sub ACURA INTEGRA 1998 Service Manual Online

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 580 of 1680

)37.

38.

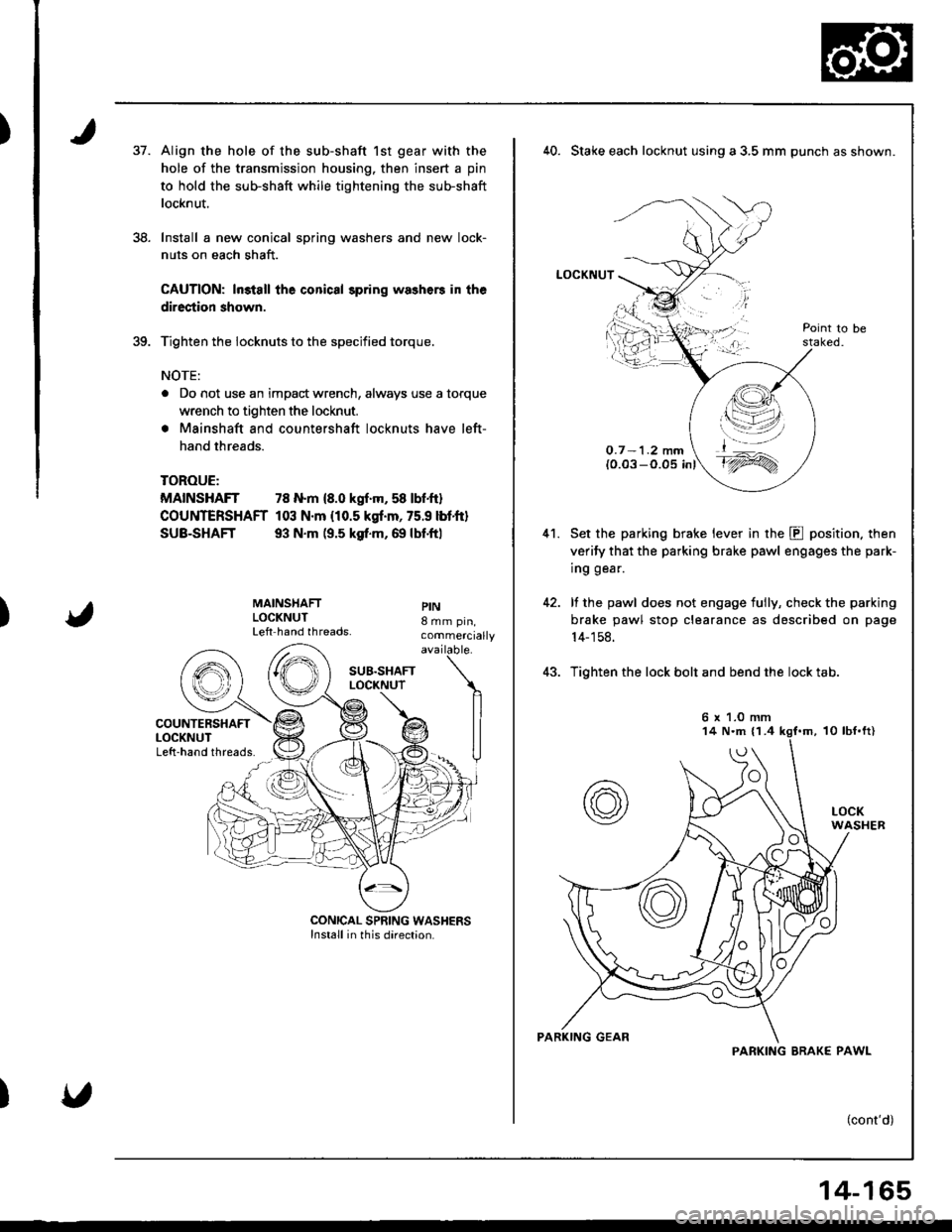

Align the hole of the sub-shaft 1st gear with the

hole of the transmission housing. then insert a pin

to hold the sub-shaft while tightening the sub-shaft

locknut.

Install a new conical spring washers and new lock-

nuts on each shaft.

CAUTION: ln3tall the conical spring washers in the

direction shown.

Tighten the iocknuts to the specified torque.

NOTE:

a Do not use an impact wrench, always use a torque

wrench to tighten the locknut.

. Mainshaft and countershaft locknuts have left-

hand threads.

TOROUE:

MAINSHAFT 78 N.m {8.0 kgf.m, 58 lbf.ft}

COUNTERSHAFT 103 N.m {10.5 kgf.m, 75.9 lbtft}

SUB-SHAFT 93 N.m (9.5 ksf.m, 69 lbf.ftl

)

MAINSHAFTLOCKNUTLeft hand threads.

PIN8 mm pin,commercially

40. Stake each locknut using a 3,5 mm punch as shown.

LOCKNUT

O.7 -1.2 mm(0.03 -O.05 inl

Set the parking brake lever in the E position. then

verify that the parking brake pawl engages the park-

ing gear.

lf the pawl does not engage tully, check the parking

brake pawl stop clearance as described on page

14- 1 58.

Tighten the lock bolt and bend the lock tab.

(cont'd)

41.

t,\--l--'-,4 l';-.-='/

t_^

t'1ry

6 x 1.0 mm

PARKING BRAK€ PAWL

14-165

Page 587 of 1680

Transmission

Cooler Flushing

S@ to pttvont iniury to face and syes' always

w6ar safety glassos or a face shield when using the trans-

mission flusher.

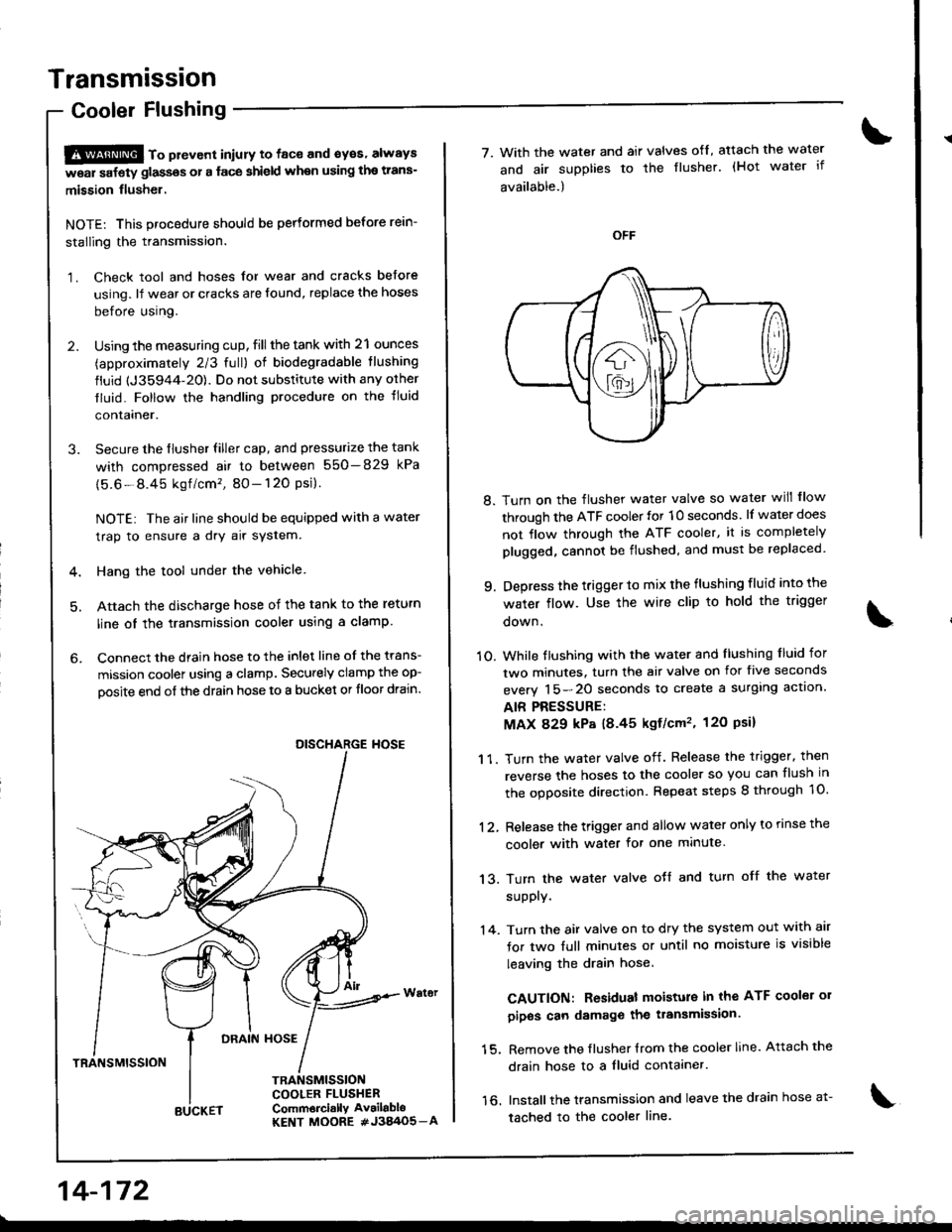

NOTE: This procedure should be performed before rein-

stalling the transmission.

1. Check tool and hoses for wear and cracks before

using. lf wear or cracks are found, replace the hoses

before using.

2. Using the measuring cup, fill the tank with 21 ounces

(approximately 2/3 full) of biodegradable tlushing

fluid {J35944-20). Do not substitute with any orher

tluid. Follow the handling procedure on the tluid

contalner.

3. Secure the flusher filler cap, and pressurize the tank

with compressed air to between 550-829 kPa

{5.6-8.45 kgf /cm'�, 80- 120 Psi}.

NOTE: The air line should be equipped with a water

trap to ensure a dry air system.

4. Hang the tool under the vehicle

5. Attach the discharge hose of the tank to the return

line oI the transmission cooler using a clamp

6. Connect the drain hose to the inlet line of the trans-

mission coolel using a clamp. Securely clamp the op-

oosite end of the drain hose to a bucket or tloor drain.

DRAIN HOSE

TRANSMISSION

TRANSMISSIONCOOLER FLUSHERComm6rci.llY Av.ilabloKENT MOORE #J3A/O5_A

DISCHARGE HOSE

14-172

BUCKET

7. With the water and air valves ofl, atach the water

and air supplies to the flusher. (Hot water if

available.)

8. Turn on the flusher water valve so water will flow

through the ATF cooler for 10 seconds. lf water does

not flow through the ATF cooler, it is completely

plugged, cannot be flushed, and must be replaced

9. Depress the trigger to mix the flushing fluid into the

water flow. Use the wire clip to hold the trigger

oown.

1O. While tlushing with the water and llushing f luid for

two minutes. turn the air valve on for five seconds

everv 15-20 seconds to create a surglng actlon.

AIR PRESSURE:

MAX 829 kP8 18.45 kgf/cm'�, 120 Psil

1 1. Turn the water valve off. Release the trigger. then

reverse the hoses to the cooler so you can flush in

the ooDosite direction. Repeat steps 8 through 1O.

12, Release the trigger and allow water only to rinse the

cooler with water for one minute.

13. Turn the water valve oJf and turn off the water

supply.

'14. Turn the air valve on to dry the system out with air

for two full minutes or until no moisture is visible

leaving the drain hose.

CAUTION: Residual moisture in the ATF coolei 01

pipos can damage the transmission.

15. Remove the flusher {rom the cooler line. Attach the

drain hose to a fluid contaaner.

16. Installthe transmission and leave the drain hose a1-

tached to the cooler line.

Page 590 of 1680

)

I

t

Shift Cable

Removal/lnstallation

CAUTION:

a All SRS wile ham€sses ar6 covcred with yollow insu-

lation. Befols you disconnect any part of an SRS wil6

harness, disconnect tho ailbag connoctors.

a Whenever th€ ignition switch is ON (ll), or has be€n

turned OFF for less than thr€e minutes, be caroful not

to bump tho SRS unit; tha airbags could accidentally

deploy and caus6 damags or iniuri€s.a For additional precautions, .ofer to th€ SRS sub-soction

!@! -u^" sure rrrs are praceq propeny rs€o

ssction 1).

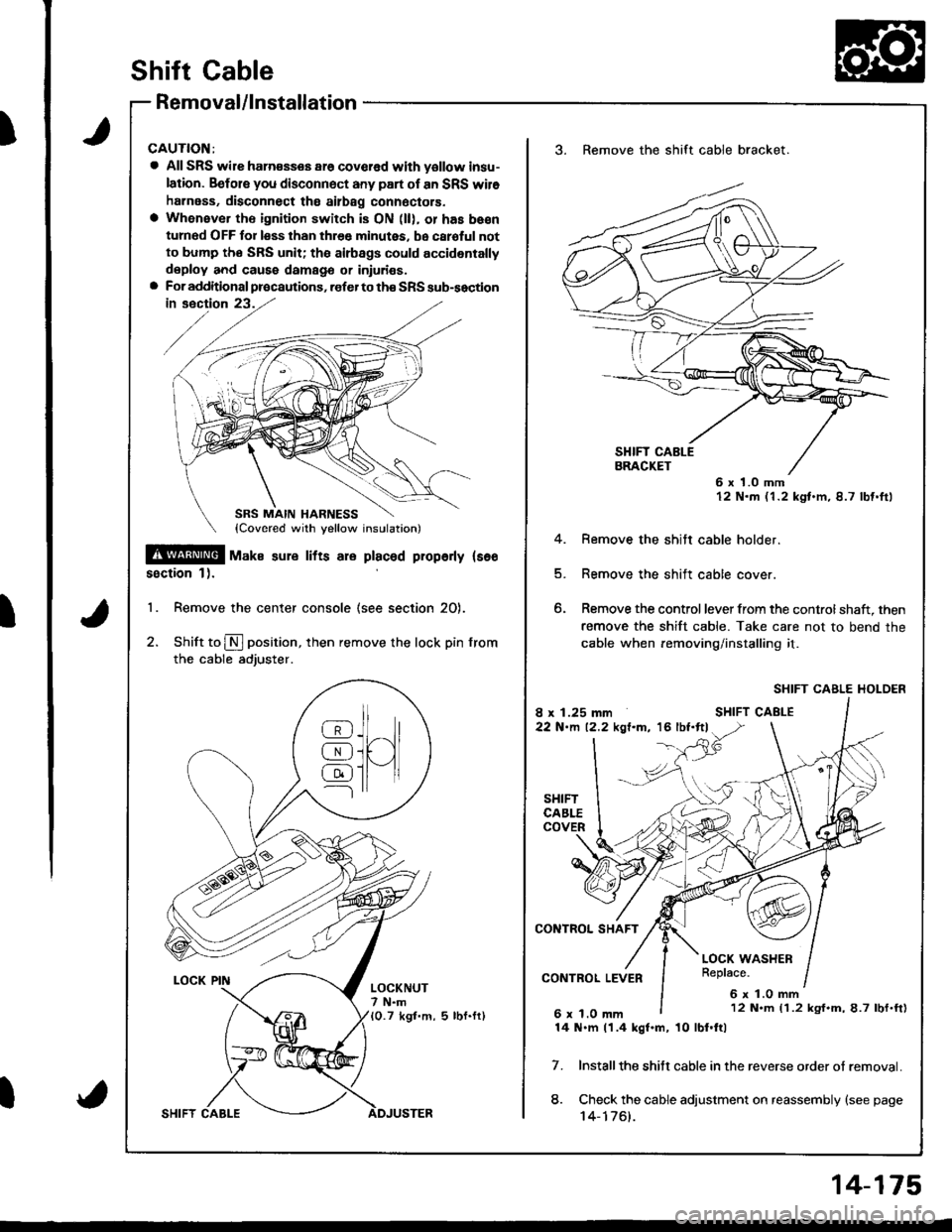

'1. Remove the center console (see section 20).

2. Shift to N position, then remove the lock pin from

the cable adjuster.

_llr_8J.ll^/l

@i[ )l

@ll-11---l rr

LOCKNUT7 N.m10.7 kgt.m, 5 lbf.fr)

3. Remove the shift cable bracket.

6 x 1.0 mm12 N.m (1.2 kgt.m,8.7 lbf.ftl

4. Remove the shitt cable holder.

5. Remove the shift cable cover.

6. Remove the control lever from the controlshaft, then

remove the shift cable. Take care not to bend the

cable when removing/installing it.

SHIFT CABLE HOLDER

Installthe shitt cable in the reverse order ot removal.

Check the cable adjustment on reassembly {see page't 4-1761.

7.

8.

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m 11.4 kgf.m, 10 lbl.ftl

14-175

Page 591 of 1680

Adiustment

CAUTION:

a All SRS wile harnesses are covered with yellow insu-

lation. Belore you disconnect any part ol an SRS wire

harness, disconnect the akbag connectors'

a Whenever the ignition switch is ON (ll), or has been

tumed OFF tol less than three minutes, be caletul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries'

a For additionalprecautions, referto the SRS sub-section

SBS MAIN HARNESS(Covered with yellow inslrlationl

$!@ rtl"t . "ure lifts are placed plope y lsee sec-

tion 1 l.

'1. Remove the center console lsee section 20)'

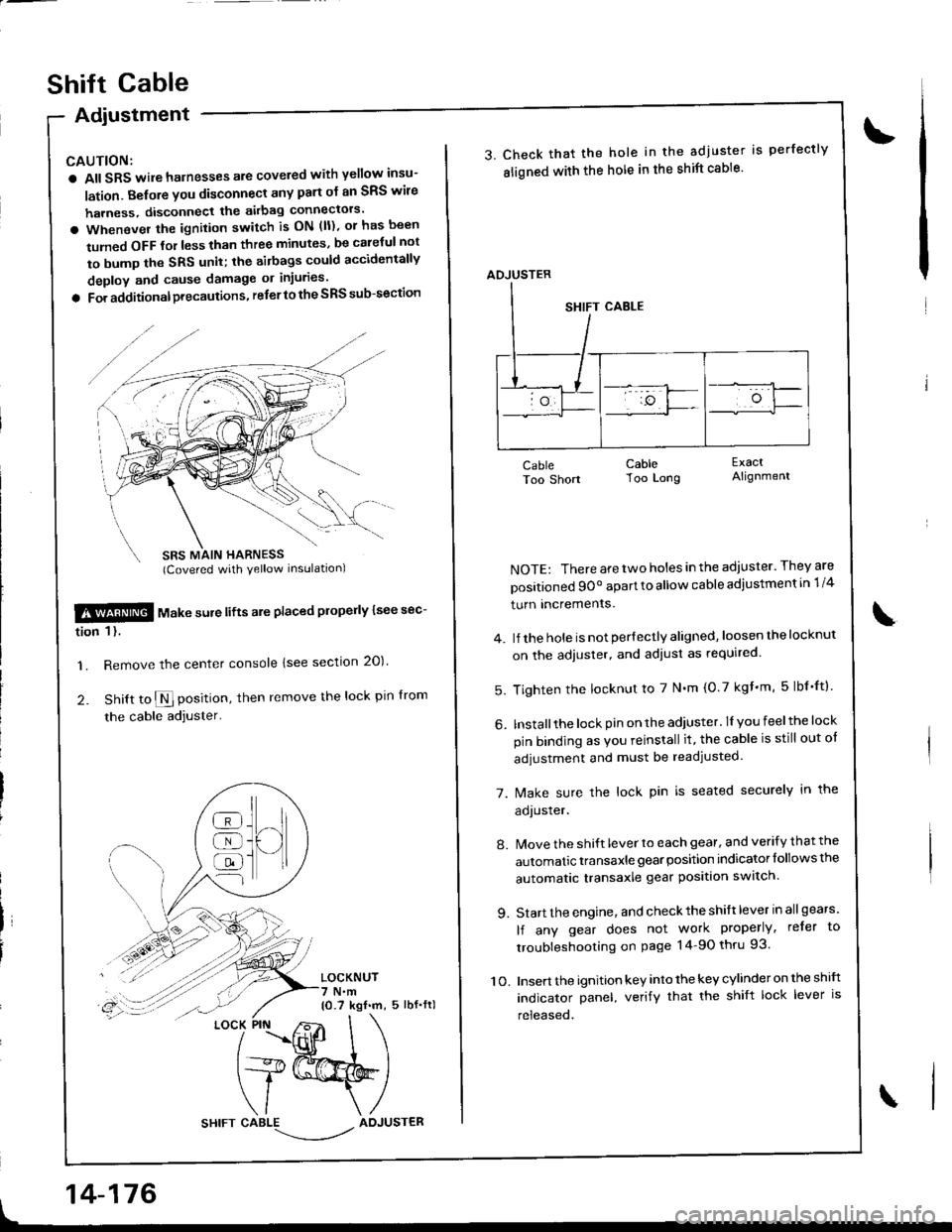

2. Snitt to $ position, then remove the lock pin lrom

the cable adjuster'

LOCKNUT7 N.m10.7 kgf.m, 5 lbf.fl)

t

]H

@

@

@

{l

LOCK PIN

14-176

shift cable

3. Check that the hole in the adjuster is perfectly

sligned with the hole in the shift cable'

CableToo Short

NOTE: There are two holes in the adjuster. They are

positioned 9Oo apart to allow cable adiustment in 1/4

turn Incremenrs.

4. lJ the hole is not per{ectly aligned, loosen the locknut

on the adjuster, and adiust as required.

5. Tighten the locknut to 7 N'm (0.7 kgf'm, 5lbf'ftl

6. Installthe lock pin on the adiuster. lI you feelthe lock

pin binding as Vou reinstall it, the cable is still out ot

adjustment and must be readjusted.

7. [/ake sure the lock pin is seated securely in the

aoJusrer.

8. Move the shift lever to each gear, and verify that the

automatic transaxle gear position indicator follows the

automatic transaxle gear position swatch.

9. Start the engine, and check the shift lever in allgears'

lf any gear does not work properly, refer to

troubleshooting on page 14-90 thru 93.

10. Insert the ignition key into the key cylinder on the shift

indicator panel, verify that the shift lock lever is

released.

CableToo Long

ExactAlignment

\

ADJUSTER

Page 592 of 1680

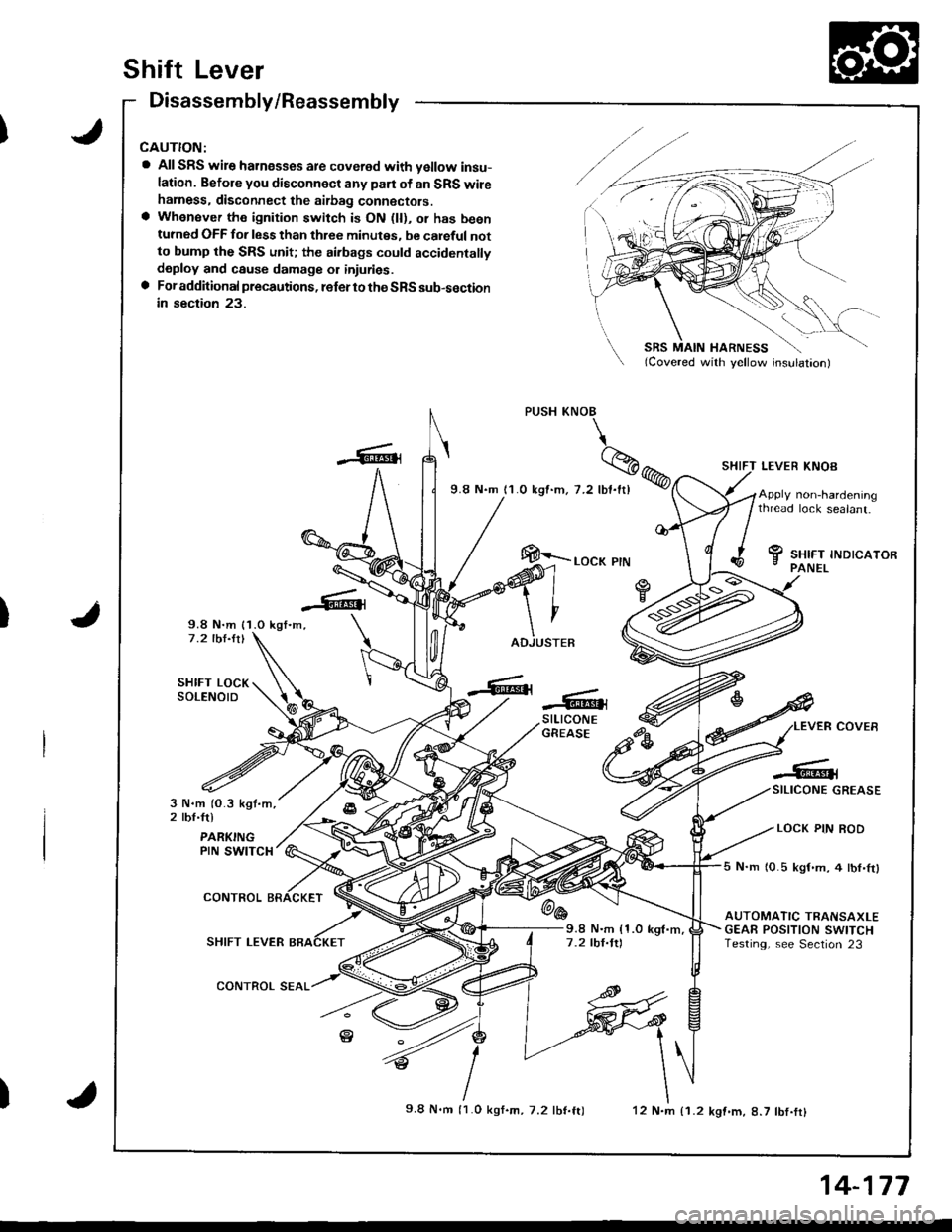

Shift Lever

Disassembly/Reassembly

a All SRS wire harnesses are covered with vellow insu-

lation. Befole you disconnect any part ol an SRS wileharness. disconnect the aitbag connectors.a Whensver the ignition switch is ON (ll), or has beenturned OFF for less than three minutes, be careful notto bump the SRS unit; the airbags could accidentallydeploy and cause damagg or iniuries.a For additional precautions, lefer to the SRS sub-sectionin section 23.

9.8 N.m {1.0 kgl.m,-7 .2 lbl.ltl

SHIFT LOCKSOLENOID

SHIFT LEVER KNOB

5 N.m 10.5 kgf.m,4lbl,Irl

AUTOMATIC TRANSAXLEGEAE POSITION SWITCHTesting, see Section 23

Apply non-hardeningthread lock sealant.

f, sxrrr rruorcaron- PANEL

PUSH KNOB

\

%

9.8 N.m 11.0 kgt.m. 7.2 lbl.ftl

@>.o"* r,"

-6{stLrcoNEGREASE

_GlSILICONE GREASE

' LOCK PIN ROD

3 N.m (O.3 kgt.m,2 tbt'trl

PARKINGPIN SWITCH

@6CONTROL

SHIFT LEVER

CONTROL SEAL

9.8 N.m (1.0 kgl.m,7 .2 tbl.ttl

)9.8 N.m l1.O kgf.m, 7.2 tbt.ft)12 N.m {1.2 kgf.m, 8.7 lbf.fr}

14-177

Page 593 of 1680

I

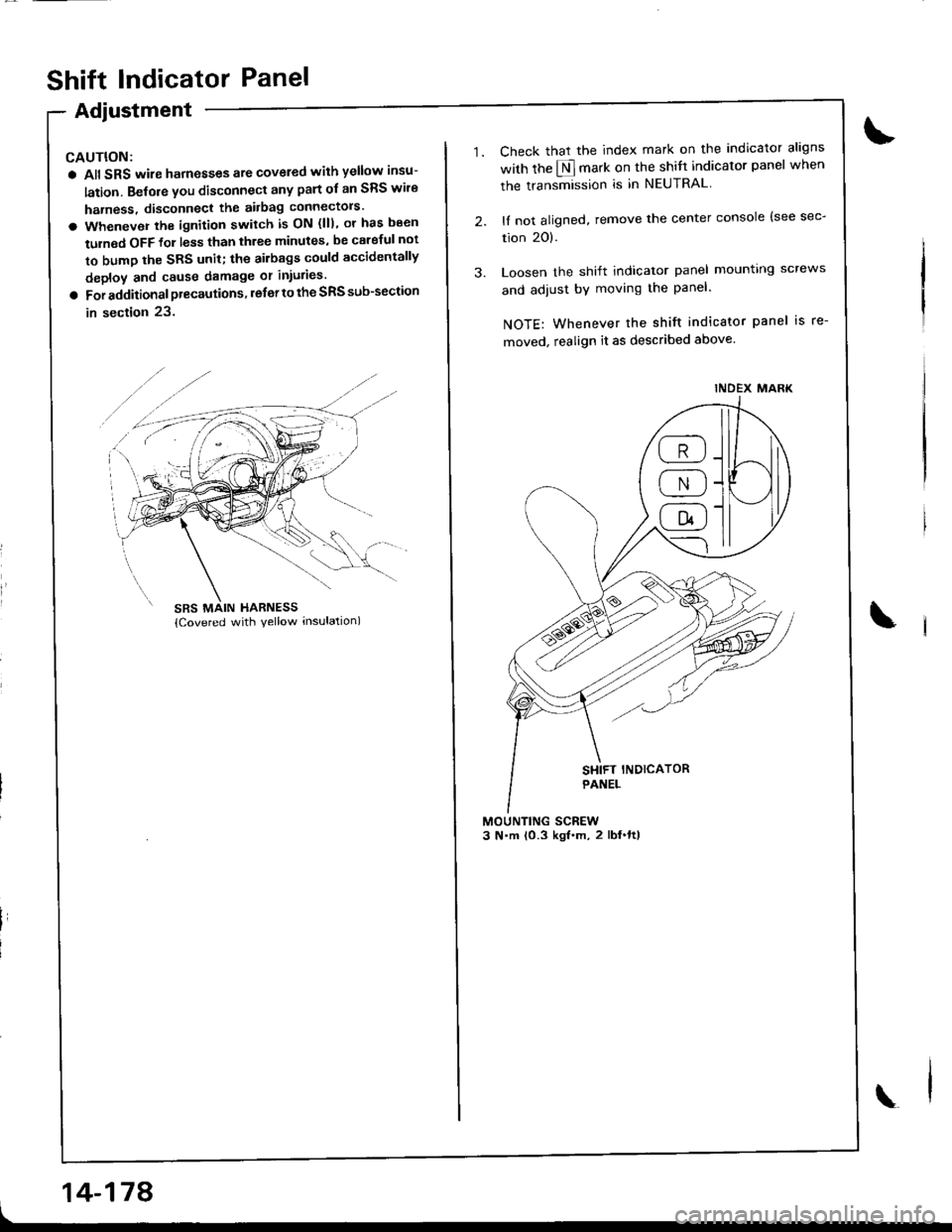

Shift lndicator Panel

Adjustment

CAUTION:

a All SRS wire harnesses ate covered with yellow insu-

lation. Belore you disconnect any part ol an SRS wire

harness, disconnect the airbag connectols'

a Whenever the ignition switch is ON (lll, ol has b€en

tulned OFF lo1 less than three minutes, be calgful not

to bump the SRS unit; the ailbags could accidentally

deploy and cause damage or iniulies.

a For additional precautions, lefer to the SRS sub-section

in section 23.

14-178

1.

3.

Check that the index mark on the indicator aligns

with the $ mark on the shitt indicator panel when

the transmission is in NEUTRAL

lI not aligned, remove the center console lsee sec-

tion 20).

Loosen the shift indicator panel mounting screws

and adiust by moving the Panel-

NOTE: Whenever the shift indicator panel is re-

moved, realign it as described above

INDEX MARK

a;-)\___ti_J -

@-

Page 613 of 1680

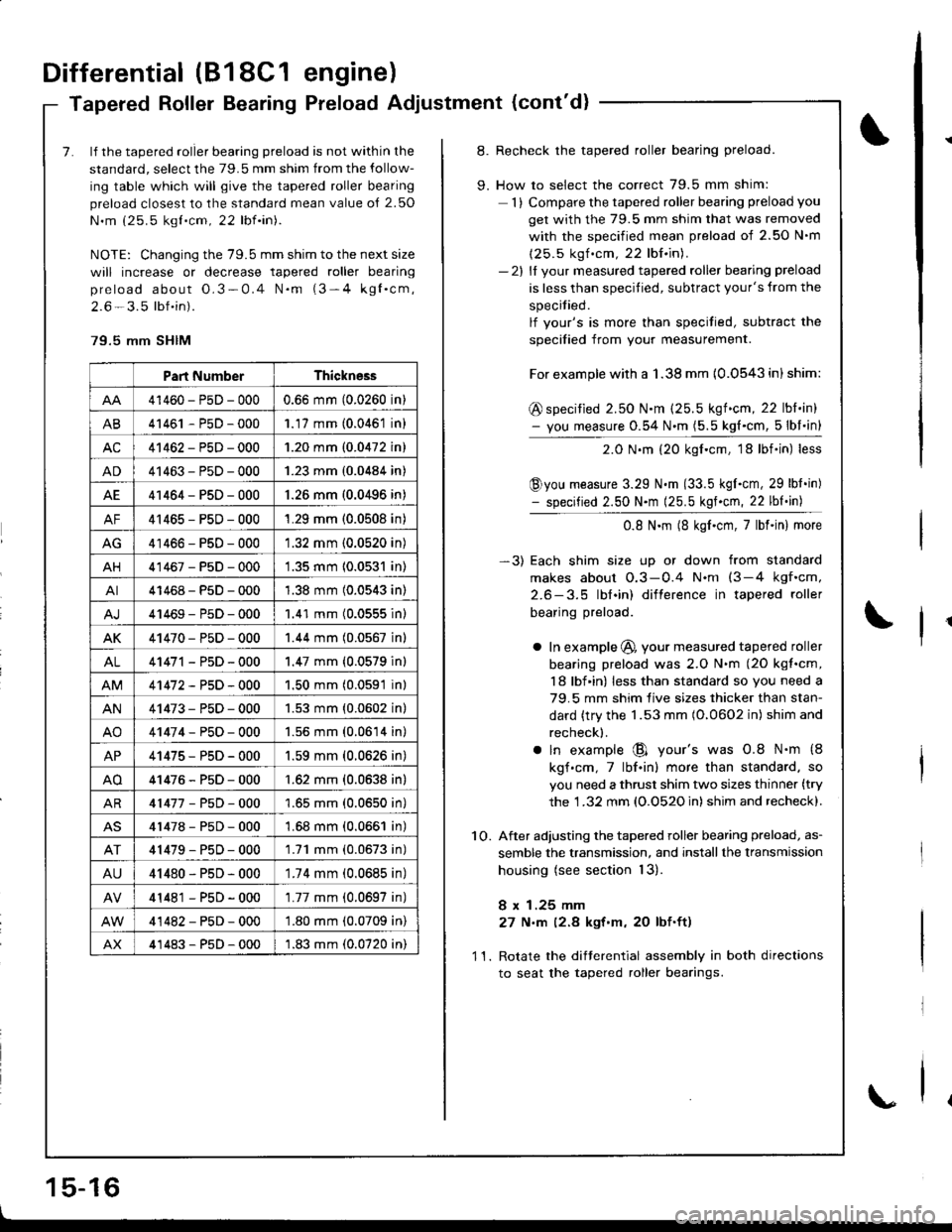

Differential

Ted Roll

(B18C1

er Bearinr

engine)

Preload Adjustment (cont'd)aperelng

7. lf the tapered roller bearing preload is not within the

standard, select the 79.5 mm shim from the follow-

ing table which will give the tapered roller bearing

preload closest to the standard mean value o{ 2.50

N.m (25.5 kgt.cm, 22 lbf.in).

NOTE: Changing the 79.5 mm shim to the next size

will increase or decrease tapered roller bearing

preload about O.3-0.4 N.m (3-4 kgl.cm,

2.6 - 3.5 lbf.in).

79.5 mm SHIM

Part NumberThickness

41460-PsD-0000.66 mm (0.0260 in)

AB41461 - P5D - 0001.17 mm (0.0461 in)

AC41462-PsD-0001.20 mm (0.0472 in)

AD41463-P5D-0001.23 mm (0.0484 in)

AE41464-PsD-000'1.26 mm (0.0496 in)

AF41465-PsD-0001.29 mm (0.0508 in)

AG41466-PsD-0001.32 mm (0.0520 in)

AH41467-PsD-0001.35 mm 10.0531 in)

AI41468-PsD-0001.38 mm (0.0543 in)

41469-P5D-0001.41 mm (0.0555 inl

AK41470-PsD-0001.44 mm (0.0567 in)

AL41471 - PsD - 000'1.47 mm {0.0579 in}

41472-P5D-0001.50 mm (0.0591 in)

AN41473-PsD-0001.53 mm {0.0602 in}

AO41474-P50-0001.56 mm (0.0614 in)

AP41475-PsD-0001.59 mm (0.0626 in)

AO41476-P5D-000'1.62 mm {0.0638 in}

AR41477-P5D-0001.65 mm (0.0650 in)

41478-P5D-0001.68 mm (0.0661 in)

41479-P50-0001.71 mm (0.0673 in)

AU41480-PsD-0001.74 mm (0.0685 in)

41481 - PsD - 000'1.77 mm (0.0697 in)

41482-PsD-000'1.80 mm (0.0709 in)

AX41483-P5D-0001.83 mm (0.0720 in)

8. Recheck the tapered roller bearing preload.

9. How to select the correct 79.5 mm shim:

1) Compare the tapered roller bearing preload you

get with the 79.5 mm shim that was removed

with the soecified mean Dreload of 2.50 N'm

(25.5 kgf .cm, 22 lbf.in).- 2l ll vour measured tapered roller bearing preload

is less than specified, subtract your's from the

specitied.

lf vour's is more than specitied, subtract the

soecified from vour measurement.

For example with a 1.38 mm {0.0543 in) shim:

@ specified 2.50 N.m (25.5 kgf.cm, 22 lbl.in)- you measure 0.54 N.m (5.5 kg{.cm, 5lbl.in}

2.0 N.m (20 kgf.cm, 18lbf.in) less

@you measure 3.29 N.m (33.5 kgI.cm, 29 lbt.in)- specified 2.50 N.m (25.5 kgf.cm, 22 lbf.in)

0.8 N.m (8 kgf.cm,7lbf.in) more

-3) Each shim size up or down from standard

makes about O.3-0.4 N.nt (3-4 kgf.cm,

2.6-3.5 lbl.in) difterence in tapered roller

bearing preload.

a In example @, your measured tapered roller

bearing preload was 2.O N.m (2O kgt.cm,

18 lbf in) less than standard so you need a

79.5 mm shim live sizes thicker than stan-

dard {try the 1.53 mm (O.0602 in) shim and

recheck).

a ln example @ your's was 0.8 N.m {8

kgf.cm,7lbf.in) more than standard. so

you need a thrust shim two sizes thinner (try

the 1 .32 mm (O.O52O in) shim and recheck).

1O. After adjusting the tapered roller bearing preload, as-

semble the transmission, and installthe lransmission

housing (see section 13).

8 x 1.25 mm

27 N,m (2.8 kgt'm, 20 lbf.ft)

11. Rotate the difterential assembly in both directions

to seat the tapered roller bearings.

1 5-16

\

Page 622 of 1680

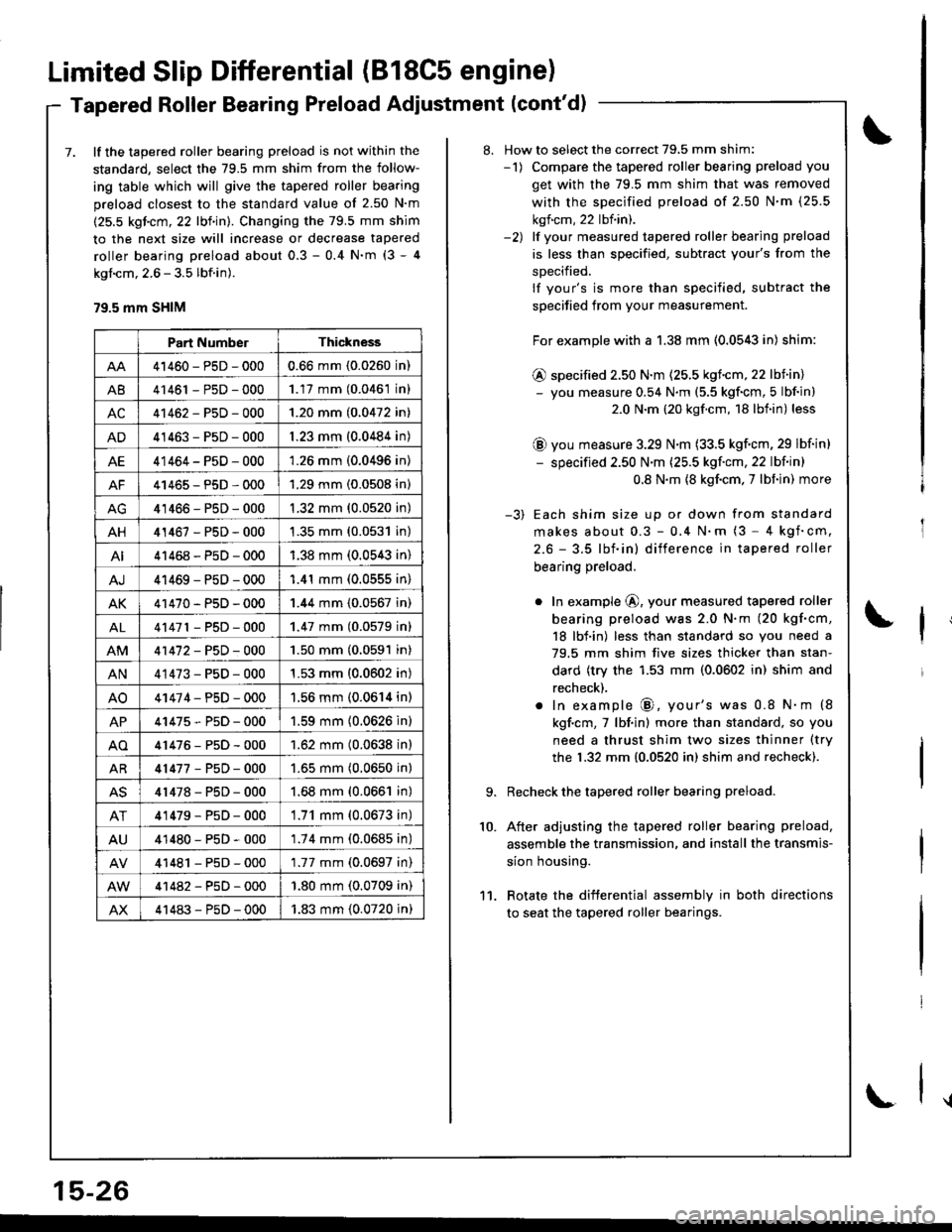

Limited Slip Differential (B18C5 engine)

Tapered Roller Bearing Preload Adiustment (cont'd)

7. lf the tapered roller bearing preload is not within the

standard, select the 79.5 mm shim from the follow-

ing table which will give the tapered roller bearing

preload closest to the standard value of 2.50 N'm

(25.5 kgicm, 22 lbf in). Changing the 79.5 mm shim

to the next size will increase or decrease tapered

roller bearing preload about 0.3 - 0.4 N'm (3 - 4

kgl.cm, 2.6 - 3.5 lbf.in).

79.5 mm SHIM

Part NumberThickness

41460-PsD-0000.66 mm (0.0260 in)

A841461 - P5D - 0001.17 mm (0.0461 in)

AC41462-P5D-0001.20 mm (0.0472 in)

AD41463-P5D-0001.23 mm (0.0484 in)

AE41464-P5D-0001.26 mm (0.0496 in)

AF41465-P5D-0001.29 mm (0.0508 in)

41466-PsD-0001.32 mm (0.0520 in)

AH41467-PsD-0001.35 mm (0.0531 in)

AI41468-P5D-0001.38 mm (0.0543 in)

AJ41469-PsD-0001.41 mm (0.0555 in)

AK41470-PsD-0001.44 mm (0.0567 in)

AL41471 - PsD - 0001.47 mm (0.0579 inl

41472-P5D-0001.50 mm (0.0591 in)

AN41473-P5D-0001.53 mm (0.0602 in)

AO41474-PsD-0001.56 mm (0.0614 in)

AP41475-P5D-0001.59 mm (0.0626 in)

AO41476-P5D-0001.62 mm (0.0638 in)

AR41477-P5D-0001.65 mm (0.0650 in)

AS41478-PsD-0001.68 mm (0.0661 in)

AT41479-P5D-0001.71 mm (0.0673 in)

AU41480-PsD-0001.74 mm (0.0685 in)

41481 - PsD - 0001.77 mm (0.0697 in)

41482-P5D-000'1.80 mm (0.0709 in)

AX41483-P5D-0001.83 mm (0.0720 in)

15-26

\

8. How to select the correct 79,5 mm shim:-1) Compare the tapered roller bearing preload you

get with the 79.5 mm shim that was removed

with the sDecified preload of 2.50 N'm (25.5

kgf.cm, 22 lbf.in).-2) lf vour measured tapered roller bearing preload

is less than specified, subtract your's from the

sDecified.

lf your's is more than specified, subtract the

specified from your measurement.

For example with a 1.38 mm (0.0543 in) shim:

@ specified 2.50 N.m (25.5 kgf.cm,22 lbiin)- you measure 0.54 N.m (5.5 kgf'cm, 5 lbf in)

2.0 N.m (20 kgf.cm, 18 lbf.in) less

@ you measure 3.29 N.m (33.5 kgf.cm, 29 lbf in)

- specified 2.50 N'm (25.5 kgf'cm, 22 lbf in)

0.8 N.m {8 kgf.cm. 7 lbf in) more

-3) Each shim size up or down from standard

makes about 0.3 - 0,4 N.m (3 - 4 kgf'cm,

2.6 - 3.5 lbf.in) difference in tapered roller

bearing preload.

o In example @, your measured tapered roller

bearing preload was 2.0 N.m (20 kgf.cm,

18 lbf.in) less than standard so you need a

79.5 mm shim five sizes thicker than stan-

dard (try the 1.53 mm (0.0602 in) shim and

recheck).

. In example @, your's was 0.8 N.m (8

kgf.cm,7 lbf.in) more than standard, so you

need a thrust shim two sizes thinner (try

the 1.32 mm {0.0520 in) shim and recheck).

Recheck the tapered roller bearing preload.

After adjusting the tapered roller bearing preload,

assemble the transmission, and install the transmis-

sion housing.

Rotate the difterential assembly in both directions

to seat the tapered roller bearings.

10.

11.

Page 646 of 1680

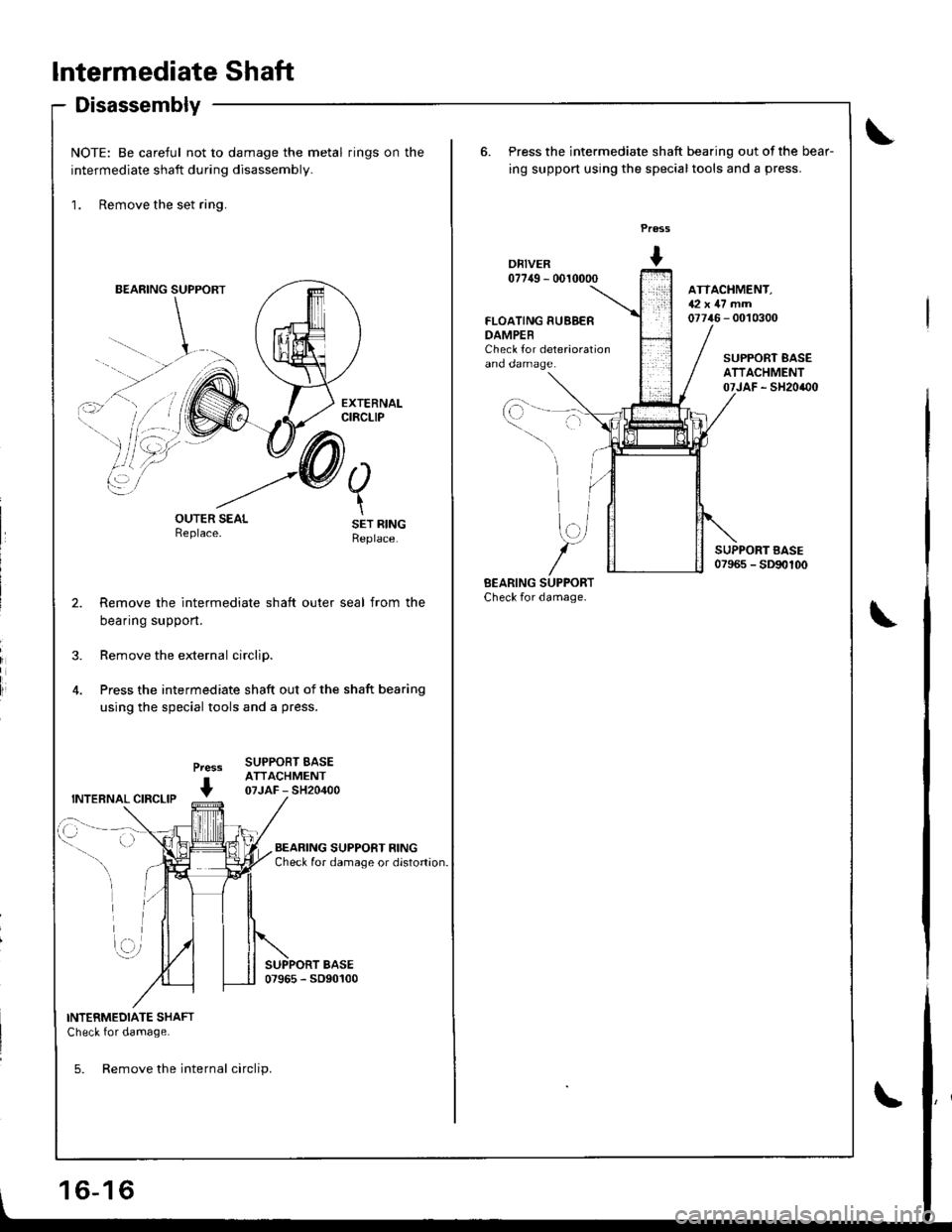

lntermediate Shaft

Disassembly

NOTE: Be careful not to damage the metal rings on the

intermediate shaft during disassembly.

1. Remove the set ring.

BEARING SUPPORT

li

OUTER SEALReplace.

Press

+

SET RINGReplace,

SUPPOBT BASEATTACHMENT07JAF - SH20400

r!:.,

,.1,l;,!&

{:i'@,1

2. Remove the intermediate shaft outer seal from the

oeaflng suppon.

Remove the external circlip.

Press the intermediate shaft out of the shaft bearing

using the special tools and a press.

6. Press the intermediate shaft bearing out of the bear-

ing support using the specialtools and a press.

Pross

I

DnrvER t

07749 - 0010000ATIACHMENT,il2 x 47 mm07746 - 0010300FLOATING SUBBERDAMPERCheck for deteriorationano oamage.

l

lol\:/I

SEARING SUPPORTCheck for damage.

SUPPORT BASEATTACHMENT07JAF - SH20.00

SUPPORT BASE07965 - SD9o100

INTERMEDIATE SHAFTCheck for damage.

Remove the internal circlip.

Page 672 of 1680

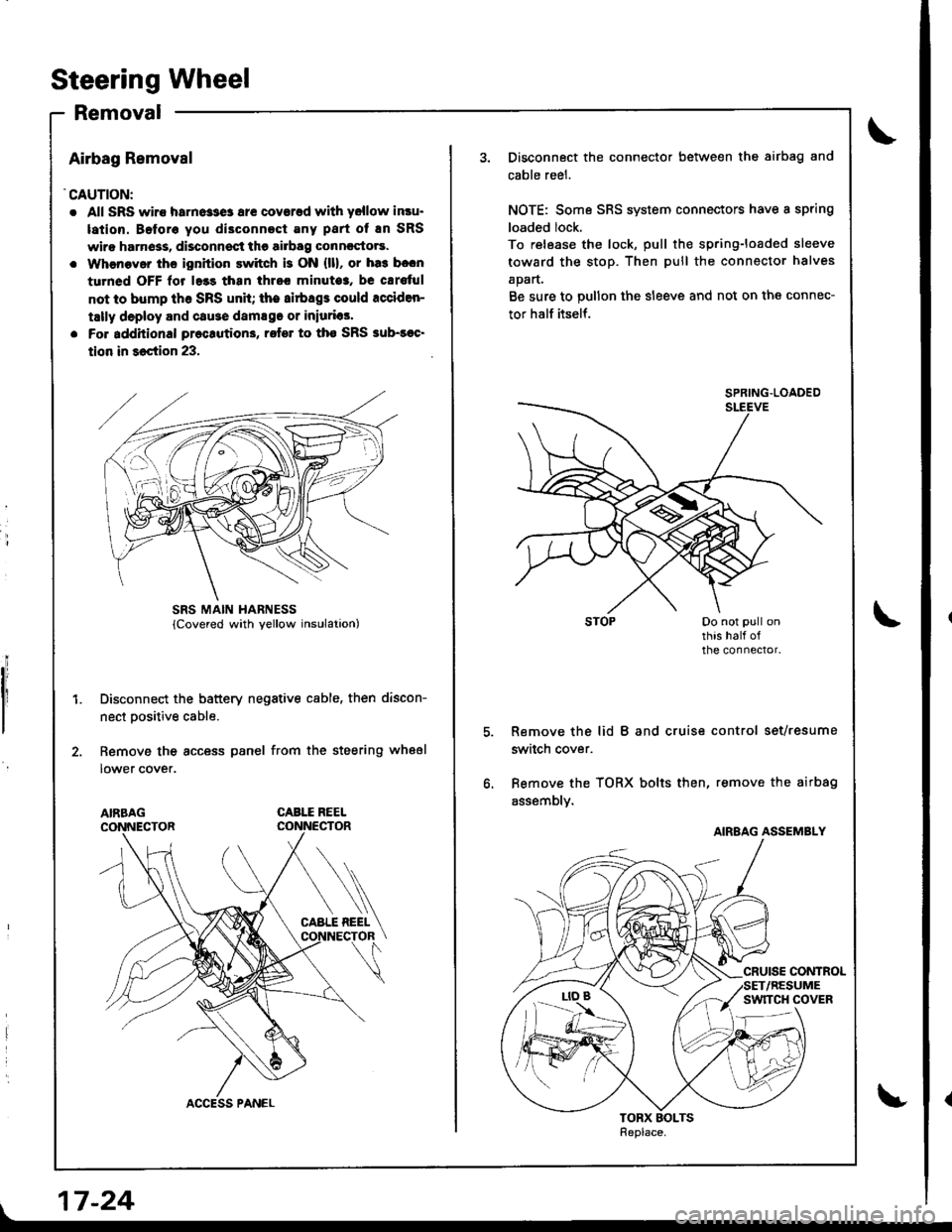

Steering Wheel

Removal

Airbag Removal

'CAUTION:

. All SRS wiro harne33e3 ar€ coverad with yellow insu.

lation. Beforo you di3connect Eny part of En SRS

wiro harn6ss, disconnsct the airbag conncctors.

. Whenaver ths ignition switch is ON {ll}, or ha3 b.cn

turned OFF lor l.3s than thrcc minuto3, be cErs{ul

not to bump th6 SRS unh; the airbags could rcciden-

tally deploy and cause damsgo or iniurias'

. Fo. additional preclution3, rofer to tho SRS sub-soc'

tion in 36ction 23,

Disconnect the battery negative cable, then discon-

nect Dositive cable.

Remove the access panel from the steering wheel

lower cover.

CABLE REEL

L

SRS MAIN HARNESS

17-24

Disconnect the connector between the airbag and

cable reel.

NOTE: Some SRS system connectors have a spring

loaded lock.

To release the lock, pull the spring-loaded sleeve

toward the stop. Then pull the connector halves

apart.

Be sure to pullon the sleeve and not on the connec-

tor half itself.

Remove the lid B and cruise control set/resume

switch cover.

Bemove the TORX bolts then, remove the airbag

assembly.

SPRING.LOADED

AIRBAG ASSEMBLY