fuel pump ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 80 of 1640

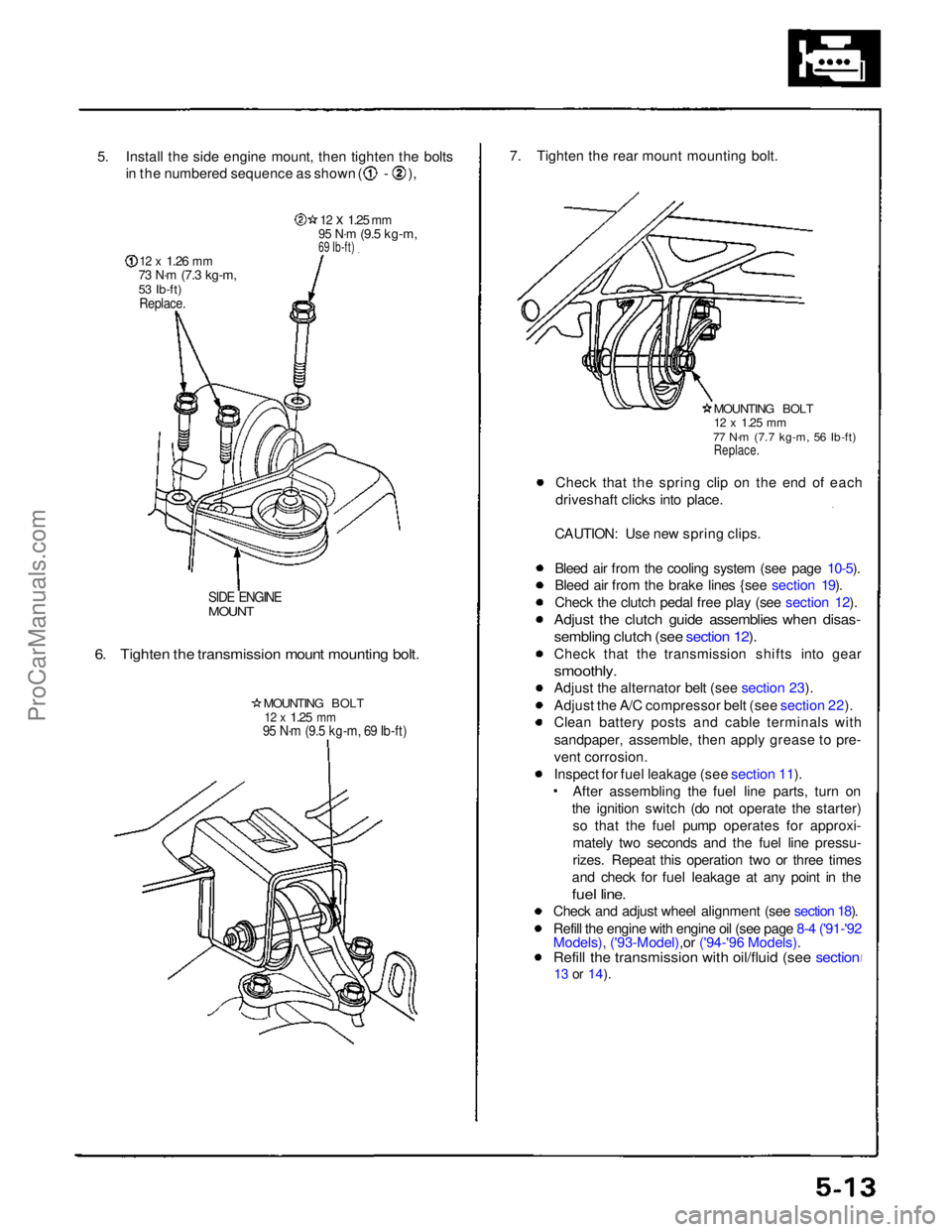

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 228 of 1640

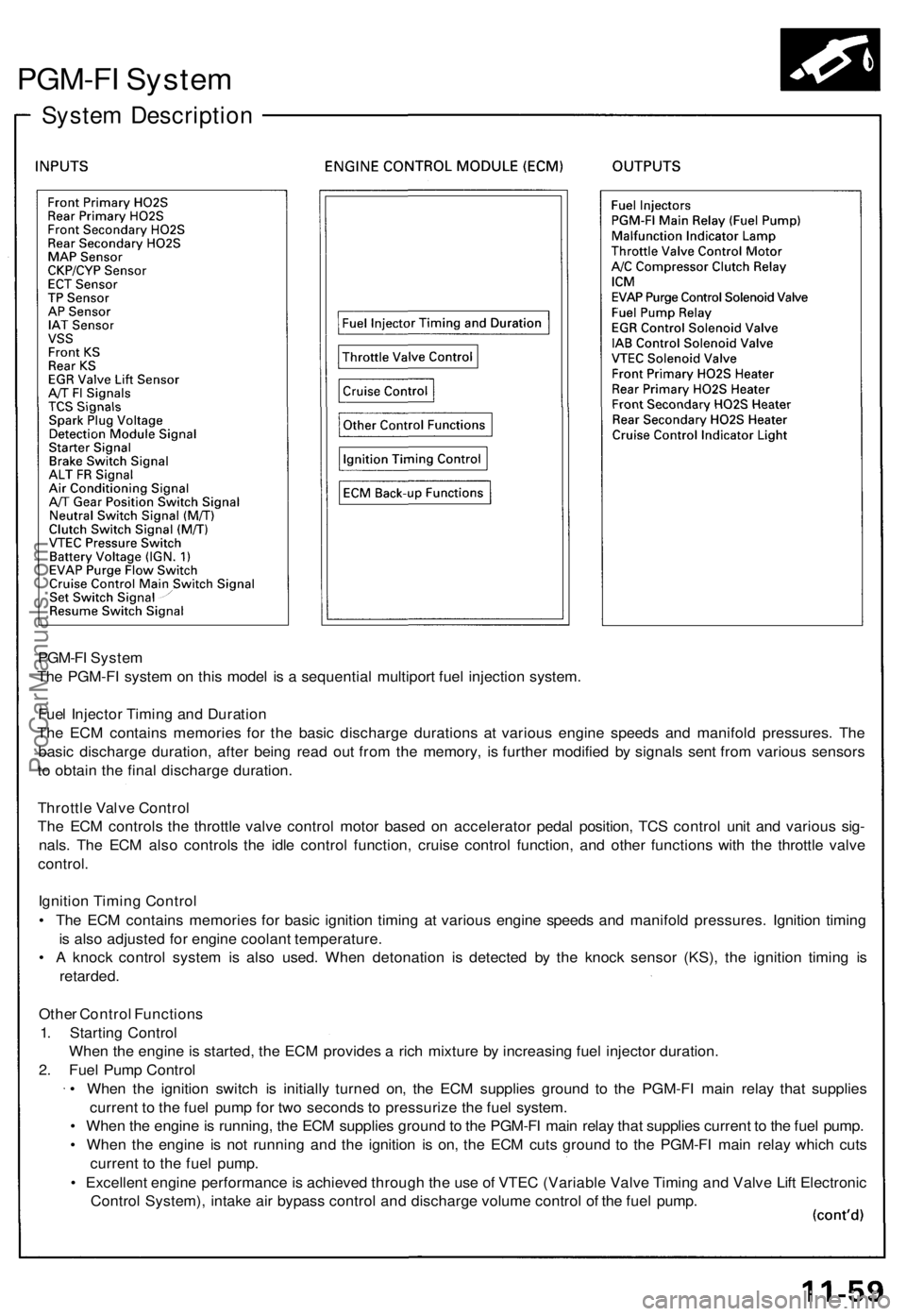

PGM-FI System

System Description

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel Injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Throttle Valve Control

The ECM controls the throttle valve control motor based on accelerator pedal position, TCS control unit and various sig-

nals. The ECM also controls the idle control function, cruise control function, and other functions with the throttle valve

control.

Ignition Timing Control

• The ECM contains memories for basic ignition timing at various engine speeds and manifold pressures. Ignition timing

is also adjusted for engine coolant temperature.

• A knock control system is also used. When detonation is detected by the knock sensor (KS), the ignition timing is

retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

• When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

• When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

• When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

• Excellent engine performance is achieved through the use of VTEC (Variable Valve Timing and Valve Lift Electronic

Control System), intake air bypass control and discharge volume control of the fuel pump.ProCarManuals.com

Page 254 of 1640

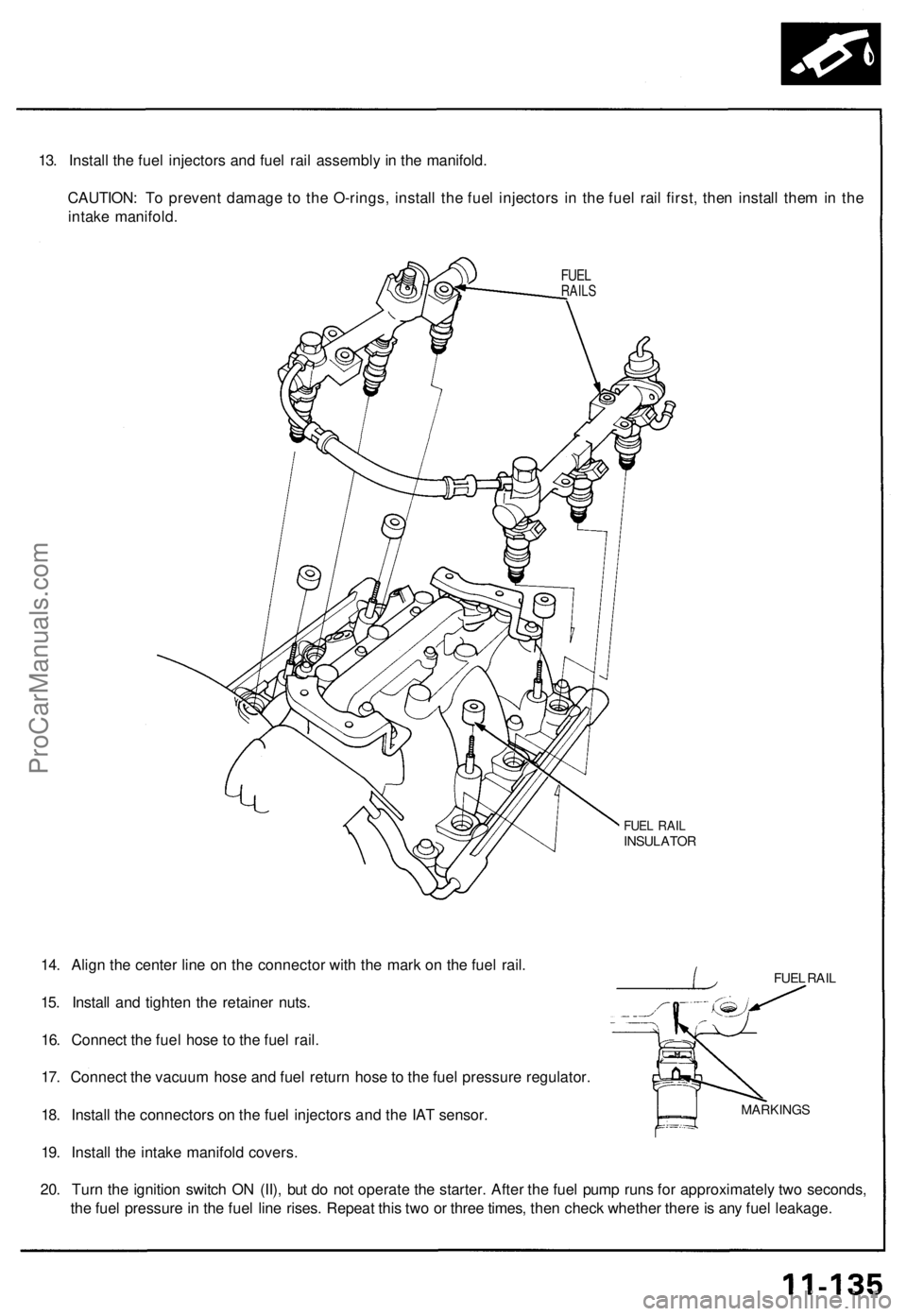

13. Install the fuel injectors and fuel rail assembly in the manifold.

CAUTION: To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the

intake manifold.

FUEL

RAILS

FUEL RAIL

INSULATOR

FUEL RAIL

14. Align the center line on the connector with the mark on the fuel rail.

15. Install and tighten the retainer nuts.

16. Connect the fuel hose to the fuel rail.

17. Connect the vacuum hose and fuel return hose to the fuel pressure regulator.

18. Install the connectors on the fuel injectors and the IAT sensor.

19. Install the intake manifold covers.

20. Turn the ignition switch ON (II), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuel pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

MARKINGSProCarManuals.com

Page 259 of 1640

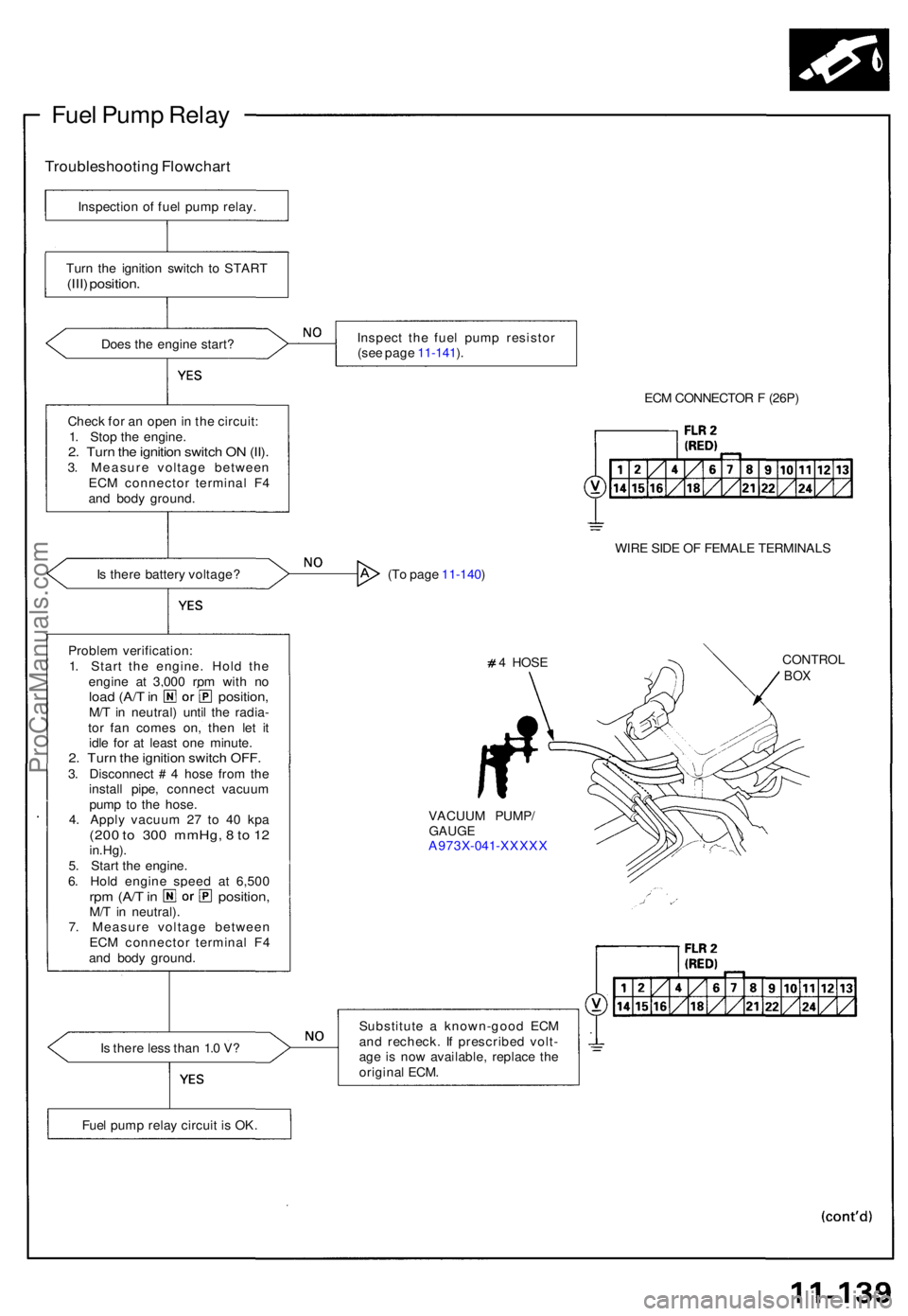

Fuel Pum p Rela y

Troubleshootin g Flowchar t

Inspection o f fue l pum p relay .

Tur n th e ignitio n switc h t o STAR T

(III) position .

Does th e engin e start ?

Chec k fo r a n ope n in th e circuit :

1 . Sto p th e engine .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e batter y voltage ?

Proble m verification :

1 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (A/ T in position ,M/T in neutral ) unti l th e radia -

to r fa n come s on , the n le t i t

idl e fo r a t leas t on e minute .

2. Tur n th e ignitio n switc h OFF .3. Disconnec t # 4 hos e fro m th e

instal l pipe , connec t vacuu m

pum p t o th e hose .

4 . Appl y vacuu m 2 7 t o 4 0 kp a

(200 t o 300 mmHg , 8 to 1 2in.Hg) .

5 . Star t th e engine .

6 . Hol d engin e spee d a t 6,50 0

rpm (A/ T in position ,M/T in neutral) .

7 . Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e les s tha n 1. 0 V ? Inspec

t th e fue l pum p resisto r

(se e pag e 11-141 ).

ECM CONNECTO R F (26P )

WIR E SID E O F FEMAL E TERMINAL S

(T o pag e 11-140 )

4 HOS E

CONTRO LBOX

VACUU M PUMP /GAUGEA973X-04 1-XXXX X

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e i s no w available , replac e th e

origina l ECM .

Fue l pum p rela y circui t i s OK .

ProCarManuals.com

Page 261 of 1640

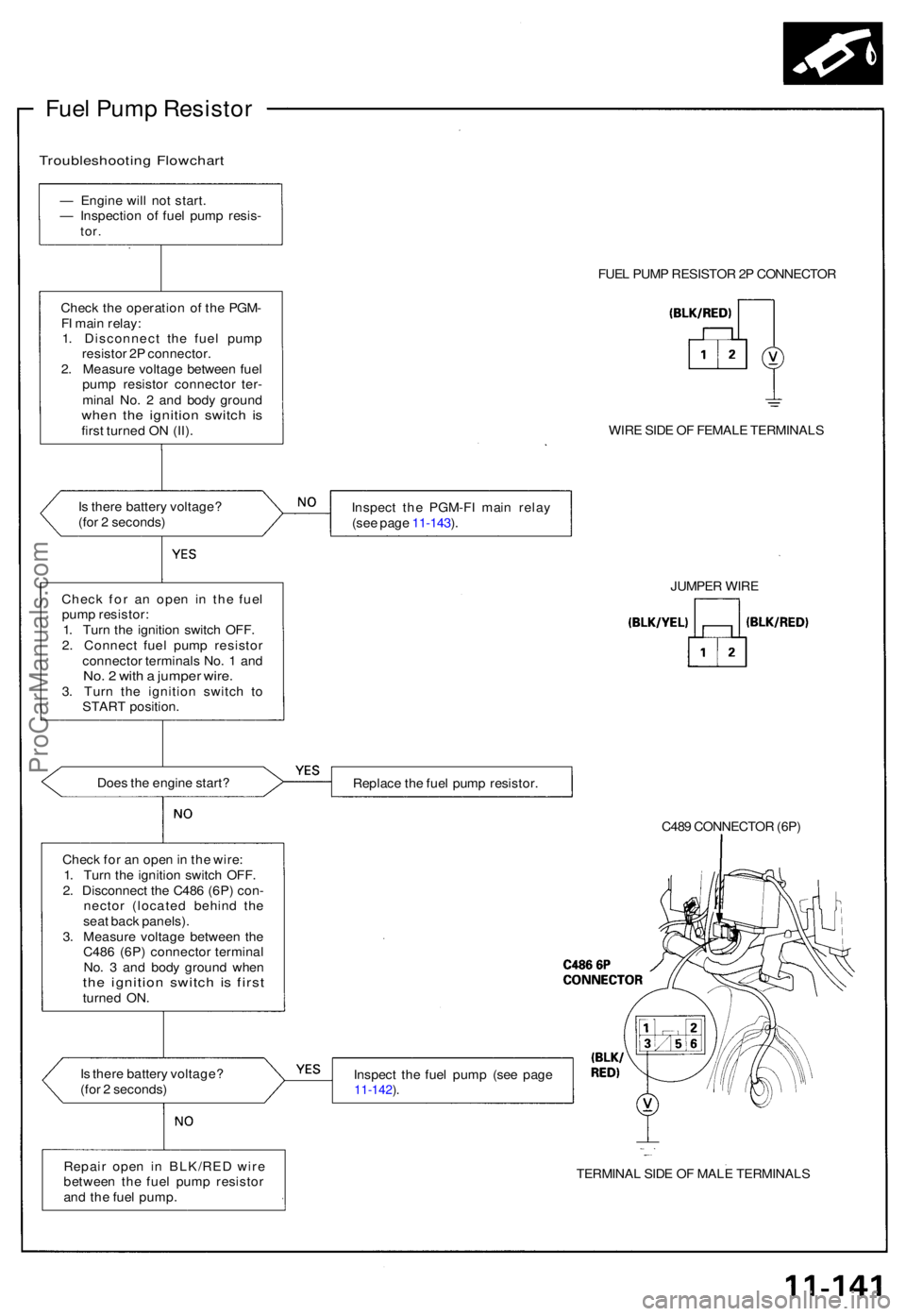

Fuel Pum p Resisto r

Troubleshootin g Flowchar t

— Engin e wil l no t start .

— Inspectio n o f fue l pum p resis -

tor.

Chec k th e operatio n o f th e PGM -

F I mai n relay :

1 . Disconnec t th e fue l pum p

resisto r 2 P connector .

2 . Measur e voltag e betwee n fue l

pum p resisto r connecto r ter -

mina l No . 2 an d bod y groun d

when th e ignitio n switc h i sfirs t turne d O N (II) .

I s ther e batter y voltage ?

(fo r 2 seconds )

Doe s th e engin e start ?

Chec k fo r a n ope n in th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e C48 6 (6P ) con -

necto r (locate d behin d th e

sea t bac k panels) .

3 . Measur e voltag e betwee n th e

C48 6 (6P ) connecto r termina l

No . 3 an d bod y groun d whe n

the ignitio n switc h i s firs tturne d ON .

I s ther e batter y voltage ?

(fo r 2 seconds ) FUE

L PUM P RESISTO R 2P CONNECTO R

WIR E SID E O F FEMAL E TERMINAL S

Inspec t th e PGM-F I mai n rela y

(se e pag e 11-143 ).

Replac e th e fue l pum p resistor .

C489 CONNECTO R (6P )

Inspec t th e fue l pum p (se e pag e

11-142 ).

TERMINA L SID E O F MAL E TERMINAL S

JUMPE

R WIR E

Chec k fo r a n ope n i n th e fue l

pum p resistor :

1 . Tur n th e ignitio n switc h OFF .

2 . Connec t fue l pum p resisto r

connecto r terminal s No . 1 an d

No. 2 wit h a jumpe r wire .3. Tur n th e ignitio n switc h t o

STAR T position .

Repai r ope n i n BLK/RE D wir e

betwee n th e fue l pum p resisto r

an d th e fue l pump .

ProCarManuals.com

Page 262 of 1640

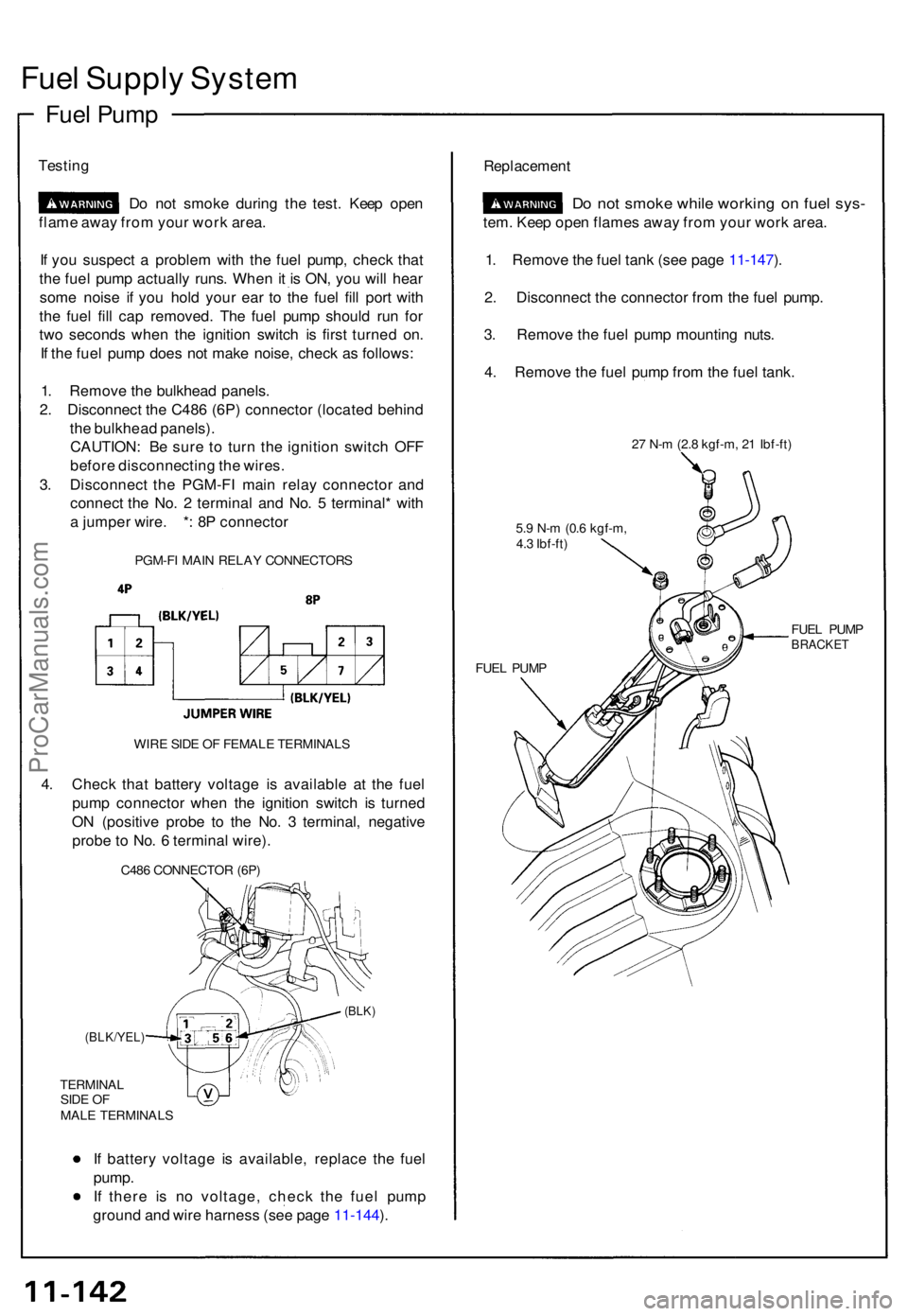

Fuel Suppl y Syste m

Fuel Pum p

Testin g

Do no t smok e durin g th e test . Kee p ope n

flam e awa y fro m you r wor k area .

I f yo u suspec t a proble m wit h th e fue l pump , chec k tha t

th e fue l pum p actuall y runs . Whe n it i s ON , yo u wil l hea r

som e nois e i f yo u hol d you r ea r t o th e fue l fil l por t wit h

th e fue l fil l ca p removed . Th e fue l pum p shoul d ru n fo r

tw o second s whe n th e ignitio n switc h i s firs t turne d on .

I f th e fue l pum p doe s no t mak e noise , chec k a s follows :

1 . Remov e th e bulkhea d panels .

2 . Disconnec t th e C48 6 (6P ) connecto r (locate d behin d

th e bulkhea d panels) .

CAUTION : B e sur e t o tur n th e ignitio n switc h OF F

befor e disconnectin g th e wires .

3 . Disconnec t th e PGM-F I mai n rela y connecto r an d

connec t th e No . 2 termina l an d No . 5 terminal * wit h

a jumpe r wire . * : 8 P connecto r

PGM-FI MAI N RELA Y CONNECTOR S

WIR E SID E O F FEMAL E TERMINAL S

4. Chec k tha t batter y voltag e i s availabl e a t th e fue l

pum p connecto r whe n th e ignitio n switc h i s turne d

O N (positiv e prob e t o th e No . 3 terminal , negativ e

prob e t o No . 6 termina l wire) .

C486 CONNECTO R (6P )

(BLK )

(BLK/YEL )

TERMINAL

SID E O F

MAL E TERMINAL S

If batter y voltag e i s available , replac e th e fue l

pump .

I f ther e i s n o voltage , chec k th e fue l pum p

groun d an d wir e harnes s (se e pag e 11-144 ).

Replacemen t

Do no t smok e whil e workin g o n fue l sys -

tem. Kee p ope n flame s awa y fro m you r wor k area .

1 . Remov e th e fue l tan k (se e pag e 11-147 ).

2 . Disconnec t th e connecto r fro m th e fue l pump .

3 . Remov e th e fue l pum p mountin g nuts .

4 . Remov e th e fue l pum p fro m th e fue l tank .

27 N- m (2. 8 kgf-m , 2 1 Ibf-ft )

5. 9 N- m (0. 6 kgf-m ,

4. 3 Ibf-ft )

FUE L PUM P FUE

L PUM P

BRACKE T

ProCarManuals.com

Page 264 of 1640

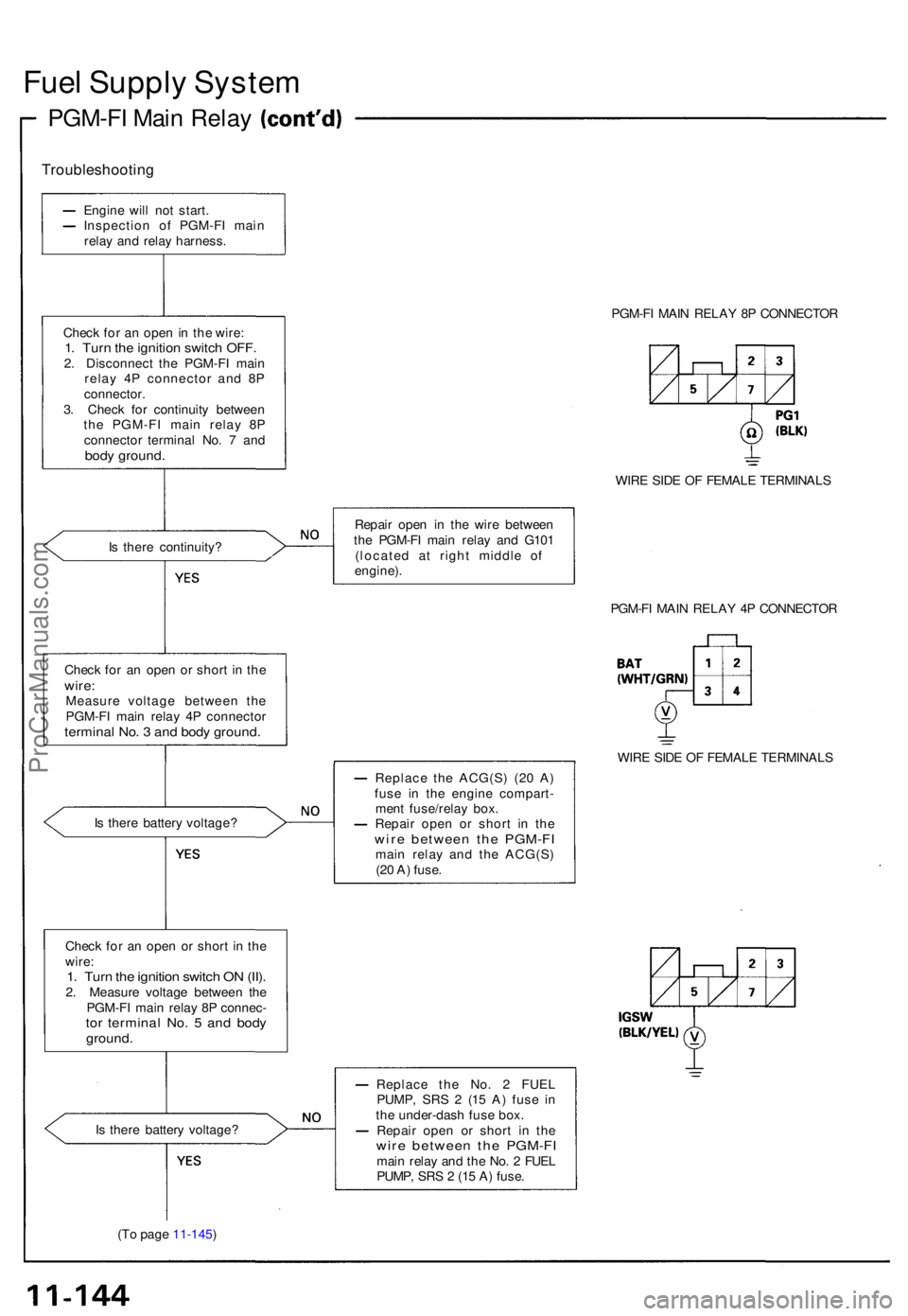

Fuel Suppl y Syste m

PGM-F I Mai n Rela y

Troubleshootin g

Is ther e continuity ?

Chec k fo r a n ope n o r shor t i n th e

wire :Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

terminal No . 3 an d bod y ground .

Is ther e batter y voltage ?

Chec k fo r a n ope n o r shor t i n th e

wire :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

PGM-F I mai n rela y 8 P connec -

tor termina l No . 5 an d bod yground .

PGM-FI MAI N RELA Y 8 P CONNECTO R

WIR E SID E O F FEMAL E TERMINAL S

Repai r ope n i n th e wir e betwee n

th e PGM-F I mai n rela y an d G10 1

(locate d a t righ t middl e o fengine) .

PGM-FI MAI N RELA Y 4 P CONNECTO R

Replac e th e ACG(S ) (2 0 A )

fus e i n th e engin e compart -

men t fuse/rela y box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F Imain rela y an d th e ACG(S )

(2 0 A ) fuse . WIR

E SID E O F FEMAL E TERMINAL S

I s ther e batter y voltage ?

(T o pag e 11-145 ) Replac

e th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fus e i n

th e under-das h fus e box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F Imain rela y an d th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fuse .

Engin

e wil l no t start .

Inspectio n o f PGM-F I mai n

rela y an d rela y harness .

Chec k fo r a n ope n in th e wire :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e PGM-F I mai n

rela y 4 P connecto r an d 8 P

connector .

3 . Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 7 an d

body ground .

ProCarManuals.com

Page 987 of 1640

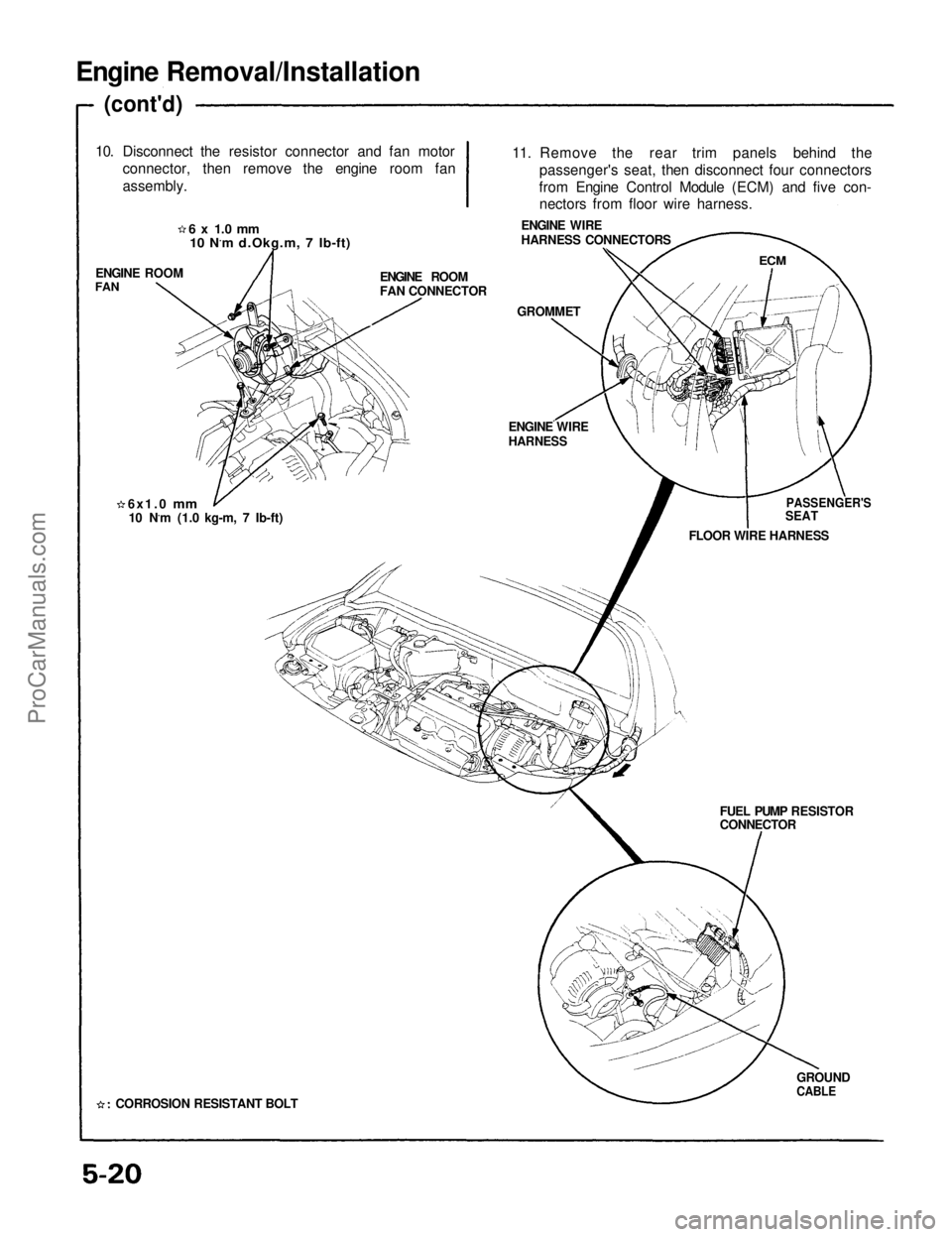

Engine Removal/Installation

(cont'd)

10. Disconnect the resistor connector and fan motor connector, then remove the engine room fan

assembly.

ENGINE ROOM

FAN

ENGINE ROOM

FAN CONNECTOR

GROMMET

11. Remove the rear trim panels behind the

passenger's seat, then disconnect four connectors

from Engine Control Module (ECM) and five con- nectors from floor wire harness.

ENGINE WIRE

HARNESS CONNECTORS

ECM

PASSENGER'S

SEAT

FLOOR WIRE HARNESS

ENGINE WIRE

HARNESS

FUEL PUMP RESISTOR

CONNECTORGROUND

CABLE

6x1.0

mm

10 N.m (1.0 kg-m, 7 Ib-ft)

CORROSION RESISTANT BOLT

6 x 1.0 mm

10 N.m d.Okg.m, 7 Ib-ft)ProCarManuals.com

Page 998 of 1640

Engine Removal/Installation

(cont'd)

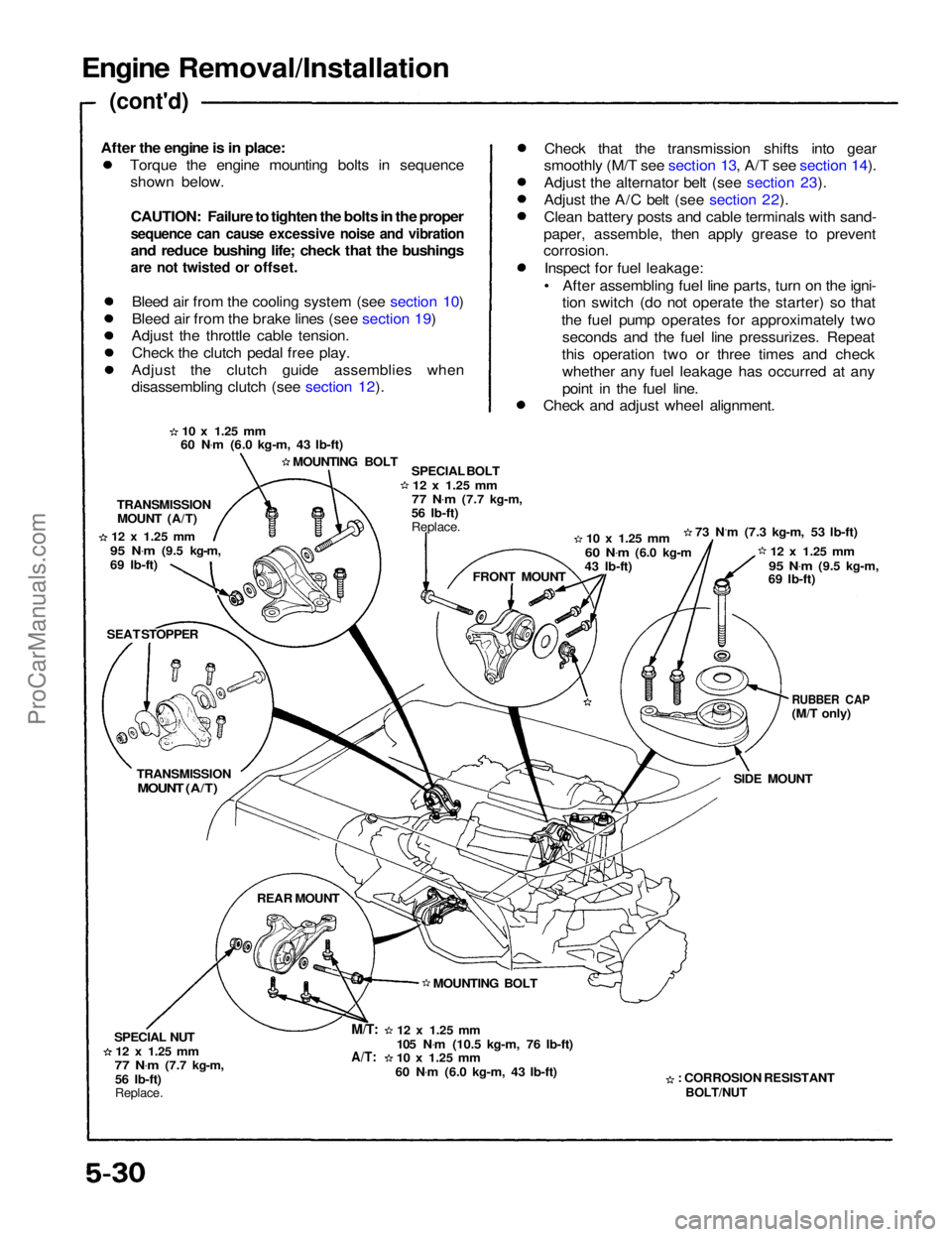

Torque the engine mounting bolts in sequenceshown below.

CAUTION: Failure to tighten the bolts in the proper

sequence can cause excessive noise and vibration

and reduce bushing life; check that the bushings

are not twisted or offset.

Bleed air from the cooling system (see section 10)

Bleed air from the brake lines (see section 19)

Adjust the throttle cable tension.

Check the clutch pedal free play.

Adjust the clutch guide assemblies when

disassembling clutch (see section 12). Check that the transmission shifts into gear

smoothly (M/T see section 13, A/T see section 14).

Adjust the alternator belt (see section 23).

Adjust the A/C belt (see section 22).

Clean battery posts and cable terminals with sand-

paper, assemble, then apply grease to prevent

corrosion.

Inspect for fuel leakage:

• After assembling fuel line parts, turn on the igni- tion switch (do not operate the starter) so that

the fuel pump operates for approximately two seconds and the fuel line pressurizes. Repeat

this operation two or three times and check whether any fuel leakage has occurred at any

point in the fuel line.

Check and adjust wheel alignment.

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

MOUNTING BOLT SPECIAL BOLT

12 x

1.25

mm

77 N .

m

(7.7 kg-m,

56 Ib-ft)

Replace.

10 x

1.25

mm

60 N .

m

(6.0 kg-m

43 Ib-ft) 73 N.m (7.3 kg-m, 53 Ib-ft)

12 x

1.25

mm

95 N .

m

(9.5 kg-m,

69 Ib-ft)

RUBBER CAP

(M/T only)

SIDE MOUNT

: CORROSION RESISTANT

BOLT/NUT

12 x

1.25

mm

105 N .

m (10.5 kg-m, 76 Ib-ft)

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft) MOUNTING BOLT FRONT MOUNT

TRANSMISSION

MOUNT (A/T)

12 x

1.25

mm

95 N .

m

(9.5 kg-m,

69 Ib-ft)

SEAT STOPPER

TRANSMISSION

MOUNT (A/T)

REAR MOUNT

SPECIAL NUT

12 x

1.25

mm

77 N .

m

(7.7 kg-m,

56 Ib-ft)

Replace.

M/T:

A/T:

After the engine is in place:ProCarManuals.com

Page 1048 of 1640

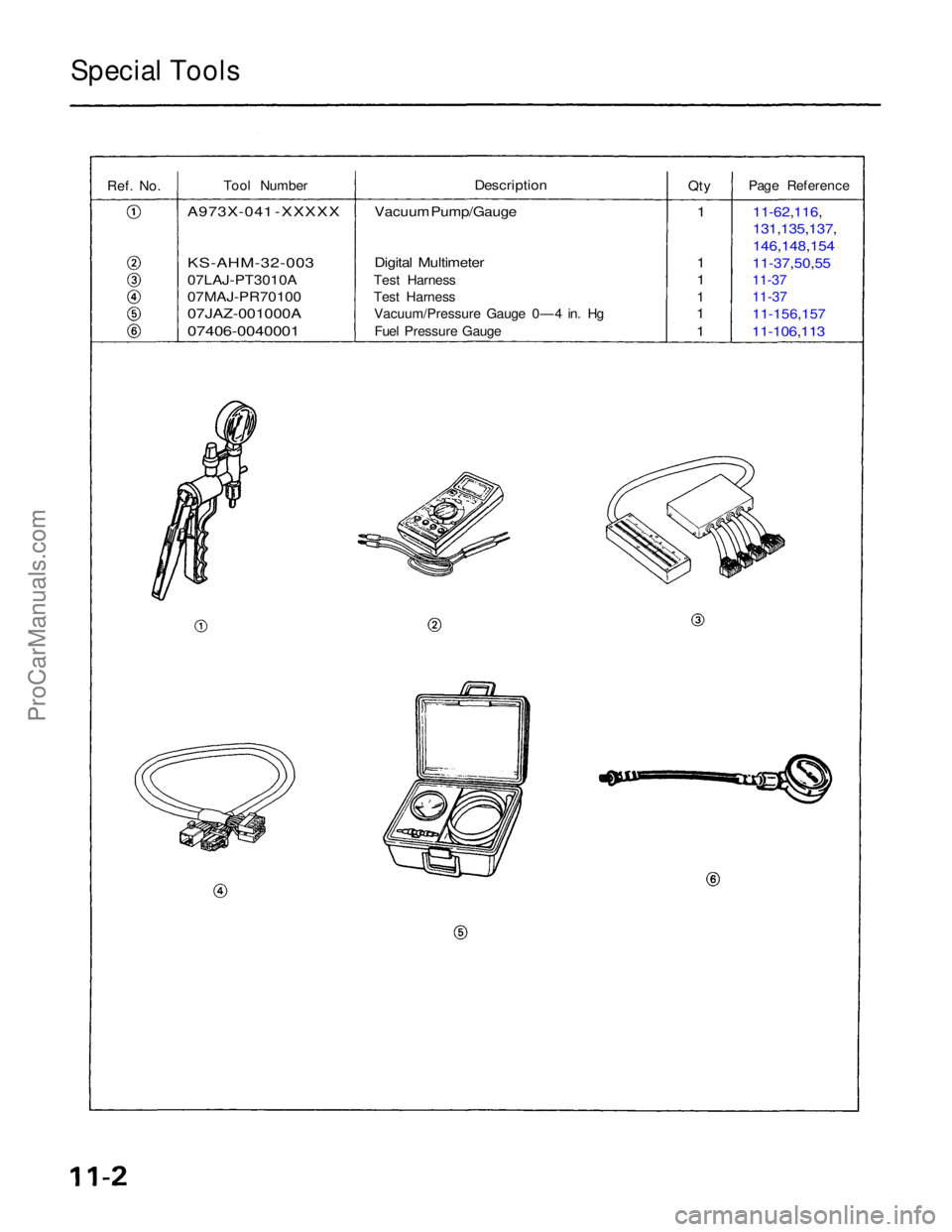

Special Tools

Ref. No.

Tool Number

A973X-041 -XXXXX

KS-AHM-32-003

07LAJ-PT3010A

07MAJ-PR70100

07JAZ-001000A

07406-0040001

Page Reference

11-62,116,

131,135,137,

146,148,154

11-37,50,55

11-37

11-37

11-156,157

11-106,113

Description

Vacuum Pump/Gauge

Digital Multimeter

Test Harness

Test Harness Vacuum/Pressure Gauge 0—4 in. Hg

Fuel Pressure Gauge

Qty

1

1

1

1

1

1ProCarManuals.com