service indicator ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 115 of 1640

Valve Guides

Valve Movement

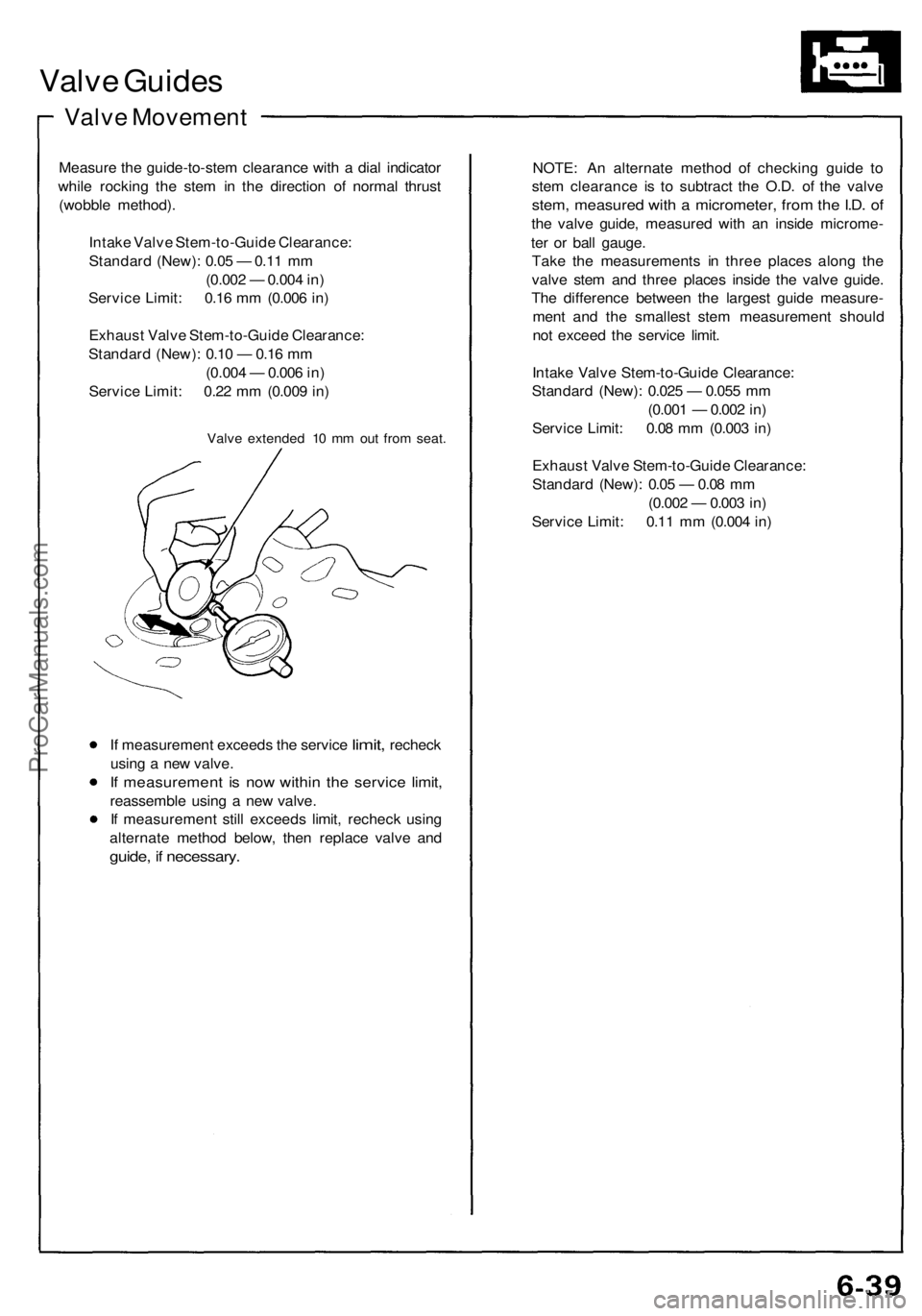

Measure the guide-to-stem clearance with a dial indicator

while rocking the stem in the direction of normal thrust

(wobble method).

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.05 — 0.11 mm

(0.002 — 0.004 in)

Service Limit: 0.16 mm (0.006 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.10 — 0.16 mm

(0.004 — 0.006 in)

Service Limit: 0.22 mm (0.009 in)

Valve extended 10 mm out from seat.

If

measurement exceeds

the

service

limit,

recheck

using a new valve.

If measurement is now within the service limit,

reassemble using a new valve.

If measurement still exceeds limit, recheck using

alternate method below, then replace valve and

guide, if necessary.

NOTE: An alternate method of checking guide to

stem clearance is to subtract the O.D. of the valve

stem, measured with a micrometer, from the I.D. of

the valve guide, measured with an inside microme-

ter or ball gauge.

Take the measurements in three places along the

valve stem and three places inside the valve guide.

The difference between the largest guide measure-

ment and the smallest stem measurement should

not exceed the service limit.

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.025 — 0.055 mm

(0.001 — 0.002 in)

Service Limit: 0.08 mm (0.003 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.05 — 0.08 mm

(0.002 — 0.003 in)

Service Limit: 0.11 mm (0.004 in)ProCarManuals.com

Page 296 of 1640

Mid Plate Guide

Replacement (cont'd)

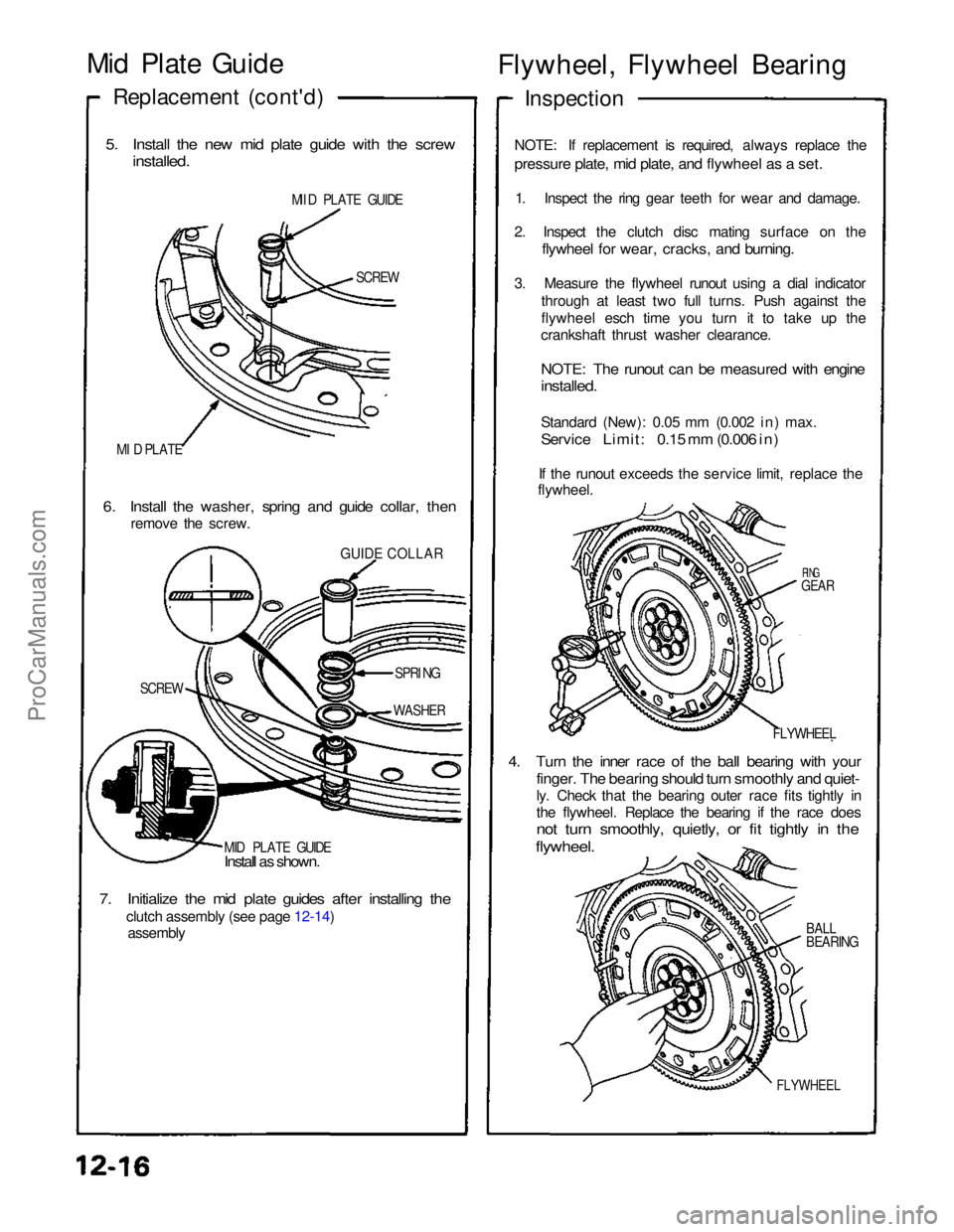

5. Install the new mid plate guide with the screw

installed.

MII D PLATE GUIDE

SCREW

MI D PLATE

6. Install the washer, spring and guide collar, then

remove the screw.

GUIDE COLLAR

SCREW SPRI

NG

WASHER

MID PLATE GUIDE

Install as shown.

7. Initialize the mid plate guides after installing the

clutch assembly (see page 12-14)

assembly Flywheel, Flywheel Bearing

Inspection

NOTE: If replacement is required, always replace the

pressure plate, mid plate, and flywheel as a set.

1. Inspect the ring gear teeth for wear and damage.

2. Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

3. Measure the flywheel runout using a dial indicator through at least two full turns. Push against the

flywheel esch time you turn it to take up the

crankshaft thrust washer clearance.

NOTE: The runout can be measured with engine

installed.

Standard (New): 0.05 mm (0.002 in) max.

Service Limit: 0.15 mm (0.006 in)

If the runout exceeds the service limit, replace the

flywheel.

RING

GEAR

FLYWHEEL

4. Turn the inner race of the ball bearing with your

finger. The bearing should turn smoothly and quiet-

ly. Check that the bearing outer race fits tightly in

the flywheel. Replace the bearing if the race does

not turn smoothly, quietly, or fit tightly in the

flywheel.

BALL

BEARING

FLYWHEELProCarManuals.com

Page 422 of 1640

Diagnostic Trouble Code (DTC) Indication

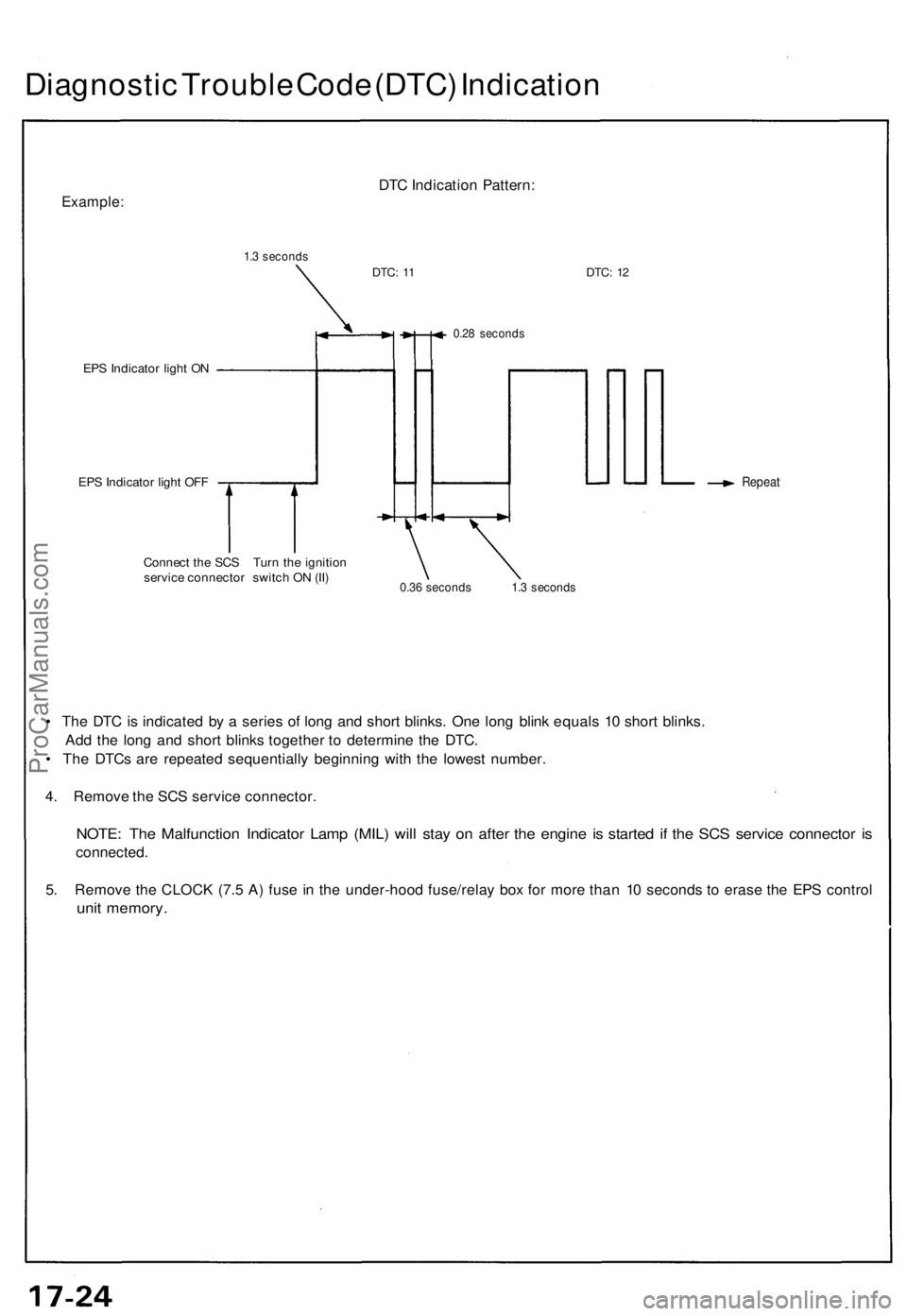

Example:

1.3 seconds

DTC Indication Pattern:

DTC:

11

DTC:

12

EPS Indicator light ON

EPS Indicator light OFF

0.28 seconds

Repeat

Connect the SCS Turn the ignition

service connector switch ON (II)

0.36 seconds 1.3 seconds

• The DTC is indicated by a series of long and short blinks. One long blink equals 10 short blinks.

Add the long and short blinks together to determine the DTC.

• The DTCs are repeated sequentially beginning with the lowest number.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the CLOCK (7.5 A) fuse in the under-hood fuse/relay box for more than 10 seconds to erase the EPS control

unit memory.ProCarManuals.com

Page 531 of 1640

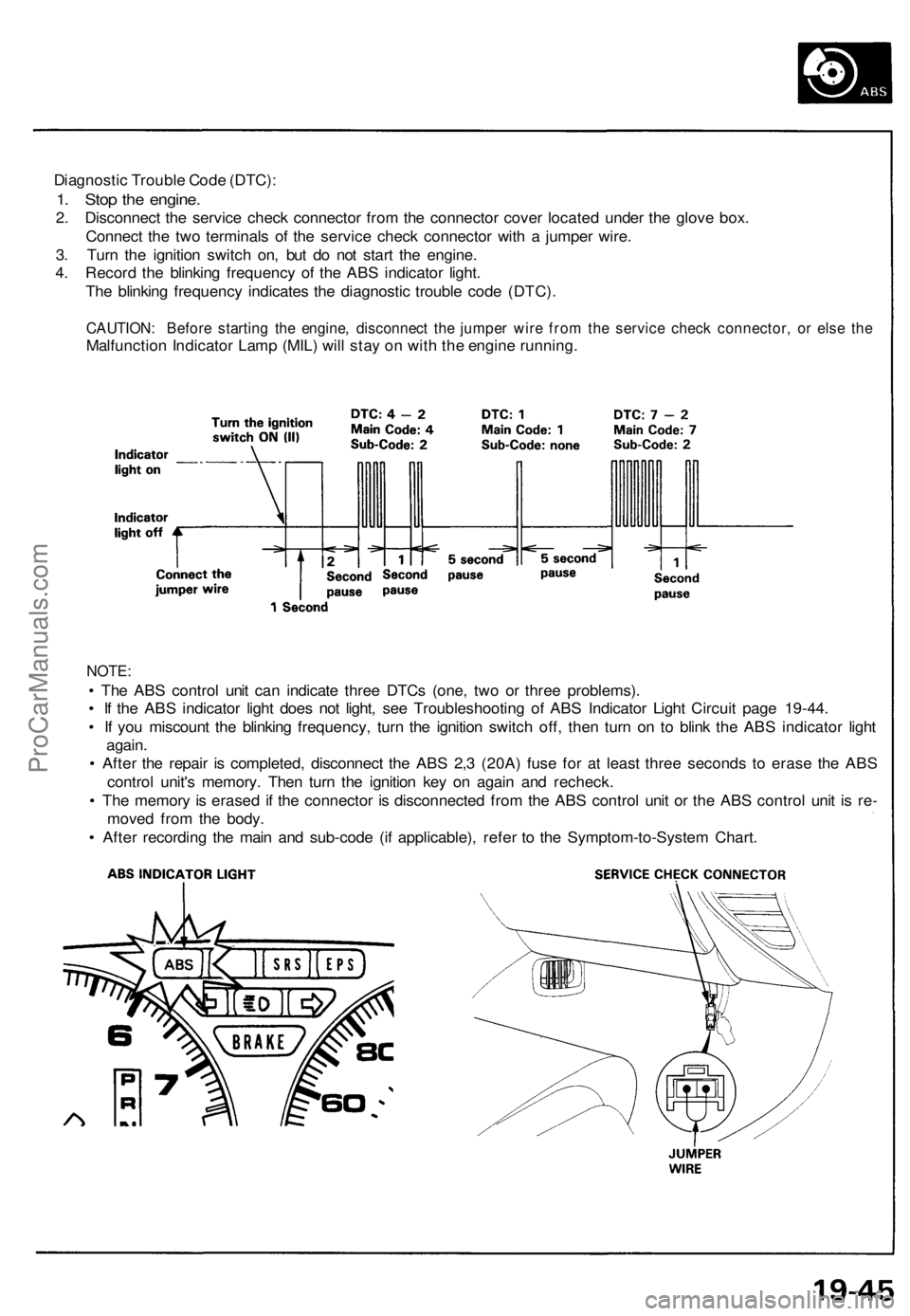

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 754 of 1640

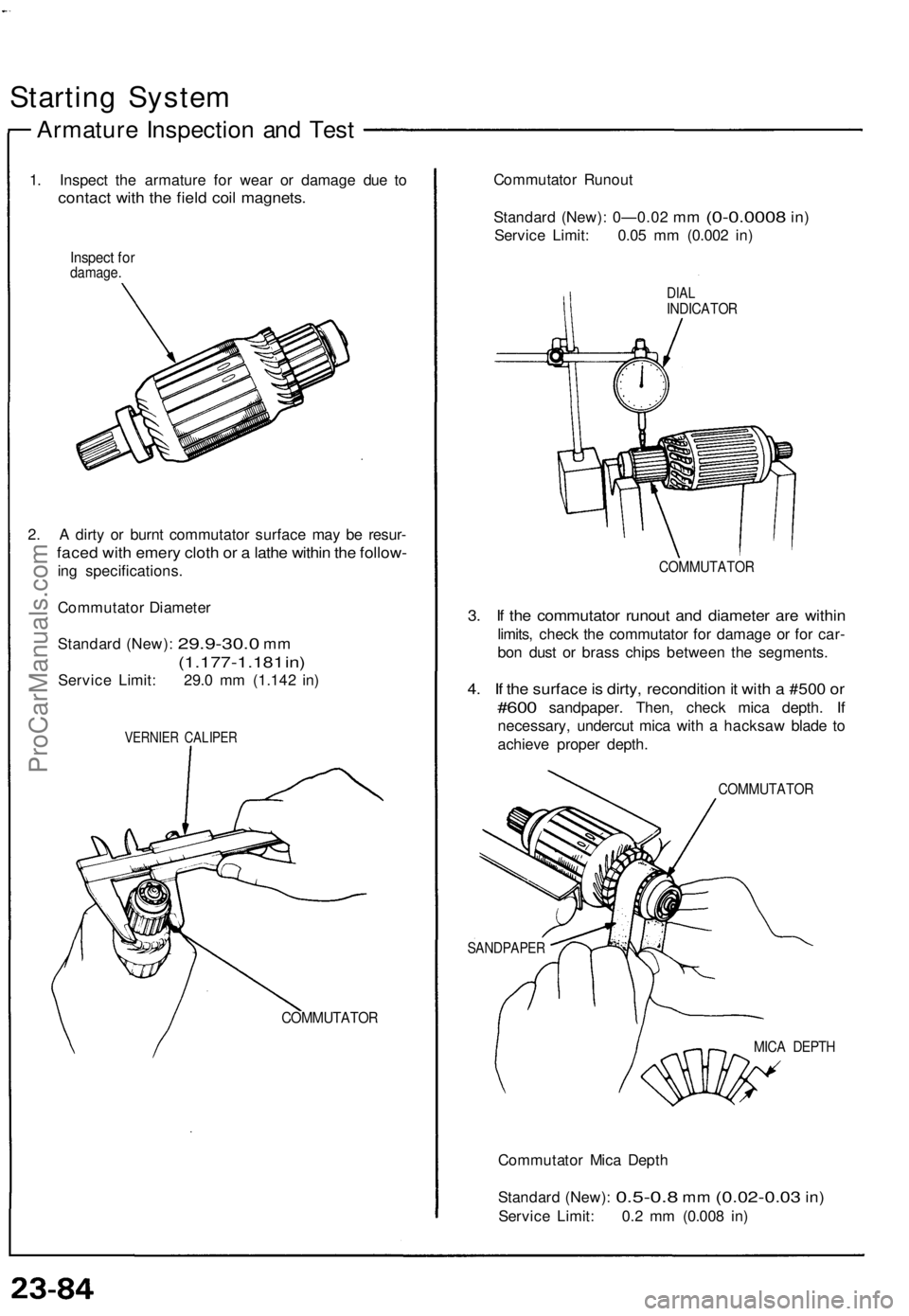

Starting System

Armature Inspection and Test

1. Inspect the armature for wear or damage due to

contact with the field coil magnets.

Inspect for

damage.

2. A dirty or burnt commutator surface may be resur-

faced with emery cloth or a lathe within the follow-

ing specifications.

Commutator Diameter

Standard (New):

29.9-30.0

mm

(1.177-1.181 in)

Service Limit: 29.0 mm (1.142 in)

VERNIER CALIPER

COMMUTATOR

Commutator Runout

Standard (New): 0—0.02

mm

(0-0.0008

in)

Service Limit: 0.05 mm (0.002 in)

DIAL

INDICATOR

COMMUTATOR

3. If the commutator runout and diameter are within

limits, check the commutator for damage or for car-

bon dust or brass chips between the segments.

4. If the surface is dirty, recondition it with a #500 or

#600

sandpaper. Then, check mica depth.

If

necessary, undercut mica with a hacksaw blade to

achieve proper depth.

COMMUTATOR

SANDPAPER

MICA DEPTH

Commutator Mica Depth

Standard (New):

0.5-0.8

mm

(0.02-0.03

in)

Service Limit: 0.2 mm (0.008 in)ProCarManuals.com

Page 786 of 1640

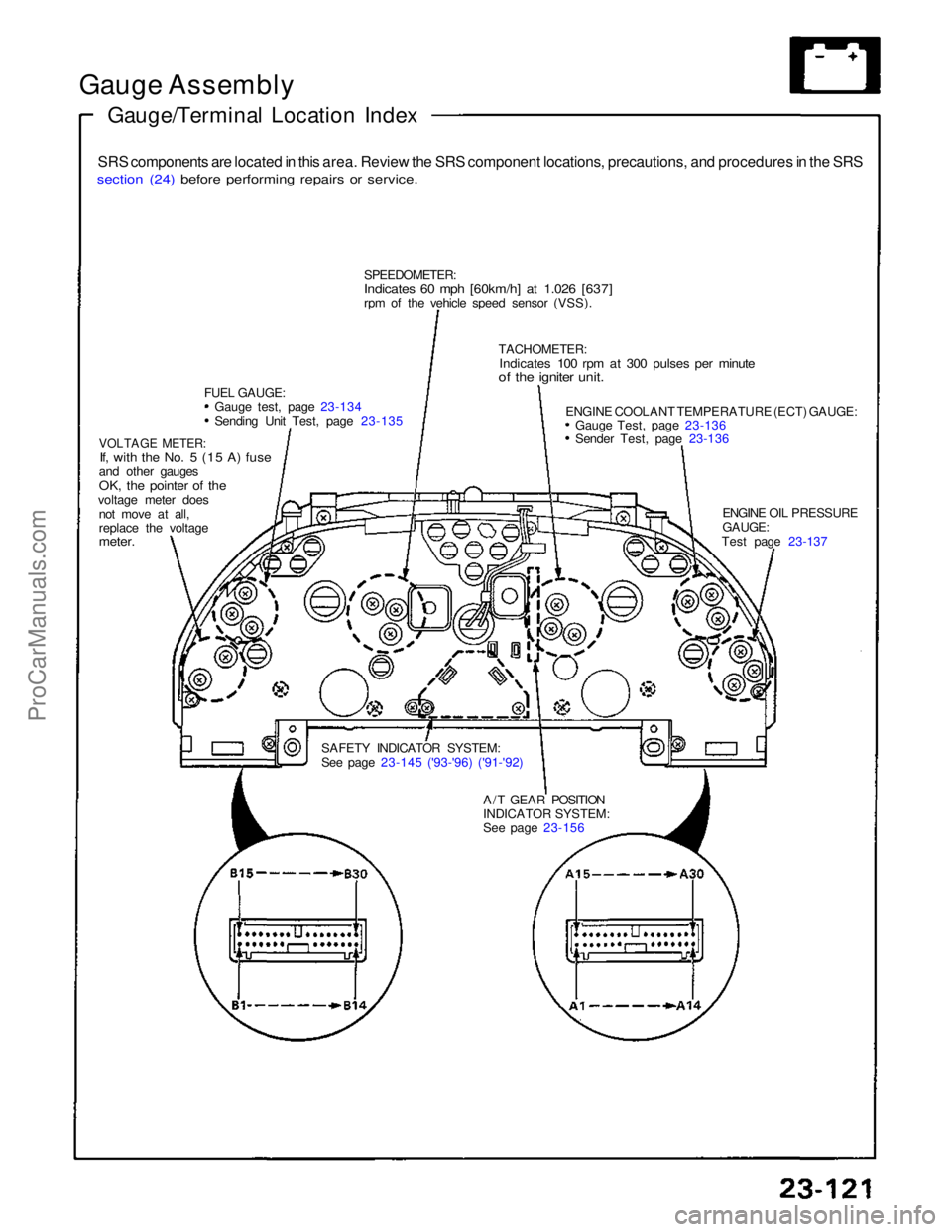

Gauge Assembly

Gauge/Terminal Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

SPEEDOMETER:

Indicates 60 mph [60km/h] at 1.026 [637]

rpm of the vehicle speed sensor (VSS).

FUEL GAUGE: Gauge test, page 23-134 Sending Unit Test, page 23-135

VOLTAGE METER:

If, with the No. 5 (15 A) fuse

and other gauges

OK, the pointer of the

voltage meter does not move at all,

replace the voltage

meter.

SAFETY INDICATOR SYSTEM:

See page 23-145 ('93-'96) ('91-'92)A/T GEAR POSITION

INDICATOR SYSTEM:

See page 23-156 ENGINE OIL PRESSURE

GAUGE:

Test page 23-137

ENGINE COOLANT TEMPERATURE (ECT) GAUGE:

Gauge Test, page 23-136 Sender Test, page 23-136

TACHOMETER:

Indicates 100 rpm at 300 pulses per minute

of the igniter unit.ProCarManuals.com

Page 805 of 1640

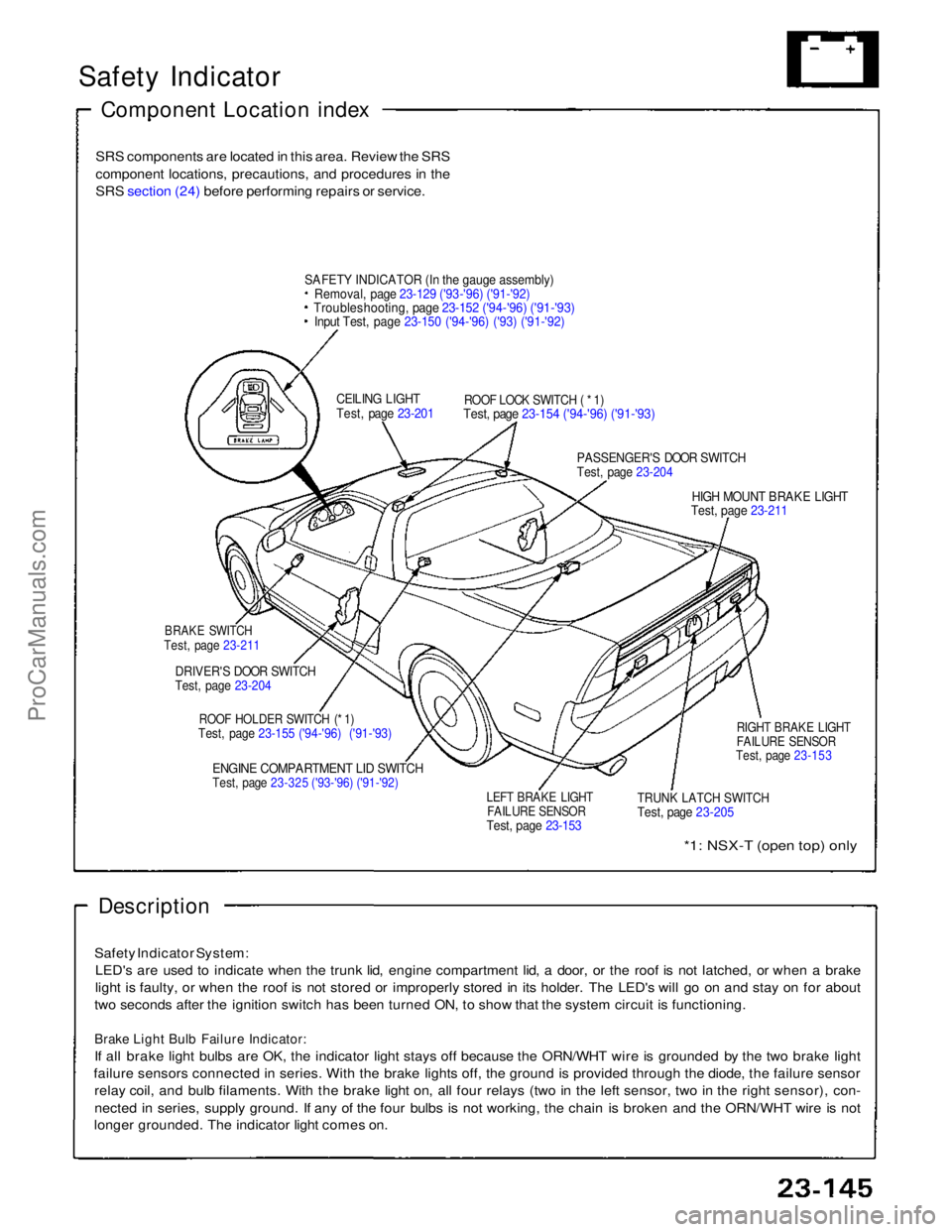

Safety Indicator

Component Location index

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

SAFET

Y

INDICATOR (In the gauge assembly)

Removal, page 23-129 ('93-'96) ('91-'92)

Troubleshooting, page 23-152 ('94-'96) ('91-'93)

Input Test, page 23-150 ('94-'96) ('93) ('91-'92)

CEILING LIGHT

Test, page 23-201

ROOF LOCK SWITCH ( * 1)

Test, page 23-154 ('94-'96) ('91-'93)

PASSENGER'S DOOR SWITCH

Test, page 23-204

HIGH MOUNT BRAKE LIGHT

Test, page 23-211

BRAKE SWITCH

Test, page 23-211

DRIVER'S DOOR SWITCH

Test, page 23-204

ROOF HOLDER SWITCH (* 1)

Test, page 23-155 ('94-'96) ('91-'93)

ENGINE COMPARTMENT LID SWITCH

Test, page 23-325 ('93-'96) ('91-'92)

LEFT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

TRUNK LATCH SWITCH

Test, page 23-205

RIGHT BRAKE LIGHT

FAILURE SENSOR

Test, page 23-153

*1: NSX-T (open top) only

Description

Safety Indicator System: LED's are used to indicate when the trunk lid, engine compartment lid, a door, or the roof is not latched, or when a brake

light is faulty, or when the roof is not stored or improperly stored in its holder. The LED's will go on and stay on for about

two seconds after the ignition switch has been turned ON, to show that the system circuit is functioning.

Brake Light Bulb Failure Indicator:

If all brake light bulbs are OK, the indicator light stays off because the ORN/WHT wire is grounded by the two brake light

failure sensors connected in series. With the brake lights off, the ground is provided through the diode, the failure sensor relay coil, and bulb filaments. With the brake light on, all four relays (two in the left sensor, two in the right sensor), con-

nected in series, supply ground. If any of the four bulbs is not working, the chain is broken and the ORN/WHT wire is not

longer grounded. The indicator light comes on.ProCarManuals.com

Page 806 of 1640

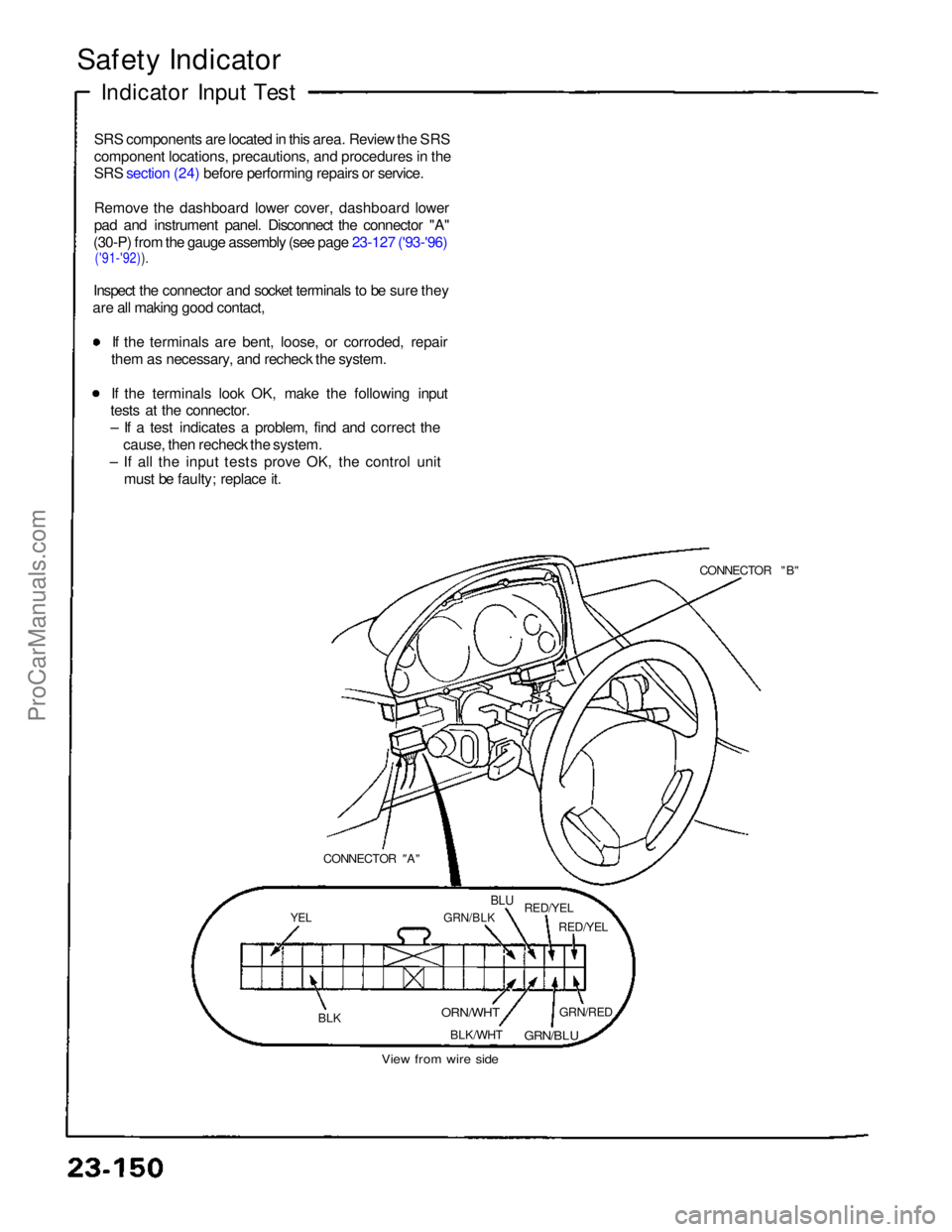

Safety Indicator

Indicator Input Test

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

Remove the dashboard lower cover, dashboard lower

pad and instrument panel. Disconnect the connector "A"

(30-P) from the gauge assembly (see page 23-127 ('93-'96)

('91-'92)).

Inspect the connector and socket terminals to be sure they

are all making good contact,

If the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system. If the terminals look OK, make the following input

tests at the connector.

– If a test indicates a problem, find and correct the

cause, then recheck the system.

– If all the input tests prove OK, the control unit must be faulty; replace it.

CONNECTOR "B"

CONNECTOR "

A"

YEL

GRN/BLK

BLU

RED/YEL

RED/YEL

BLK

ORN/WHT

BLK/WHT GRN/RED

GRN/BLU

View from wire sideProCarManuals.com

Page 862 of 1640

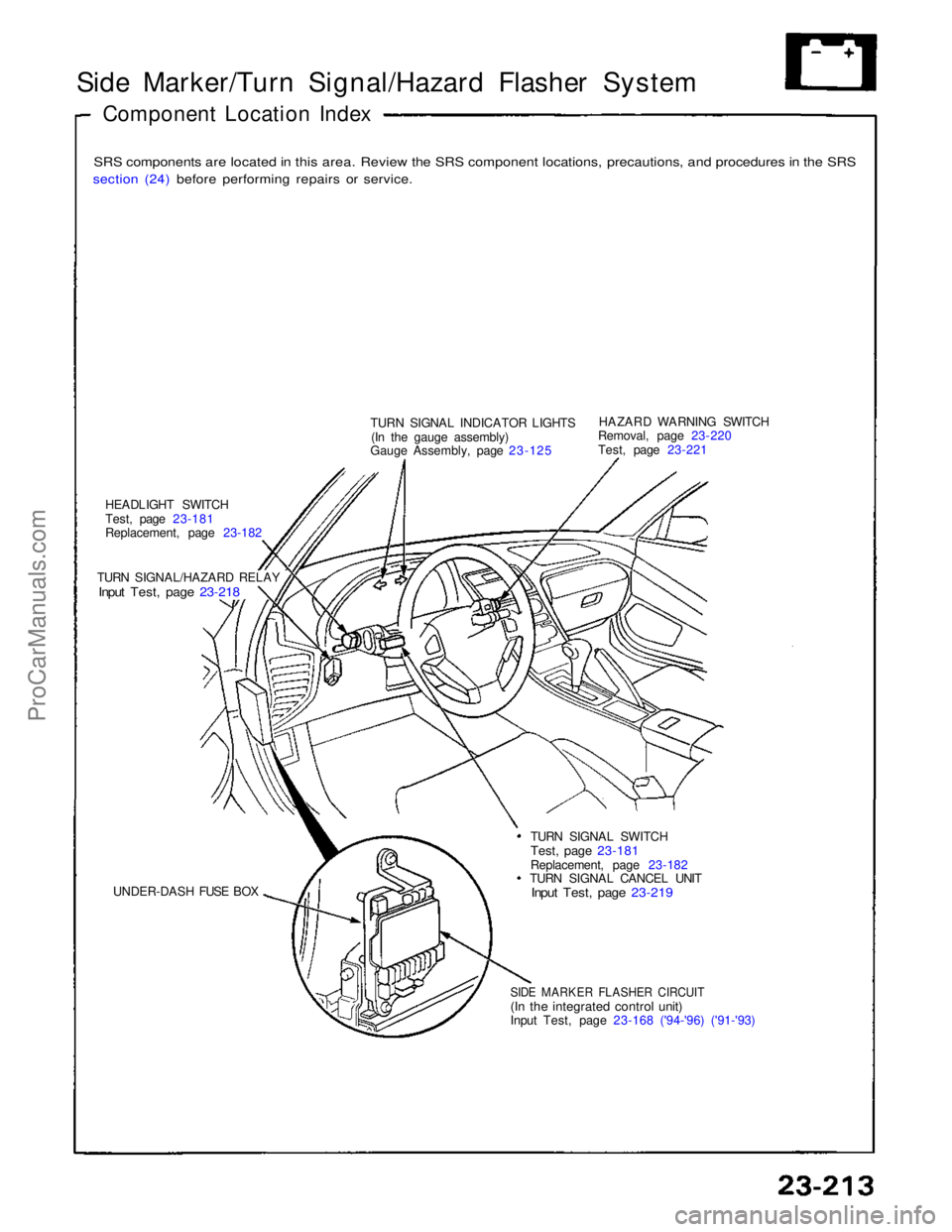

Side Marker/Turn Signal/Hazard Flasher System

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

TURN SIGNAL INDICATOR LIGHTS(In the gauge assembly)

Gauge Assembly, page 23-125 HAZARD WARNING SWITCH

Removal, page 23-220

Test, page 23-221

HEADLIGHT SWITCH

Test, page 23-181

Replacement, page 23-182

TURN SIGNAL/HAZARD RELAY

Input Test, page 23-218

UNDER-DASH FUSE BOX TURN SIGNAL SWITCH

Test, page 23-181

Replacement, page 23-182 TURN SIGNAL CANCEL UNIT

Input Test, page 23-219

SIDE MARKER FLASHER CIRCUIT

(In the integrated control unit)

Input Test, page 23-168 ('94-'96) ('91-'93)ProCarManuals.com

Page 971 of 1640

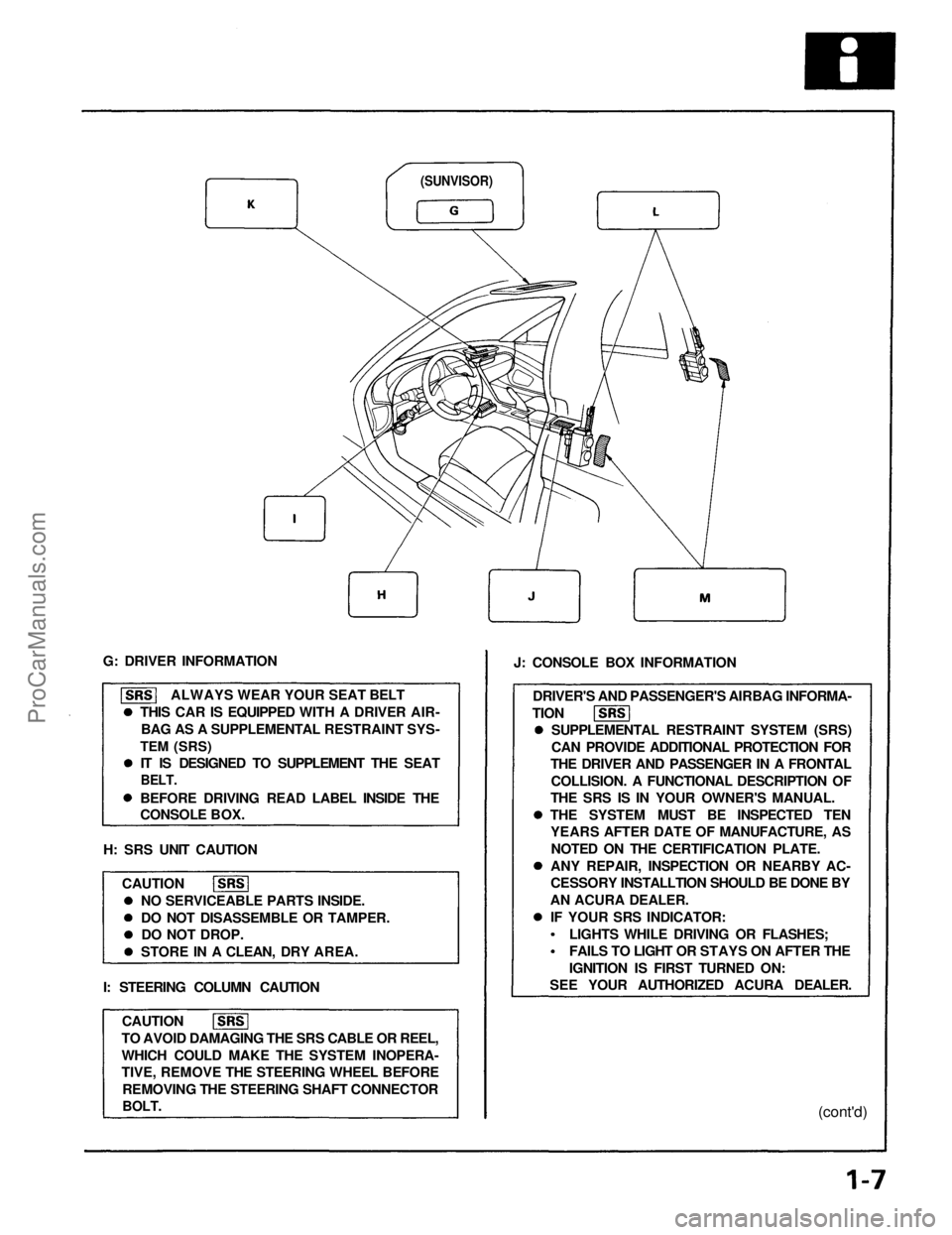

G: DRIVER INFORMATION

ALWAYS WEAR YOUR SEAT BELT

THIS CAR IS EQUIPPED WITH A DRIVER AIR- BAG AS A SUPPLEMENTAL RESTRAINT SYS-

TEM

(SRS) IT IS DESIGNED TO SUPPLEMENT THE SEAT

BELT.

BEFORE DRIVING READ LABEL INSIDE THE

CONSOLE BOX.

H: SRS UNIT CAUTION CAUTION NO SERVICEABLE PARTS INSIDE.

DO NOT DISASSEMBLE OR TAMPER.DO NOT DROP.

STORE IN A CLEAN, DRY AREA.

I: STEERING COLUMN CAUTION CAUTION

TO AVOID DAMAGING THE SRS CABLE OR REEL,

WHICH COULD MAKE THE SYSTEM INOPERA-

TIVE, REMOVE THE STEERING WHEEL BEFORE REMOVING THE STEERING SHAFT CONNECTOR

BOLT.

J: CONSOLE BOX INFORMATION

DRIVER'S AND PASSENGER'S AIRBAG INFORMA-

TION SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

CAN PROVIDE ADDITIONAL PROTECTION FOR

THE DRIVER AND PASSENGER IN A FRONTAL

COLLISION. A FUNCTIONAL DESCRIPTION OF

THE SRS IS IN YOUR OWNER'S MANUAL.

THE SYSTEM MUST BE INSPECTED TEN YEARS AFTER DATE OF MANUFACTURE, AS

NOTED ON THE CERTIFICATION PLATE.

ANY REPAIR, INSPECTION OR NEARBY AC-

CESSORY INSTALLTION SHOULD BE DONE BY

AN ACURA DEALER. IF YOUR SRS INDICATOR:

(cont'd)

LIGHTS WHILE DRIVING OR FLASHES;

FAILS TO LIGHT OR STAYS ON AFTER THE

IGNITION IS FIRST TURNED ON:

SEE YOUR AUTHORIZED ACURA DEALER.

(SUNVISOR)ProCarManuals.com