sub ACURA INTEGRA 1998 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 533 of 1680

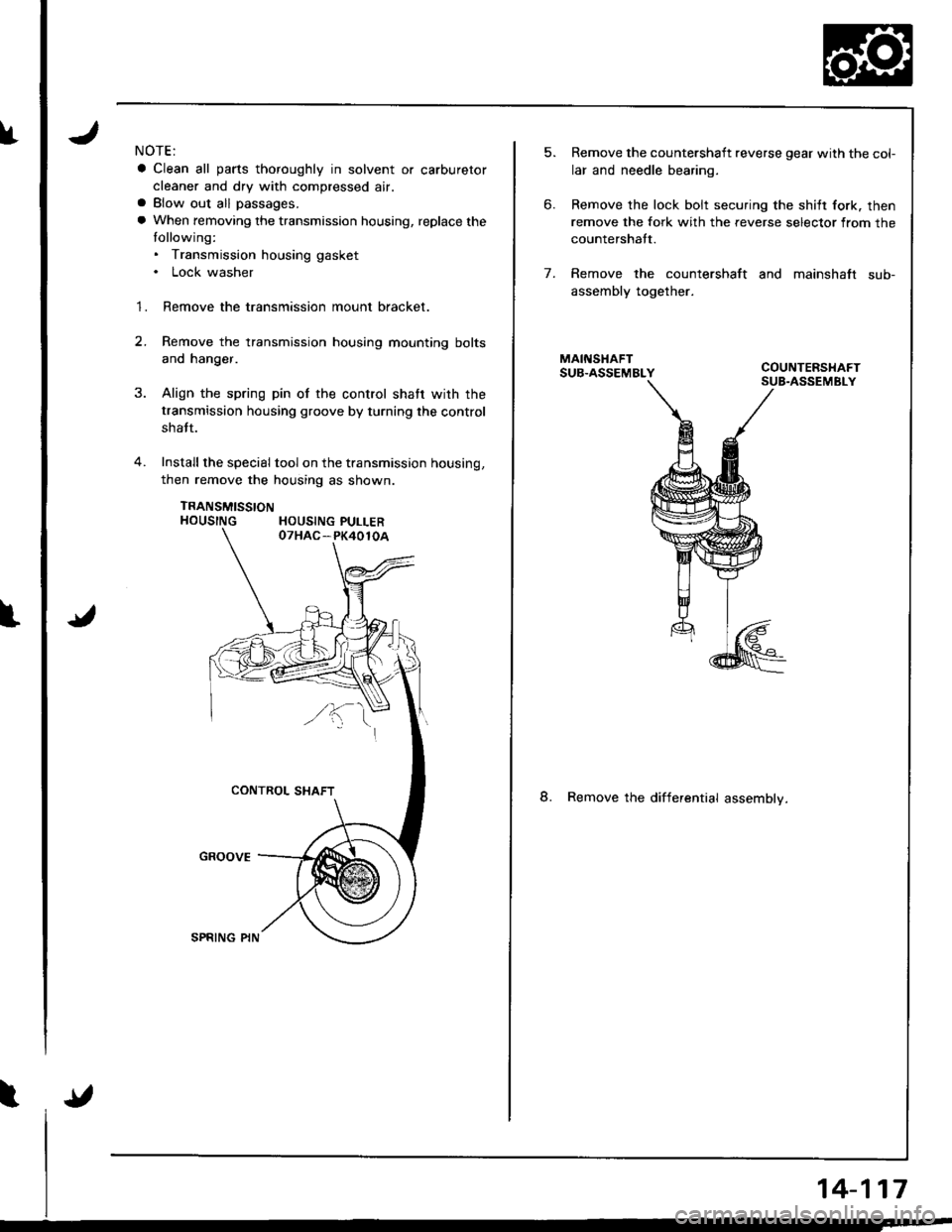

fNOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.a Blow out all passages.

a When removing the transmission housing, replace the

tollowing:. Transmission housing gasket. Lock washer

1. Remove the transmission mount bracket.

2.Remove the transmission housing mounting bolts

and hanger.

Align the spring pin of the control shatr wirh the

transmission housing groove by turning the control

shatt.

Install the special tool on the transmission housing,

then remove the housing as shown.

TRANSMISSTONHOUSING HOUSING PULLER

5.

6.

Remove the countershaft reverse gear with the col-

lar and needle bearing.

Remove the lock bolt securing the shilt fork. then

remove the fork with the reverse selector from the

countershatt.

Remove the countershaft and mainshaft sub-

assembly together.

8. Remove the differential assemblv.

7.

14-117

Page 554 of 1680

Countershaft

Disassembly/Reassembly (cont'dl

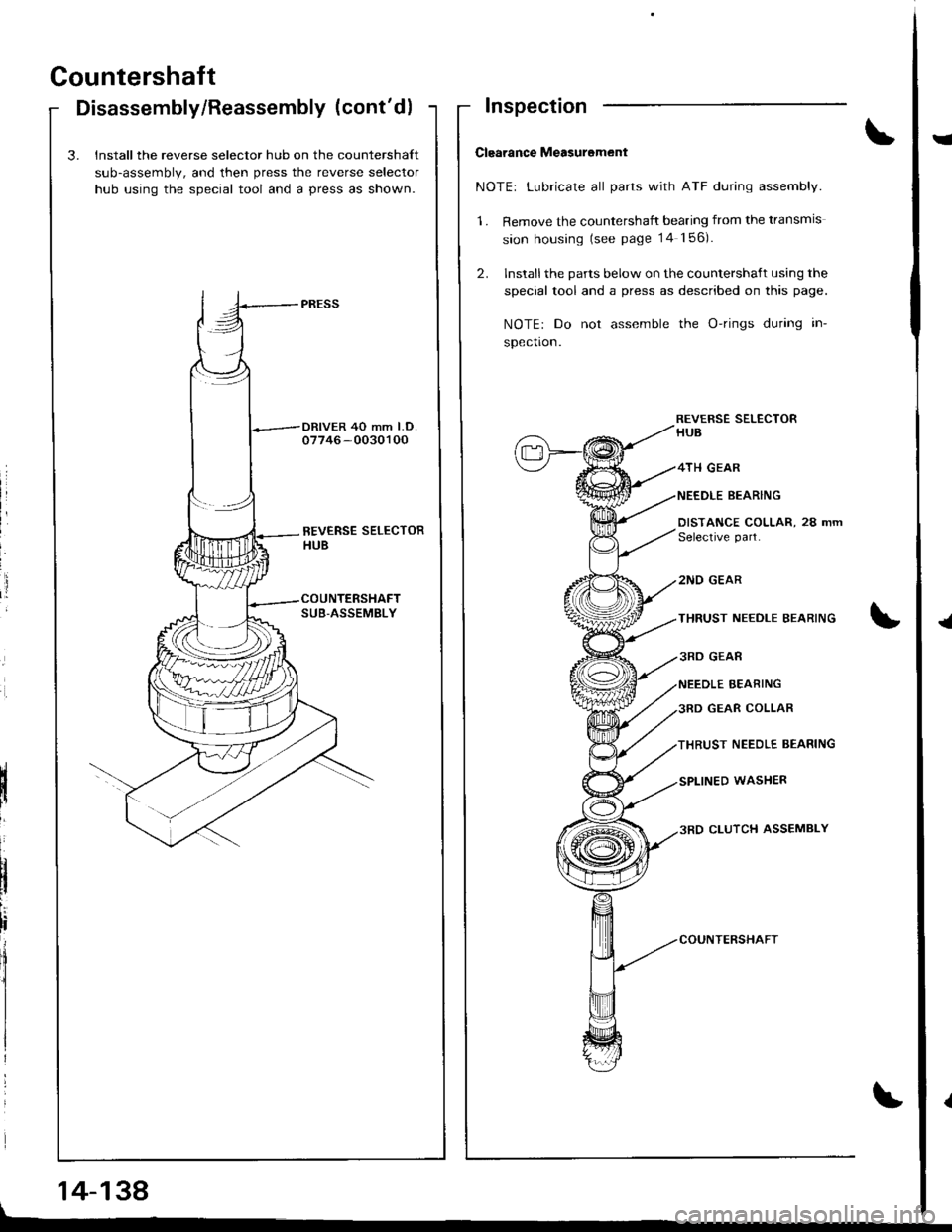

3. Install the reverse selector hub on the countershaft

sub-assembly, and then press the reverse selector

hub using the special tool and a press as shown.

Clearance Measurement

NOTEr Lubricate all parts with ATF during assembly.

1. Remove the countershaft bearing from the transmis

sion housing (see page 14 156).

2. lnstallthe parts below on the countershaft using the

special tool and a press as described on this page.

NOTE: Do not assemble the O-rings during an-

spection.

REVERSE SELECTORHUB

4TH GEAR

BEARING

DISTANCE COLLAR, 28 mmSelective part.

2ND GEAR

THRUST NEEDLE BEARING

3RO GEAR

THRUST NEEDLE BEARING

SPLINED WASHER

BEARING

GEAR COLLAR

CLUTCH ASSEMBLY

14-138

Page 555 of 1680

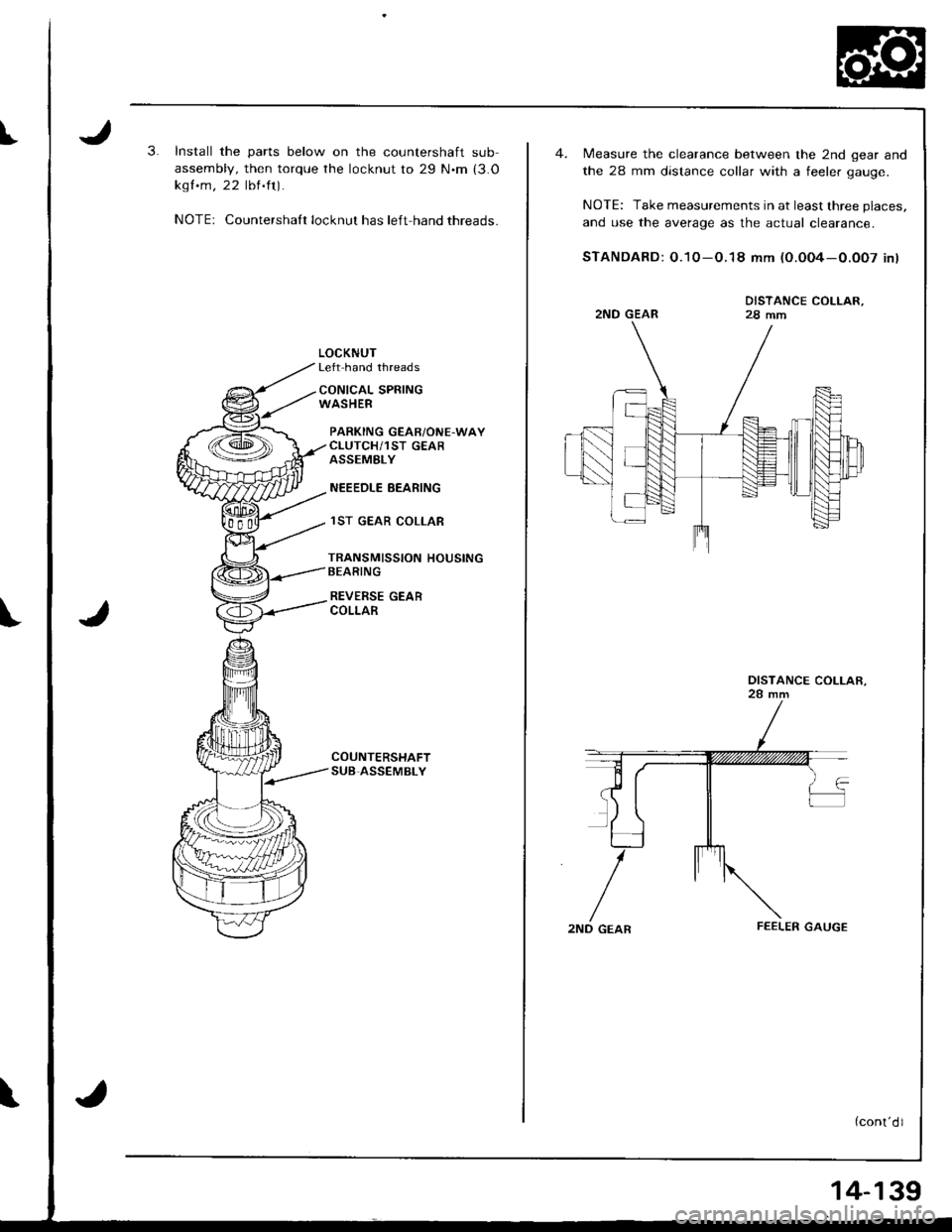

I3.Install the parts below on the countershaft sub

assembly, then torque the locknut to 29 N.m (3.O

kgf .m, 22 lbl'ft).

NOTE: Countershalt locknut has left hand threads.

LOCKNUTLeft hand threads

CONICAL SPRINGWASHEB

PARKING GEABiONE.WAYCLUTCH/1ST GEARASSEMELY

NEEEDLE EEARING

lST GEAR COLLAR

TRANSMISSION HOUSINGBEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB,ASSEMBLY

Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler oauoe.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: O.10-O.18 mm (O.0O4-O.OO7 inl

2ND GEARFEELER GAUGE

DISTANCE COLLAR,

DISTANCE COLLAR.

14-139

Page 558 of 1680

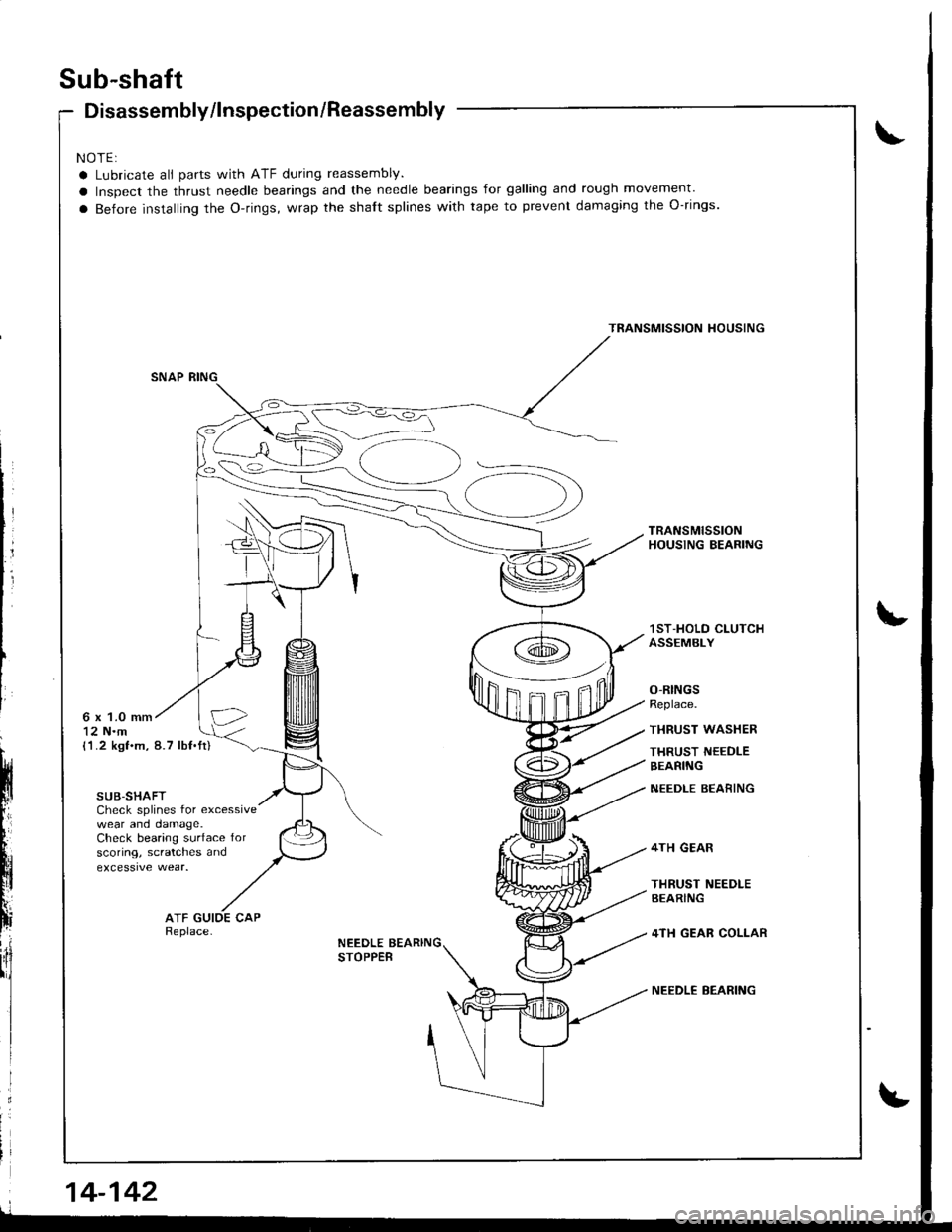

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

a Lubricate all parts with ATF during reassembly.

a Inspect the thrust needle bearings and the needle bearings for galling and rough movement'

a Before installing the o-rings, wrap the shaft splines with tape to prevent damaging the o-rings.

TRANSMISSION HOUSING

TRANSMISSIONHOUSING BEARING

1ST-HOLO C|-UTCHASSEMBLY

O-RINGSReplace.

THRUST WASHER

THRUST NEEDLEBEARING

NEEDLE BEARING

4TH GEAR

THRUST NEEDLEAEARING

4TH GEAR COLLAR

NEEDLE BEARING

6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbf.tt)

SUB-SHAFTCheck splines for excessivewear and oamage.Check bearing surface forscoring, scratches and

ATFReplace-NEEDLE BEARINGSTOPPEB

14-142

Page 559 of 1680

t

Disassembly/Reassembly

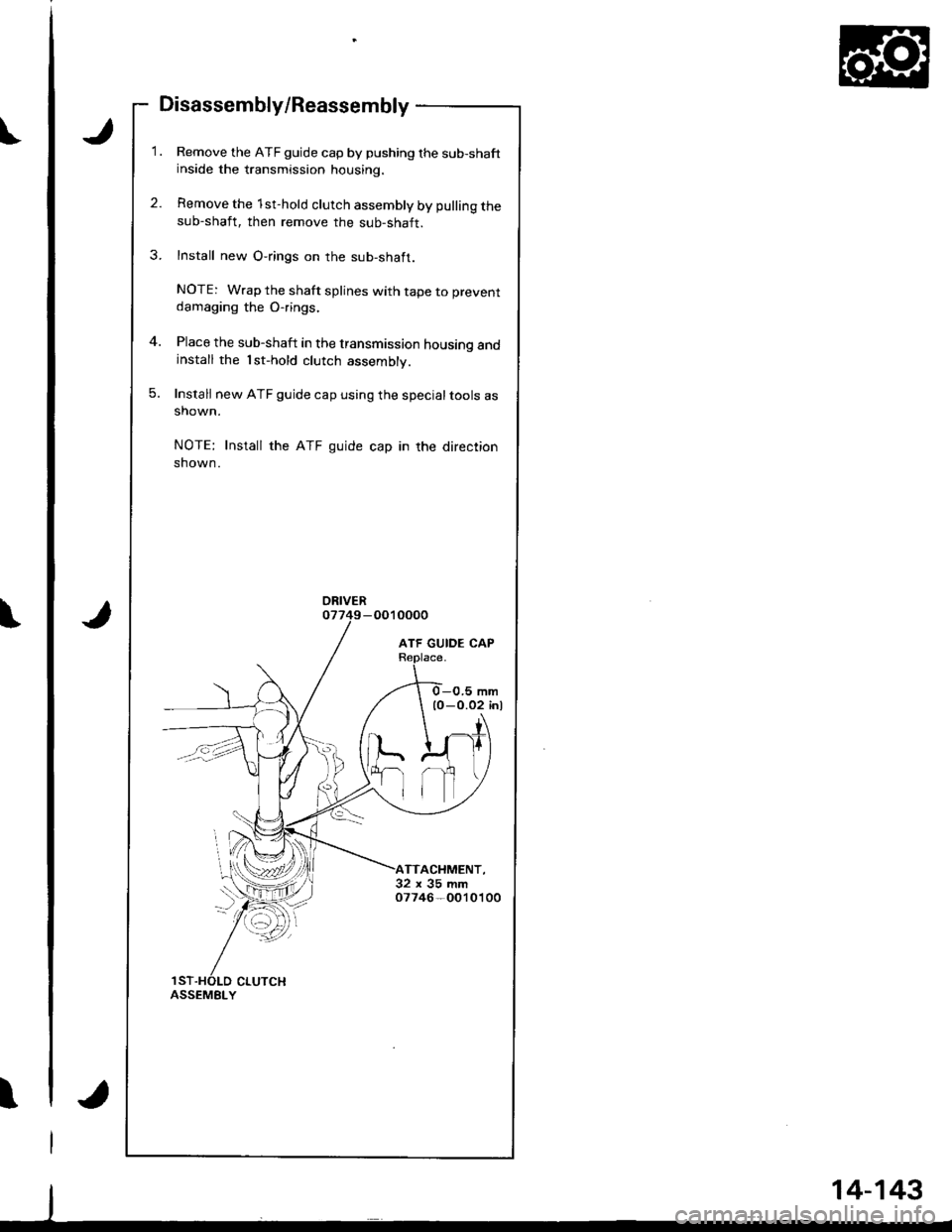

Remove the ATF guide cap by pushing the sub-shaftinside the transmission housing.

Remove the 1st-hold clutch assembly by pulling thesub-shaft, then remove the sub-shaft.

Install new O-rings on the sub-shaft.

NOTE: Wrap the shaft splines with tape to preventdamaging the Orings,

Place the sub-shaft in the transmission housing andinstall the 1st-hold clutch assembly.

Install new ATF guide cap using the specialtools asshown.

NOTE: Install the ATF guide cap in the direction

shown.

ORIVER

TTACHMENT,32x35mm07746-O010100

CLUTCHASSEMBLY

14-143

Page 560 of 1680

Sub-shaft Bearings

Replacement

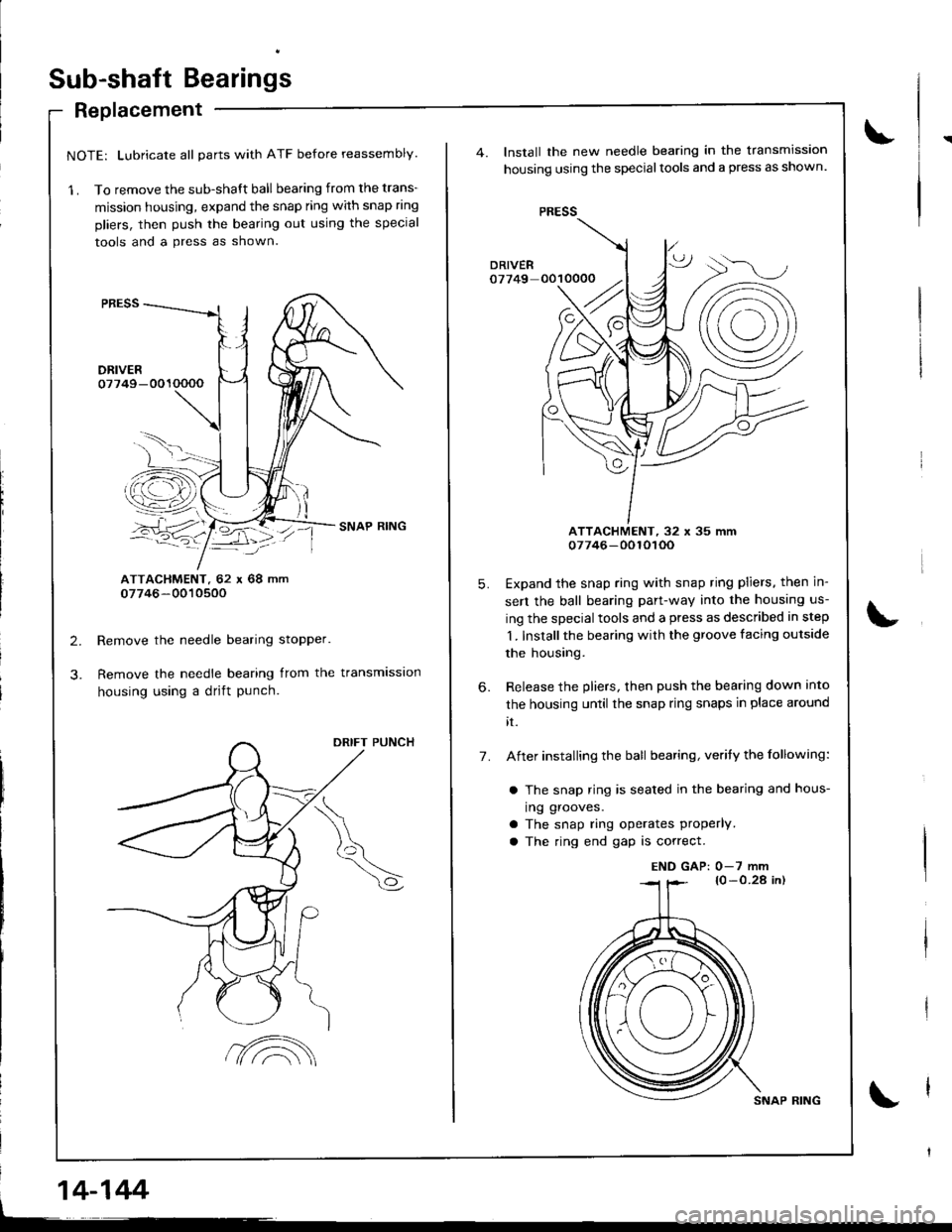

NOTE: Lubricate all parts with ATF before reassembly.

1 . To remove the sub-shaft ball bearing from the trans-

mission housing, expand the snap ring with snap ring

pliers, then push the bearing out using the special

tools and a press as shown.

ATTACHMENT. 62 r 68 mm07746-0010500

Remove the needle bearing stopper.

Remove the needle bearing from the transmission

housing using a drift punch.

DRIFT PUNCH

L

14-144

7A

SNAP RING

Install the new needle bearing in the transmission

housing using the specialtools and a press as shown.

PRESS

ATTACHMENT, 32 x 35 mm07746-0010roo

Expand the snap ring with snap ring pliers, then in-

sert the ball bearing part-way into the housing us-

ing the special tools and a press as described in step

1. Installthe bearing with the groove facing outside

the housing.

Release the pliers, then push the bearing down into

the housing until the snap ring snaps in place around

rt.

After installing the ball bearing, verity the following:

a The snap ring is sealed in the bearing and hous-

ing grooves.

a The snap ring operates Properly.a The ring end gap is correct.

5.

6.

7.

END GAP: 0-7 mm

Page 573 of 1680

JI

JI

)

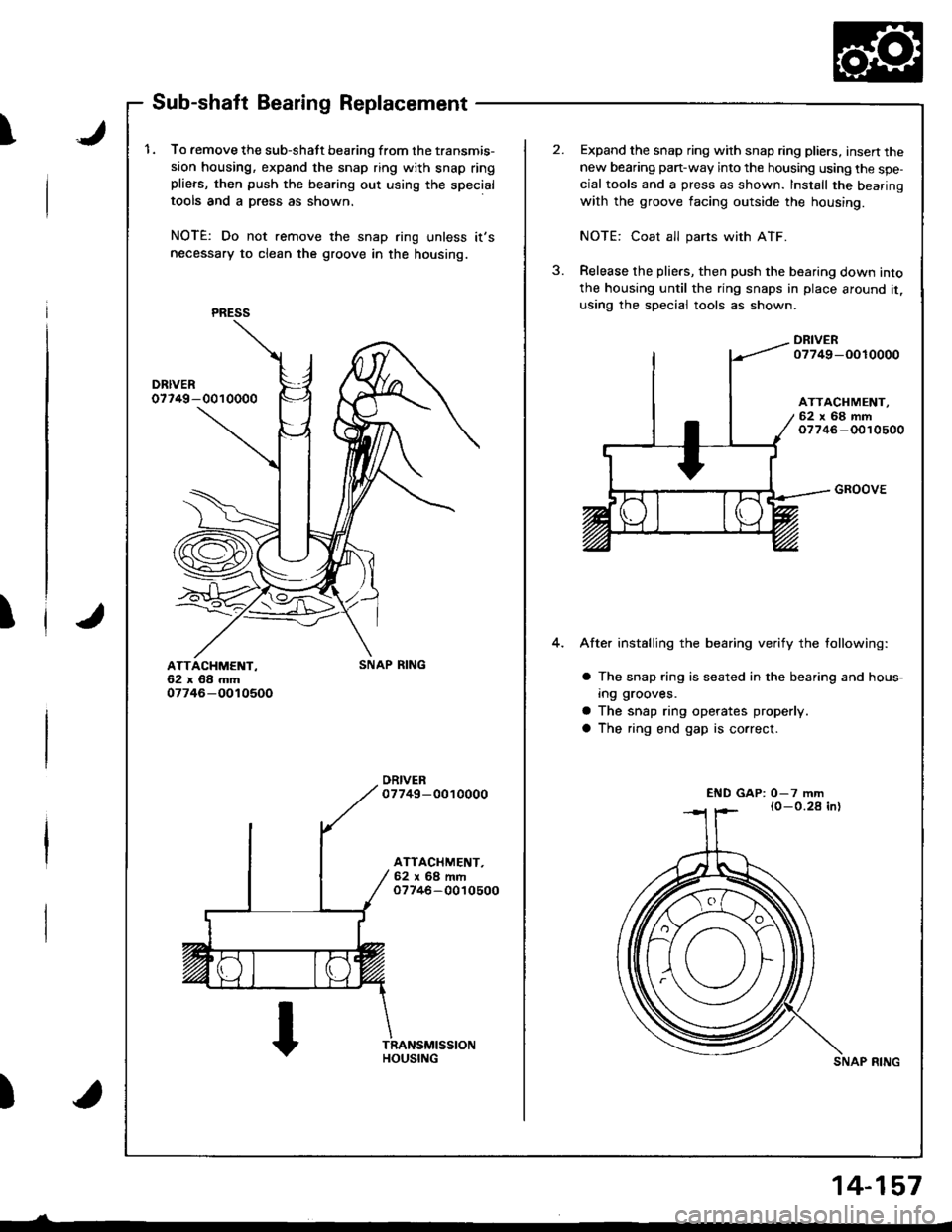

1.To remove the sub-shatt bearing from the transmis-

sion housing, expand the snap ring with snap ringplie.s, then push the bearing out using the special

tools and a Dress as shown.

NOTE: Do not remove the snap ring unless it's

necessary to clean the groove in the housing.

PRESS

ATTACHMENT-62r68mm07746-OOr 0500

SNAP RING

ATTACHMENT-62x68mm07746-0010500

Expand the snap ring with snap ring pliers, insert thenew bearing pan-way into the housing using the spe-cial tools and a press as shown. Install the bearing

with the groove facing outside the housing.

NOTE: Coat all pans with ATF.

Release the plie.s, then push the bearing down into

the housing until the ring snaps in place around it,using the special tools as shown.

DRIVER07749-OOlOO00

ATTACHMENT,62x68mm07746 -0010500

4.

GROOVE

After installing the bearing verify the following:

a The snap ring is seated in the bearing and hous-

ing grooves.

a The snap ring operates properlY

a The ring end gap is correct.

SNAP RING

END GAP: 0-7 mm

t

14-157

Page 577 of 1680

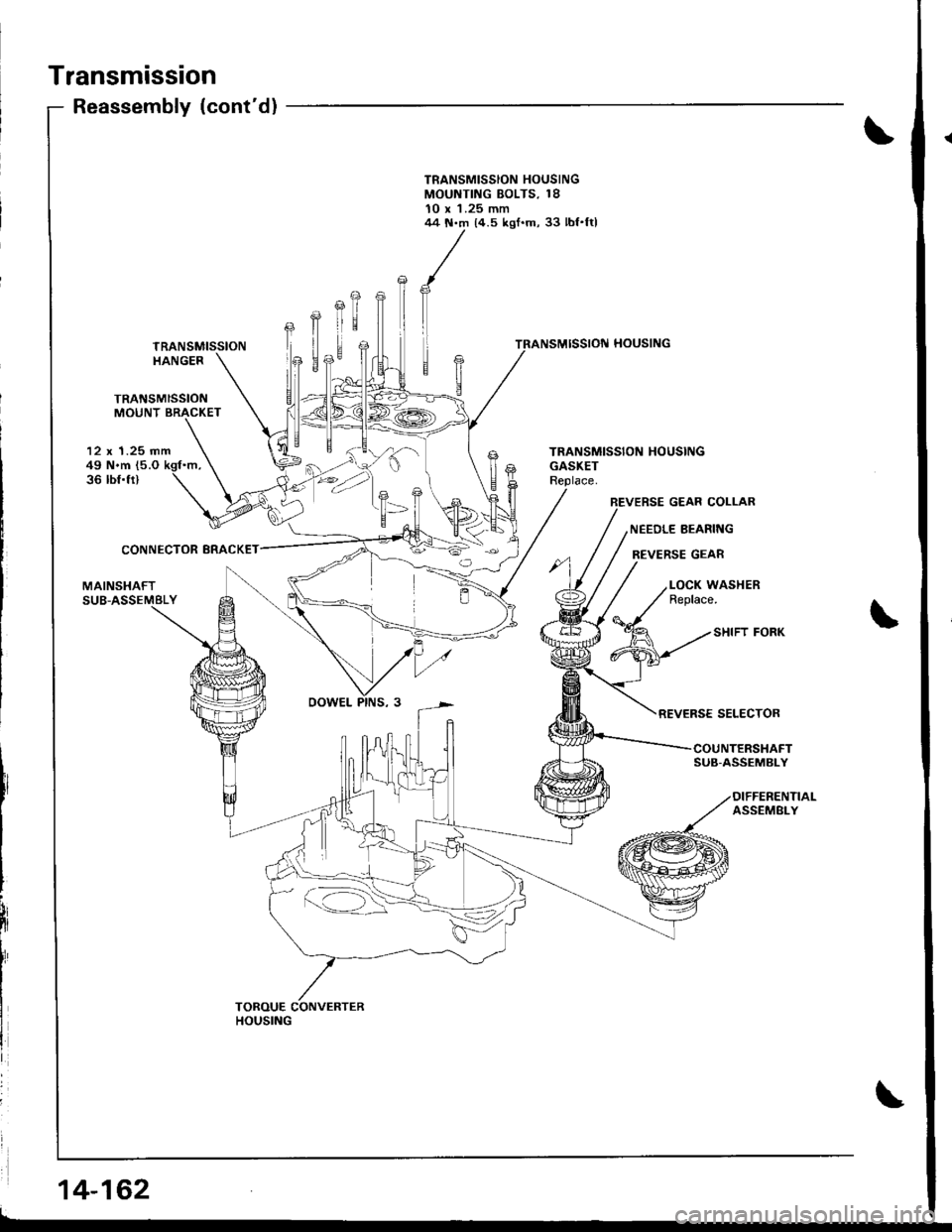

Transmission

TRANSMISSIONMOUNT BRACKET

Reassembly (cont'd)

TRANSMISSIONHANGER

Efr

E

12 x 1.25 mm49 N.m (5.O

36 tbf.fr)

CONNECTOR BRACKET

NEEDLE BEARII{G

REVERSE GEAR

MAINSHAFT

SHIFT FORK

REVERSE SELECTOR

SUB-ASSEMBLY

14-162

r=-42

TOROUE CONVERTERHOUSING

TRANSMISSION HOUSINGMOUNTING BOLTS, 1810 x 'l.25 mm44 N.m 14.5 kgf.m, 33 lbf.ftl

TRANSMISSION HOUSINGGASKET

BEVERSE GEAR COLLAR

LOCK WASHERReplace.

I

Page 578 of 1680

![ACURA INTEGRA 1998 Service Manual PDF 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in ACURA INTEGRA 1998 Service Manual PDF 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in](/img/32/56983/w960_56983-577.png)

18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

'19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in the torque con

verter housrng.

21. Assemble the mainshaft and countershaft sub-

assembly, then install them together in the torque

converler noustng.

22. Turn the shilt fork so the large chamlered hole is fac-

ing the fork bolt hole, then installthe shift tork with

the reverse selector and torque the lock bolt. Bend

the lock tab against the bolt head.

SHIFT FORK

23. Install the reverse gear with the collar and needte

bearing on the countershaft.

24. Align the spring pin of the control shaft with the

transmission housing groove by turning the control

shaft.

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins.

CONTROL

TRANSMISSION HOUSING

lnstall the transmission housing mounting bolts along

with the transmission hanger and the connector

bracket, then torque the bolts in two or more steps

in the sequence shown.

TOROUE: rt4 N'm (4.5 kgt.m, 33 lbt.lt)

TRANSMISSION

26.

LOCK WASHERReplace.

6 x 1.0 mm4 t{.m(1.4 kgf.m, 10

e

Large chamfered hole

/ -'K\,,

a

14-163

Page 579 of 1680

Transmission

SUB.SHAFT

MAINSHAFT

Reassembly {cont'd)

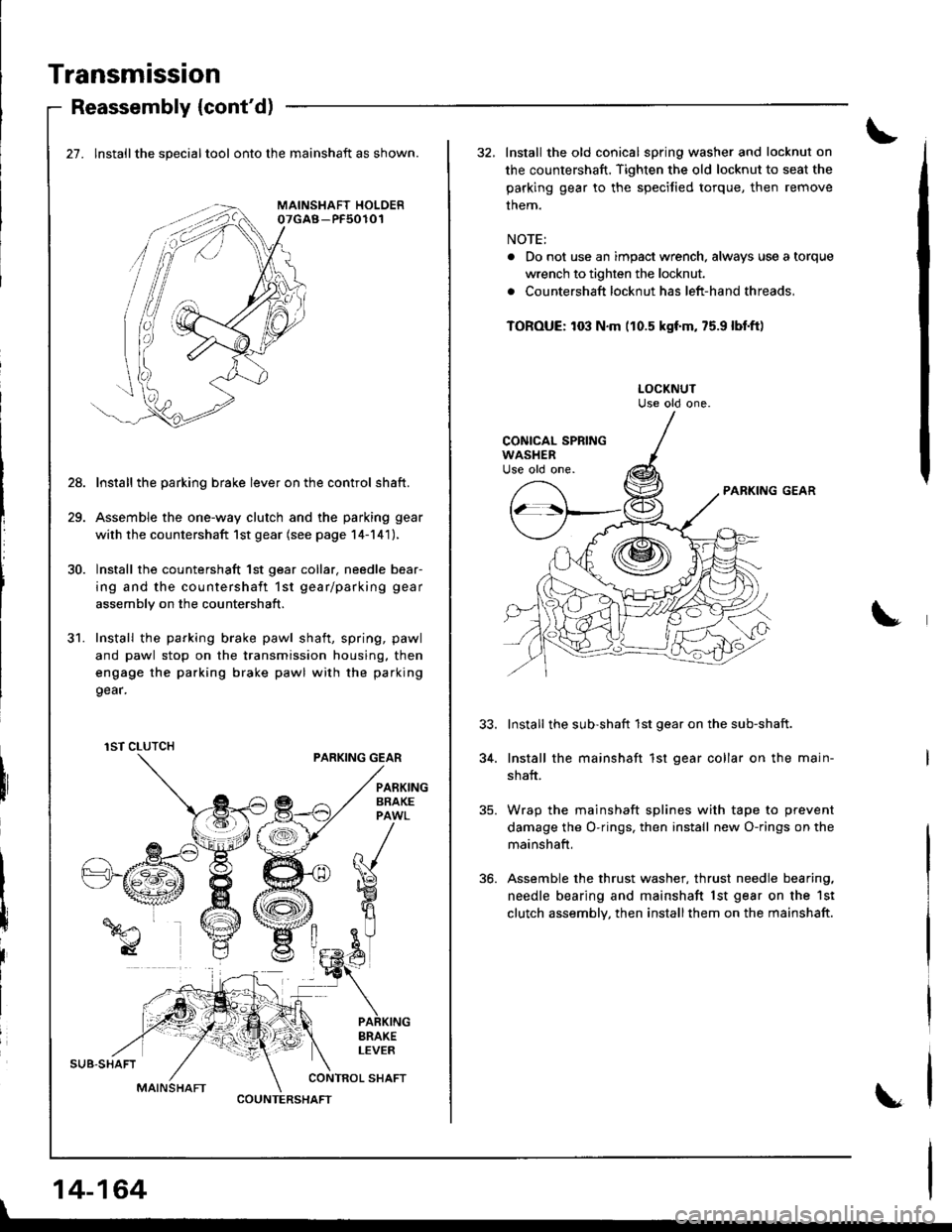

27. lnstallthe specialtool onto the mainshaft as shown.

Install the parking brake lever on the control shaft.

Assemble the one-way clutch and the parking gear

with the countershaft 1st gear (see page 14-141),

Install the countershaft 1st gear collar. needle bear-

ing and the countershaft 1st gear/parking gear

assembly on the countershaft.

Install the parking brake pawl shaft, spring, pawl

and pawl stop on the transmission housing. then

engage the parking brake pawl with the parking

9ear.

PARKING GEAR

28.

31.

I

I

iIBRAKELEVER

CONTROL SHAFT

1ST CLUTCH

COUNTERSHAFT

|

14-164

32, Install the old conical spring washer and locknut on

the countershaft. Tighten the old locknut to seat the

parking gear to the speciJied torque, then remove

them.

NOTE:

. Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Countershaft locknut has left-hand threads,

TOROUE: to3 N.m (10.5 kgf'm, 75.9 lbl.ft)

PARKING GEAR

Install the sub-shaft 1st gear on the sub-shaft.

Install the mainshaft 1st gear collar on the main-

shaft.

Wrap the mainshaft splines with tape to prevent

damage the O-rings, then install new O-rings on the

mainshaft,

Assemble the thrust washer, thrust needle bearing,

needle bearing and mainshaft lst gear on the 1st

clutch assembly, then installthem on the mainshaft.

34.