battery cells.

Flames and sparks near open battery cells

are dangerous. Hydrogen gas, produced

during normal battery operation, could

ignite and cause the battery to explode. An

exploding battery can cause serious burns

and injuries.

187)Do not jump-start a frozen battery or

one with a low fluid level. Jump-starting a

frozen battery or one with a low fluid level is

dangerous. It may rupture or explode,

causing serious injury.

188)Route the jumper leads away from

parts that will be moving. Connecting a

jumper lead near or to moving parts

(cooling fans, belts) is dangerous. The lead

could get caught when the engine starts

and cause serious injury.

189)Never tow a vehicle to start it. Towing

a vehicle to start it is dangerous. The

vehicle being towed could surge forward

when its engine starts, causing the two

vehicles to collide. The occupants could be

injured.190)Connect the negative lead to a good

ground point (see figure) away from the

battery. Connecting the end of the second

jumper lead to the negative (–) terminal of

the discharged battery is dangerous. A

spark could cause the gas around the

battery to explode and injure someone.

IMPORTANT

34)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

TOWING THE

VEHICLE

ATTACHING THE TOW

HOOKS

35) 36) 37)

Proceed as follows:

remove the towing eyelet and the

wheel brace from the luggage

compartment;

wrap a flathead screwdriver or similar

tool with a soft cloth to prevent damage

to a painted bumper, and open the cap

located on the front 1 fig. 147 or rear

bumper 2 fig. 148.

14708060203-121-001AB

161

Page 164 of 224

IMPORTANT Do not use excessive

force as it may damage the cap or

scratch the painted bumper surface.

NOTE Remove the cap completely and

store it so as not to lose it.

securely install the towing eyelet

using the wheel brace or equivalent

front fig. 149 and rear fig. 150;

hook the towing rope to the towing

eyelet.

IMPORTANT If the towing eyelet is not

securely tightened, it may loosen or

disengage from the bumper when

towing the vehicle. Make sure that the

towing eyelet is securely tightened to

the bumper.

IMPORTANT Be careful not to damage

the towing eyelet and towing hook,

vehicle body, or transmission system

when towing under the following

conditions:

do not tow a vehicle heavier than yours;do not suddenly accelerate your vehicle

as it will apply a severe shock to the towing

eyelet and towing hook or rope;

do not attach any rope other than to the

towing eyelet and towing hook.

IMPORTANT The towing eyelet should

be used in an emergency (to get the

vehicle out of a ditch or a snow bank,

for example).IMPORTANT When using the towing

eyelets, always pull the lead or chain in

a straight direction with respect to the

eyelet. Never apply a sideways force.

IMPORTANT When towing with chain

or lead, wrap the chain or lead with a

soft cloth near the bumper to prevent

damage to the bumper.

IMPORTANT

35)Before starting towing operations, put

the ignition switch to OFF position.

36)Before tightening the tow hook, clean

the threaded housing thoroughly. Make

sure that the tow hook is fully fastened in

the housing before towing the vehicle.

37)The front and rear tow hooks should be

used only for emergencies on the road. You

are allowed to tow the vehicle for short

distances using an appropriate device in

accordance with the highway code (a rigid

bar), to move the vehicle on the road in

readiness for towing or transport via a

breakdown vehicle. Tow hooks MUST NOT

be used to tow vehicles off the road or

where there are obstacles and/or for

towing operations using ropes or other

non-rigid devices. Respecting the above

conditions, towing must take place with

two vehicles (one towing, the other towed)

aligned as much as possible along the

same center line.

14808060203-122-001AB

14908060201-121-001AB

15008060201-122-001AB

162

IN CASE OF EMERGENCY

Page 165 of 224

EMERGENCY

TOWING

TOWING DESCRIPTION

Proper lifting and towing are necessary

to prevent damage to the vehicle.

Government and local laws must be

followed.

A towed vehicle usually should have its

drive wheels (rear wheels) off the

ground. If excessive damage or other

conditions prevent this, use wheel

dollies.

When towing with the rear wheels on

the ground, release the parking brake.

IMPORTANT Do not tow the vehicle

pointed backward with driving wheels

on the ground. This may cause internal

damage to the transmission.

IMPORTANT Do not tow with sling-type

equipment. This could damage your

vehicle. Use wheel-lift or flatbed

equipment.

If towing service is not available in an

emergency, the vehicle may be towed

with all four wheels on the ground using

the towing hook at the front of the

vehicle. Only tow the vehicle on paved

surfaces for short distances at low

speeds.Follow these instructions when towing

the vehicle with all wheels on the

ground:

shift to neutral (manual transmission),

or the N position (automatic

transmission);

switch the ignition to ACC;

release the parking brake.

NOTE Remember that power assist for

the brakes and steering will not be

available when the engine is not

running.

163

Page 166 of 224

MAINTENANCE AND CARE

Correct maintenance permits the

performance of the vehicle to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.SCHEDULED SERVICING.......165

ENGINE COMPARTMENT......171

BATTERY RECHARGING.......176

WHEELS AND TIRES..........177

BODYWORK...............178

INTERIORS................180

164

MAINTENANCE AND CARE

Page 167 of 224

SCHEDULED

SERVICING

INTRODUCTION

Be careful not to hurt yourself when

inspecting your vehicle, replacing a tyre,

or doing some kind of maintenance

such as car washing. In particular, wear

thick work gloves such as cotton gloves

when touching areas that are difficult to

see while inspecting or working on your

vehicle. Doing inspections or

procedures with your bare hands could

cause injury.

If you are unsure about any procedure it

describes, we strongly urge you to have

a reliable and qualified service shop

perform the work, preferably at Abarth

Dealership.

Factory-trained FCA technicians and

genuine FCA parts are best for your

vehicle. Without this expertise and the

parts that have been designed and

made especially for your vehicle,

inadequate, incomplete, and insufficient

servicing may result in problems. This

could lead to vehicle damage or an

accident and injuries.

For expert advice and quality service,

contact an Abarth Dealership.

The owner should retain evidence that

proper maintenance has been

performed as prescribed.A claim against a warranty will not

qualify if it results from lack of

maintenance and not from defective

material or authorised workmanship.

Claims against the warranty resulting

from lack of maintenance, as opposed

to defective materials or authorized FCA

workmanship, will not be honored.

The malfunction diagnosis connector is

designed exclusively for connecting the

specially designed device to perform

on-board diagnosis. Do not connect

any devices other than the specially

designed malfunction diagnosis devices

for servicing. If any device other than

the malfunction diagnosis device is

connected, it may affect the vehicle's

electrical devices or lead to damage

such as battery depletion

Scheduled maintenance

NOTE After the prescribed period,

continue to follow the described

maintenance at the recommended

intervals.

Emission control and related

systems

The ignition and fuel systems are highly

important to the emission control

system and to efficient engine

operation. Do not tamper with them.

All inspections and adjustments must

be made by Abarth Dealership.

OWNER MAINTENANCE

PRECAUTIONS

191) 192) 193)

38)

Routine service

We highly recommend that these items

be inspected daily, or at least every

week:

Engine oil level

Engine coolant level

Brake and clutch fluid Level

Washer fluid level

Battery maintenance

Tire inflation pressure

Improper or incomplete service may

result in problems. This section gives

instructions only for items that are easy

to perform.

As explained in the “Introduction”

paragraph, several procedures can be

done only by a qualified service

technician with special tools.

Improper do-it yourself maintenance

during the warranty period may affect

warranty coverage. For details, read the

separate Warranty statement provided

with the vehicle. If you are unsure about

any servicing or maintenance

procedure, have it done by Abarth

Dealership.

There are strict environmental laws

regarding the disposal of waste oil and

165

Page 168 of 224

fluids. Please dispose of your waste

properly and with due regard to the

environment.

We recommend that you entrust the oil

and fluid changes of your vehicle to an

Abarth Dealership.

PERIODIC CHECKS

Every1,000 kmor before long trips

check and, if necessary, top up:

engine coolant level;

brake fluid level;

windscreen washer fluid level;

tire inflation pressure and condition;

operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of windscreen

washer/wiper system and

positioning/wear of windscreen window

wiper blades.

Every 3,000 km, check and top up if

required: engine oil level.

HEAVY-DUTY USE OF THE

VEHICLE

If the vehicle is used under one of the

following conditions:

dusty roads;

short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;

the following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks,

cleanliness and lubrication of linkage;

visually inspect conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (gaiters/sleeves/

bushes, etc.);

check battery charge and battery

fluid level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace

pollen filter;

check and, if necessary, replace air

cleaner.

166

MAINTENANCE AND CARE

Page 169 of 224

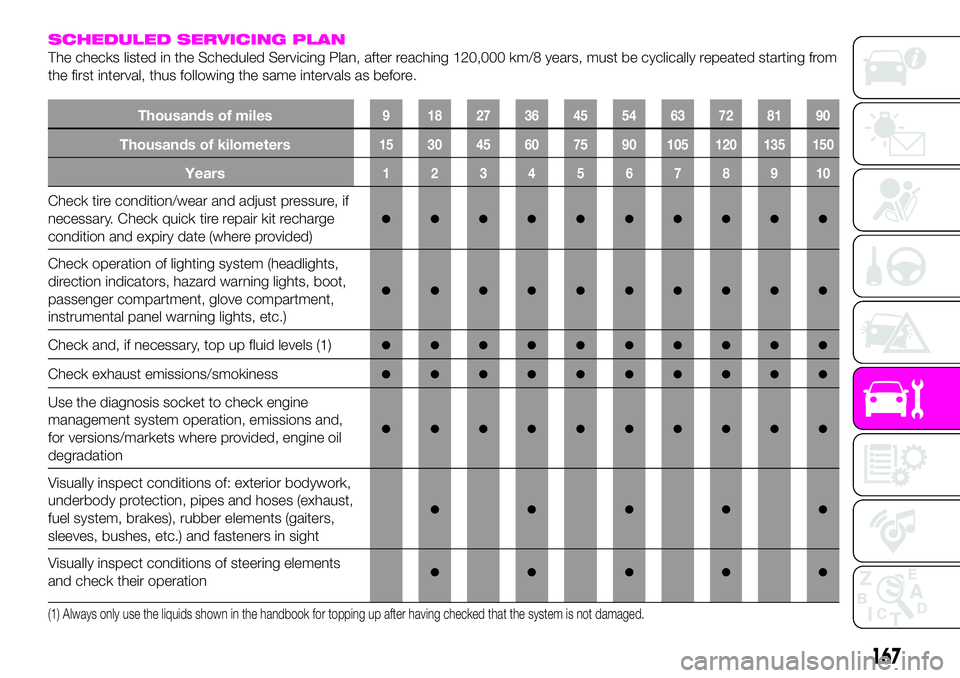

SCHEDULED SERVICING PLAN

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles9 182736455463728190

Thousands of kilometers15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tire condition/wear and adjust pressure, if

necessary. Check quick tire repair kit recharge

condition and expiry date (where provided)

●●●●●●●●●●

Check operation of lighting system (headlights,

direction indicators, hazard warning lights, boot,

passenger compartment, glove compartment,

instrumental panel warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine

management system operation, emissions and,

for versions/markets where provided, engine oil

degradation

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust,

fuel system, brakes), rubber elements (gaiters,

sleeves, bushes, etc.) and fasteners in sight

●●●●●

Visually inspect conditions of steering elements

and check their operation●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

167

Page 170 of 224

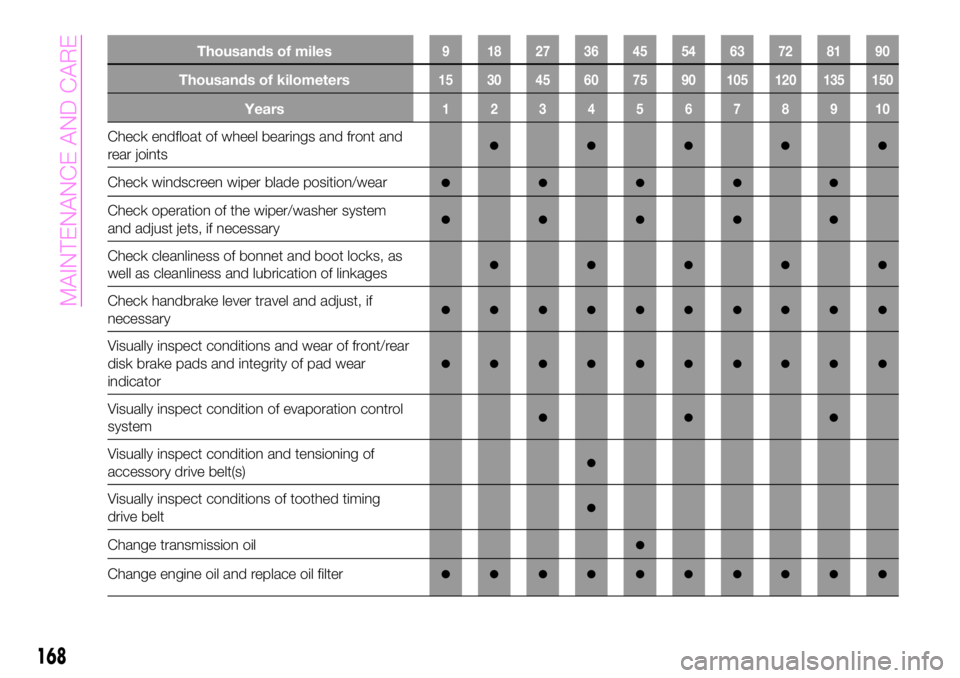

Thousands of miles9 182736455463728190

Thousands of kilometers15 30 45 60 75 90 105 120 135 150

Years12345678910

Check endfloat of wheel bearings and front and

rear joints●●●●●

Check windscreen wiper blade position/wear●●●●●

Check operation of the wiper/washer system

and adjust jets, if necessary●●●●●

Check cleanliness of bonnet and boot locks, as

well as cleanliness and lubrication of linkages●●●●●

Check handbrake lever travel and adjust, if

necessary●●●●●●●●●●

Visually inspect conditions and wear of front/rear

disk brake pads and integrity of pad wear

indicator

●●●●●●●●●●

Visually inspect condition of evaporation control

system●●●

Visually inspect condition and tensioning of

accessory drive belt(s)●

Visually inspect conditions of toothed timing

drive belt●

Change transmission oil●

Change engine oil and replace oil filter●●●●●●●●●●

168

MAINTENANCE AND CARE