differential ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 20 of 1640

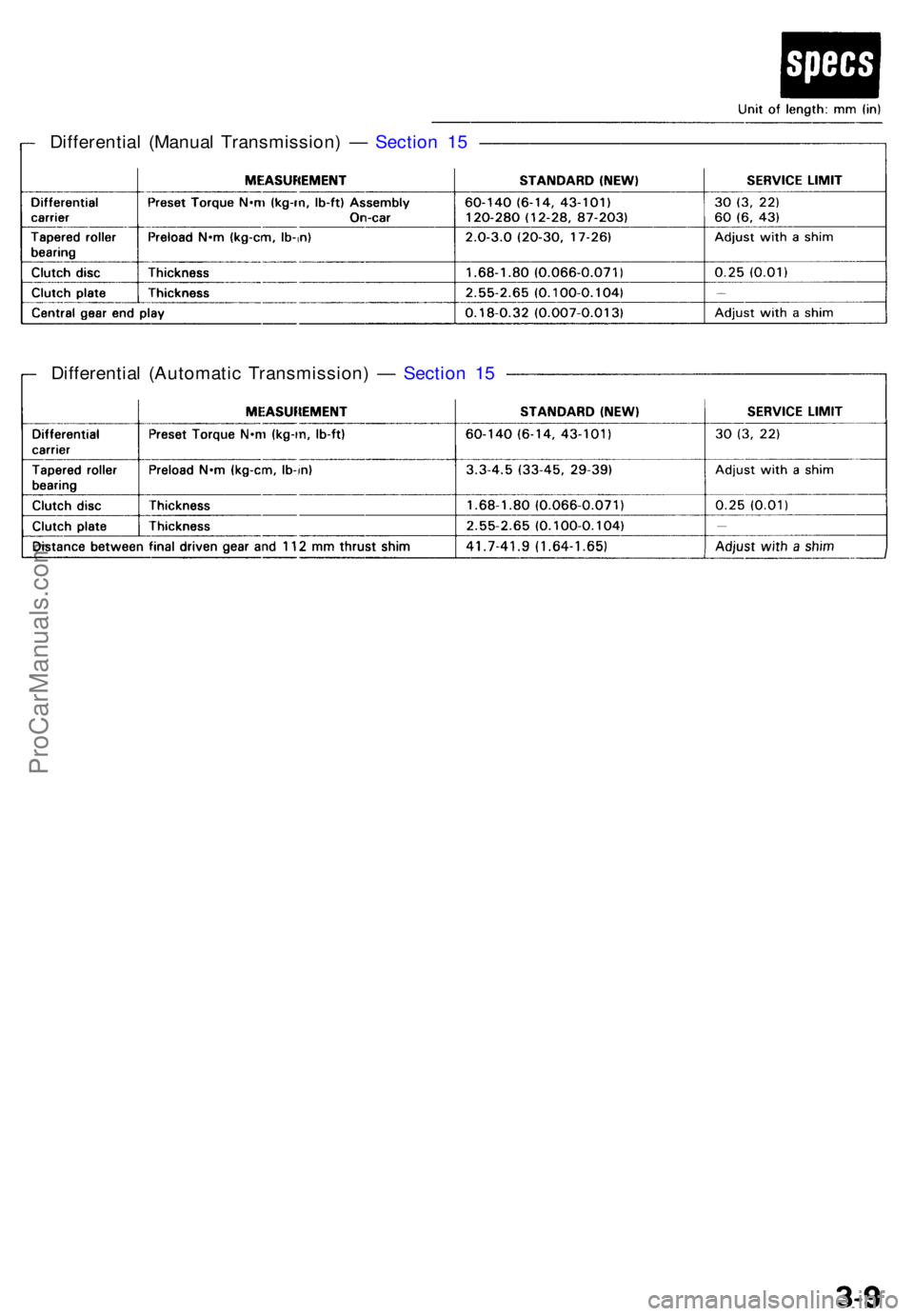

Differential (Manua l Transmission ) — Sectio n 1 5

Differentia l (Automati c Transmission ) — Sectio n 1 5

ProCarManuals.com

Page 56 of 1640

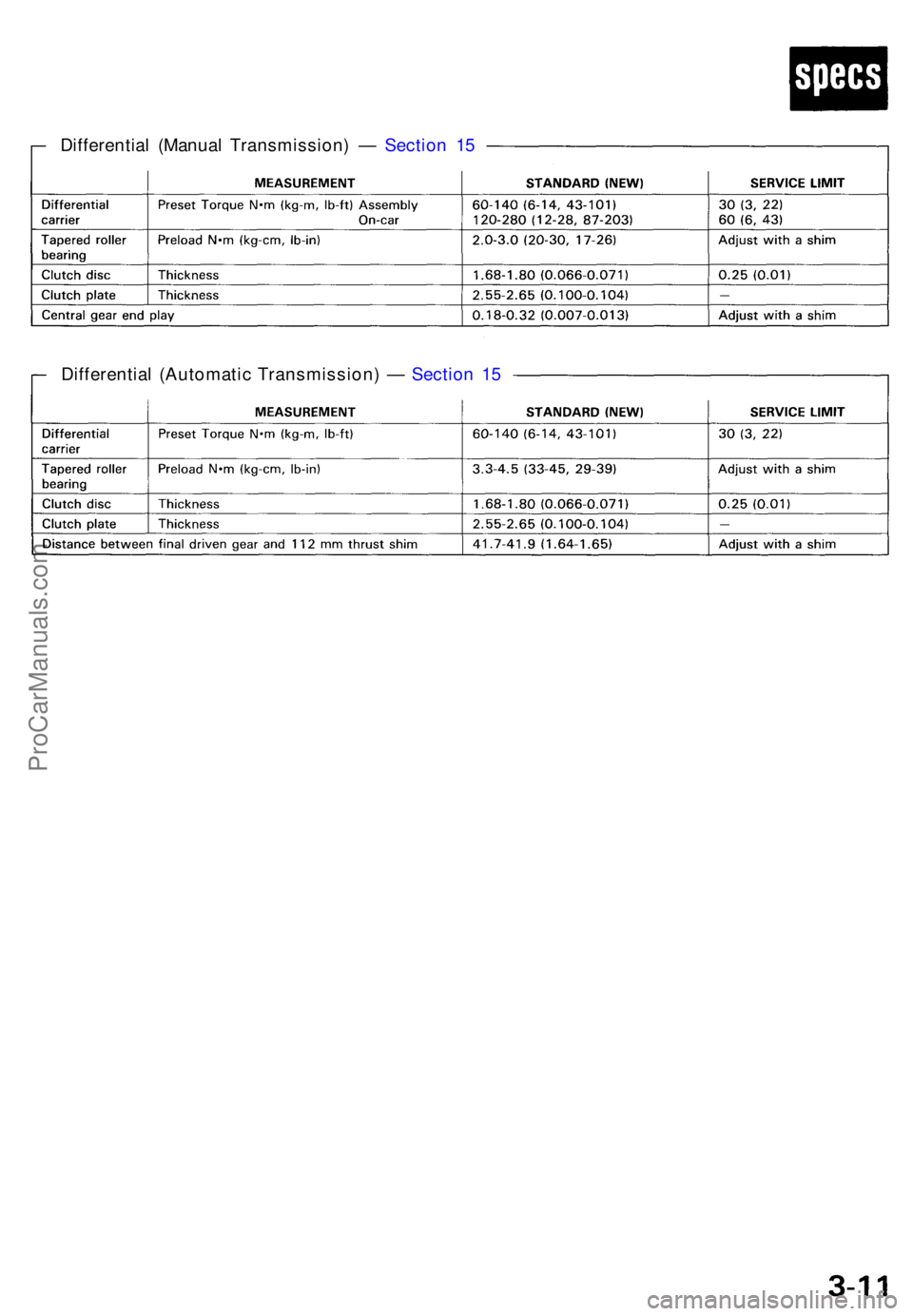

Differential (Manua l Transmission ) — Sectio n 1 5

Differentia l (Automati c Transmission ) — Sectio n 1 5

ProCarManuals.com

Page 305 of 1640

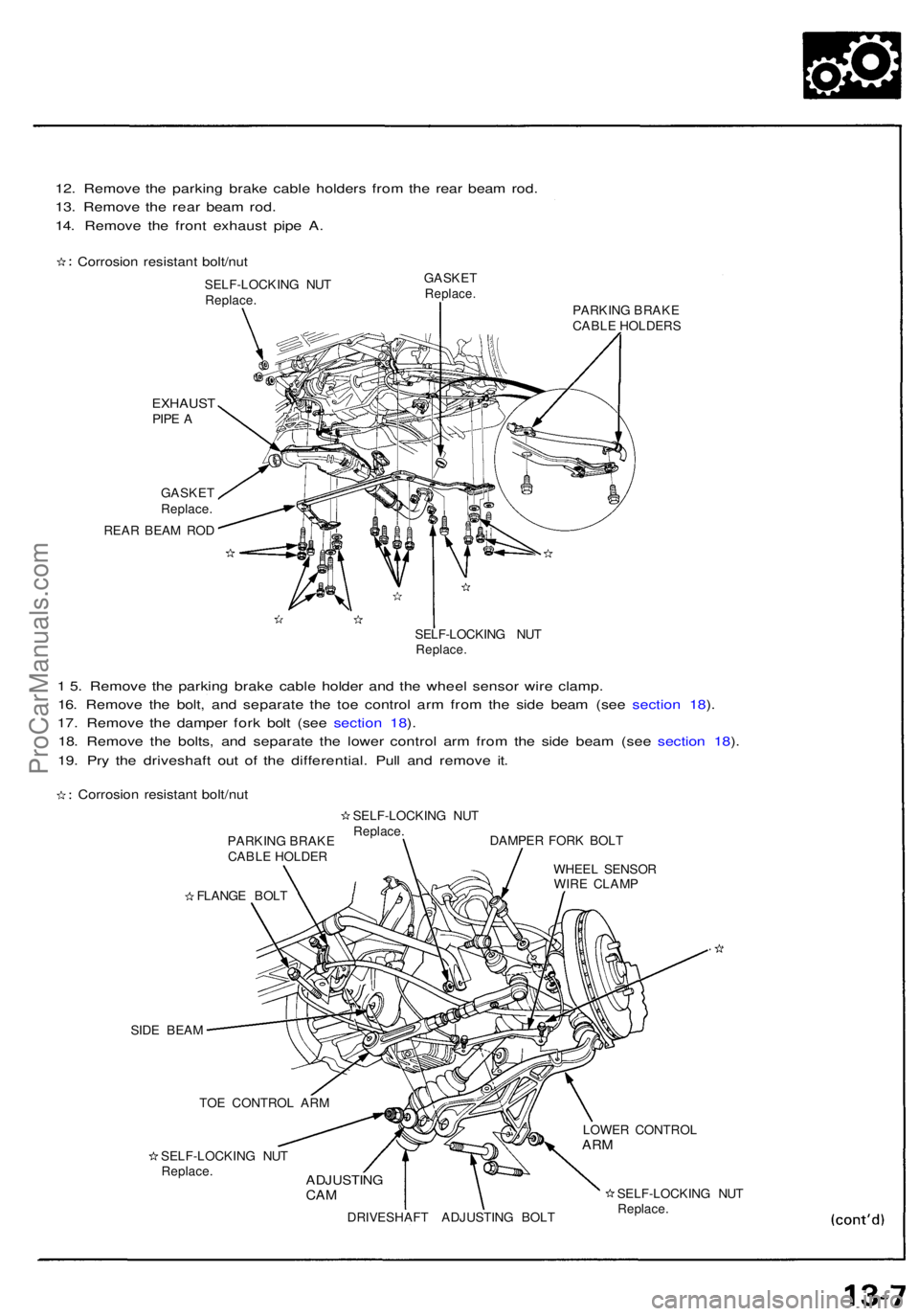

12. Remov e th e parkin g brak e cabl e holder s fro m th e rea r bea m rod .

13 . Remov e th e rea r bea m rod .

14 . Remov e th e fron t exhaus t pip e A .

Corrosio n resistan t bolt/nu t

SELF-LOCKIN G NU T

Replace .

EXHAUS TPIPE A

GASKE T

Replace .

REAR BEA M RO D

GASKE TReplace .PARKING BRAK E

CABL E HOLDER S

SELF-LOCKIN G NU T

Replace .

1 5 . Remov e th e parkin g brak e cabl e holde r an d th e whee l senso r wir e clamp .

16 . Remov e th e bolt , an d separat e th e to e contro l ar m fro m th e sid e bea m (se e sectio n 18 ).

17 . Remov e th e dampe r for k bol t (se e sectio n 18 ).

18 . Remov e th e bolts , an d separat e th e lowe r contro l ar m fro m th e sid e bea m (se e sectio n 18 ).

19 . Pr y th e driveshaf t ou t o f th e differential . Pul l an d remov e it .

Corrosio n resistan t bolt/nu t

PARKIN G BRAK E

CABL E HOLDE RSELF-LOCKIN

G NU T

Replace .

FLANG E BOL T DAMPE

R FOR K BOL T

WHEE L SENSO R

WIR E CLAM P

SID E BEA M

SELF-LOCKIN G NU T

Replace .ADJUSTIN GCAM

DRIVESHAF T ADJUSTIN G BOL T LOWE

R CONTRO L

ARM

SELF-LOCKIN G NU T

Replace .

TO

E CONTRO L AR M

ProCarManuals.com

Page 306 of 1640

Transmission Assembly

Removal

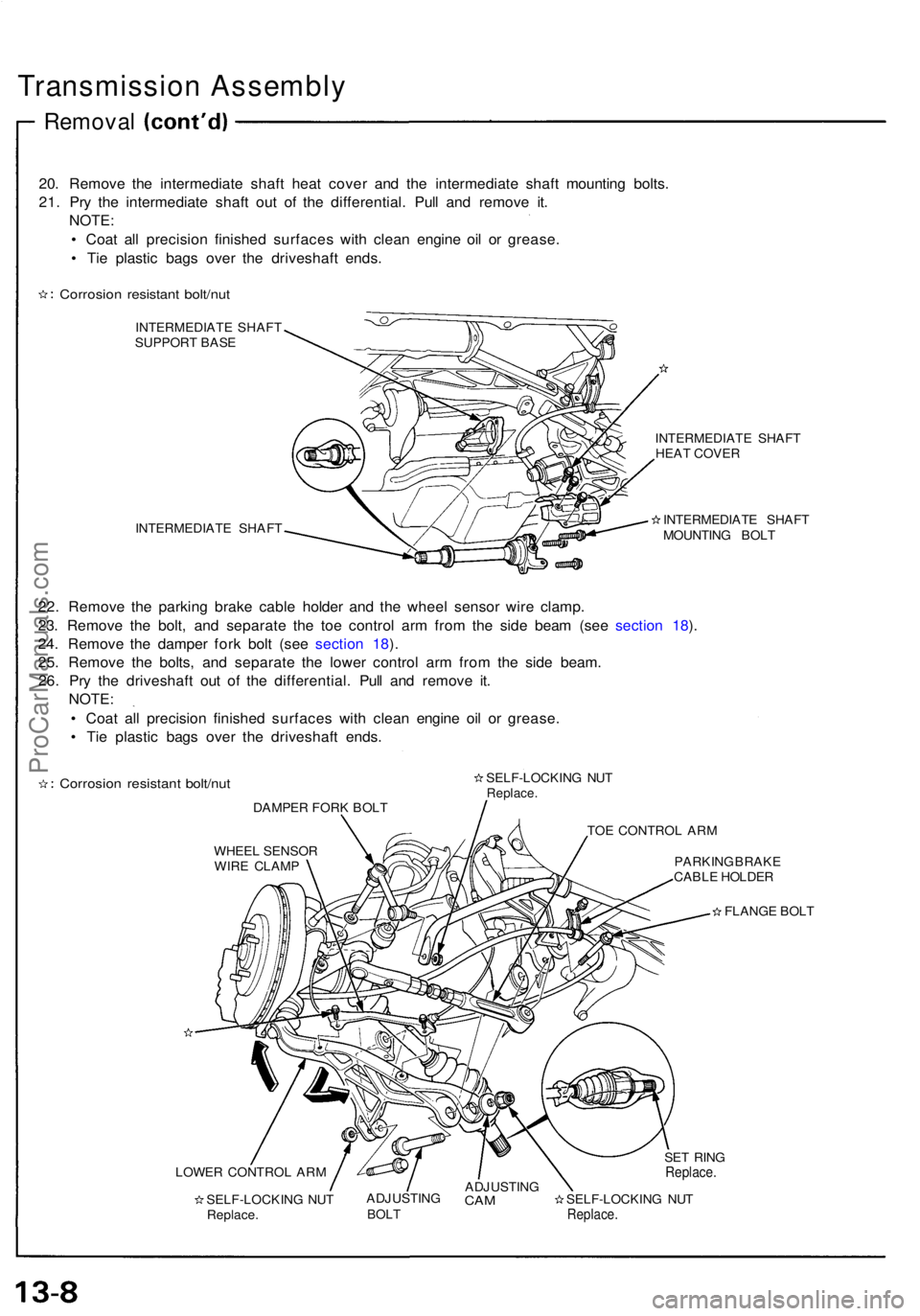

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

INTERMEDIATE SHAFT INTERMEDIATE SHAFT

HEAT COVER

INTERMEDIATE SHAFT

MOUNTING BOLT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt, and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18).

25. Remove the bolts, and separate the lower control arm from the side beam. 26. Pry the driveshaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT SELF-LOCKING NUT

Replace.

TOE CONTROL ARM

WHEEL SENSOR WIRE CLAMP PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.

SET RING

Replace.ProCarManuals.com

Page 310 of 1640

Transmission Housing

Removal

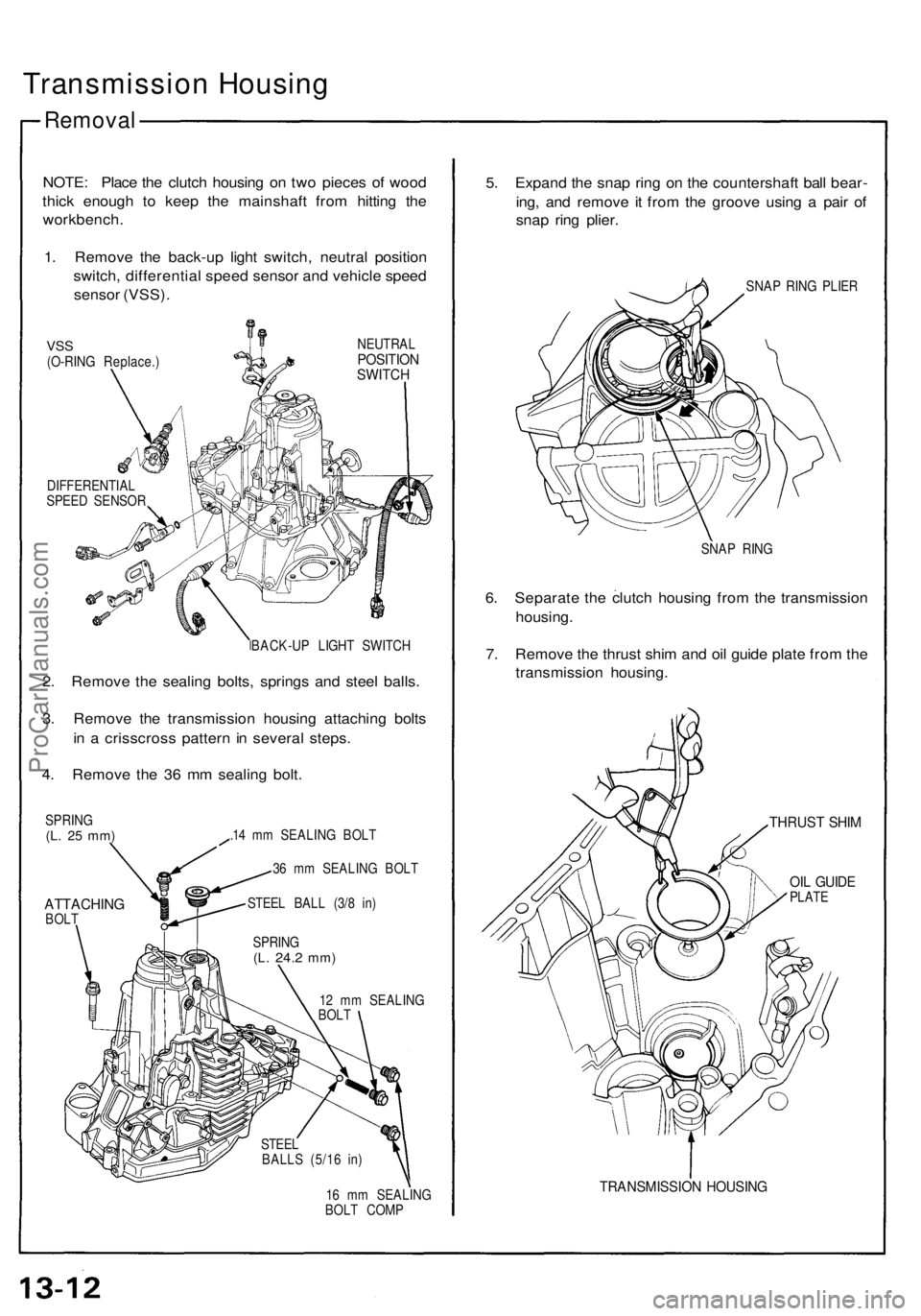

NOTE: Place the clutch housing on two pieces of wood

thick enough to keep the mainshaft from hitting the

workbench.

1. Remove the back-up light switch, neutral position

switch, differential speed sensor and vehicle speed

sensor (VSS).

VSS

(O-RING Replace.)

NEUTRAL

POSITION

SWITCH

DIFFERENTIAL

SPEED SENSOR

BACK-UP LIGHT SWITCH

2. Remove the sealing bolts, springs and steel balls.

3. Remove the transmission housing attaching bolts

in a crisscross pattern in several steps.

4. Remove the 36 mm sealing bolt.

SPRING

(L. 25 mm)

ATTACHING

BOLT

.14 mm SEALING BOLT

36 mm SEALING BOLT

STEEL BALL (3/8 in)

12 mm SEALING

BOLT

16 mm SEALING

BOLT COMP

5. Expand the snap ring on the countershaft ball bear-

ing, and remove it from the groove using a pair of

snap ring plier.

SNAP RING PLIER

SNAP RING

6. Separate the clutch housing from the transmission

housing.

7. Remove the thrust shim and oil guide plate from the

transmission housing.

THRUST SHIM

OIL GUIDE

PLATE

TRANSMISSION HOUSING

SPRING

(L.

24.2

mm)

STEEL

BALLS (5/16 in)ProCarManuals.com

Page 316 of 1640

Mainshaft, Countershaft,

Differential Assemblies

Removal

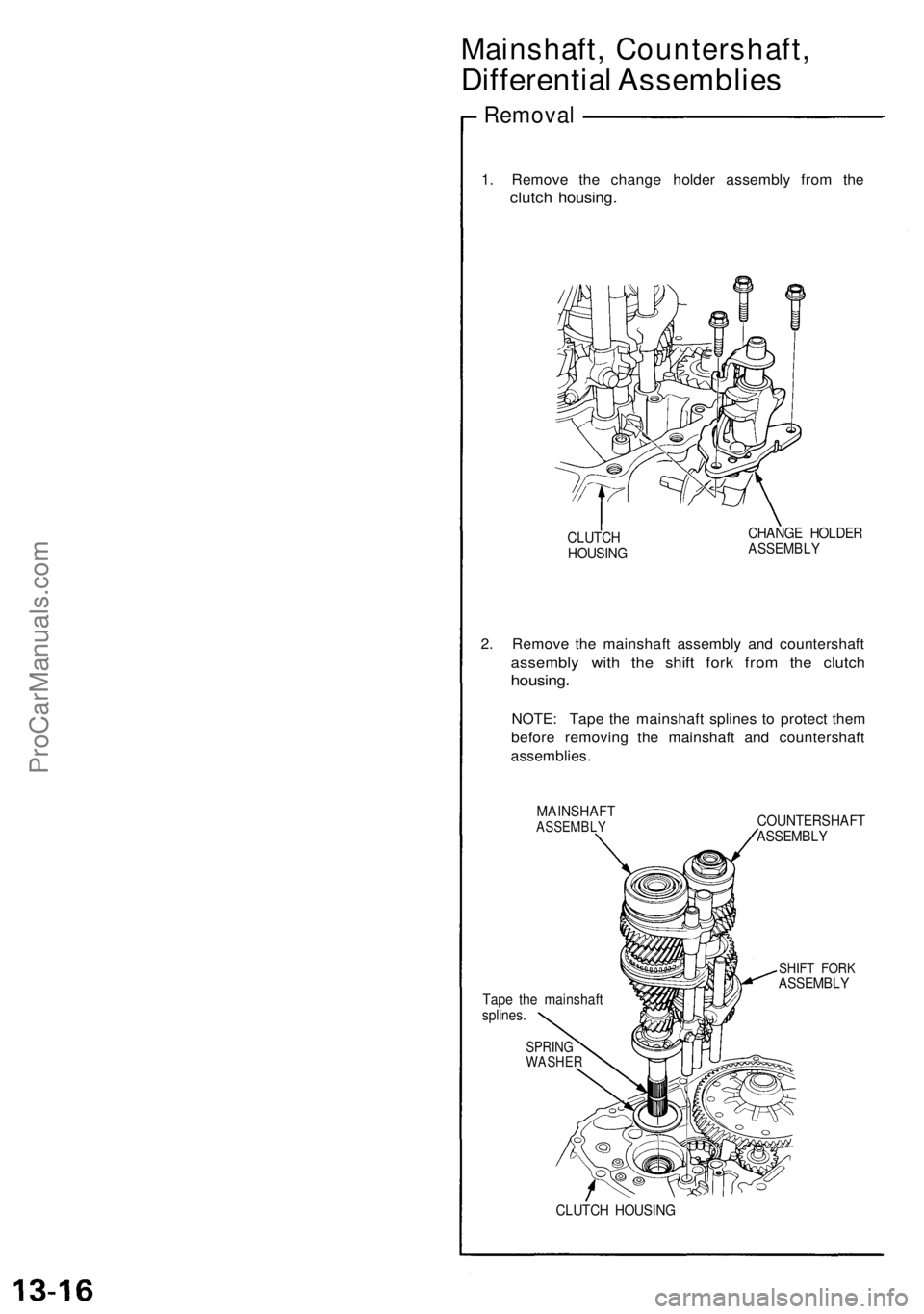

1. Remove the change holder assembly from the

clutch housing.

CLUTCH

HOUSING

CHANGE HOLDER

ASSEMBLY

2. Remove the mainshaft assembly and countershaft

assembly with the shift fork from the clutch

housing.

NOTE: Tape the mainshaft splines to protect them

before removing the mainshaft and countershaft

assemblies.

MAINSHAFT

ASSEMBLY

COUNTERSHAFT

ASSEMBLY

SHIFT FORK

ASSEMBLY

Tape the mainshaft

splines.

SPRING

WASHER

CLUTCH HOUSINGProCarManuals.com

Page 317 of 1640

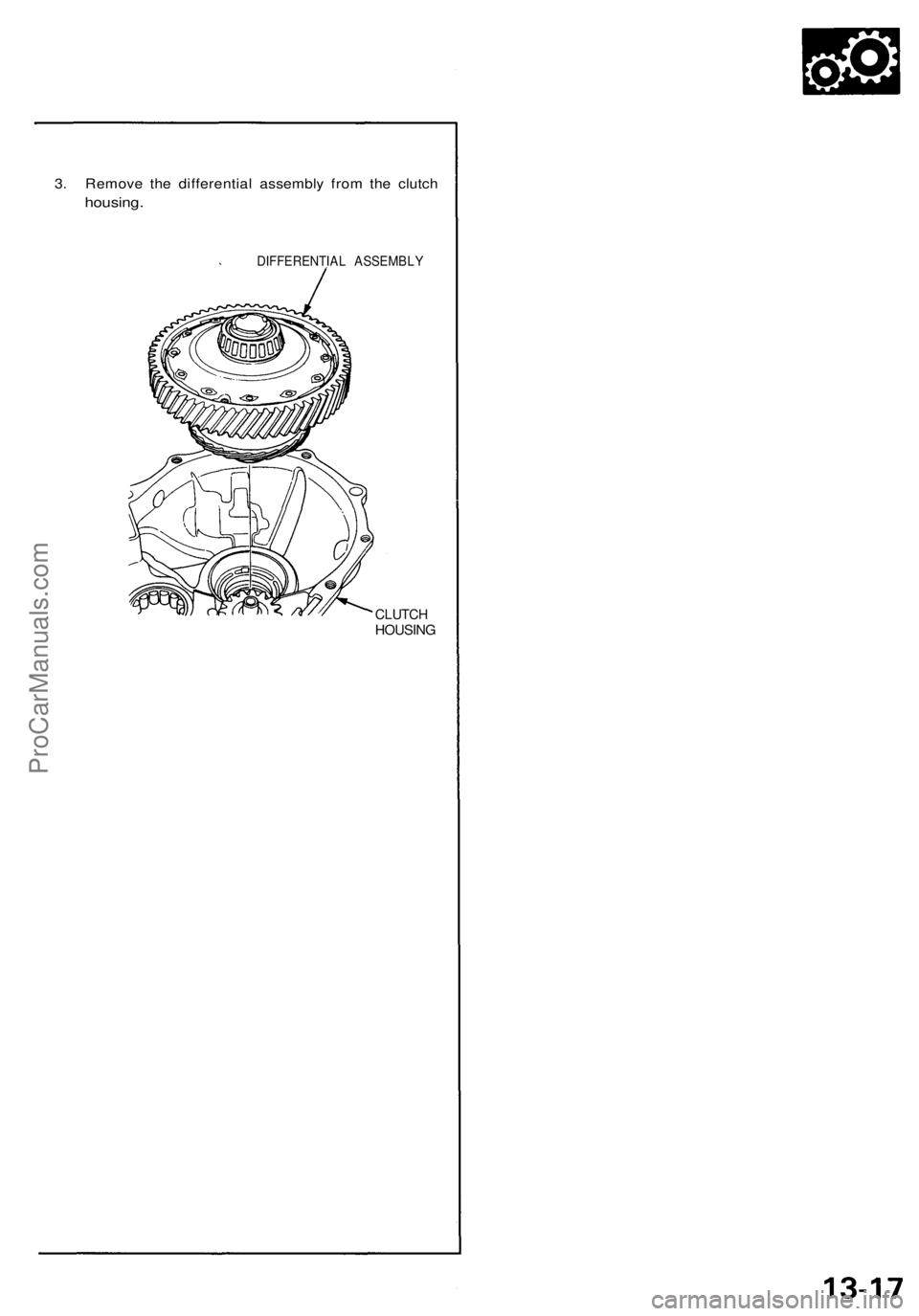

3. Remove the differential assembly from the clutch

housing.

DIFFERENTIAL ASSEMBLY

CLUTCH

HOUSINGProCarManuals.com

Page 347 of 1640

Transmission

Reassembly

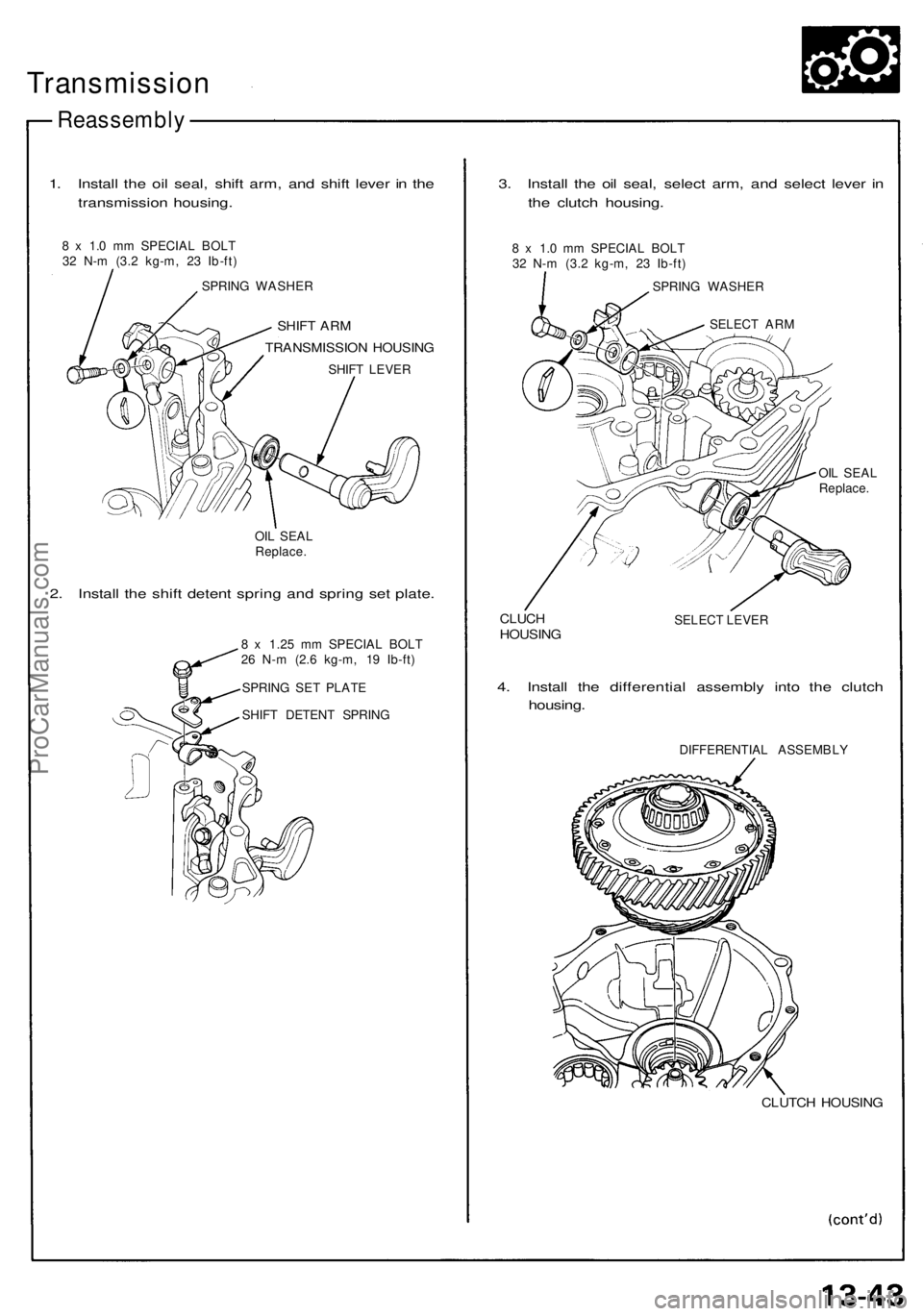

1. Install the oil seal, shift arm, and shift lever in the

transmission housing.

8 x 1.0 mm SPECIAL BOLT

32 N-m (3.2 kg-m, 23 Ib-ft)

SPRING WASHER

SHIFT ARM

TRANSMISSION HOUSING

SHIFT LEVER

OIL SEAL

Replace.

2. Install the shift detent spring and spring set plate.

8 x 1.25 mm SPECIAL BOLT

26 N-m (2.6 kg-m, 19 Ib-ft)

SPRING SET PLATE

SHIFT DETENT SPRING

3. Install the oil seal, select arm, and select lever in

the clutch housing.

8 x 1.0 mm SPECIAL BOLT

32 N-m (3.2 kg-m, 23 Ib-ft)

SPRING WASHER

SELECT ARM

OIL SEAL

Replace.

CLUCH

HOUSING

SELECT LEVER

4. Install the differential assembly into the clutch

housing.

DIFFERENTIAL ASSEMBLY

CLUTCH HOUSINGProCarManuals.com

Page 356 of 1640

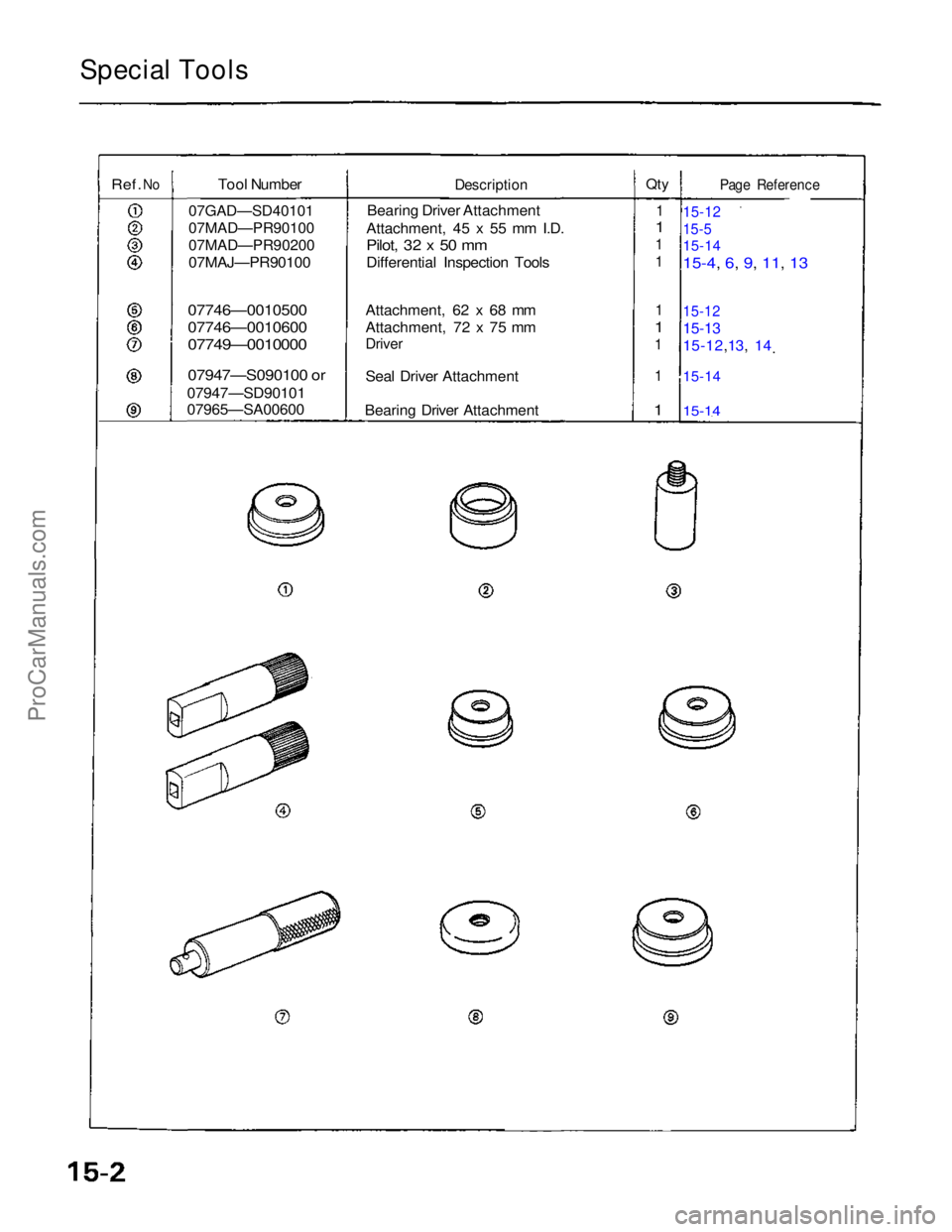

Special Tools

Ref.

No

Tool Number

Description

Qty

Page Reference

07GAD—SD40101

07MAD—PR90100

07MAD—PR90200

07MAJ—PR90100

07746—0010500

07746—0010600

07749—0010000

07947—S090100 or

07947—SD90101

07965—SA00600 Bearing Driver Attachment

Attachment, 45 x 55 mm I.D.

Pilot, 32 x 50 mm

Differential Inspection Tools

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver

Seal Driver Attachment

Bearing Driver Attachment

1

1

1

1

1

1

1

1

1

15-12

15-5

15-14

15-4 , 6, 9, 11, 13

15-12

15-13

15-12,13,

14

15-14

15-14

ProCarManuals.com

Page 357 of 1640

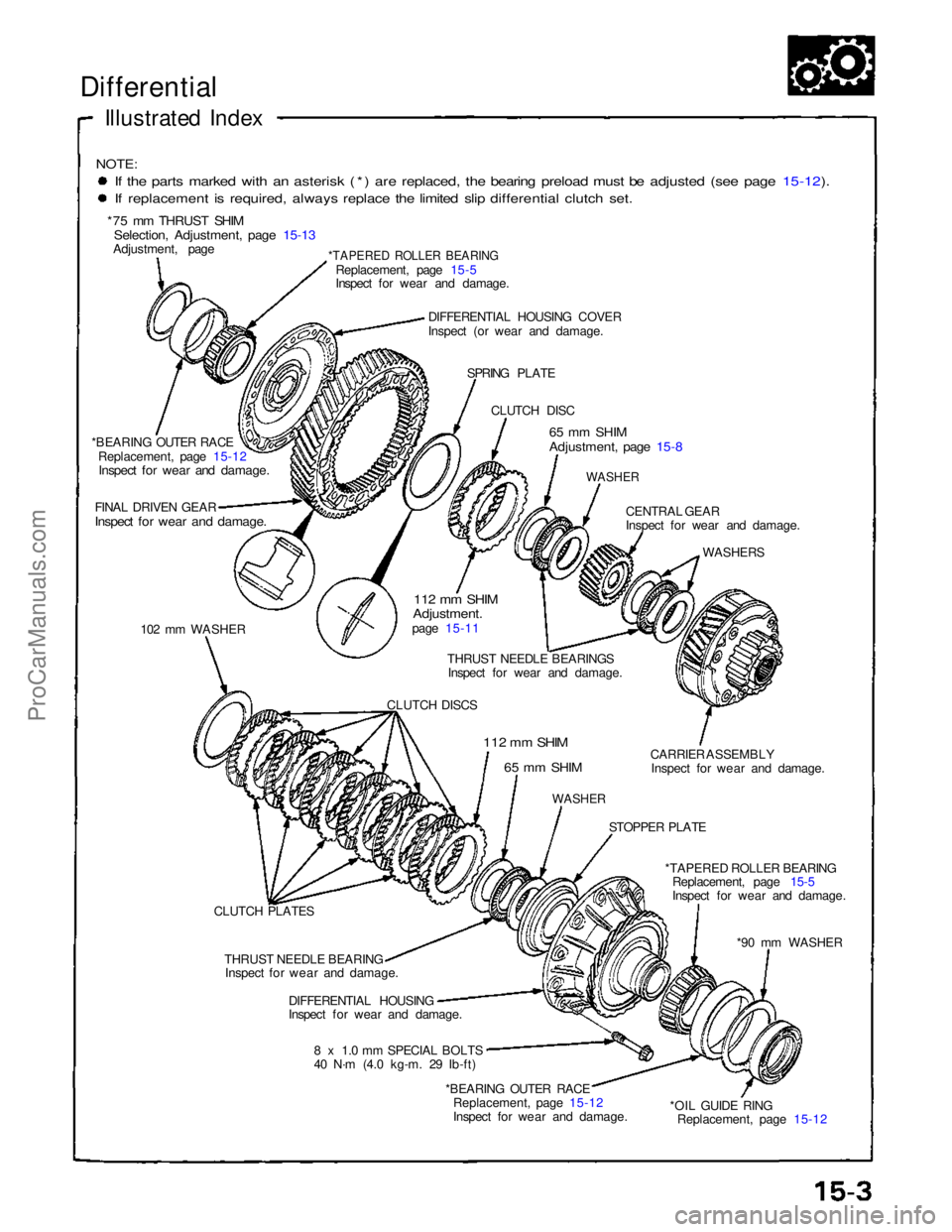

Differential

Illustrated Index

NOTE:

If the parts marked with an asterisk (*) are replaced, the bearing preload must be adjusted (see page 15-12).

If replacement is required, always replace the limited slip differential clutch set.

*75 mm THRUST SHIM

Selection, Adjustment, page 15-13

Adjustment, page

*TAPERED ROLLER BEARING

Replacement, page 15-5

Inspect for wear and damage.

DIFFERENTIAL HOUSING COVER

Inspect (or wear and damage.

SPRING PLATECLUTCH DISC

65 mm SHIM

Adjustment, page 15-8

*BEARING OUTER RACE

Replacement, page 15-12

Inspect for wear and damage.

FINAL DRIVEN GEAR

Inspect for wear and damage.

WASHER

112 mm SHIM

Adjustment.

page 15-11 CENTRAL GEAR

Inspect for wear and damage.

WASHERS

102 mm WASHER THRUST NEEDLE BEARINGSInspect for wear and damage.

CLUTCH DISCS

112 mm SHIM

65 mm SHIM

WASHER

CARRIER ASSEMBLY

Inspect for wear and damage.

STOPPER PLATE *TAPERED ROLLER BEARINGReplacement, page 15-5

Inspect for wear and damage.

*90 mm WASHER

CLUTCH PLATES

THRUST NEEDLE BEARINGInspect for wear and damage.

DIFFERENTIAL HOUSING

Inspect for wear and damage.

8 x 1.0 mm SPECIAL BOLTS

40 N·m (4.0 kg-m. 29 Ib-ft) *BEARING OUTER RACEReplacement, page 15-12

Inspect for wear and damage. *OIL GUIDE RING

Replacement, page 15-12ProCarManuals.com