ESP ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 73 of 1640

Engine Removal/Installation

Removal

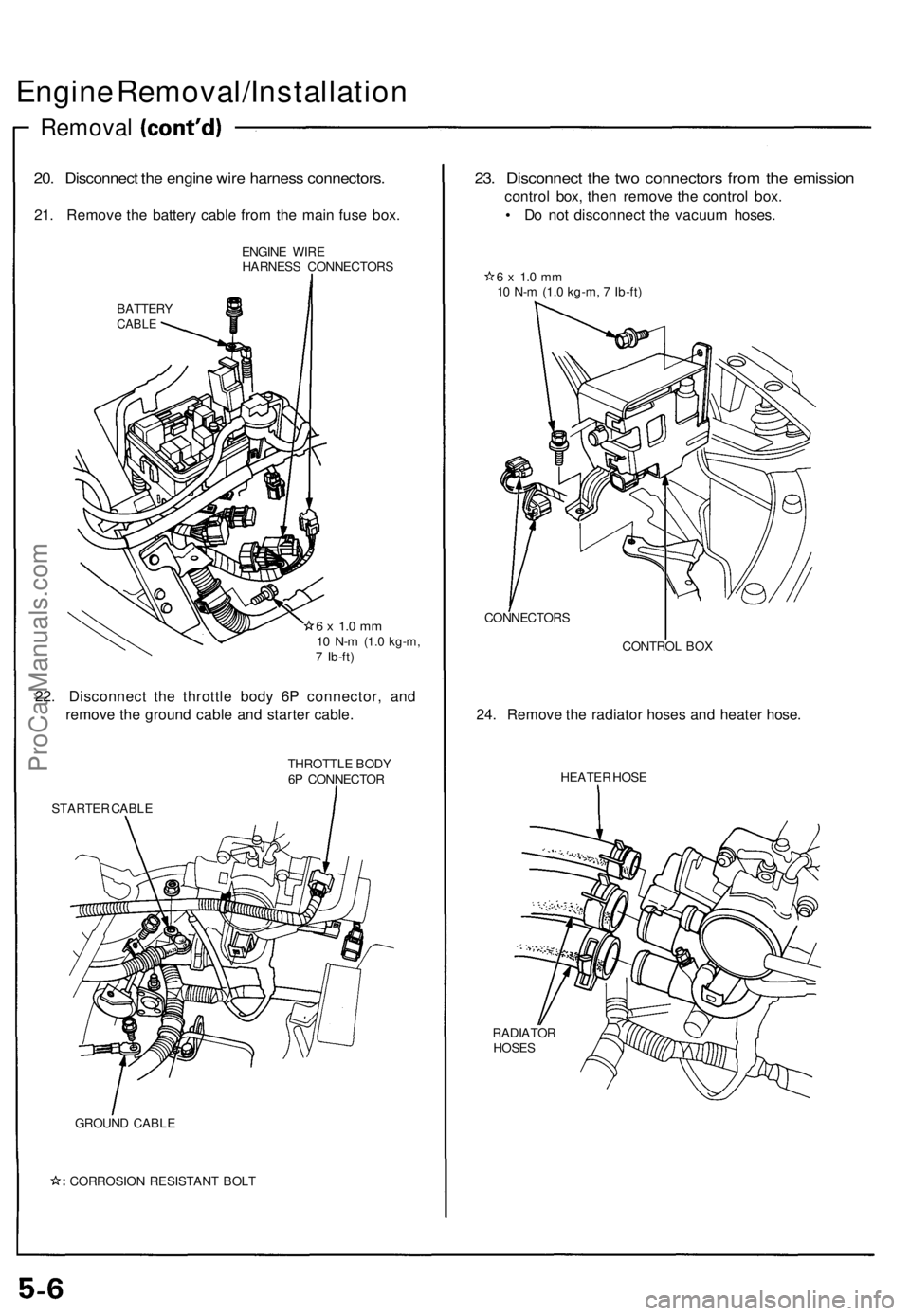

20. Disconnect the engine wire harness connectors.

21. Remove the battery cable from the main fuse box.

ENGINE WIRE

HARNESS CONNECTORS

BATTERY

CABLE

6 x 1.0 mm

10 N-m

(1.0 kg-m,

7 Ib-ft)

22. Disconnect the throttle body 6P connector, and

remove the ground cable and starter cable.

STARTER CABLE

THROTTLE BODY

6P CONNECTOR

GROUND CABLE

CORROSION RESISTANT BOLT

23. Disconnect the two connectors from the emission

control box, then remove the control box.

• Do not disconnect the vacuum hoses.

6 x 1.0 mm

10 N-m (1.0 kg-m, 7 Ib-ft)

CONNECTORS

CONTROL BOX

24. Remove the radiator hoses and heater hose.

HEATER HOSE

RADIATOR

HOSESProCarManuals.com

Page 119 of 1640

Valves, Valv e Spring s an d Valv e Seal s

Installatio n Sequenc e

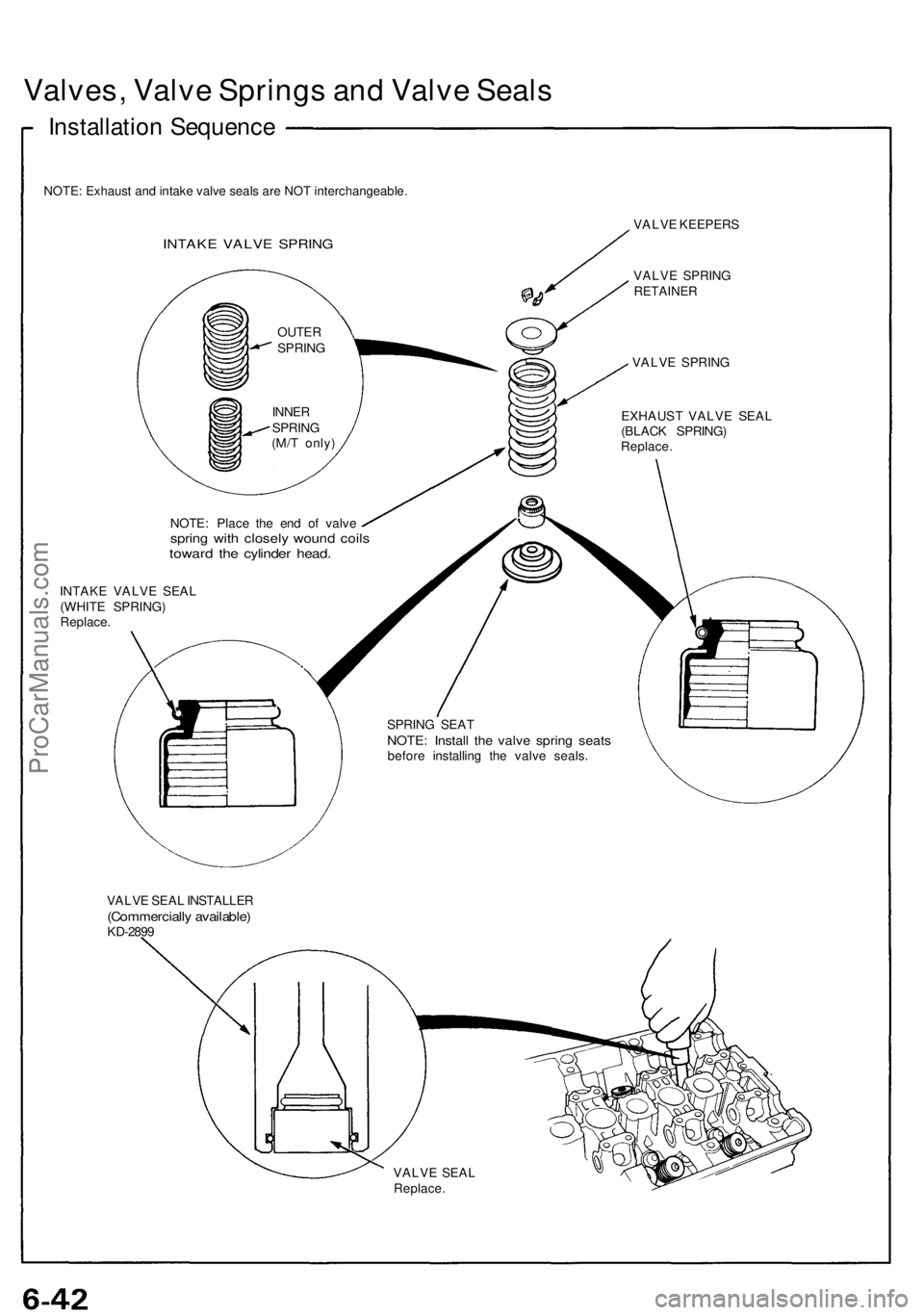

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALV E SPRIN G

VALVE KEEPER S

VALV E SPRIN G

RETAINE R

VALVE SPRIN G

EXHAUS T VALV E SEA L

(BLAC K SPRING )

Replace.

NOTE: Plac e th e en d o f valv espring wit h closel y woun d coil stowar d th e cylinde r head .

INTAK E VALV E SEA L

(WHIT E SPRING )

Replace .

SPRING SEA T

NOTE : Instal l th e valv e sprin g seat sbefor e installin g th e valv e seals .

VALV E SEA L INSTALLE R

(Commerciall y available )KD-2899

VALVE SEA L

Replace .

OUTER

SPRIN G

INNE R

SPRIN G

(M/ T only )

ProCarManuals.com

Page 134 of 1640

Piston/Connecting Rod Assemblies and Crankshaft

Removal

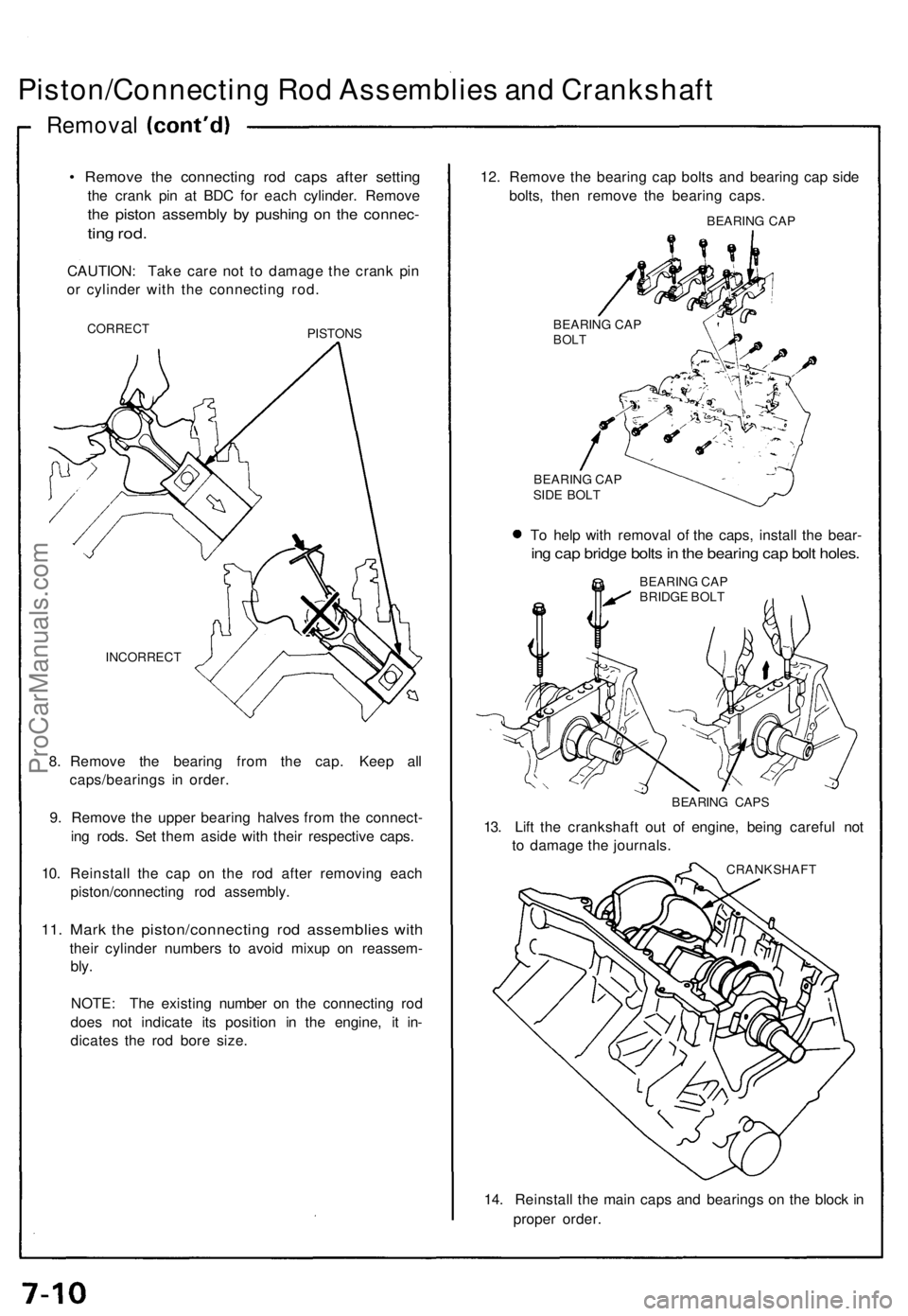

• Remove the connecting rod caps after setting

the crank pin at BDC for each cylinder. Remove

the piston assembly by pushing on the connec-

ting rod.

CAUTION: Take care not to damage the crank pin

or cylinder with the connecting rod.

CORRECT

PISTONS

INCORRECT

8. Remove the bearing from the cap. Keep all

caps/bearings in order.

9. Remove the upper bearing halves from the connect-

ing rods. Set them aside with their respective caps.

10. Reinstall the cap on the rod after removing each

piston/connecting rod assembly.

11. Mark the piston/connecting rod assemblies with

their cylinder numbers to avoid mixup on reassem-

bly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it in-

dicates the rod bore size.

12. Remove the bearing cap bolts and bearing cap side

bolts, then remove the bearing caps.

BEARING CAP

BEARING CAP

BOLT

BEARING CAP

SIDE BOLT

To help with removal of the caps, install the bear-

ing cap bridge bolts in the bearing cap bolt holes.

BEARING CAP

BRIDGE BOLT

BEARING CAPS

13. Lift the crankshaft out of engine, being careful not

to damage the journals.

CRANKSHAFT

14. Reinstall the main caps and bearings on the block in

proper order.ProCarManuals.com

Page 255 of 1640

Fuel Supply System

Fuel Injector Resistor

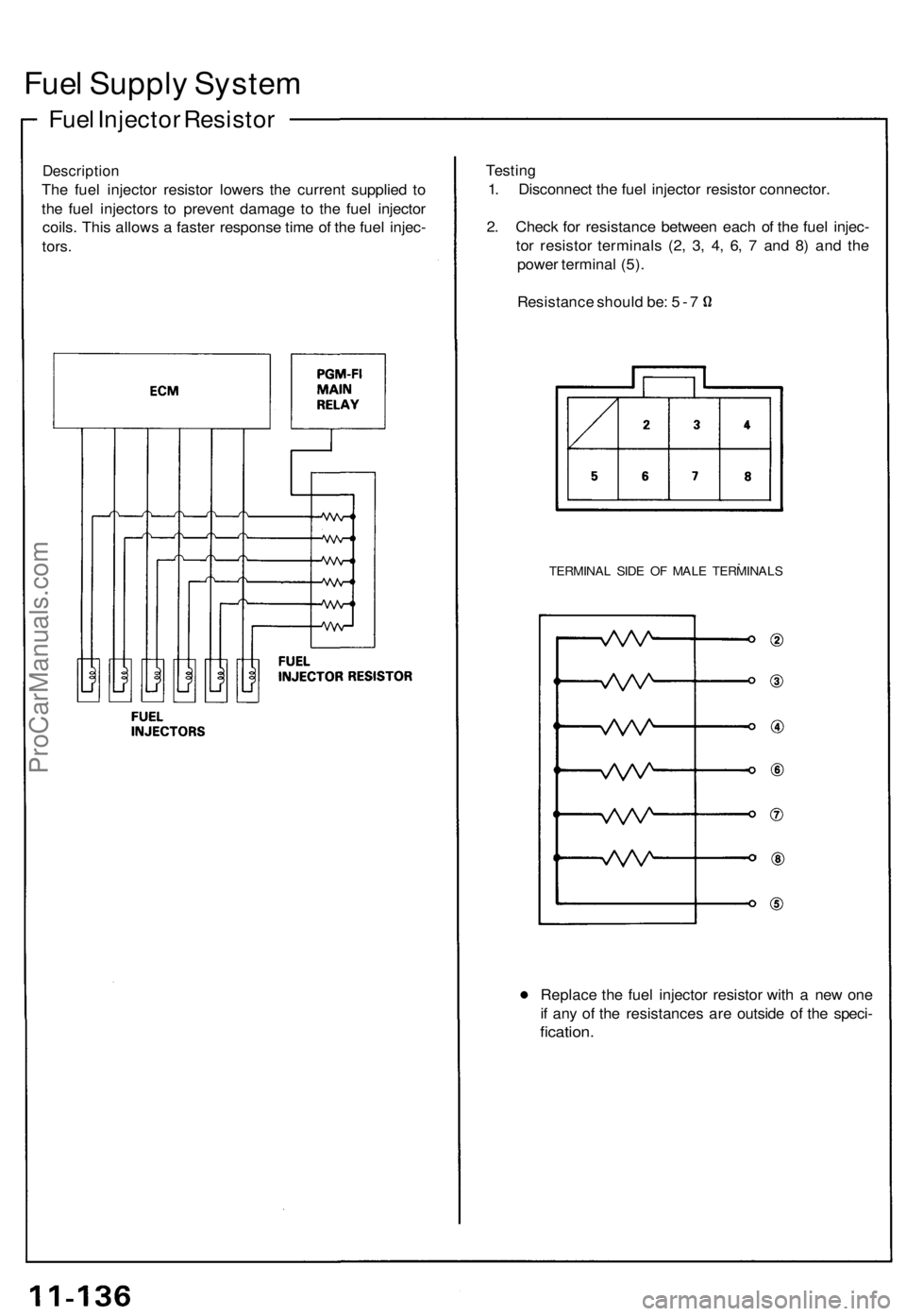

Description

The fuel injector resistor lowers the current supplied to

the fuel injectors to prevent damage to the fuel injector

coils. This allows a faster response time of the fuel injec-

tors.

Testing

1. Disconnect the fuel injector resistor connector.

2. Check for resistance between each of the fuel injec-

tor resistor terminals (2, 3, 4, 6, 7 and 8) and the

power terminal (5).

Resistance should be: 5 - 7

TERMINAL SIDE OF MALE TERMINALS

Replace the fuel injector resistor with a new one

if any of the resistances are outside of the speci-

fication.ProCarManuals.com

Page 449 of 1640

System Description

Suspension Composition

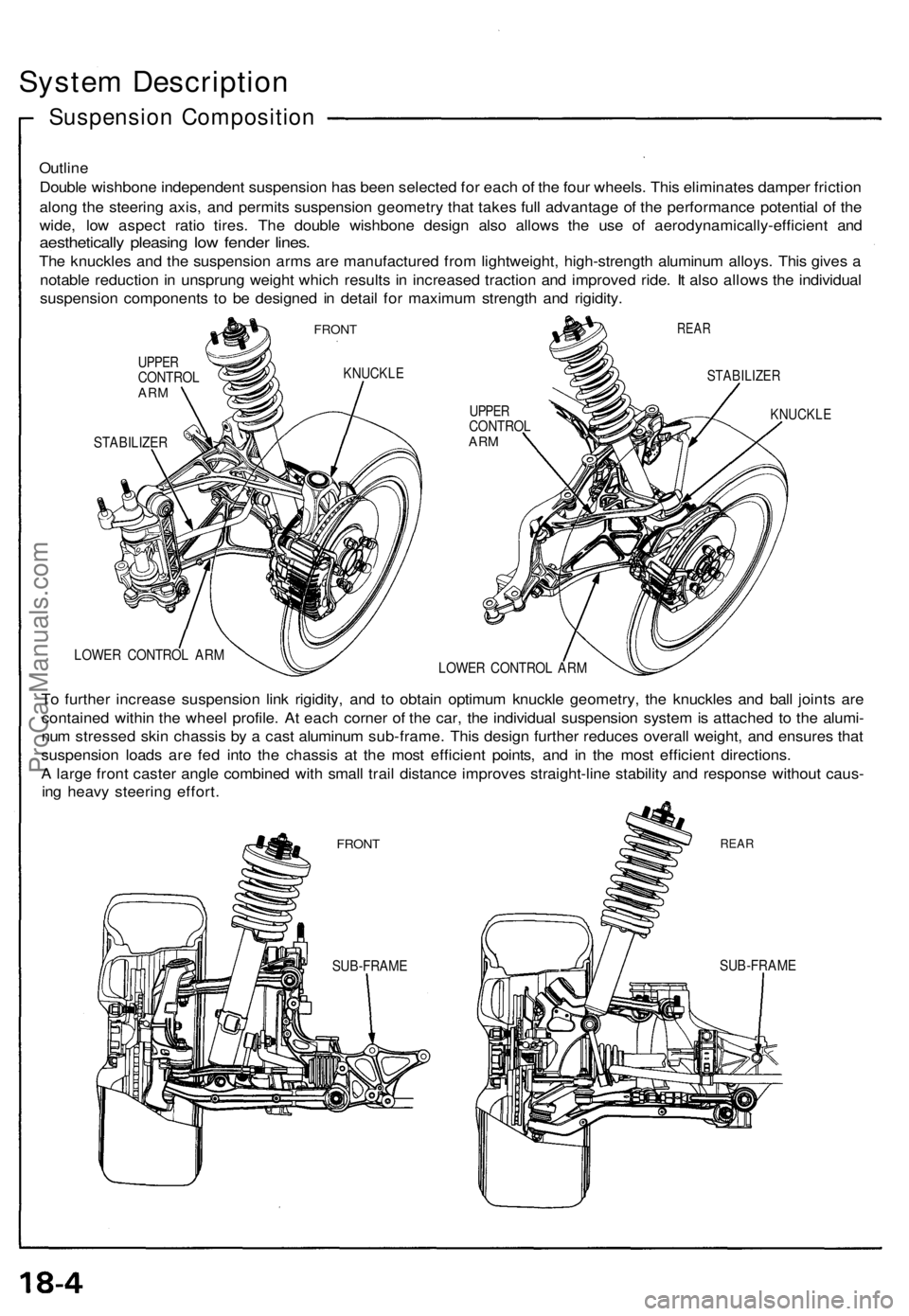

Outline

Double wishbone independent suspension has been selected for each of the four wheels. This eliminates damper friction

along the steering axis, and permits suspension geometry that takes full advantage of the performance potential of the

wide, low aspect ratio tires. The double wishbone design also allows the use of aerodynamically-efficient and

aesthetically pleasing low fender lines.

The knuckles and the suspension arms are manufactured from lightweight, high-strength aluminum alloys. This gives a

notable reduction in unsprung weight which results in increased traction and improved ride. It also allows the individual

suspension components to be designed in detail for maximum strength and rigidity.

FRONT

UPPER

CONTROL

ARM

KNUCKLE

STABILIZER

REAR

UPPER

CONTROL

ARM

STABILIZER

KNUCKLE

LOWER CONTROL ARM

LOWER CONTROL ARM

To further increase suspension link rigidity, and to obtain optimum knuckle geometry, the knuckles and ball joints are

contained within the wheel profile. At each corner of the car, the individual suspension system is attached to the alumi-

num stressed skin chassis by a cast aluminum sub-frame. This design further reduces overall weight, and ensures that

suspension loads are fed into the chassis at the most efficient points, and in the most efficient directions.

A large front caster angle combined with small trail distance improves straight-line stability and response without caus-

ing heavy steering effort.

FRONT

REAR

SUB-FRAME

SUB-FRAMEProCarManuals.com

Page 450 of 1640

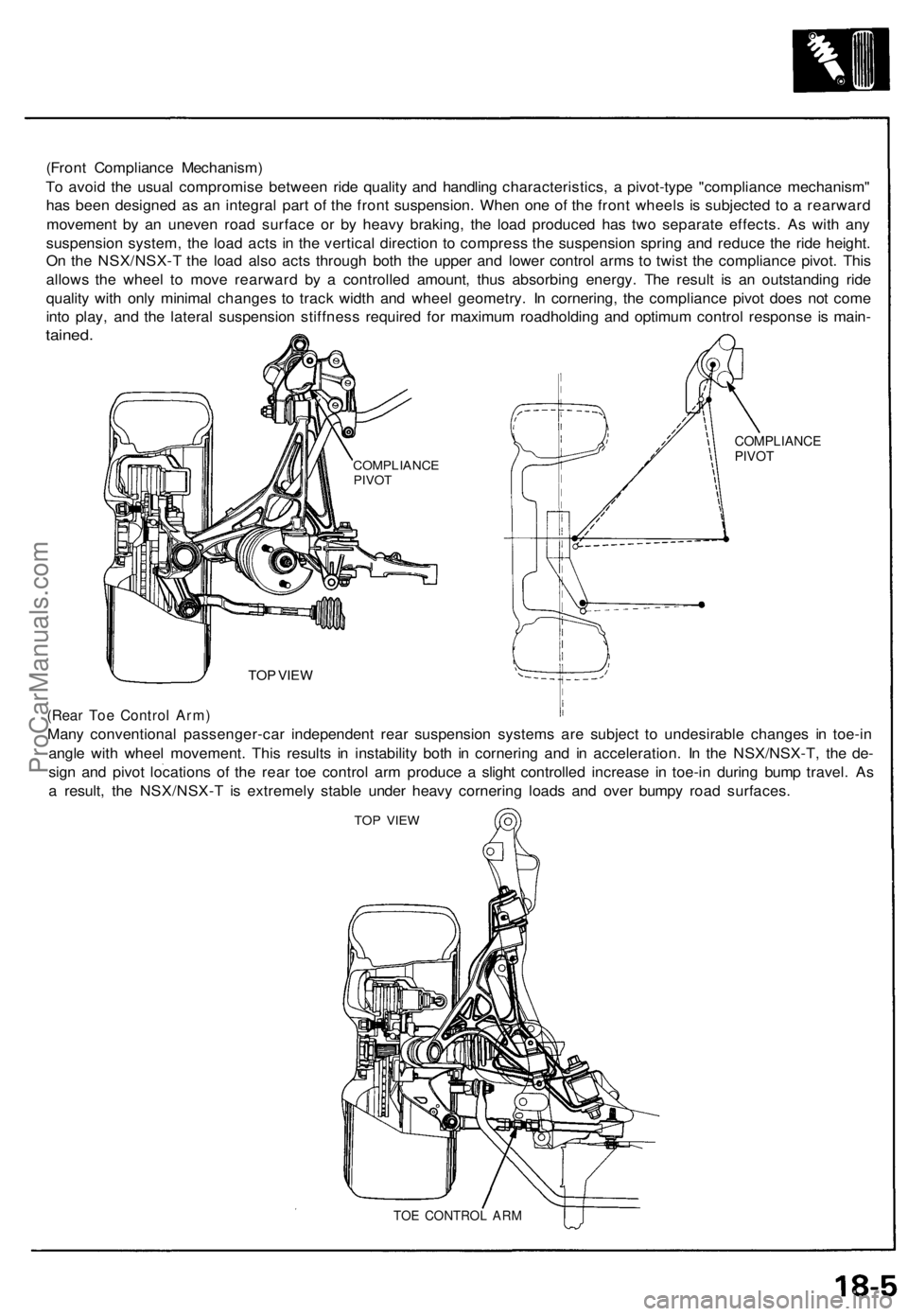

(Front Compliance Mechanism)

To avoid the usual compromise between ride quality and handling characteristics, a pivot-type "compliance mechanism"

has been designed as an integral part of the front suspension. When one of the front wheels is subjected to a rearward

movement by an uneven road surface or by heavy braking, the load produced has two separate effects. As with any

suspension system, the load acts in the vertical direction to compress the suspension spring and reduce the ride height.

On the NSX/NSX-T the load also acts through both the upper and lower control arms to twist the compliance pivot. This

allows the wheel to move rearward by a controlled amount, thus absorbing energy. The result is an outstanding ride

quality with only minimal changes to track width and wheel geometry. In cornering, the compliance pivot does not come

into play, and the lateral suspension stiffness required for maximum roadholding and optimum control response is main-

tained.

COMPLIANCE

PIVOT

TOP VIEW

(Rear Toe Control Arm)

Many conventional passenger-car independent rear suspension systems are subject to undesirable changes in toe-in

angle with wheel movement. This results in instability both in cornering and in acceleration. In the NSX/NSX-T, the de-

sign and pivot locations of the rear toe control arm produce a slight controlled increase in toe-in during bump travel. As

a result, the NSX/NSX-T is extremely stable under heavy cornering loads and over bumpy road surfaces.

TOP VIEW

TOE CONTROL ARM

COMPLIANCE

PIVOTProCarManuals.com

Page 517 of 1640

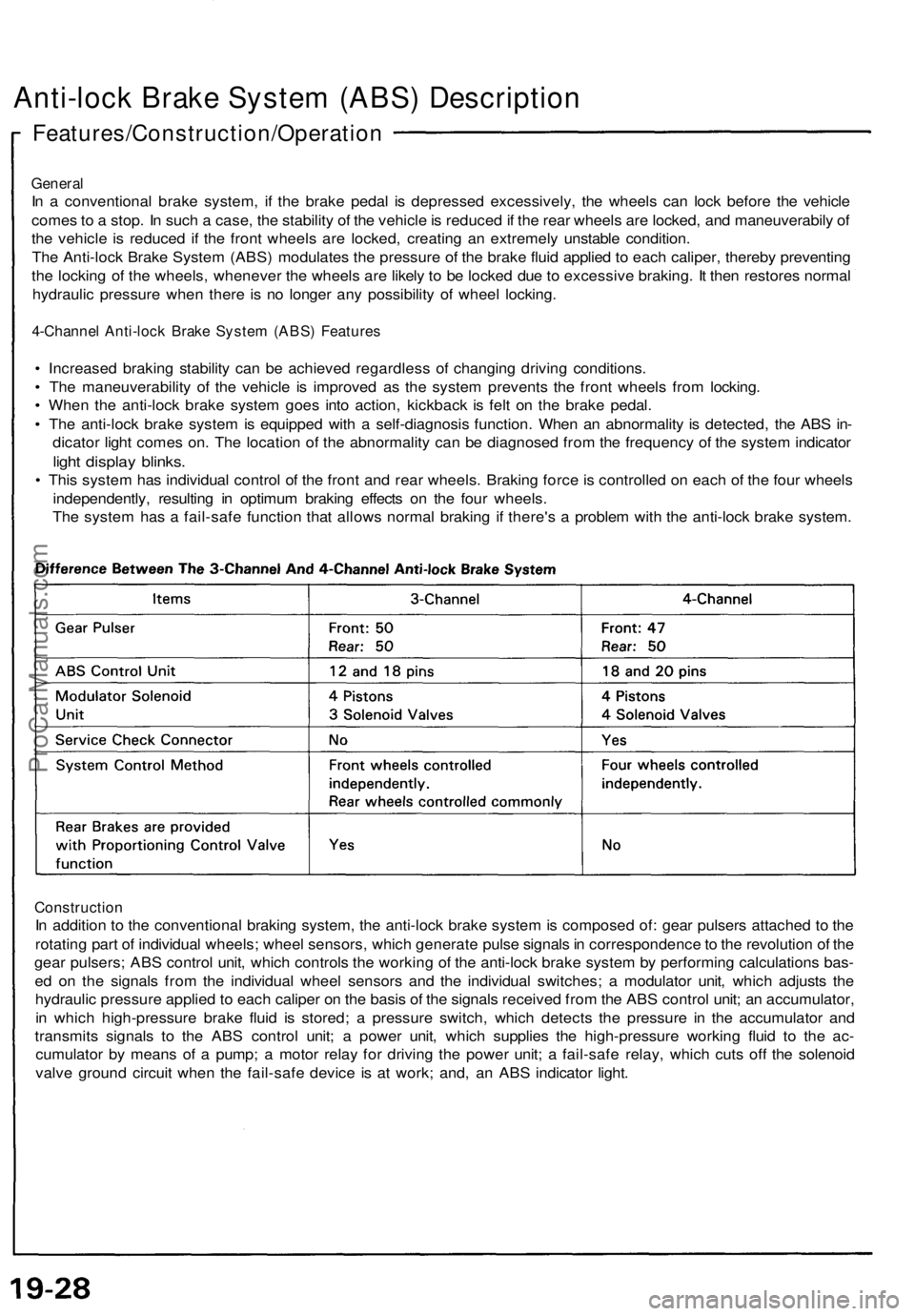

Anti-lock Brake System (ABS) Description

Features/Construction/Operation

General

In a conventional brake system, if the brake pedal is depressed excessively, the wheels can lock before the vehicle

comes to a stop. In such a case, the stability of the vehicle is reduced if the rear wheels are locked, and maneuverabily of

the vehicle is reduced if the front wheels are locked, creating an extremely unstable condition.

The Anti-lock Brake System (ABS) modulates the pressure of the brake fluid applied to each caliper, thereby preventing

the locking of the wheels, whenever the wheels are likely to be locked due to excessive braking. It then restores normal

hydraulic pressure when there is no longer any possibility of wheel locking.

4-Channel Anti-lock Brake System (ABS) Features

• Increased braking stability can be achieved regardless of changing driving conditions.

• The maneuverability of the vehicle is improved as the system prevents the front wheels from locking.

• When the anti-lock brake system goes into action, kickback is felt on the brake pedal.

• The anti-lock brake system is equipped with a self-diagnosis function. When an abnormality is detected, the ABS in-

dicator light comes on. The location of the abnormality can be diagnosed from the frequency of the system indicator

light display blinks.

• This system has individual control of the front and rear wheels. Braking force is controlled on each of the four wheels

independently, resulting in optimum braking effects on the four wheels.

The system has a fail-safe function that allows normal braking if there's a problem with the anti-lock brake system.

Construction

In addition to the conventional braking system, the anti-lock brake system is composed of: gear pulsers attached to the

rotating part of individual wheels; wheel sensors, which generate pulse signals in correspondence to the revolution of the

gear pulsers; ABS control unit, which controls the working of the anti-lock brake system by performing calculations bas-

ed on the signals from the individual wheel sensors and the individual switches; a modulator unit, which adjusts the

hydraulic pressure applied to each caliper on the basis of the signals received from the ABS control unit; an accumulator,

in which high-pressure brake fluid is stored; a pressure switch, which detects the pressure in the accumulator and

transmits signals to the ABS control unit; a power unit, which supplies the high-pressure working fluid to the ac-

cumulator by means of a pump; a motor relay for driving the power unit; a fail-safe relay, which cuts off the solenoid

valve ground circuit when the fail-safe device is at work; and, an ABS indicator light.ProCarManuals.com

Page 519 of 1640

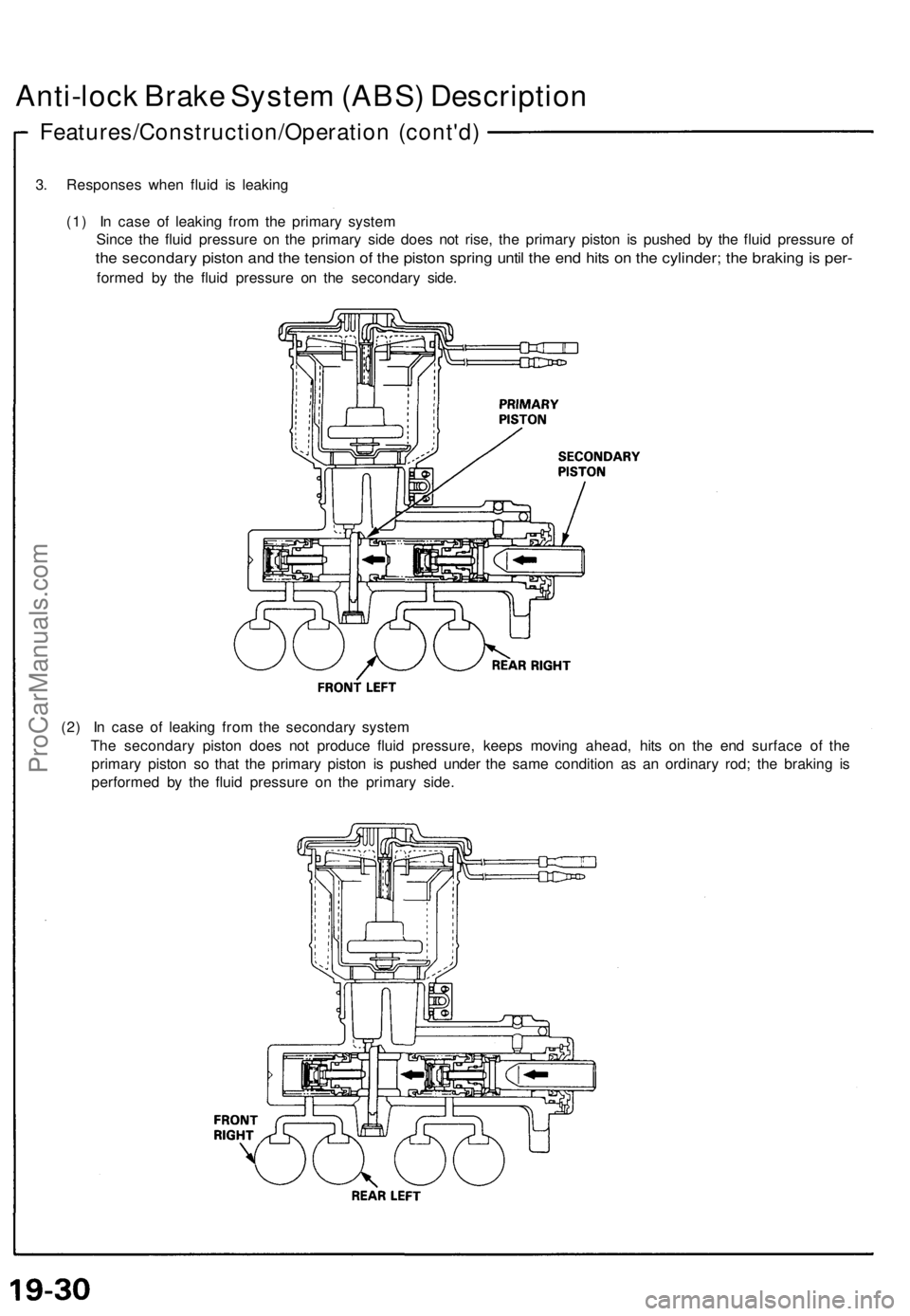

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

3. Responses when fluid is leaking

(1) In case of leaking from the primary system

Since the fluid pressure on the primary side does not rise, the primary piston is pushed by the fluid pressure of

the secondary piston and the tension of the piston spring until the end hits on the cylinder; the braking is per-

formed by the fluid pressure on the secondary side.

(2) In case of leaking from the secondary system

The secondary piston does not produce fluid pressure, keeps moving ahead, hits on the end surface of the

primary piston so that the primary piston is pushed under the same condition as an ordinary rod; the braking is

performed by the fluid pressure on the primary side.ProCarManuals.com

Page 522 of 1640

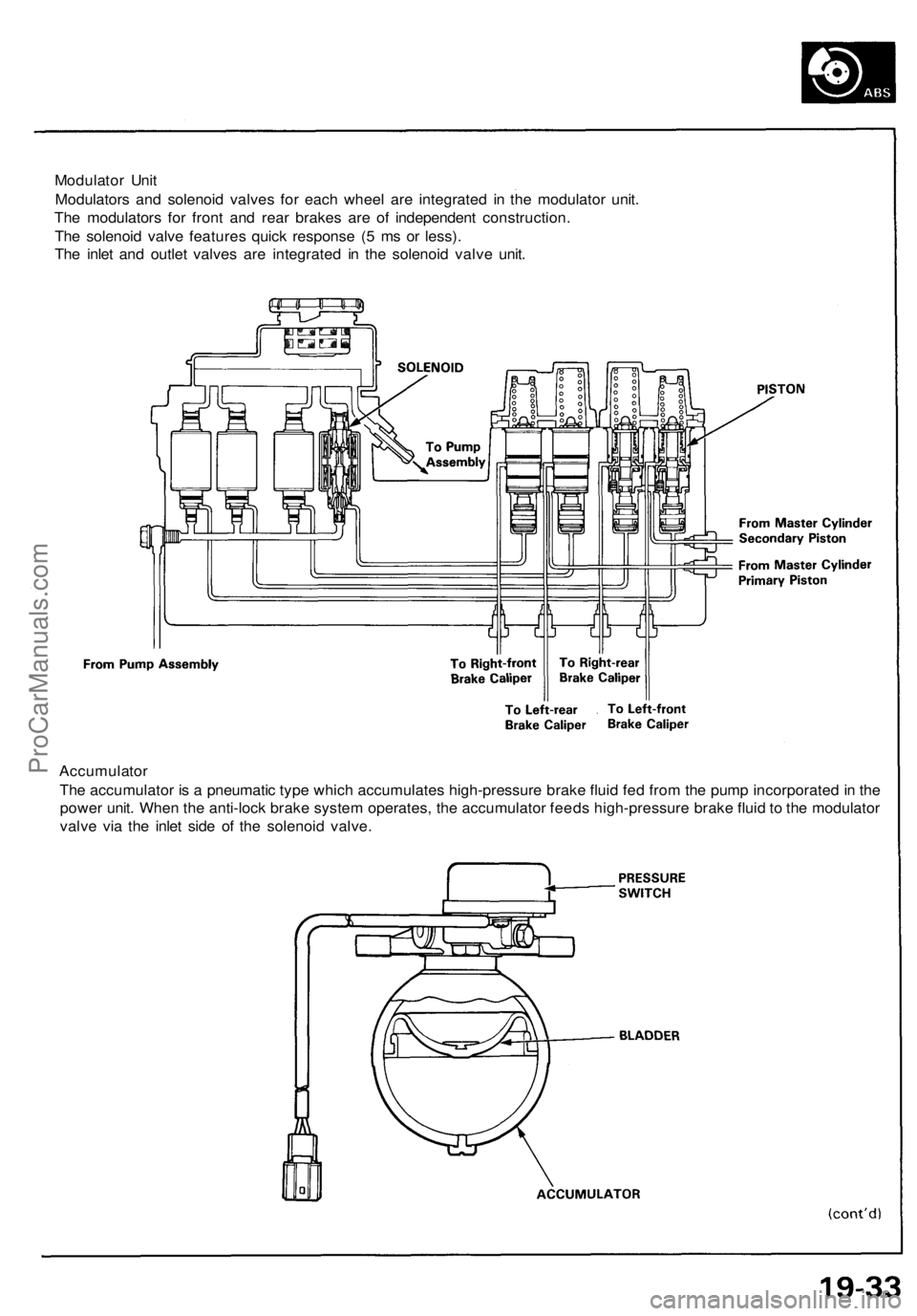

Modulator Unit

Modulators and solenoid valves for each wheel are integrated in the modulator unit.

The modulators for front and rear brakes are of independent construction.

The solenoid valve features quick response (5 ms or less).

The inlet and outlet valves are integrated in the solenoid valve unit.

Accumulator

The accumulator is a pneumatic type which accumulates high-pressure brake fluid fed from the pump incorporated in the

power unit. When the anti-lock brake system operates, the accumulator feeds high-pressure brake fluid to the modulator

valve via the inlet side of the solenoid valve.ProCarManuals.com

Page 529 of 1640

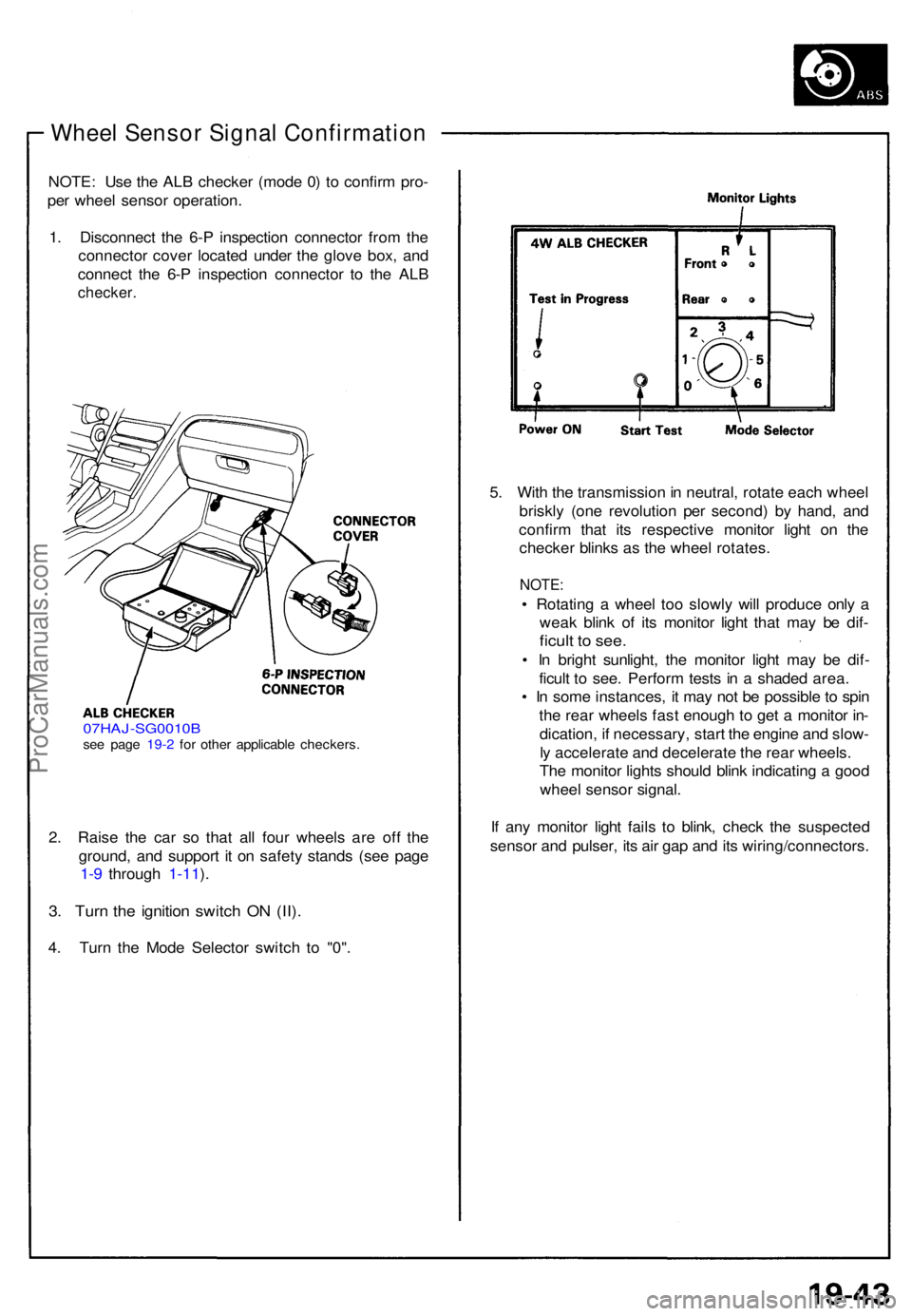

Wheel Sensor Signal Confirmation

NOTE: Us e th e AL B checke r (mod e 0 ) t o confir m pro -

pe r whee l senso r operation .

1 . Disconnec t th e 6- P inspectio n connecto r fro m th e

connecto r cove r locate d unde r th e glov e box , an d

connec t th e 6- P inspectio n connecto r t o th e AL B

checker .

07HAJ-SG0010 Bsee pag e 19- 2 fo r othe r applicabl e checkers .

2. Rais e th e ca r s o tha t al l fou r wheel s ar e of f th e

ground , an d suppor t i t o n safet y stand s (se e pag e

1-9 throug h 1-11 ).

3 . Tur n th e ignitio n switc h O N (II) .

4. Tur n th e Mod e Selecto r switc h t o "0" . 5

. Wit h th e transmissio n in neutral , rotat e eac h whee l

briskl y (on e revolutio n pe r second ) b y hand , an d

confir m tha t it s respectiv e monito r ligh t o n th e

checke r blink s a s th e whee l rotates .

NOTE:

• Rotatin g a whee l to o slowl y wil l produc e onl y a

wea k blin k o f it s monito r ligh t tha t ma y b e dif -

ficul t t o see .

• I n brigh t sunlight , th e monito r ligh t ma y b e dif -

ficul t t o see . Perfor m test s i n a shade d area .

• I n som e instances , i t ma y no t b e possibl e to spi n

th e rea r wheel s fas t enoug h t o ge t a monito r in -

dication , i f necessary , star t th e engin e an d slow -

l y accelerat e an d decelerat e th e rea r wheels .

Th e monito r light s shoul d blin k indicatin g a goo d

whee l senso r signal .

I f an y monito r ligh t fail s t o blink , chec k th e suspecte d

senso r an d pulser , it s ai r ga p an d it s wiring/connectors .

ProCarManuals.com