sub ACURA INTEGRA 1998 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 298 of 1680

PGM-FI System

A/T Fl Data Line (cont'dl

(From page '11-93)

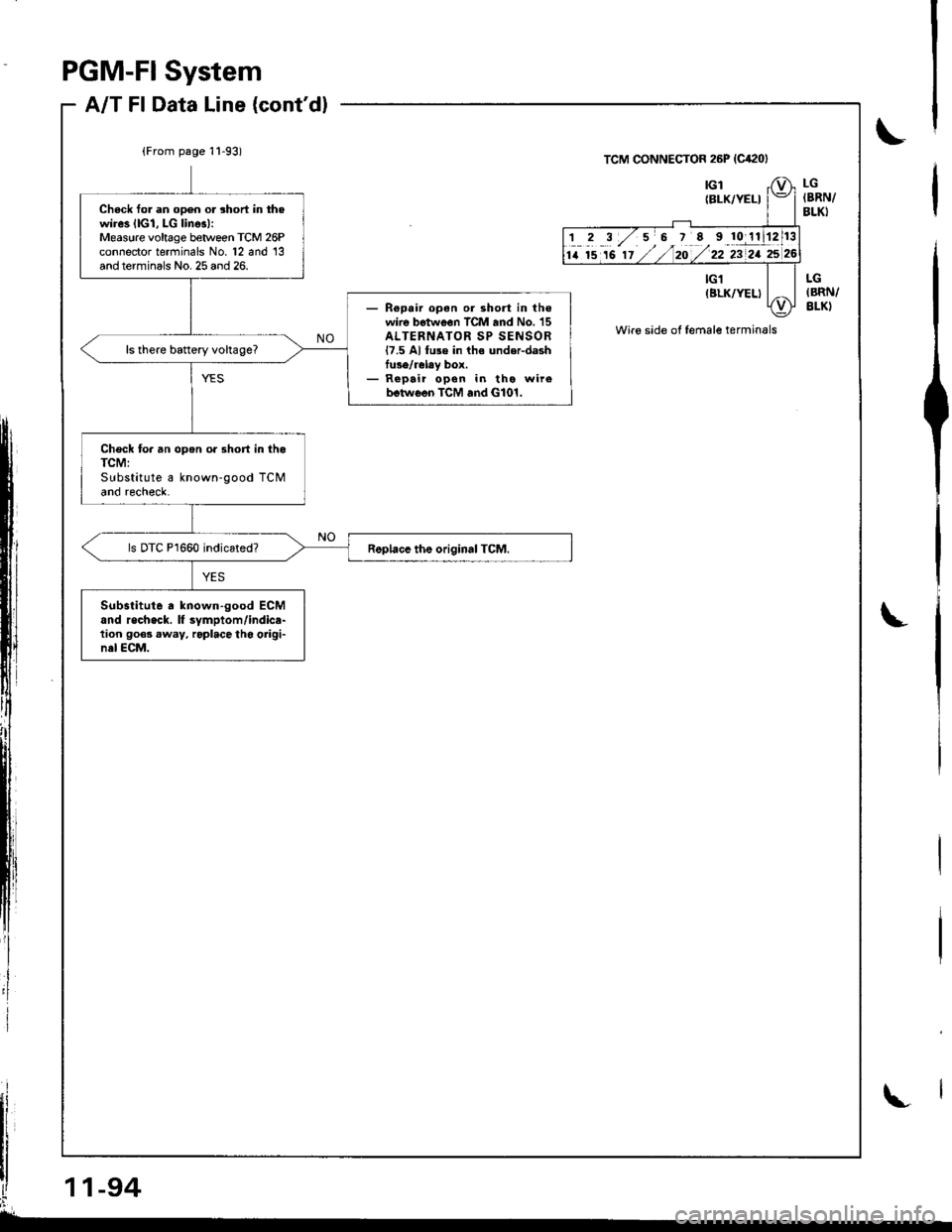

Check fo. an ooen or rhort in thewires llGl, LG lines):Measure voltage between TCM 26Pconnector terfiinals No. 12 and 13and terminals No. 25 aod 26.

- Ropair opan or short in thewire bgtwoen TCM and No. 15ALTERNATOR SP SENSOR17.5 Al tu3e in th€ under-dashfu3e/r€lay box.- Repair opon in tho wireb.twoen TCM and G101.

ls there banery voltage?

Check to. an open o. 3hort in thaTCM:Substitute a known-good TCMand recheck.

ls DTC P1660 indicated?

Substitute a known.good ECMand rschsck. lf symptom/indica-lion 9o€! .w.y, roplace tho origi-nal ECM.

TCM CONNECTOR 26P {Cir2ol

LG(BRN/

BLK}

1 2 3 ,/ 5 6 7 E 910 11

14 15 16 17

Wir6 side of lemale terminals

i

-94

Page 299 of 1680

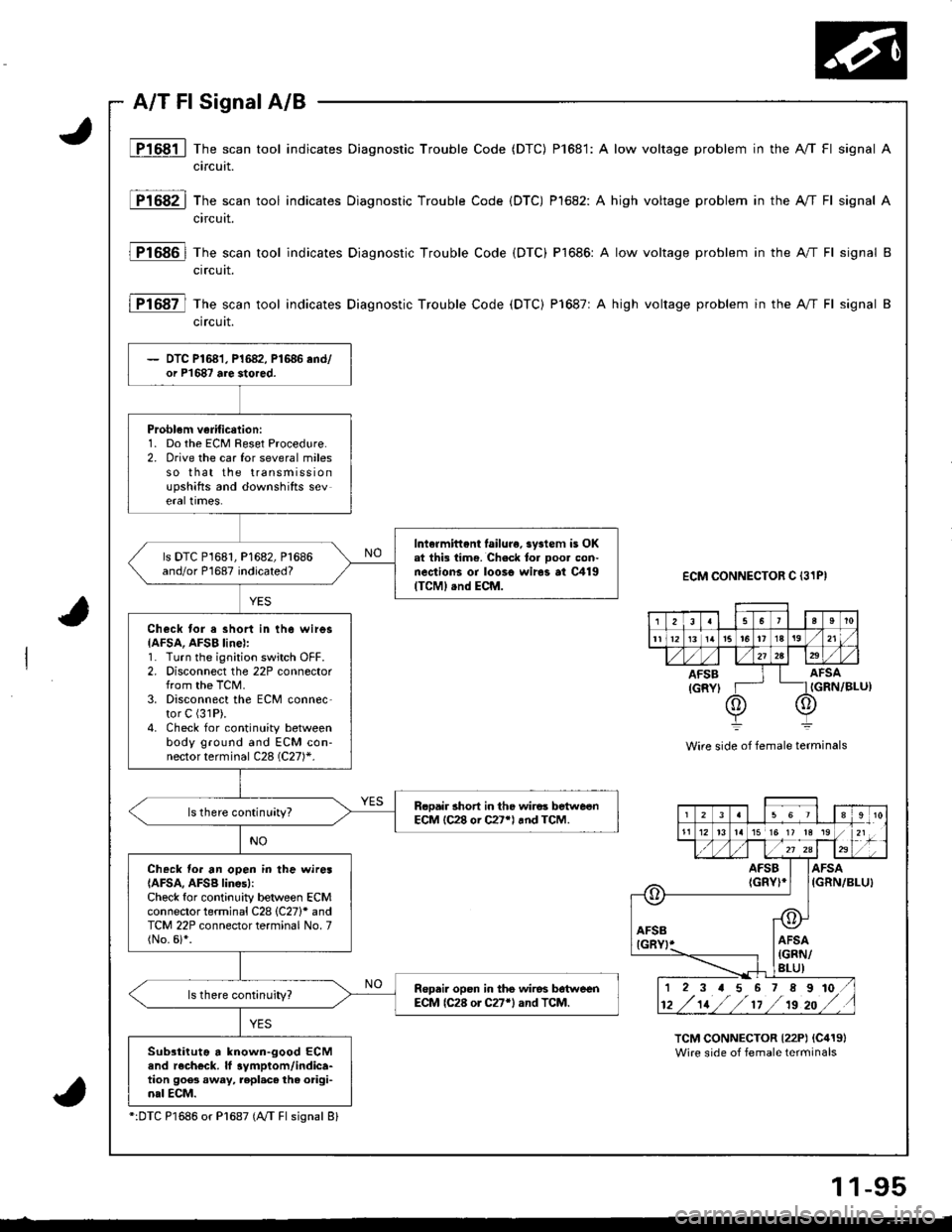

JP1681 | The scan tool indicates Diagnostic Trouble Code (DTC) P1681: A low voltage problem in the A/T Fl signal A

circuit.

P1682 | The scan tool indicates Diagnostic Trouble Code {DTC) Pl682: A high voltage problem in the A//T Fl signal A

circuit.

]TtOgOl fh" scan tool indicates Diagnostic Trouble Code (DTC) P1686: A low voltage problem in the A"/T Fl signal B

ctrcutt.

lFt Ogt-l fh" scan tool indicates Diagnostic Trouble Code (DTC) P1687: A high voltage problem in the A"/T Fl signal B

crrcurt.

ECM CONNECTOR C {31PI

IGRN/BLU)

Wire side of female terminals

TCM CONNECTOR {22P) {C419}Wire side of female terminals

2!a5't0

tl1213 tatat6It1a19 ,/

AFSB I I AFSA

{GRYI T- _IIGRN

@)o

2311to21 ;'15 15 17 13 13

E./ zl za

G-\

AFSIGR

\-

a

AFlGl

I

sBl

L]

r@!I AFSA

| {GRN/lRt ltl

iFSGRIA[/BLUt

12 3 a 5 6 7 89

tz /'tt //t't /ts zo

to ,/

DTC P1681, P1682, P1686 end/or P'1687 are stored.

Problem verificetion:1. Do the ECM Reset Procedure.2. orive the car for several milesso that the transmissionupshifts and downshifts severarlrmes.

Intormittent lailure. system is OKat thi3 tim€. Check tor ooo. con-nections or loo3o wir6s al C419{TCM} .nd ECM.

ls DTC P1681, P1682, Pl686and/or P1687 indicated?

Check tor a short in th6 wires{AFSA, AFSB linel:1. Turn the ignition switch OFF.2, Disconnect the 22P connectorfrom the TCM.3. Disconnect the ECM conn6c-tor C (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C28 (C27)*.

Rcoair 3hort in tho wiros betweenECM lC28 or C27*l rnd TCM.ls there continuity?

Check fo. an open in the wiresIAFSA, AFSB lines):Check for continuity between ECMconnector terminal C28 (C27)* andTCM 22P connector terminal No. 7(No.6i*.

Repai. opsn in the wiros bdtweenECM lC28 or C27'l and TCM.

Subsiiiutg a known-good ECMend r6ch€ck. lf 3ymptom/indica-tion goes away, repl.c6 the origi-nal ECM.

":DTC P1686 or Pl687 (NT Fl sisnal 8l

1 1-95

Page 301 of 1680

2.

1.

1.

2.

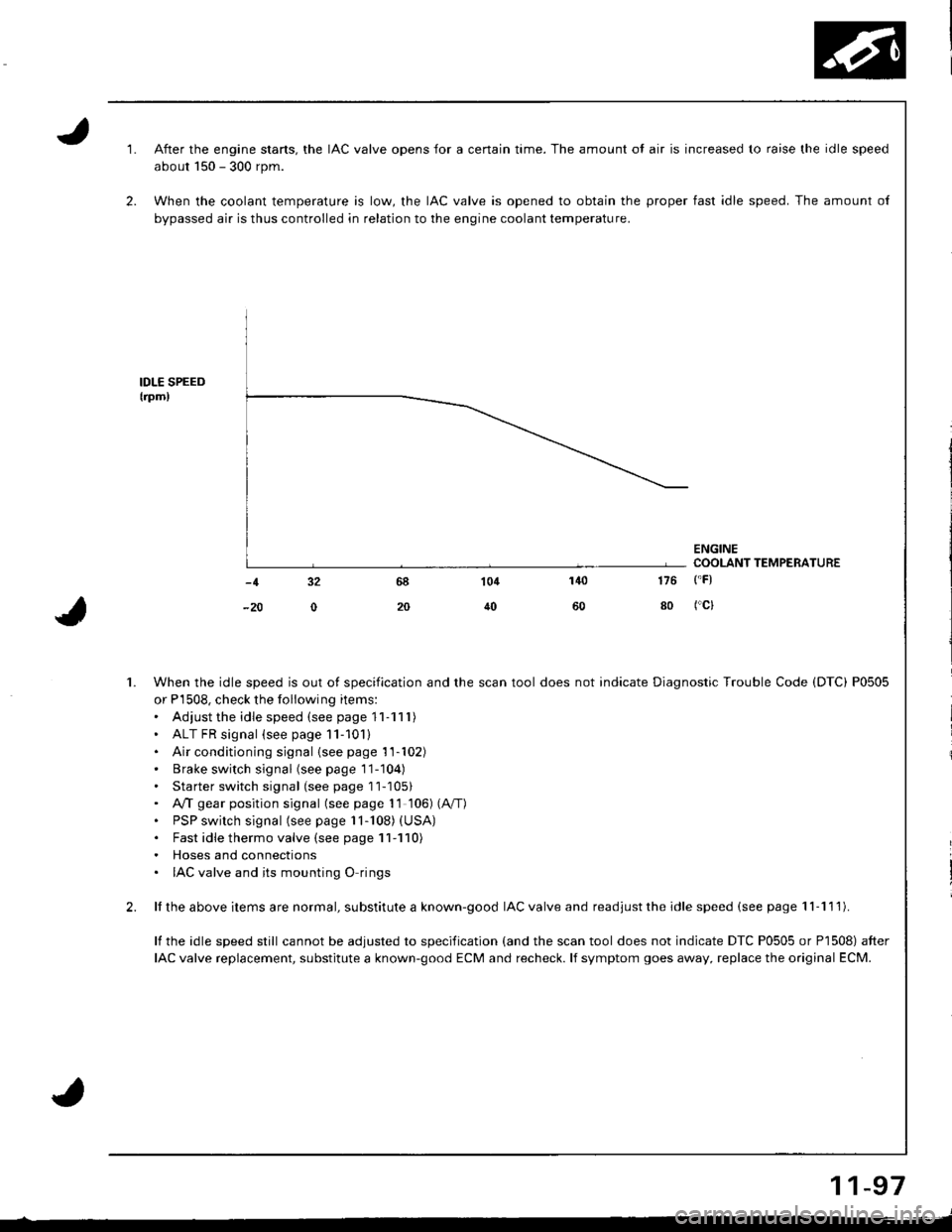

After the engine stans, the IAC valve opens for a certain time. The amount ol air is increased to raise the idle speed

about 150 - 300 rpm.

When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount of

bypassed air is thus controlled in relation to the engine coolant temperature.

IDLE SPEEDtrpm,

ENGINECOOLANT TEMPERATURE

140

50

104

40

-1 32

-20 0

176 ('F)

80 fcl

When the idle speed is out of specification and the scan tool does not indicate Diagnostic Trouble Code (DTC) P0505

or P'1508, check the following items:. Adiust the idle speed (see page '11-111)

' ALT FR signal (see page 11-101). Air conditioning signal {seepage'11-102)' Brake switch signal (seepagell-104)

. Starter switch signal (see page 11-1051. A,4 gear position signal (see page 1l 106) (A"/T)

. PSP switch signal (see page 11-108) (USA)

. Fast idle thermo valve (see page 11-110). Hoses and connections. IAC valve and its mounting O rings

ll the above items are normal, substitute a known-good IAC valve and readjust the idle speed (see page 'l I -1 1 l).

lf the idle speed still cannot be adjusted to specification (and the scan tool does not indicate DTC P0505 or P1508) after

IAC valve replacement, substitute a known-good ECM and recheck. lf symptom goes away, replace the original ECM.

11-97

Page 304 of 1680

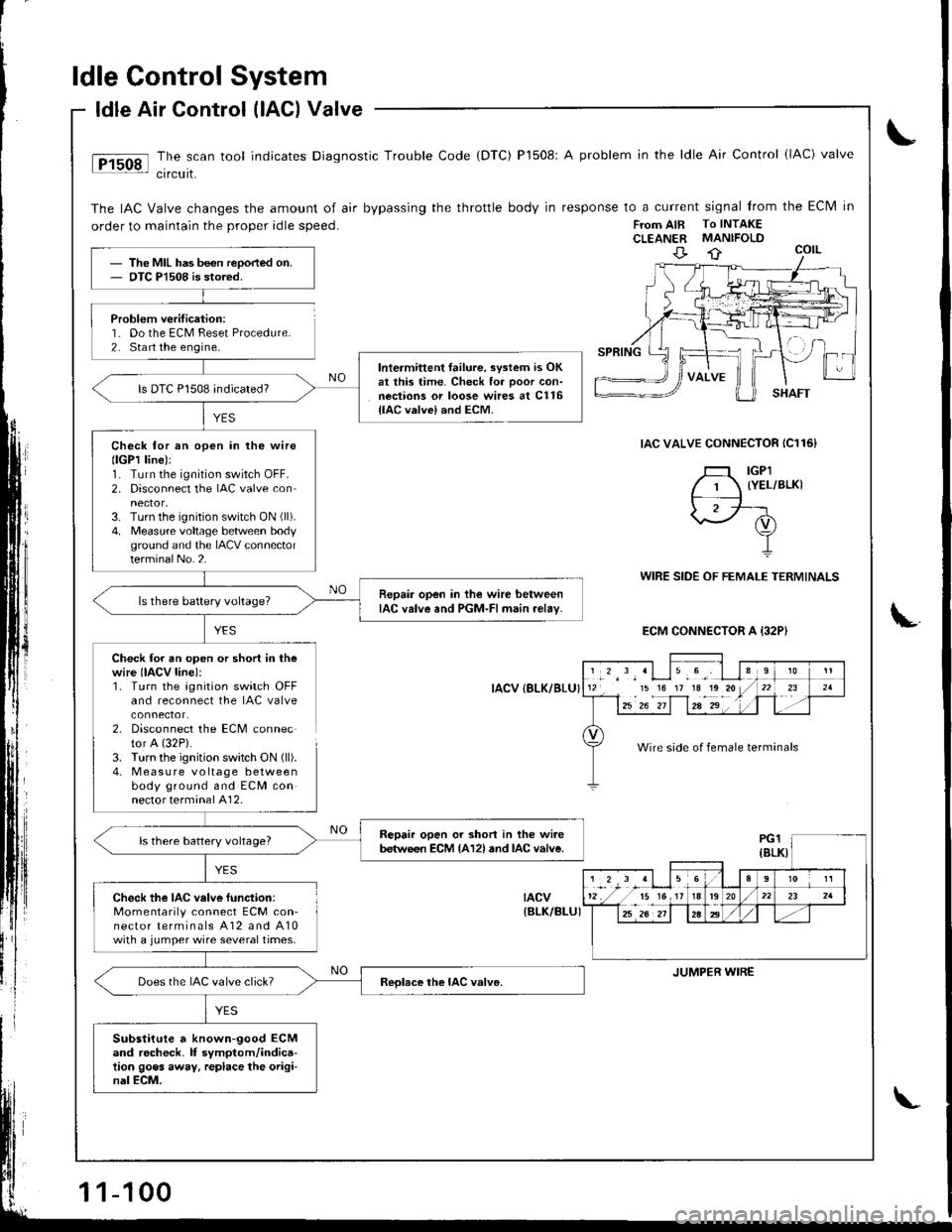

ldle Control System

Problem verification:'1. Do the ECM Feset Procedure.2. Sta rt the engine.

ldle Air Control (lAG) Valve

The scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Control (lAC) valve

crrcurt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the Eclvl in

order to maintain the proper idle speed.FTom AIB To INTAKECLEANER MANIFOLD

IAC VALVE CONNECTOR IC116}

YES

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR A {32PI

Check for an open or short in thewire IIACV line):1. Turn the agnition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connector A (32P).

3. Turn the ignition swatch ON (ll).

4. M easu re voltage betweenbody ground and ECM connector terminal A12.

IACV {8LK/BLU}

tacv{BLK/BI-UI

The MIL has been reoorted on.OTC Pl508 is stored.

lntermittent failure, svstem is OKat this time. Check for ooor con-nections or loose wires at C116{lAC valvel and ECM.

ls DTC P1508 indicated?

Check tor an open in lhe wirellGPl line):1. Turn the ignition switch OFF.2. Disconnect the IAC valve con

3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen bodyground and the IACV connectorterminalNo.2.

Repair open in the wire betweenIAC valve and PGM-FI main relav-ls there battery voltage?

Repair open or shon in the wi.ebetween ECM {A12l and lAc valve.ls there battery voltage?

Check the IAC velve function:Momentarily connect ECM con-nector terminals A12 and A10with a jumper wire several times.

Does the IAC valve click?

Substitute a known-good ECMand rocheck. lf symptom/indica-tion goes away. replace the origi-nal ECM.

','*',,'Llu.9', I l112 15 16 17 1a1o20/

l--12u1 z"-if1za-2"' . '1 .

910

t-r '21

Wire side of female terminals

JUMPER WIRE

1-100

Page 305 of 1680

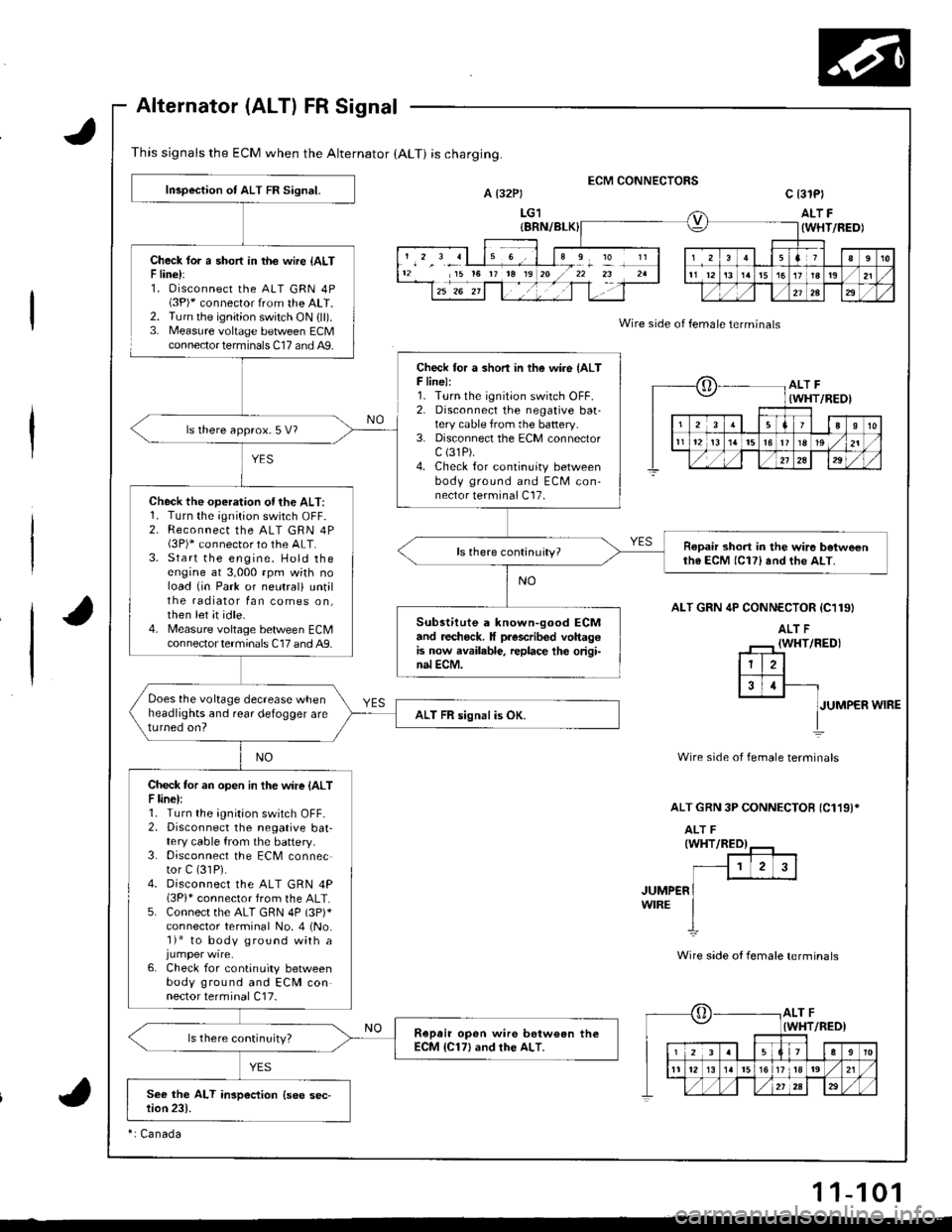

This signals the ECM when the Alternator (ALT) is charging.

Alternator (ALT) FR Signal

Check lor a short in th€ wire {ALTF line):1. Oisconnect the ALT GRN 4P(3P)* connector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECMconnector terminals C17 and A9.

ECM CONNECTORSA t32Pt

LG1

c 13lPl

ALT F(WHT/FEDI

Wire side of female terminals

ALT GRN 4P CONN€CTOR {C119}

JUMPER WIRE

Wire side of female terminals

ALT GRN 3P CONNECTOB {C119)*

JUMP€RWIRE

Wire side ot female terminals

12 15 t6 rr t8 19I

?

oALT F(WHT/REOI

23aI10

t112t3t5l6r819 ,/21

./,/,/2a29

[,ALT FIWHT/RED)

12339

11 12l517 tla19 ,/21

Inspection of ALT FR Signal.

Check for a shon in the wire {ALTF line):1. Turn the ignition switch OFF.2. Disconnecl the negative baatery cable from the battery.3. Disconnect the ECM connectorc (31P).

4. Check for continuity betweenbody ground and ECM con-nector terminal C17.

ls there approx.5 V?

Check the operation ofthe ALT:1. Turn the;Onition switch OFF-2. Reconnect the ALT GRN 4P(3P)* connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm wkh noload {in Park or neutral) untilthe radiator fan comes on,then let it idle.4. Measure voltage bet/veen ECMcon nector termina ls C17 and A9.

Ropair short in the wir6 betweenth6 ECM (C17) and the ALT.

Substitute a known-good ECMand recheck. It prescribed voltagGis now available, replace th€ origi-nal ECM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire {ALTF line):1. Turn the ignition switch OFF-2. Disconnect the negative bat-tery cable from the battery.3. Disconnect the ECM connector C (31P).

4. Disconnect the ALT GRN 4P(3Pi* connector from the ALT.5. Connect the ALT GRN 4P (3p)*

connector terminal No. 4 (No.'l)* to body ground with a

6. Check for continuity betweenbody ground and ECM connector terminal C17.

Ropair open wire bstw€an theECM {C17} and rhe ALT.ls there continuity?

ri Canada

11-101

Page 306 of 1680

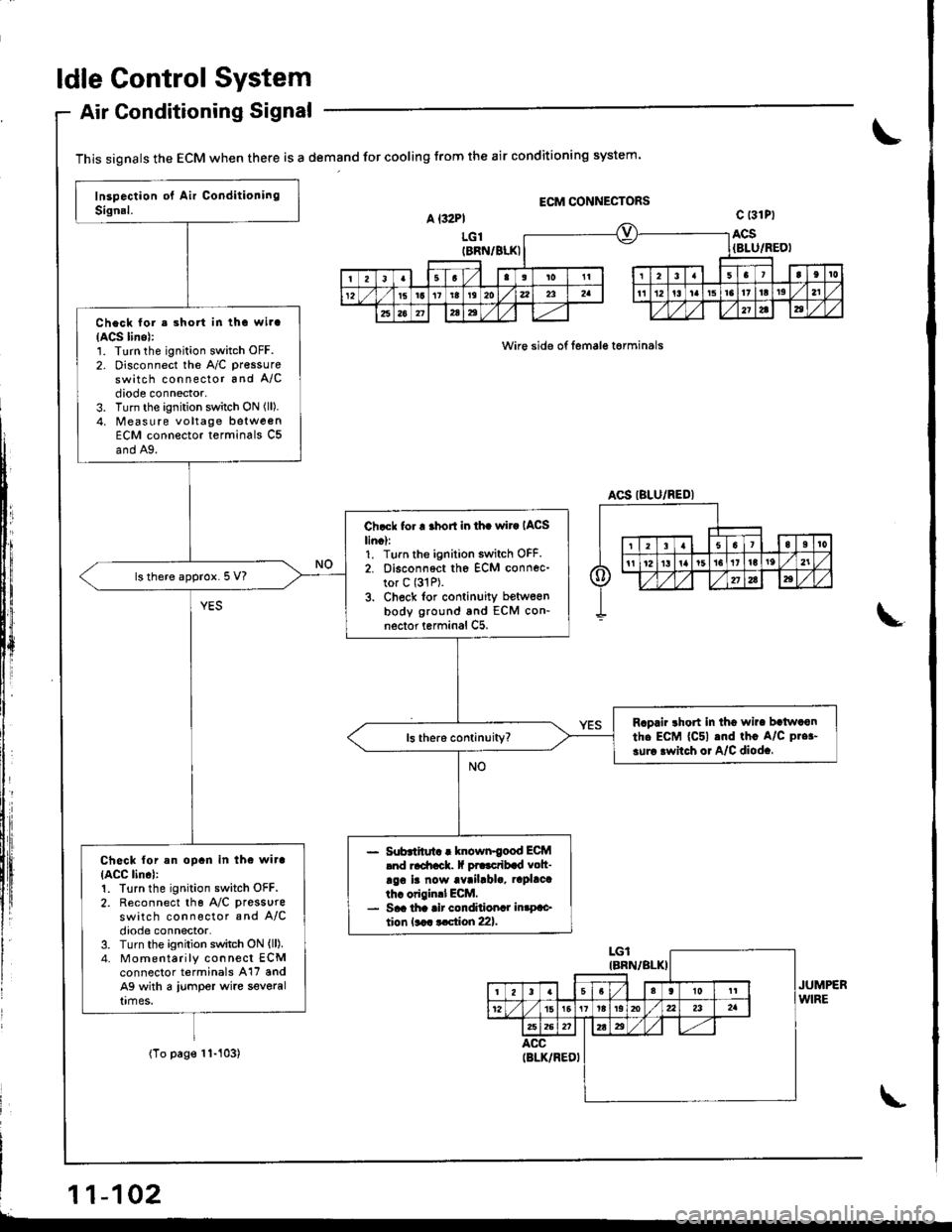

ldle

Air

Gontrol System

Gonditioning Signal

\

This signals the ECM when there is a demand for cooling from the air conditioning system'

ECM CONNECTORS

a l32Pl

LGl(BRN/BLKI

c t31Pt

ACSIBLU/REDI

wire side of femal€ torminals

;

L

LGI

JUMPERWIRE

ACS IBLU/REDI

Check lor.3hort in thG wira(ACS lino):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch connector and A/Cdiode connector,3. Turn the ignition switch ON (ll).

4. Measu re voltage betwo€nECM connector terminals C5and A9.

Ch.ck to.. rhorl in th. wir. IACSlincl:1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Ch6ck {or continuity betwe€n

body ground tnd ECM con-nector terminal C5.

lsthere approx.5 V?

Rapair rhort In tho wira batwaon

th. EcM {c5l and thc A/c pre.-

sur. rwitch ot A/C diod.,

- Subtlilut I known{ood Ecttllnd raahack. lf prtactibad voft-

rgo ir now avaihbla, tcplacalh. originll ECM.- Saa tha air condhiond in.plction 1... r.ction 221.

Check lor an opan in th€ wi.a(ACC lin.l:'1. Turn the ignition switch OFF.2. Reconnect th6 A,/C pressure

switch connector and A/Cdiode connector.3. Turn the ignilion switch ON (ll).

4. Momentarily connect ECMconnector terminals A'17 andAg wkh a iumper wire severaltimes,

(To page 11"103)

IBRN/BLKI

Ial,/l l8 I r0 I rl

12't516 11alrslzo ,/ l4l a3 | 2.

aa2621zel dt

IBLK/REDI

11-102

\

Page 307 of 1680

(From page t 1'102)

Ch6ck {or an op6n in the wireIACC linel:Mo m enta rily connect the A/Cclutch relay 4P connector termi-nal No. 4 to body ground with a,umper wire several times.

ls there a clicking noise fromthe A,/C compressor clutch?

ls there a clicking noise fromthe 4,./C compressor clutch?See air conditione. insoection{s€e section 22).

Repai. op6n in the wire betwe€ntho ECM lA17l and the A/C clutch

Check tor the oparation of theA/C:1. Start the eogine.2. Turn the blower switch ON.3. Turn the !y'C switch ON.

Check lor sn open in th6 wireIACS line):Measure voltage between ECMconnector terminals C5 and A9,

Air conditioning signal i3 OK.Repafu open in the wire betweenthe ECM {C5} and th€ A/C D.es-sure switch or A/C diode.

ls voltage less than 1.0 V?

- Substitute e known-good ECM.nd .echeck. lf 3ymptom/indi-cation goes away, rcplaco th€original ECM.- 56€ the air conditionor inspcc-tion {3eo soction 221.

UNDER HOOD FUSE/RELAYBOX 9P CONNECTOR tC216)

JUMPERWIREACC {SLK/RED)Wire side of temale- terminals

A {32P)

LGl(BRN/BLKI

ECM CONNECTORS

Wire side of female terminals

c (31P)

ACS{BLU/RED}

I

'1.1-103

Page 310 of 1680

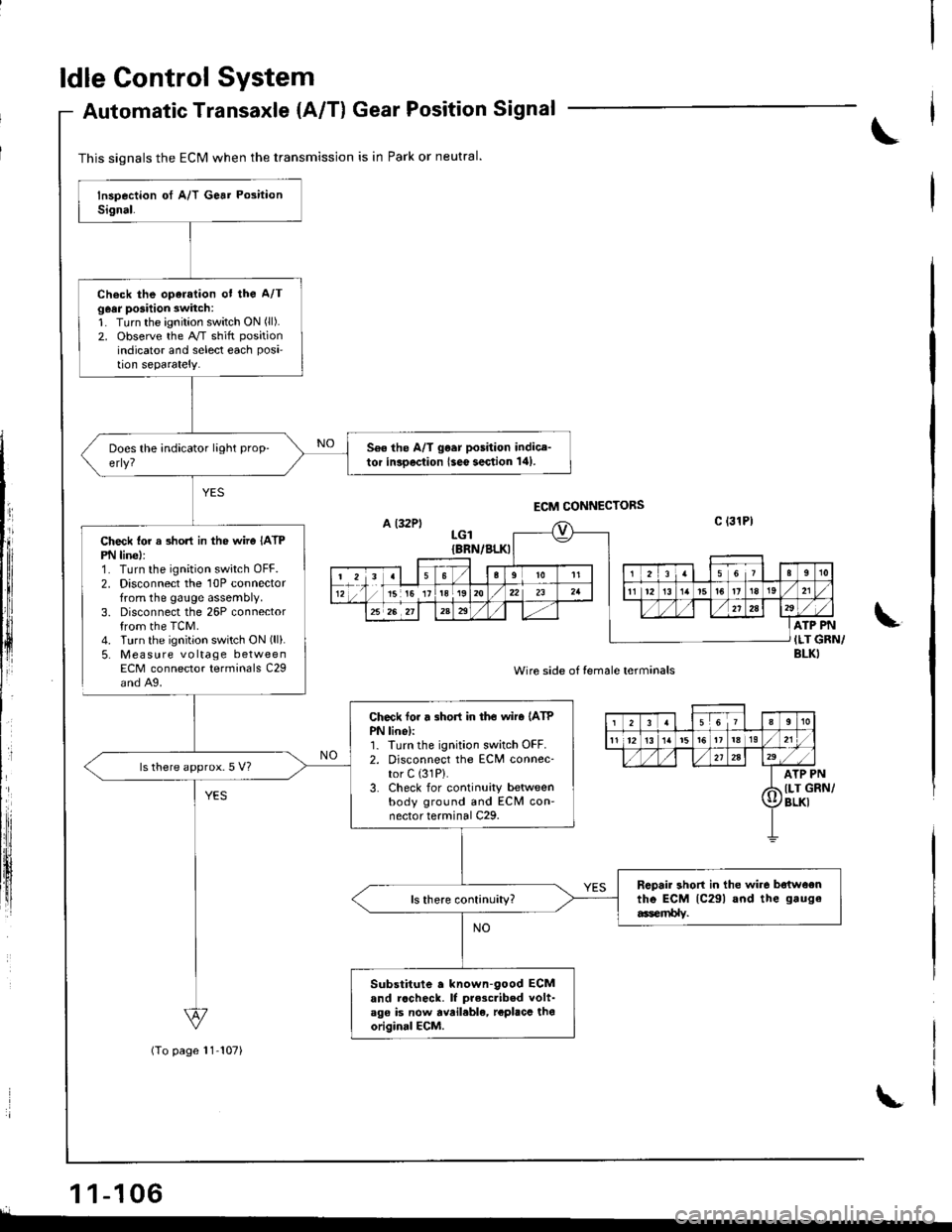

ldle Control System

Check lor a 3hon in the wiro IATPPN linel:1. Turn the ignition switch OFF.2. Disconnect the 10P connectorfrom the gauge assembly.3. Disconnect the 26P connectorfrom the TCM.4. Turn the ignition switch ON (ll).

5. Mea su re voltage betweenECM connector terminals C29and A9.

Automatic Transaxle {A/T) Gear Position Signal

1 1-106r.

This signals the ECM when the transmission is in Park or neutral.

(To page 11-107)

Check the oparation ot the A/Tg6ar posilion switch:1. Turn the ignition switch ON (ll).

2. observe the A/T shitt position

indicator and select each Posi'tion separately.

560 the A/T go.r position indice-tor inroection lseo section 141.

Check tor r 3hort in tho wiro (ATP

PN lino):1. Iurn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Check for continuity betweenbody ground and ECM con'nector terminal C29.

ls there approx.5 V?

Rcpair short in the wir6 batwoentho ECM lc29l and the gauge

6er$lv.

Substitute a known-90od ECMand rccheck. lf prescribed volt-ago is now avail.ble, rcplacc thooriginal ECM.

,PN

GRN/

LGIIBRN/BLKI

ATP PN

ILT GRN/BLKI

Wire side of temale terminals

12355It0

11 1213t319

2A29/,a

I ArP

d llr (

Il/BLKI

Page 313 of 1680

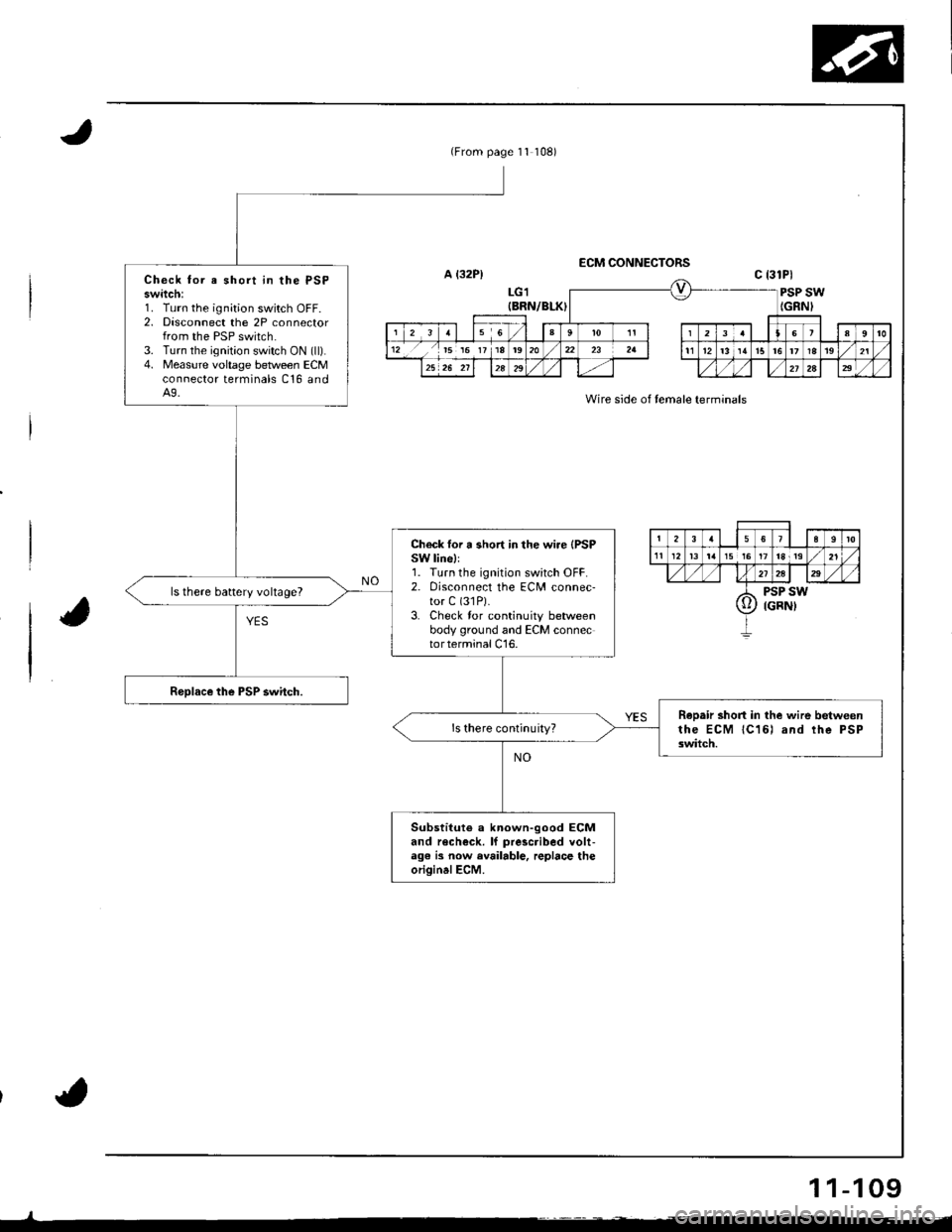

(From page 11 108)

Check tor e short in the PSPswitch:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorfrom the PSP switch.3. Turn the ignition switch ON (ll).4. Measure voltage between ECMconnector terminals C16 andA9.

Ch€ck for a short in the wire {PSPSW lihell1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor C (31P).

3. Check tor continuity betweenbody ground and ECM connectorterminalCl6.

ls there battery voltage?

ReDair short in the wire betweenthe ECM lC16) and lhe PSPswitch.

Substituto a known-good ECMand recheck. lf prescribed volt-a96 is now available, replace theoriginalECM.

A {32P)ECM CONNECTORS

Wire side of temale terminals

c 13lPl

LG1{BRN/BLK)PSP SWIGRNI

1 1-109

Page 327 of 1680

'*

1i

v3

I

l

i

I

1.

Testing

!@ Do not smoke during tho t€st. Keep open

flame away from your work area.

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is ON, you will hear

some noise it you hold your ear to the fuel fill pon with

the fuel fill cap removed. The fuel pump should run for

two seconds, when ignition switch is first turned on. lf

the fuel pump does not make noise, check as followsl

Remove the rear seat (see section 20).

Remove the access panel.

Disconnect the 2P connector from the tuel pump.

CAUTION: Be sure to turn the ignition switch OFF

before disconnecting the wires,

Connect the PGM-Fl main relay 7P connector termi-

nals No. 4 and No. 5 with a jumper wire.

PGM-FI MAIN RELAY CONNECTOR {C,14:}l

2.

3.

4.

5.

FUEL PUMP

{YEL/GRNI

IGN, 1

IYEL/GRN)

JUMPER WIRE

Wire side of female terminals

Check that battery voltage is available between the

fuel unit sub-harness connector terminal No. 2 and

body ground when the ignition switch is turned ON(

).

Wire side of female terminals

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK. replace the

fuel pump.

lf there is no voltage, check the wire harness (see

page 11'125).

FUEL PUMPCoNNECTOR 1C510)

L]l

lrl-r

6l FUEL PUMP

\:/ (YEL/GRNI

4.

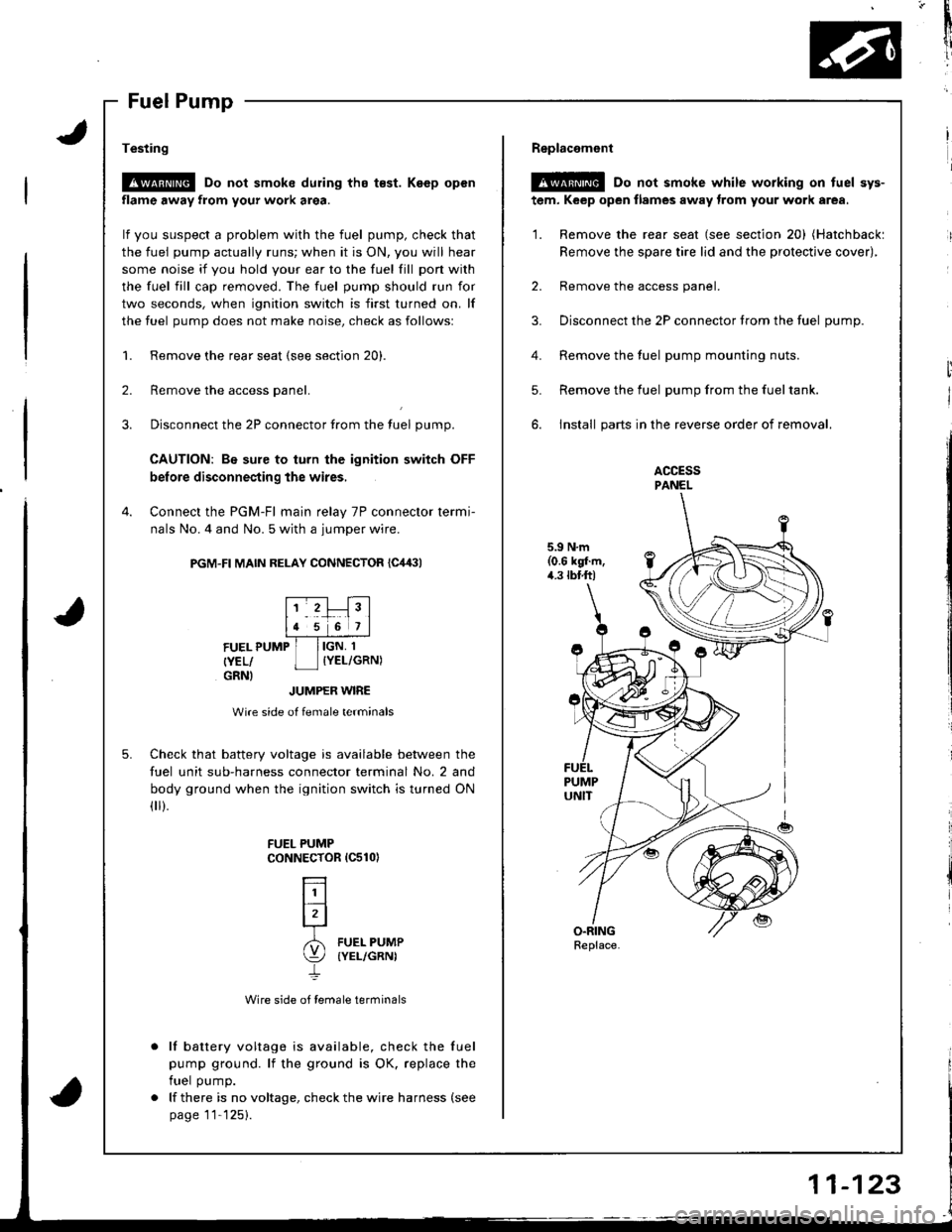

Replacemont

@ Do not smoke while working on tuel sys-

tem, Keep open flames away trom your work area.

'1. Remove the rear seat (see section 20) (Hatchbackl

Remove the spare tire lid and the protective cover),

2. Remove the access panel.

3. Disconnect the 2P connector trom the fuel oumD.

Remove the fuel pump mounting nuts.

Remove the fuel pump from the fueltank.

install parts in the reverse order of removal.

ACCESSPANEL

5.9 N.m(0.6 kgl.m,4.3 tbtft)

5.

Replace.