ACURA INTEGRA 1998 Service Repair Manual

Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 161 of 1680

I

i

Pistons

Installation (cont'dl

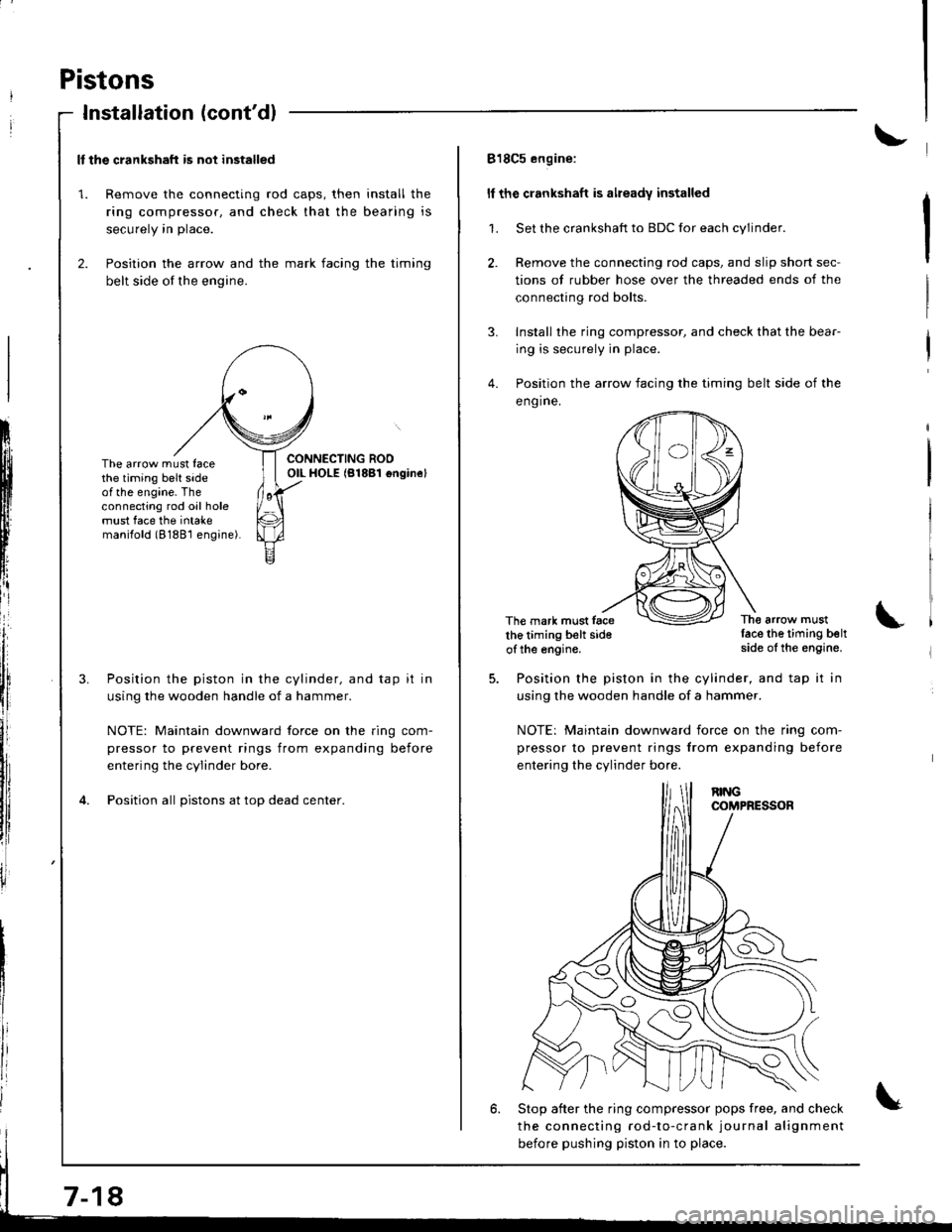

ll the crankshaft is not installed

1. Remove the connecting rod caps, then install the

ring compressor. and check that the bearing is

securely in place.

2. Position the arrow and the mark facing the timing

belt side of the engine.

ItIl

Iti

tfll|lflI[lrB

[:

i"lrt

i'

ff

ll,

illi

llillr

il

The arrow must facethe timing belt sideof the engine. Theconnecting rod oil holemust face the intakemanilold (8188'l engine).

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer.

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Position all pistons at top dead center.

7-18

818C5 engine:

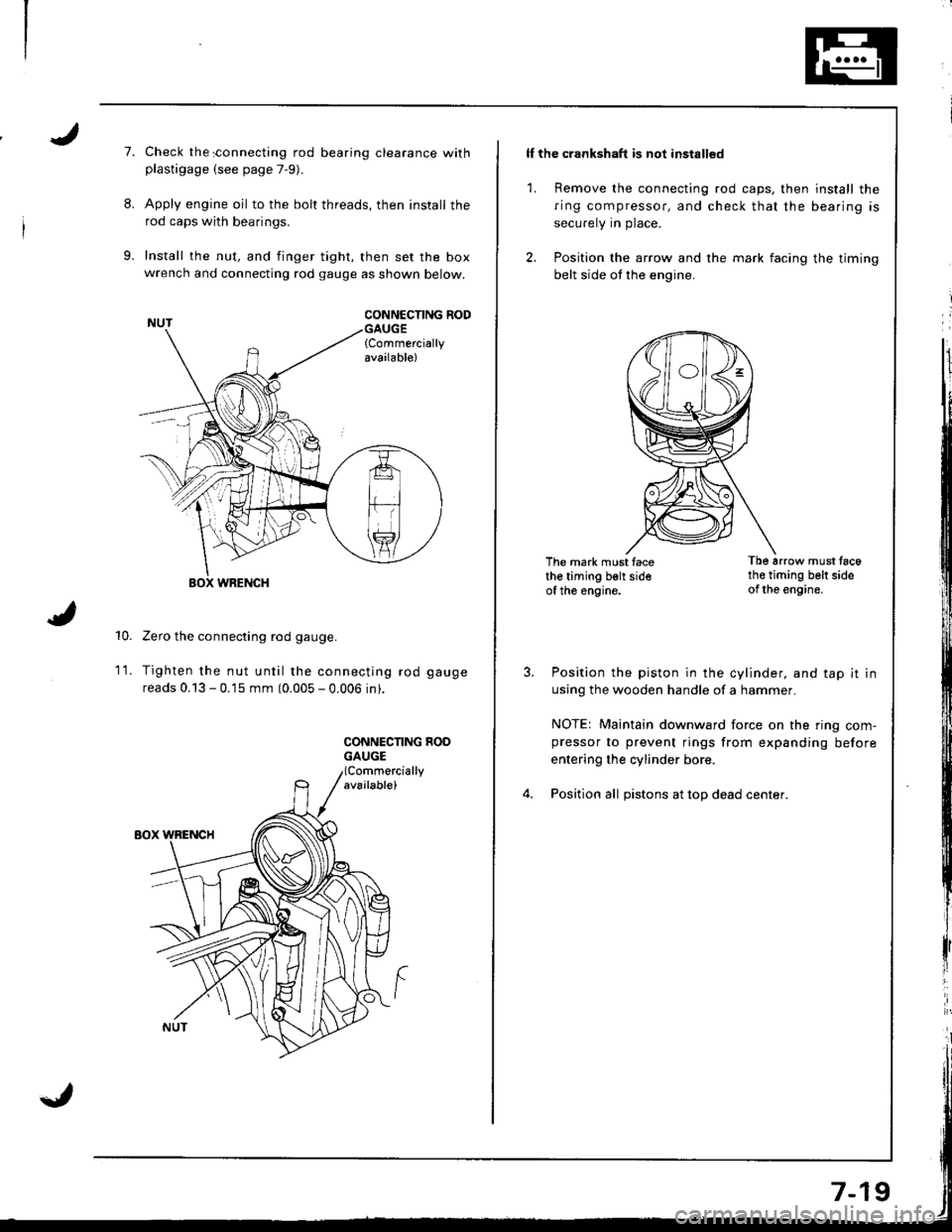

ll the crankshaft is already installed

1. Set the crankshaft to BDC for each cylinder.

2. Remove the connecting rod caps, and slip short sec-

tions of rubber hose over the threaded ends of the

connecting rod bolts.

3. Install the ring compressor, and check that the bear-

ing is securely in place.

4. Position the arrow facing the timing belt side of the

eng ine.

The mark must facethe timing belt sideof the engine.

The arrow mustlace the timing beltside of the engine.

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer.

NOTE: Maintain downward iorce on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bo.e.

6. Stop after the ring compressor pops free, and check

the connecting rod-to-crank journal alignment

before pushing piston in to place.

Page 162 of 1680

I

7.

8.

9.

Check the sonnecting rod bearing clearance withplastigage (see page 7-9).

Apply engine oil to the bolt threads, then install the

rod caps with bearings.

Install the nut, and finger tight, then set the boxwrench and connecting rod gauge as shown below.

CONNCCNNG RODGAUGE{Commerciallyavailable)

10.

WRENCH

Zero the connecting rod gauge.

Tighten the nut until the connecting rod gauge

reads 0.13 - 0.15 mm (0.005 - 0.006 in).

CONNECNNG HOOGAUGE

1t.

ll the crankshaft is not installed

1. Remove the connecting rod caps, then install the

ring compressor, and check that the bearing is

securely in place.

2. Position the arrow and the mark facing the timing

belt side ot the engine.

The mark must facethe timing belt sideof the engine.

Tb6 arrow must tac6th€ timing belt sideof the engine.

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer.

NOTE: Maintain downward force on the ring com-pressor to prevent rings from expanding before

entering the cylinder bore.

Position all pistons at top dead center.

Page 163 of 1680

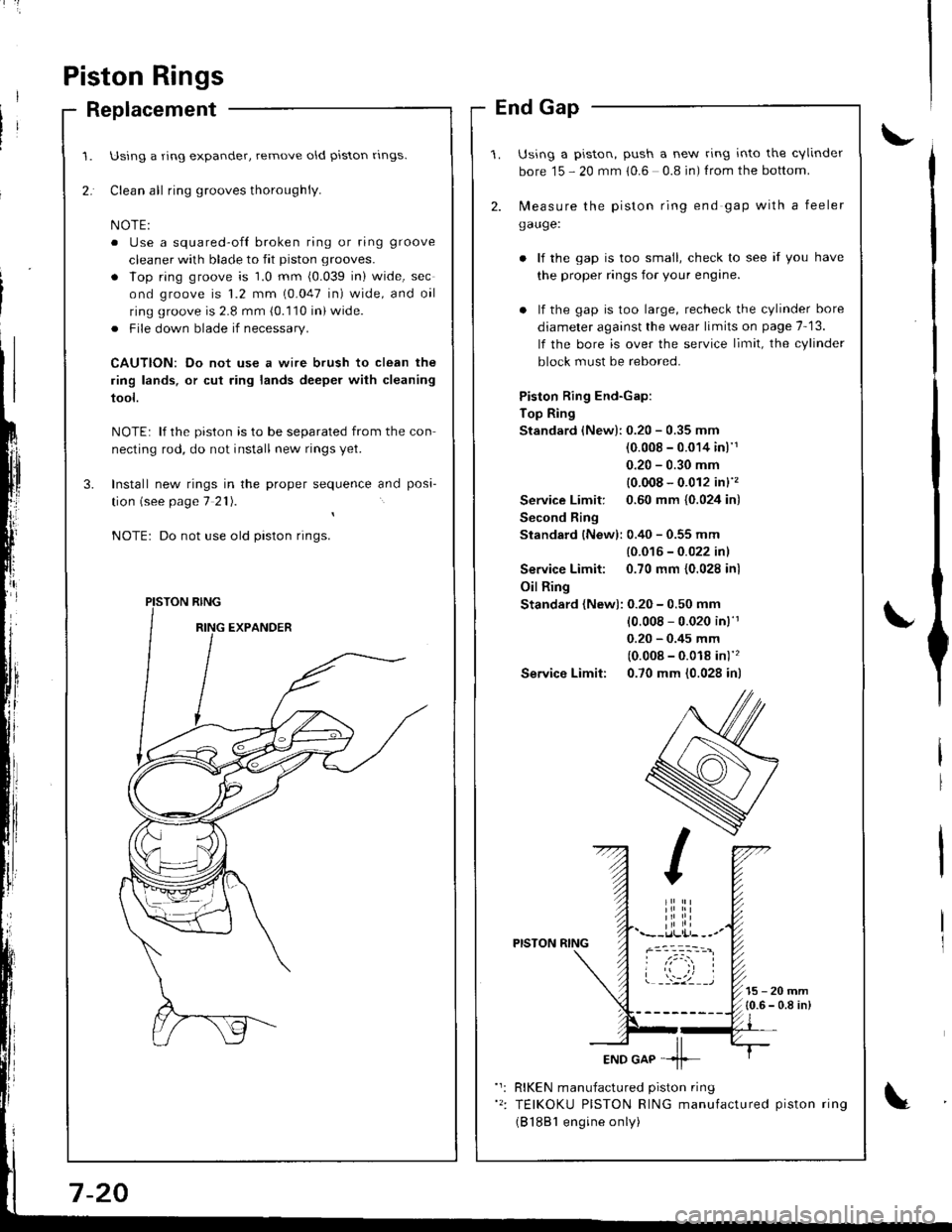

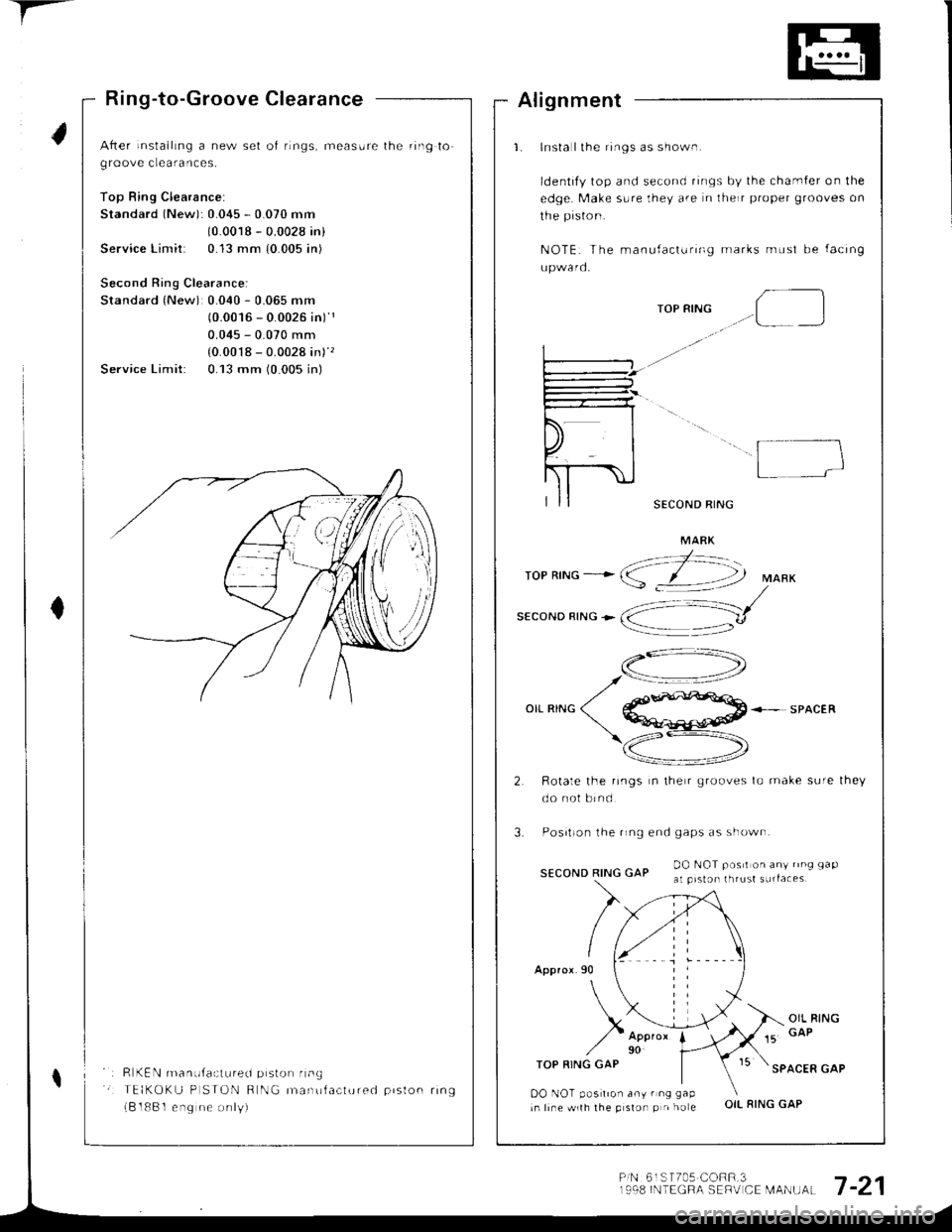

Piston Rings

Replacement

Using a ring expander, remove old piston rlngs.

Clean all ring grooves thoroughly.

o Use a squared-ofl broken ring or ring groove

cleaner with blade to fit piston grooves.

. lop ring groove is 1.0 mm (0.039 in) wide, sec

ond groove is 1.2 mm (0.047 in) wide, and oil

ring groove is 2.8 mm (0.110 in) wide.

. File down blade if necessary.

CAUTION: Do not use a wire brush to clean the

ring lands, or cut ring lands deeper with cleaning

tool.

NOTE: lf the piston is to be separated from the con

necting rod, do not install new rings yet.

Install new rings in the proper sequence and posa-

tion (see page 7 21).

Do not use old piston rings.

PISTON RING

End Gap

Using a piston, push a new ring into the cvlinder

bore 15 - 20 mm 10.6 0.8 in) f rom the bottom.

2. N,4easure the piston ring end gap with a feeler

gauge:

lf the gap is too small, check to see if you have

the proper rings for your engine.

. lf the gap is too large, recheck the cylinder bore

diameter against the wear limits on page 7-13.

lf the bore is over the service limit, the cylinder

block must be rebored.

Piston Ring End-Gap:

Top Ring

Standard (New):0.20 - 0.35 mm

(0.008 - 0.014 inl'1

0.20 - 0.30 mm

{0.008 - 0.012 in}''�

Service Limit: 0.60 mm {0.024 in)

Second Ring

Standard {New): 0.40 - 0.55 mm

{0.016 - 0.022 inl

Service Limit: 0.70 mm {0.028 inl

Oil Ring

Standard (New): 0.20 - 0.50 mm

10.008 - 0.020 in)'r

0.20 - 0.45 mm

(0.008 - 0.018 in)''�

Service Limit: 0.70 mm (0.028 in)

PISTON RING

15-20mm{0.6 - 0.8 in)

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured piston ring

(B 1881 engine only)

Page 164 of 1680

Page 165 of 1680

Piston Pins

Removal

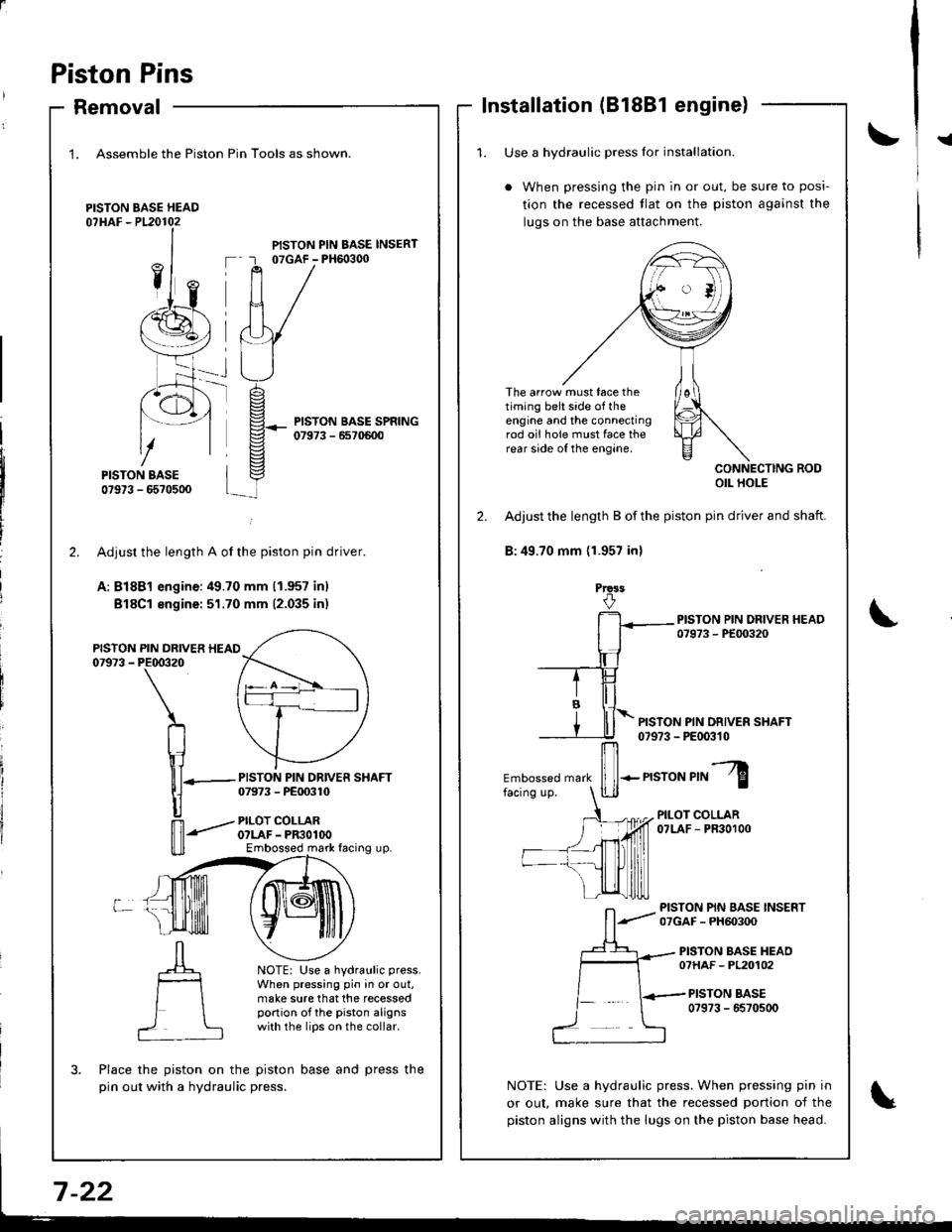

1. Assemble the Piston

PISTON BASE HEAD07HAF - P120102

Pin Tools as shown.

PISTON PIN BASE INSERT07GAF - PH6o3q)

PISTON BASE SPRING07973 - 6570600

-rt_

2.

PISTON07973 -

L

PISTON PIN DRIVER SHAFT07973 - PE00310

PILOT COLLARO?LAF - PR3OlOOEmbossed mark facing up.

NOTE: Use a hydraulic press.

When pressing pin in or out,make sure that the recessedportion of the piston alignswith the lips on the collar.

?

Adjusr the length A of the piston pin driver.

A: Bl8Bl engine:49.70 mm (1.957 inl

Bl8Cl engine: 51.70 mm (2.035 inr

PIN DRIVER HEAIPE00320

\

n

\1lll-

|]

n'-"'

Place the piston on the piston base and press the

pin out with a hydraulic press.

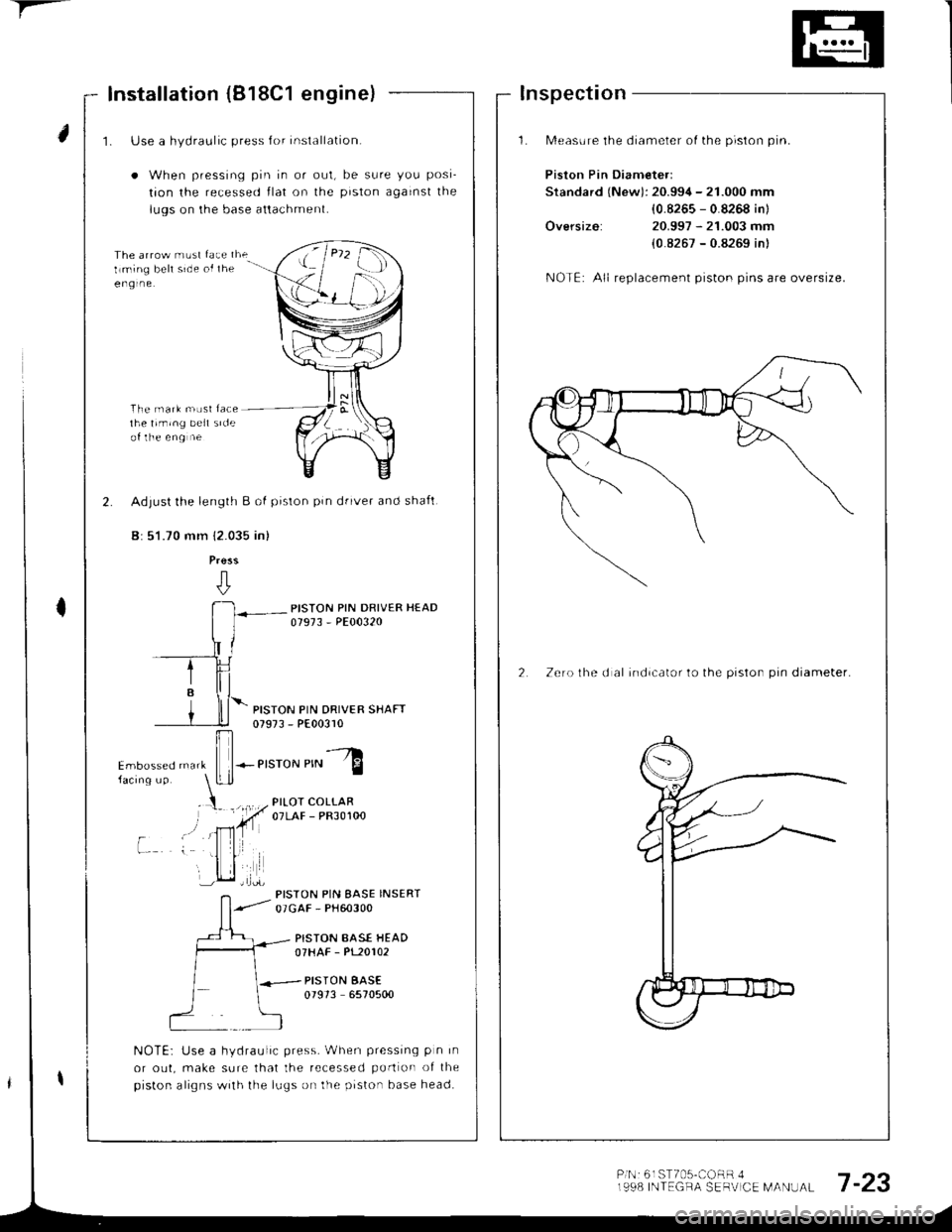

Installation (81881 engine)

!{1. Use a hvdraulic Dress lor installation.

When pressing the pin in or out, be sure to posi-

tion the recessed tlat on the piston against the

luqs on the base attachment.

The arrow must face thetiming belt side of theengine and the connectingrod oii hole must face therear side of the engine.

CONNECTING RODOIL HOLE

2. Adjust the length B of the piston pin driver and shaft.

B:49.70 mm (1.957 inl

Prca3

PISTON PIN DRIVER SHAFT07973 - PE00310

Embossed mark

ffi-n"ro"r,"l

PILOT COLLAR07LAF - PR30100

PISTON PIN BASE INSERT07GAF - PH60300

PISTON BASE HEAO07HAF - PL20102

PISTON BASE0?973 - 6570500

NOTE: Use a hydraulic press. When pressing pin in

or out, make sure that the recessed portion of the

piston aligns with the lugs on the piston base head.

Page 166 of 1680

Page 167 of 1680

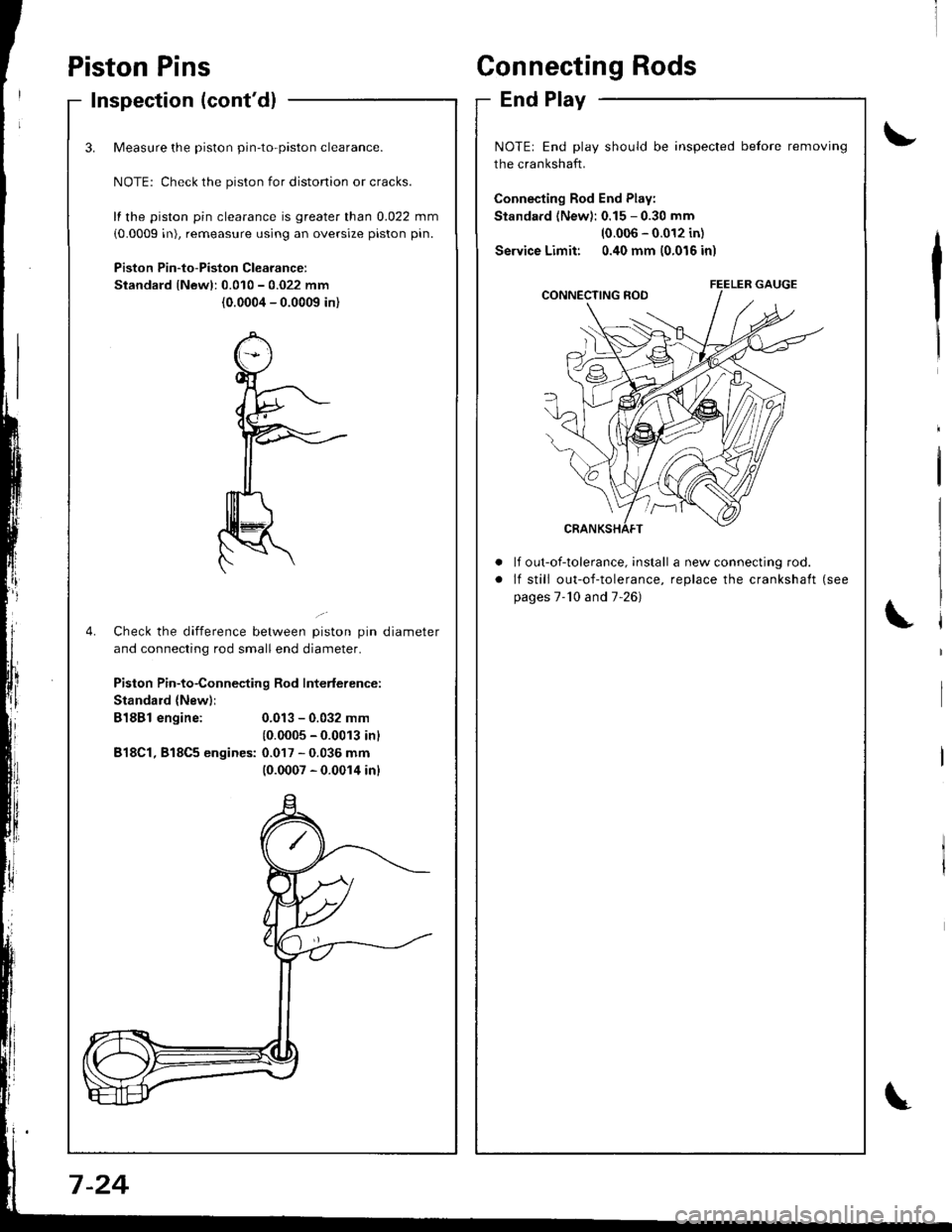

Inspection (cont'dl

3.

4.

Measure the piston pin-to-piston clearance.

NOTE: Check the piston for distonion or cracks.

fl the piston pin clearance is greater than 0.022 mm

(0.0009 in), remeasure using an oversize piston pin.

Piston Pin-to-Piston Clearancer

Standard lNewl:0.010 - 0.022 mm

(0.0004 - 0.0009 in)

Check the difference between piston pin diameter

and connecting rod small end diameter.

Piston Pin-to-Connecting Rod Interlerence:

Standard {New)i

B18Bl engine:

B18Cl, 818C5 engines:

0.013 - 0.032 mm

10.0005 - 0.0013 inl

0.017 - 0.036 mm(0.0007 - 0.0014 inl

Piston PinsConnecting Rods

End Play

\,

\

t'

NOTE: End play should be inspected before removing

the crankshaft.

Connecting Rod End Play:

Standard (New): 0.15 - 0.30 mm

10.006 - 0.012 in)

Service Limit: 0.40 mm (0.016 in)

a

a

It out-of-tolerance, install a new connecting rod.

lf still out-of-tolerance, replace the crankshaft (see

pages 7-'10 and 7-26)

7 -24

Page 168 of 1680

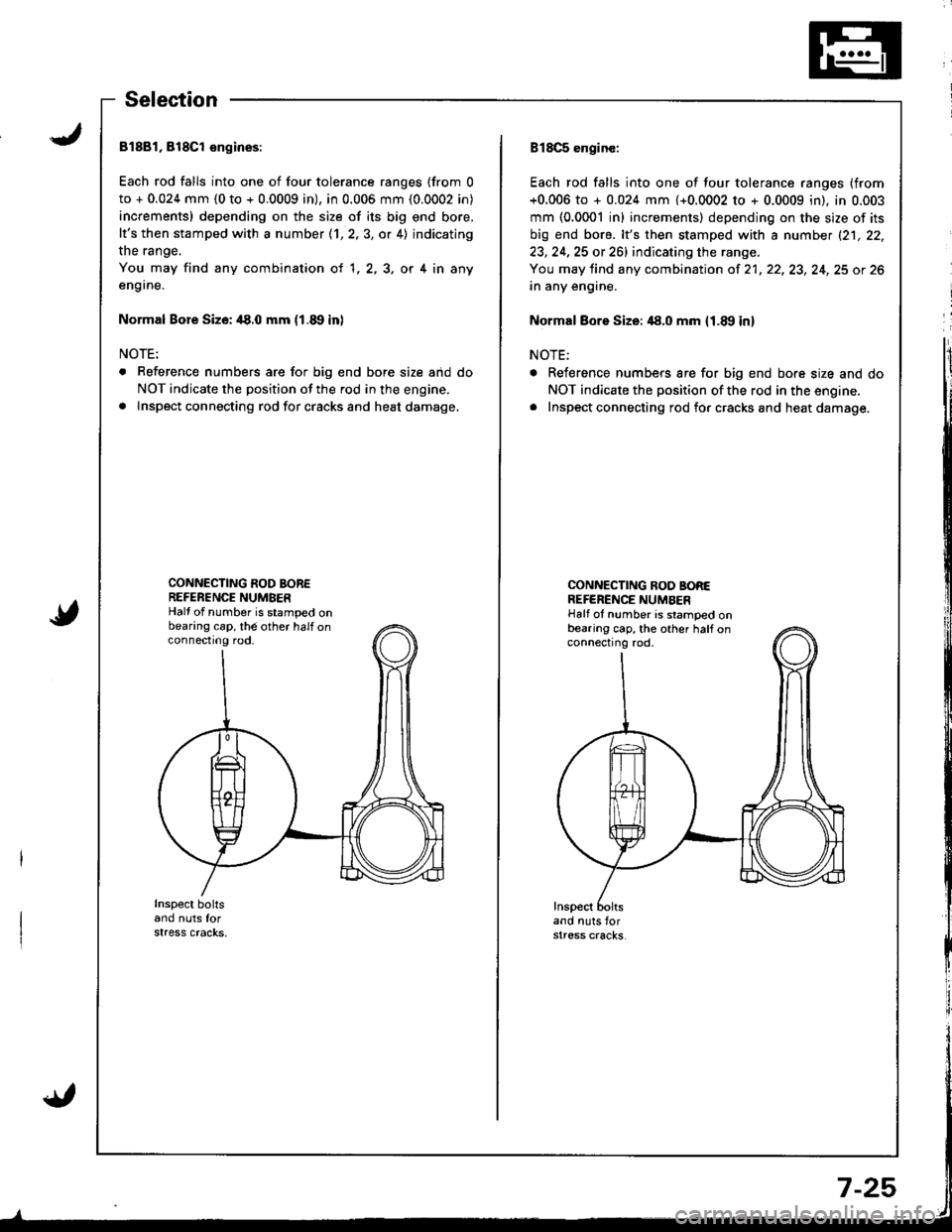

Selection

81881, 818Cl engioes:

Each rod falls into one of four tolerance ranges (from 0

to + 0.024 mm (0 to + 0.0009 in), in 0.006 mm (0.0002 in)

increments) depending on the size of its big end bore,

It's then stamped with a number (1,2,3, or 4) indicating

the range.

You may find any combination ot 1,2,3, or 4 in any

en9rne.

Normal Bore Size: /|8.0 mm (1.8, in)

NOTE:

. Reference numbers are for big end bore size aid do

NOT indicate the position of the rod in the engine.

a Inspect connecting rod for cracks and heat damage,

CONNECTING ROD BOREREFERENCE NUMBERHalf of number is stamped onbearing cap, th6 other half onconnectrng rod,

Inspect boltsand nuts forstress cracks.

B18C5 enginc:

Each rod falls into one of four tolerance ranges (from

+0.006 to + 0.024 mm {+0.0002 to + 0.0009 in). in 0.003

mm (0.0001 inl increments) depending on the size of its

big end bore. lt's then stamped with a number (21, 22,

23, 24,25 or 261 indicating the range.

You may tind any combination of 21, 22, 23, 24, 25 ot 26

in any engine.

Normal Bore Size: 48.0 mm {1.8!, in}

NOTE:

a Reference numbers are for big end bore size and do

NOT indicate the position of the rod in the engine.. Inspect connecting rod fo. cracks and heat damage.

CONNECNNG NOO BOREREFERENCE NUMAERHalf oI number is stamped onbearing cap, the other half onconnecting rod,

Inspectand nuts forstress cracks,

Page 169 of 1680

t'

Crankshaft

lnstallation

-Q Before installing the crankshaft, apply a coat of

E engine oilto the main bearings and rod bearings.

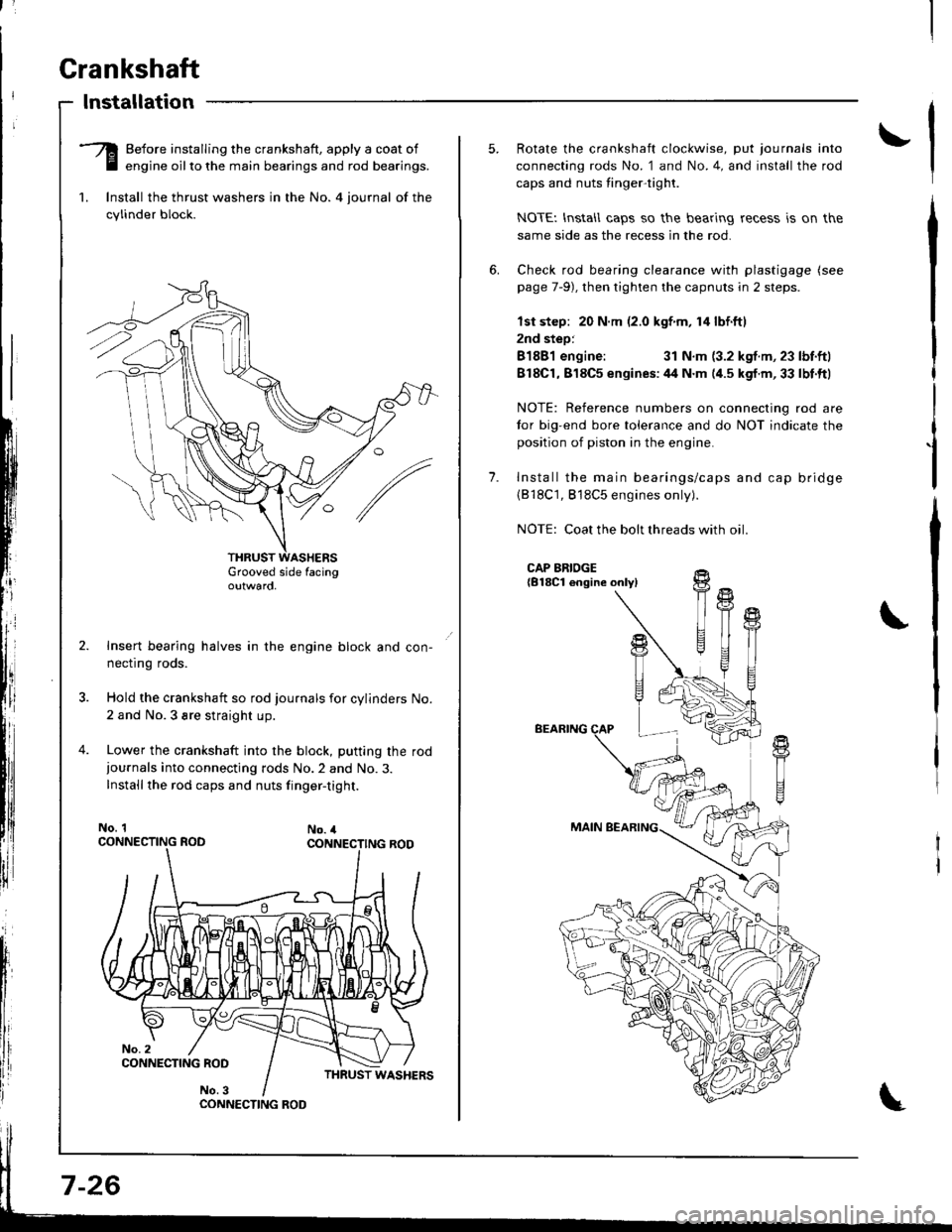

1. lnstall the thrust washers in the No. 4 iournal of the

cylinder block.

Grooved side facingoutwaro,

Insert bearing halves in the engine block and con-

necflng roos.

Hold the crankshaft so rod journals for cylinders No.

2 and No.3 sre straight up.

Lower the crankshaft into the block, putting the rod

iournals into connecting rods No.2 and No.3.

Installthe rod caps and nuts finger-tight.

No. 1No. 4

CONNECTING ROO

7-26

1.

Rotate the crankshaft clockwise, put journals into

connecting rods No. 1 and No.4, and install the rod

caps and nuts tinger-tight.

NOTEI lnstall caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-9), then tighten the capnuts in 2 steps.

lst step: 20 N.m (2.0 kgf m, 14 lbf.ftl

2nd step:

81881 engine:31 N.m (3.2 kgf.m, 23 lbf.ftl

818C1,818C5 enqines:44 N.m (4.5 kgf.m,33 lbt.ftl

NOTE: Reference numbers on connecting rod are

tor big-end bore tolerance and do NOT indicate the

position of piston in the engine.

Install the main bearings/caps and cap bridge(818C1, 818C5 engines only).

NOTE: Coat the bolt threads with oil

CAP BRIDGE{B18Cl engine onlyl

BEARING

MAIN BEARING

fi

U

t{

T

!+

T1

Page 170 of 1680

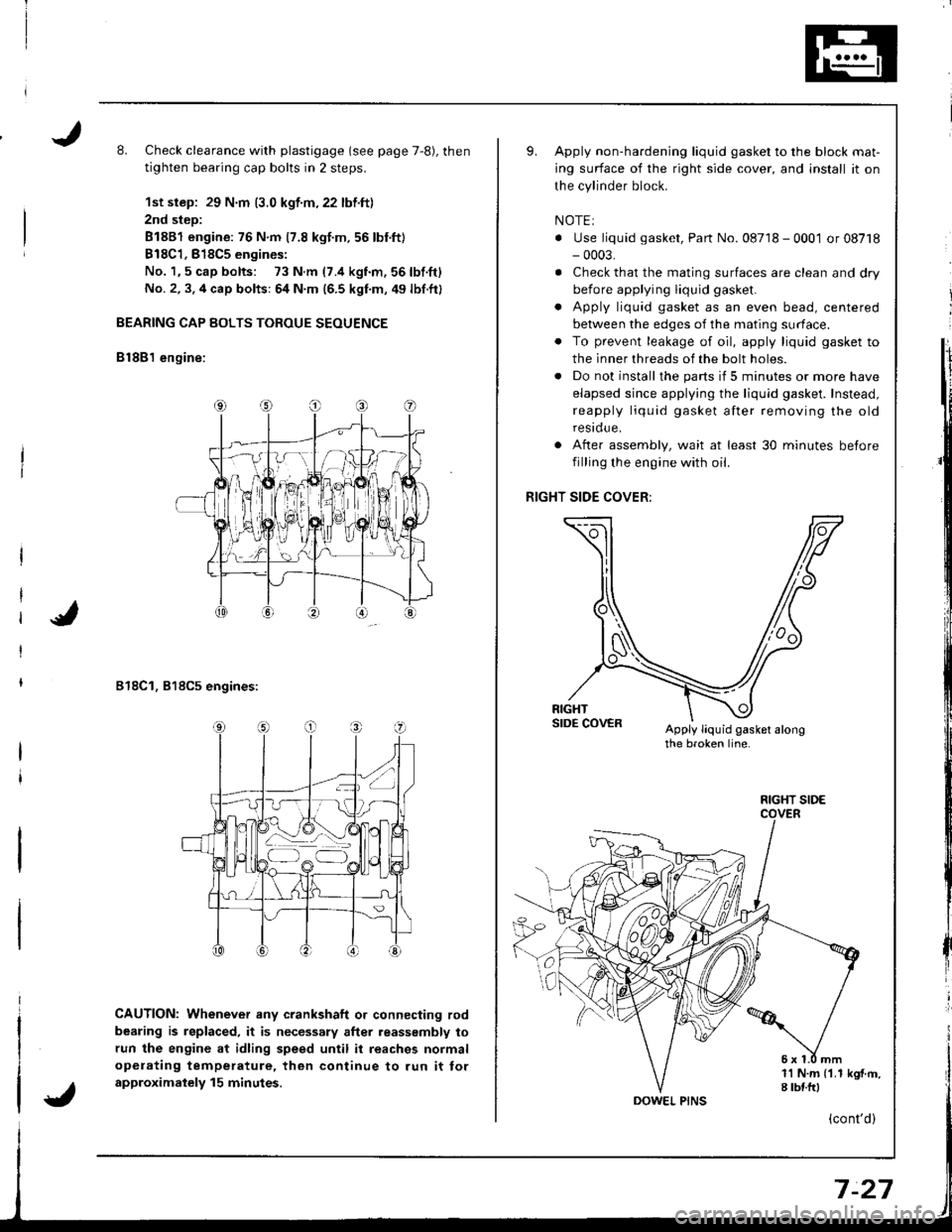

L Check clearance with plastigage (see page 7,8), then

tighten bearing cap bolts in 2 steps.

1st step: 29 N.m (3.0 kgf.m,22 lbf.ft)

2nd step:

81881 engine: 76 N.m 17.8 kgt.m.56 lbnft)

B18C1,818C5 engines:

No. 1,5 cap bolts: 73 N.m (7.4 kgnm,56lbf.ft)

No. 2, 3. 4 cap bolts: 64 N.m (6.5 kgf.m, 49 lbf.ft)

BEARING CAP BOLTS TOROUE SEOUENCE

B lSB'l engine:

818C1, 818C5 engines:

CAUTION: Whenever any crankshaft o. connecting rod

bearing is replaced, it is necessary after reassembly to

run the engine at idling speed until it reaches normal

opelating temperature, then continue to run it tor

approximalely 15 minutes.

Apply non-hardening liquid gasket to the block mat-

ing surface of the right side cover, and install it on

the cylinder block.

NOTEI

. Use liquid gasket, Part No. 08718 - 0001 or 08718- 0003,

. Check that the mating surfaces are clean and dry

before applying liquid gasket.

. Apply liquid gasket as an even bead, centered

between the edges of the mating surface.

. To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes.

. Do not install the parts if 5 minutes or more have

elapsed since applying the liquid gasket. Instead,

reapply liquid gasket after removing the old

residue.

After assembly, wait at least 30 minutes betore

filling the engine with oil.

RIGHT SIDE COVER:

Apply liquid gasket alongthe broken line.

o

a

1l N.m {1.1 kgf.m,I tbf.frl

FIGHT SIDE

(cont'd)