Flywheel ACURA INTEGRA 1994 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1994, Model line: INTEGRA, Model: ACURA INTEGRA 1994Pages: 1413, PDF Size: 37.94 MB

Page 395 of 1413

The Automatic Transmission is a combination of a 3-e,ement torque convefter and triple-shaft electfonically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator assembly in a single unit, The torque converter is connected

to the engine crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter

is a ring gear which meshes with the starter pinion when the engine is being staned. The entire torque converter assem-

bly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft. countershaft and sub-shaft. The mainshatt is in line with the

engine crankshaft.

The mainshaft includes the clutches for 1 st, and 2ndl4th, and gears for 3rd. 2nd, 4th, reverse and l st (3rd gear is in-

tegral with the mainshaft, while reverse gear is integral with the 4th gear).

The countershaft includes the 3rd clutch and gears Ior 3rd, 2nd,4th, reverse, lst and parking. Reverse and 4th gears

can be locked to the countershaft at its center, providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the lst-hold clutch and gears for 1st and 4th

The gears on the mainshait are in constant mesh with those on the countershaft and sub-shaft. When certain combina-

tions of gears in the transmission are engaged by the clutches, power is transmitted from the mainshaft to the counter-

shaft via the sub-shatt to provide @, E, tr. tr and @ position.

Electronic Control

The electronic control system consists of the Transmission Control Module {TCM), sensors, and 4 solenoid valves. Shift-

ing and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the left side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body. servo body, and lock-up valve

body throuqh the respective separator plates.

They are bolted on the torque converter housing.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, Clutch Pressure Cont.ol (CPC) valve,

4th exhaust valve, relief valve, and oil pump gears.

The secondary valve body contains the 4-3 kick-down valve,3-2 kick-down valve,2-3 orifice cont.ol valve, 3-4 shitt

valve, orifice control valve. modulator valve, and servo control valve

The regulator valve body contains the pressure regulator valve. lock-up control valve, torque converter check valve, and

cooler check valve.

The servo bodv contains the servo valve which is integrated with the reverse shift fork, throttle valve B, and accumulators.

The lock-ug valve bodv contains the lock-up shift valve and lock-up timing B valve. and is bolted on the secondary valve

body.

Fluid from the regulator passes through the manual valve to the various control valves.

Shitt Control Mochanism

Input to the TCM i.om various sensors located throughout the car determines which shift control solenoid valve should

be activated.

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear.

Lock-up Mechanism

In @ position. in 2nd, 3rd and 4th, and E position in 3rd, pressurized tluid can be drained from the back of the tor-

que converter through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this

takes Dlace, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM

optimizes the timing ol the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

14-3

Page 1183 of 1413

5. Check lor 8n op€n in the BLKMHT wire circuit be-

tween the staner and ignition switch, and con-

nectors.

6. Check the ignition switch (see page 23-70).

7, On cars with automatic transmission, check the A/Tgear position switch (neutral position switchl and

connector. On cars with manualtransmission, check

the staner cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 39 (5O A) fuse in the under-hood

fuse/relay box for the starter cut relay.

Check tor Woar and Damago:

The starter should crank the engine smoothly and stead-

ily. lf th€ startsr engages, but cranks the engine errati-

cally, remove it. Inspect the starter, drive gear, and

flywheel ring gesr for damage.

a Check the drive gear overunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gesrs if damaged.

Check Cranking Voltago 8nd Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than 360 amperes.

lf cranking voltag€ is too low, or current draw too high,

check for:

a Fully charged battery

a Open circuit in starter armature commutatot segments

a Starter armature dragging

a Shoned armature winding

a Excessive drag in engine

Chack Cranking rpm:

Engine spsod during cranking should be above 1O0 rpm.

lf spe6d is too low, ch€ck for:

a Loose battsry or starter teminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Chock StErtor Disongagomoni:

Press the clutch pedal allth€ way in (M/T), turn the ioni-

tion switch to "lll" and rolease to "11".

The starter drive gear should disengage from the tlywheel

ring gear. When you rolease the key.

lf the drive gear hangs up on th€ flywheel ring gear, check

for:

a Solenoid plunger and switch malfunction

a Dirty drive gear assembly or damaged overrunning

clutch

23-77

Page 1190 of 1413

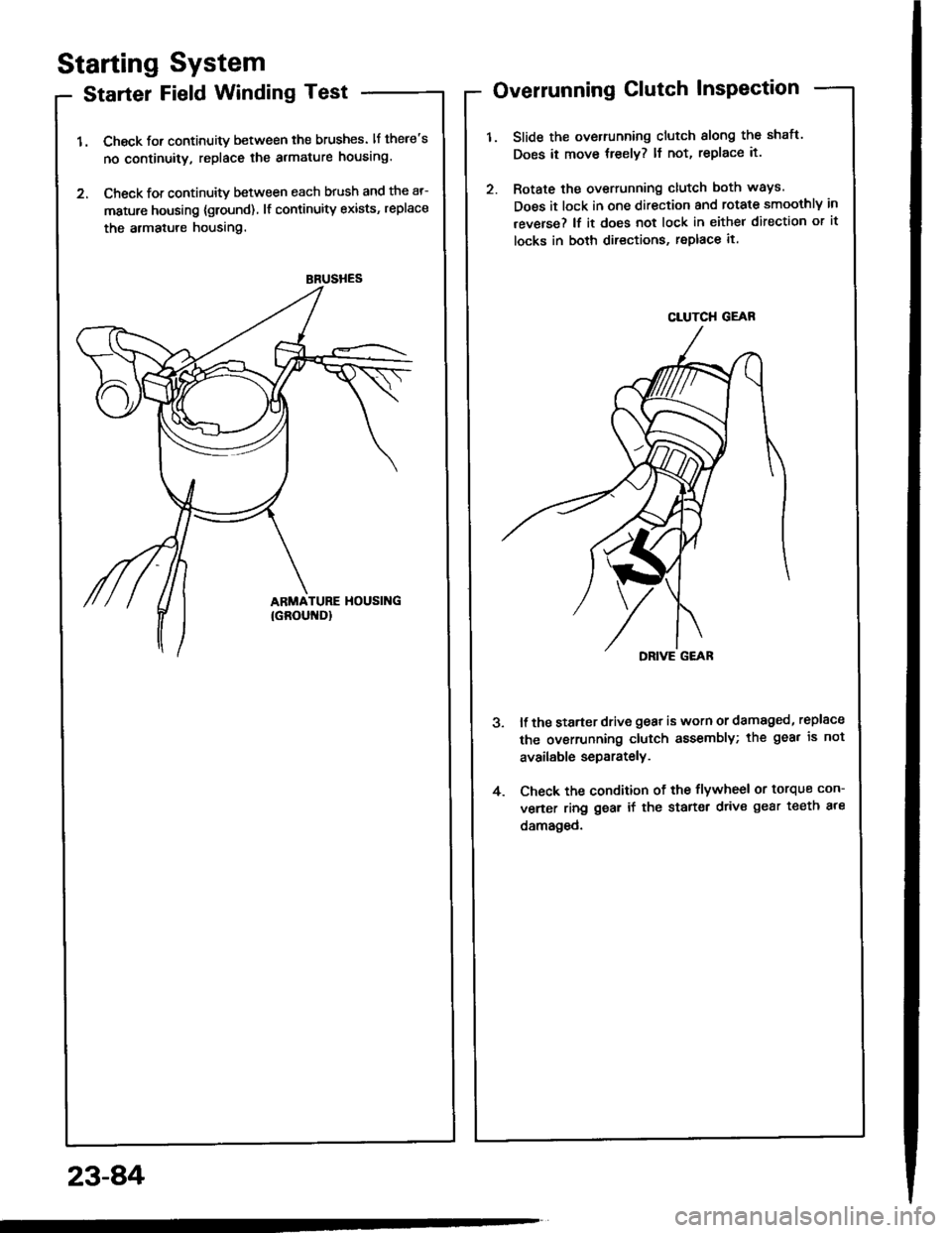

BRUSHES

Starting System

Starter Field Winding Test

1. Check for continuity between the brushes. lf there's

no continuity, replace the armature housing.

2. Check for continuity between each brush and the ar-

mature housing {ground) lf continuity exists, replace

the armatule housing.

Overrunning Clutch InsPection

Slide the overrunning clutch slong the shatt.

Does it move treely? ll not, replace it.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

DRIVE G€AR

ll the starter drive gear is worn or damaged, replsce

the ovsrrunning clutch assembly; the gea. is not

available separately.

Check the condition of the flywheel or torque con-

verter ring gear if the starter drive gear teeth ale

damaged.

4.

23-8,4

CLUTCH GEAR