engine coolant ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 72 of 1640

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

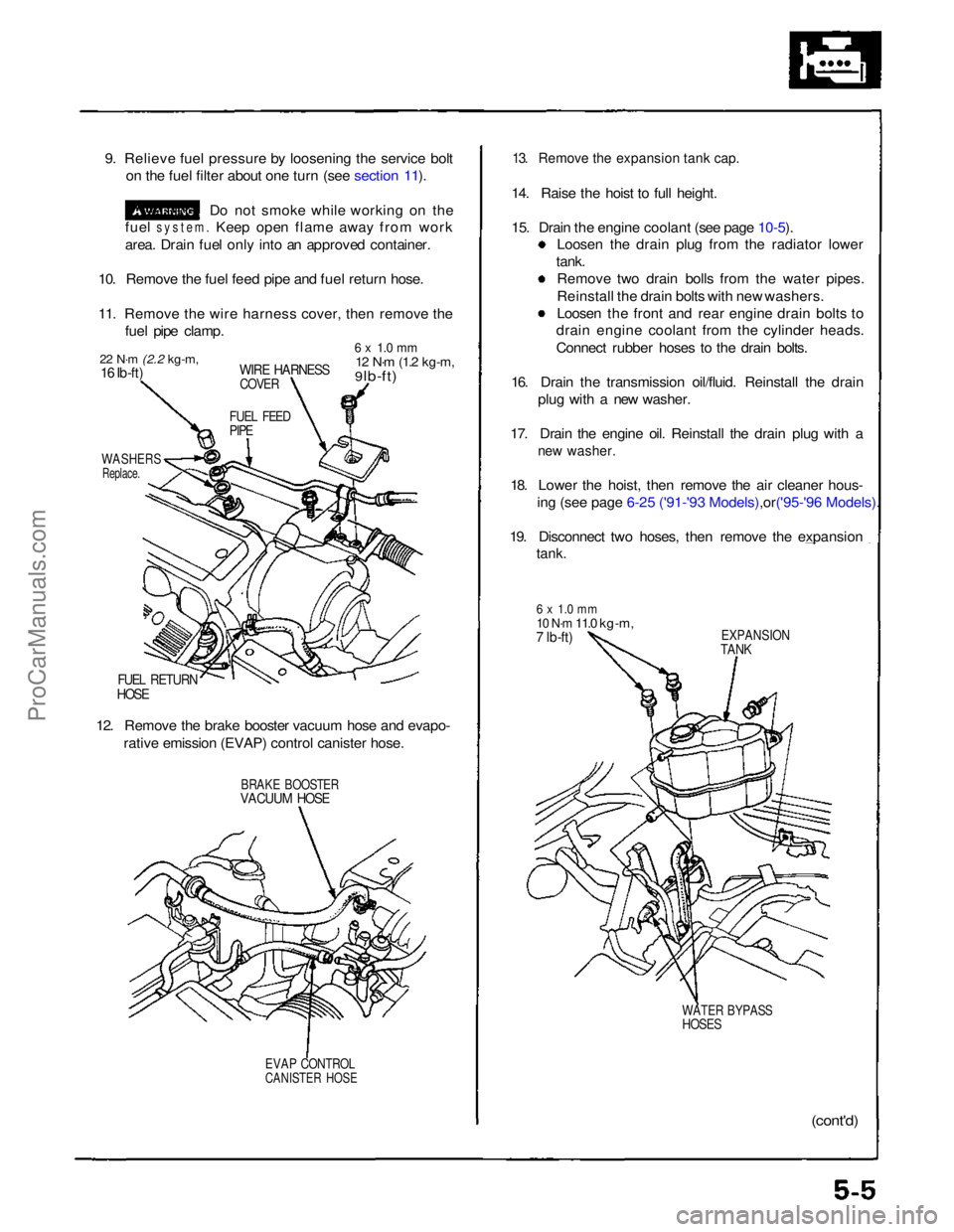

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 89 of 1640

Timing Belt

Inspection

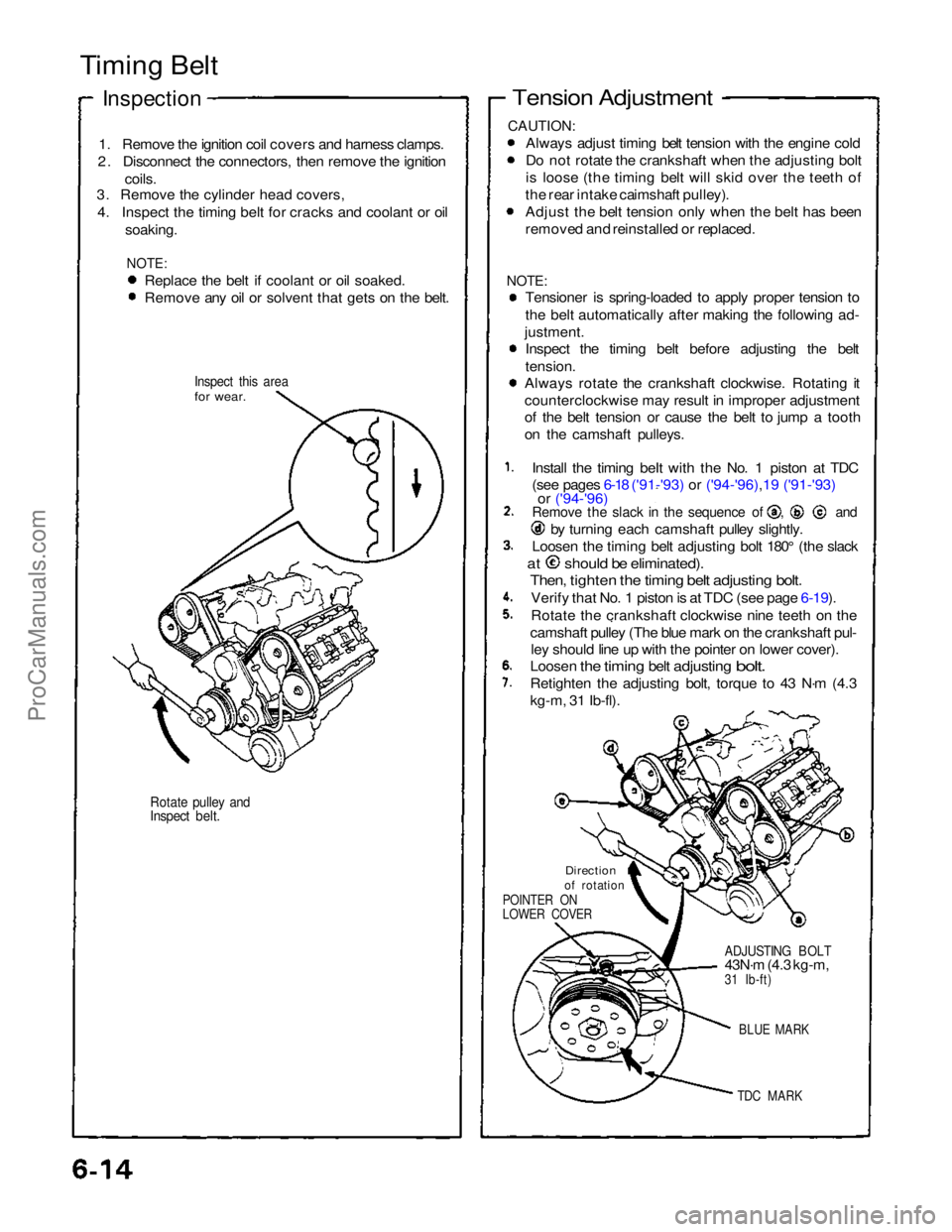

1. Remove the ignition coil covers and harness clamps.

2. Disconnect the connectors, then remove the ignition

coils.

3. Remove the cylinder head covers,

4. Inspect the timing belt for cracks and coolant or oil soaking.

NOTE:

Replace the belt if coolant or oil soaked.

Remove any oil or solvent that gets on the belt.

Inspect this area

for wear.

Rotate pulley and

Inspect belt.

Tension Adjustment

CAUTION:

Always adjust timing belt tension with the engine cold

Do not rotate the crankshaft when the adjusting bolt

is loose (the timing belt will skid over the teeth of

the rear intake caimshaft pulley).

Adjust the belt tension only when the belt has been

removed and reinstalled or replaced.

NOTE:

Tensioner is spring-loaded to apply proper tension to

the belt automatically after making the following ad-

justment. Inspect the timing belt before adjusting the belt

tension.

Always rotate the crankshaft clockwise. Rotating it

counterclockwise may result in improper adjustment

of the belt tension or cause the belt to jump a tooth

on the camshaft pulleys.

Install the timing beIt with the No. 1 piston at TDC

(see pages 6-18 ('91-'93) or ('94-'96),19 ('91-'93)

or ('94-'96) Remove the slack in the sequence of , and

by turning each camshaft pulley slightly.

Loosen the timing belt adjusting bolt 180° (the slack

at should be eliminated).

Then, tighten the timing belt adjusting bolt.

Verify that No. 1 piston is at TDC (see page 6-19).

Rotate the crankshaft clockwise nine teeth on the

camshaft pulley (The blue mark on the crankshaft pul- ley should line up with the pointer on lower cover).

Loosen

the

timing

belt

adjusting

bolt.

Retighten the adjusting bolt, torque to 43 N·m (4.3

kg-m, 31 Ib-fl).

Direction

of rotation

POINTER ON

LOWER COVER

ADJUSTING BOLT

43N·m (4.3 kg-m,

31 Ib-ft)

BLUE MARK

TDC MARK

ProCarManuals.com

Page 97 of 1640

![ACURA NSX 1991 Service Repair Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N ACURA NSX 1991 Service Repair Manual

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

N](/img/32/56988/w960_56988-96.png)

Cylinder Heads

Illustrated Index (cont'd)

CAUTION:

To

avoid

damage,

wait

until

the

engine

coolant

temperature

drops

below

100°F

(39-C]

before

removing

the

cylin-

der head.

NOTE: Use new O-rings and gaskets when reassembling.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

REAR VARIABLE VALVE TIMING

AND VALVE LIFT ELECTRONIC CONTROL

SYSTEM (VTEC) SOLENOID VALVE

Troubleshooting, page 6-3 ('91-'93) or ('94-'96)

EXHAUST GAS

RECIRCULATI0N (EGR) VALVE

6 x 1 .0 mm

12 N·m

(1.2 kg-m.

9 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

ENGINE COOLANT

TEMPERATURE (ECT) SENSOR

18 N·m (1.8 kg-m, 13 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 lb-ft)

FRONT VTEC SOLENOID VALVE

Troubleshooting. page 6-3

SEALING BOLTS

60 N·m

(6.0 kg-m,

43 lb-ft)

OIL PRESSURE

GAUSE SENDING

UNIT (section 23)

ROCKER

SHAFTS

WASHERS

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,16 Ib-ft)

DOWEL PIN

0-RING

Replace.

ECT SWITCH

28 N·m

12.8 kg-m.

20 lb-ft

O-RING

Replace.

O-RING

Replace.

ROCKER ARM ASSEMBLY[PRIMARY. MID, SECONDARY]

Inspection, page 6-32 ('91-'93) or ('94-'96)

ROCKER SHAFT

OIL CONTROL

ORIFICE

Remove with 5 mm

boit and clean.

FILTER

Replace.

GASKET

Replace.

O-RING

Replace.ProCarManuals.com

Page 99 of 1640

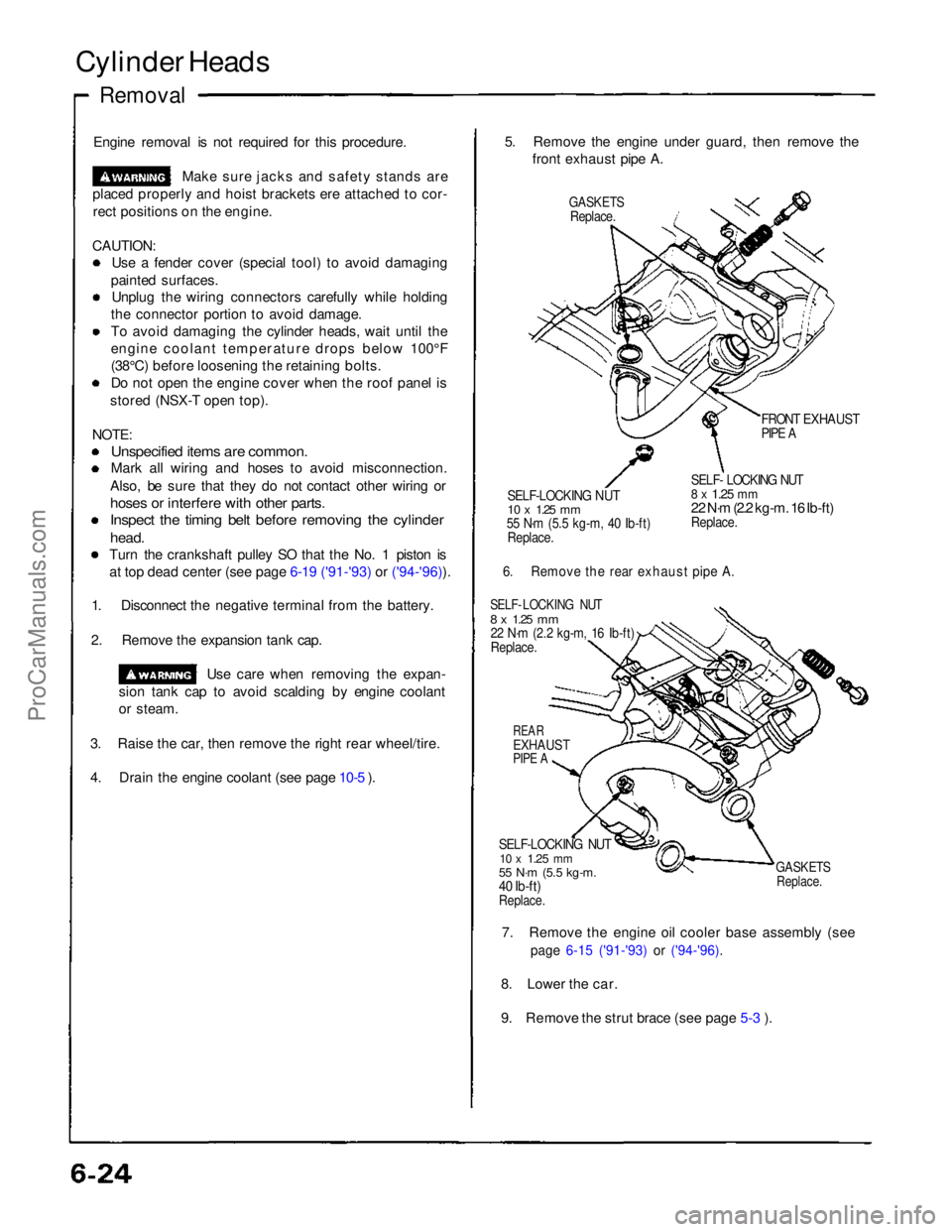

Cylinder Heads

Removal

Engine removal is not required for this procedure. Make sure jacks and safety stands are

placed properly and hoist brackets ere attached to cor- rect positions on the engine.

CAUTION: Use a fender cover (special tool) to avoid damaging

painted surfaces. Unplug the wiring connectors carefully while holding

the connector portion to avoid damage.

To avoid damaging the cylinder heads, wait until the

engine coolant temperature drops below 100°F

(38°C) before loosening the retaining bolts. Do not open the engine cover when the roof panel is

stored (NSX-T open top).

NOTE:

Unspecified items are common.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses or interfere with other parts.

Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley SO that the No. 1 piston is at top dead center (see page 6-19 ('91-'93) or ('94-'96)).

1. Disconnect the negative terminal from the battery.

2. Remove the expansion tank cap. Use care when removing the expan-

sion tank cap to avoid scalding by engine coolant

or steam.

3. Raise the car, then remove the right rear wheel/tire.

4. Drain the engine coolant (see page 10-5 ). 5. Remove the engine under guard, then remove the

front exhaust pipe A.

GASKETS

Replace.

FRONT EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m, 40 Ib-ft)

Replace.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m. 16 Ib-ft)

Replace.

6. Remove the rear exhaust pipe A.

SELF- LOCKING NUT

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

Replace.

REAR

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m.

40 Ib-ft)

Replace.

GASKETS

Replace.

7. Remove the engine oil cooler base assembly (see

page 6-15 ('91-'93) or ('94-'96).

8. Lower the car.

9. Remove the strut brace (see page 5-3 ).ProCarManuals.com

Page 102 of 1640

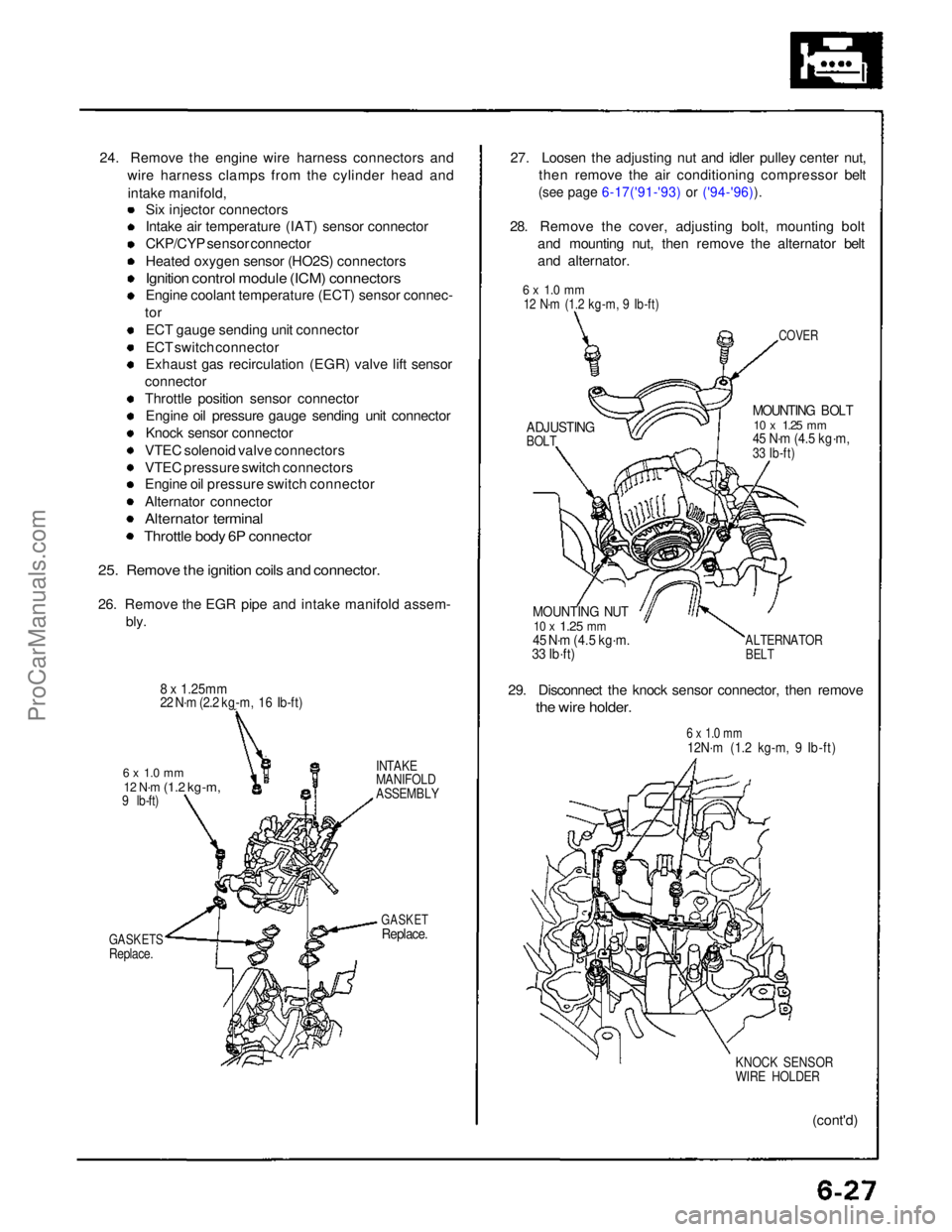

24. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and

intake manifold, Six injector connectors

Intake air temperature (IAT) sensor connector

CKP/CYP sensor connector

Heated oxygen sensor (HO2S) connectors

Ignition control module (ICM) connectors

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Throttle position sensor connector Engine oil pressure gauge sending unit connector

Knock sensor connector

VTEC solenoid valve connectors

VTEC pressure switch connectors

Engine oil pressure switch connector

Alternator connector

Alternator terminal

Throttle body 6P connector

25. Remove the ignition coils and connector.

26. Remove the EGR pipe and intake manifold assem- bly.

8 x 1.25mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

GASKETS

Replace. INTAKE

MANIFOLD

ASSEMBLY

GASKET

Replace.

27. Loosen the adjusting nut and idler pulley center nut,

then remove the air conditioning compressor belt

(see page 6-17('91-'93) or ('94-'96)).

28. Remove the cover, adjusting bolt, mounting bolt and mounting nut, then remove the alternator belt

and alternator.

COVER

MOUNTING BOLT

10 x

1.25

mm

45 N·m (4.5 kg·m,

33 Ib-ft)

MOUNTING NUT

10 x

1.25

mm

45 N·m (4.5 kg·m.

33 Ib·ft)

ALTERNATOR

BELT

29. Disconnect the knock sensor connector, then remove

the wire holder.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)

KNOCK SENSOR

WIRE HOLDER

(cont'd)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

ADJUSTING

BOLTProCarManuals.com

Page 162 of 1640

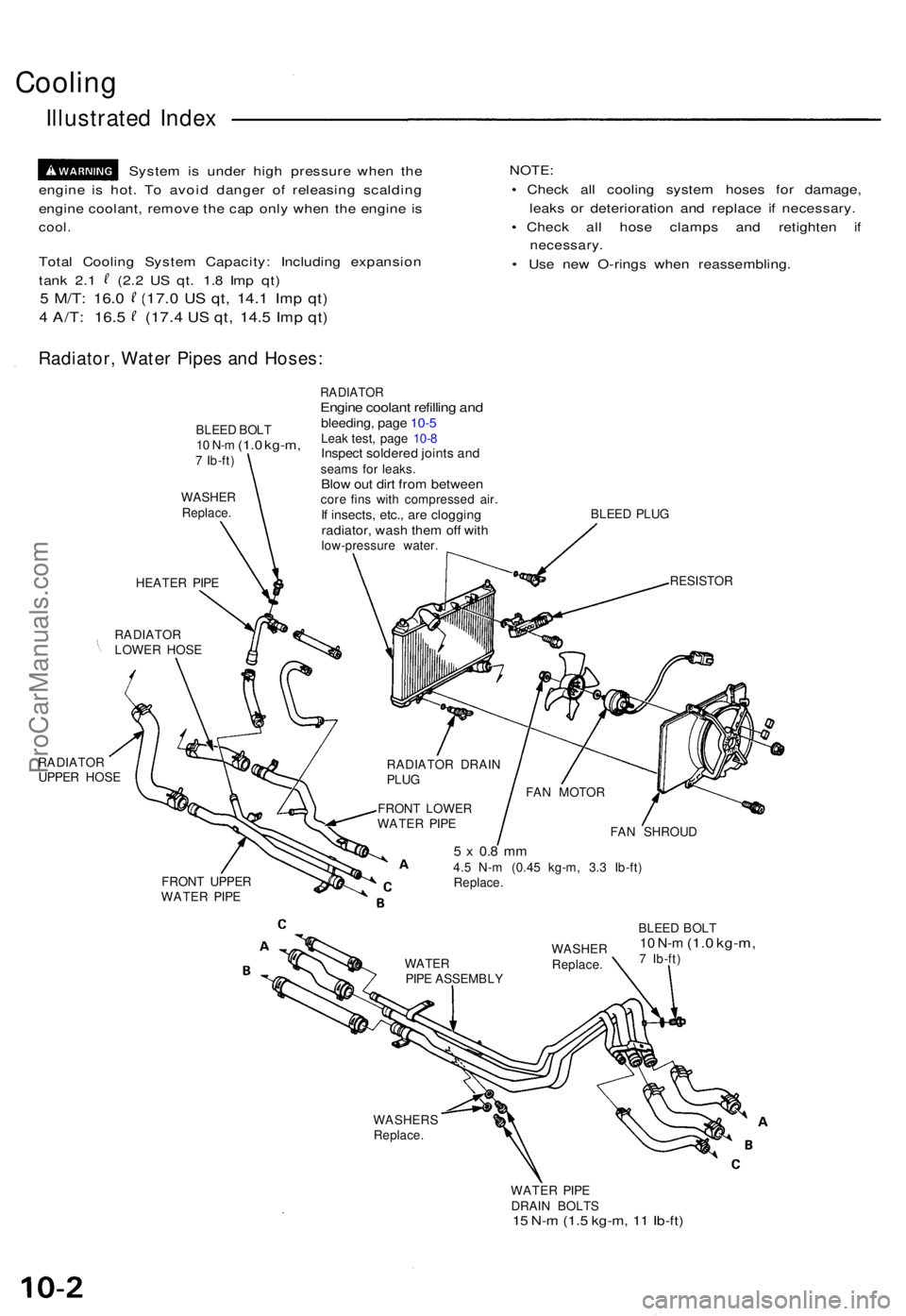

Cooling

Illustrated Index

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

engin e coolant , remov e th e ca p onl y whe n th e engin e i s

cool .

Tota l Coolin g Syste m Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt . 1. 8 Im p qt )

5 M/T : 16. 0 (17. 0 US qt , 14. 1 Imp qt )

4 A/T : 16. 5 (17. 4 US qt , 14. 5 Imp qt )

NOTE :

• Chec k al l coolin g syste m hose s fo r damage ,

leak s o r deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f

necessary .

• Us e ne w O-ring s whe n reassembling .

Radiator, Wate r Pipe s an d Hoses :

BLEED BOL T10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHE RReplace .

HEATER PIP E

RADIATO R

LOWE R HOS E

RADIATO R

UPPE R HOS E

RADIATO REngine coolan t refillin g an dbleeding , pag e 10- 5Leak test , pag e 10- 8Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water . BLEE

D PLU G

RESISTO R

RADIATO R DRAI N

PLU G

FRON T LOWE R

WATE R PIP E

FRON T UPPE R

WATE R PIP E FA

N SHROU D

5 x 0. 8 m m4.5 N- m (0.4 5 kg-m , 3. 3 Ib-ft )

Replace .

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHER S

Replace .

WATER PIP E

DRAI N BOLT S

15 N- m (1. 5 kg-m , 1 1 Ib-ft )

WATE RPIPE ASSEMBL YWASHE

RReplace .

FAN MOTO R

ProCarManuals.com

Page 165 of 1640

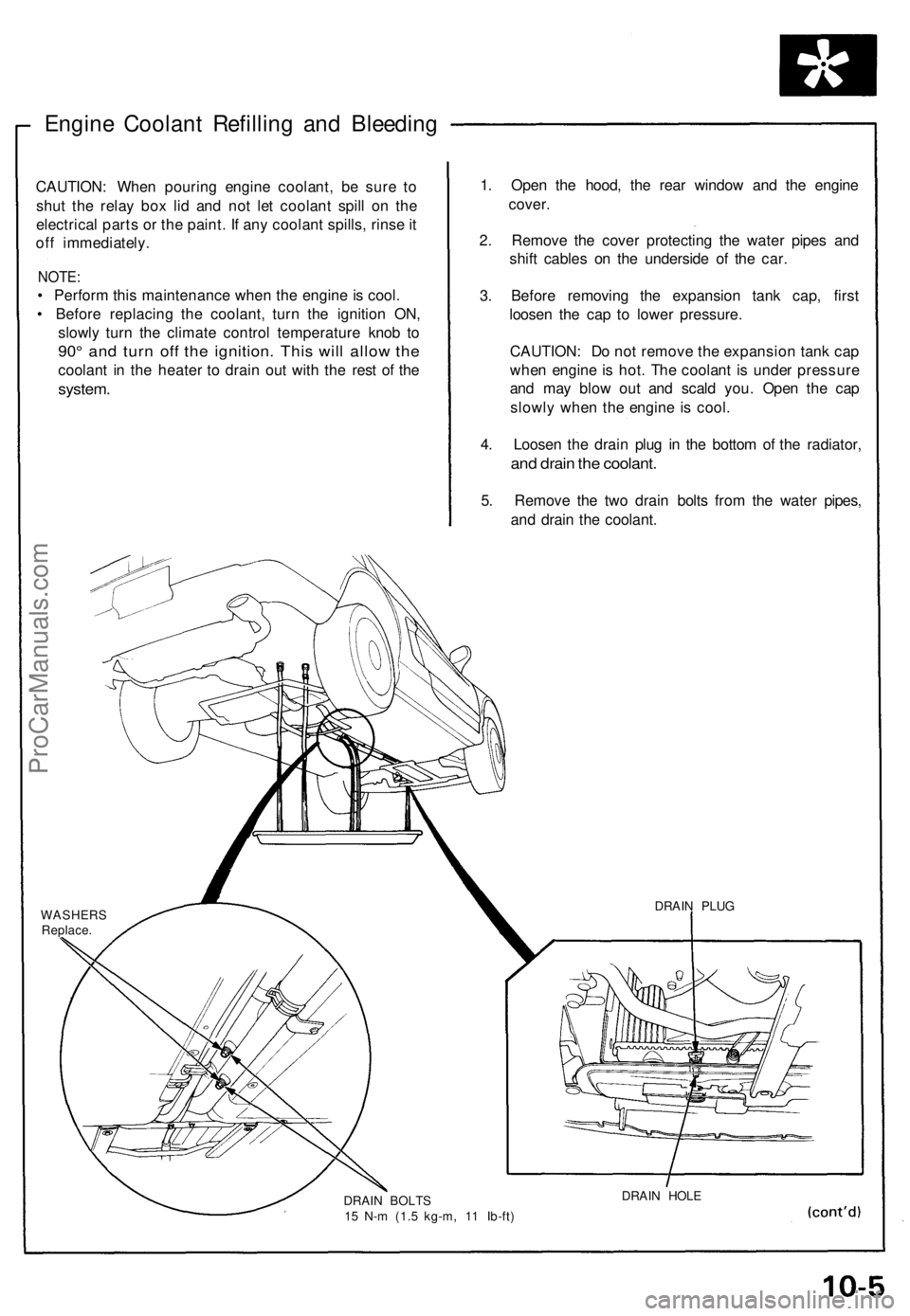

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 166 of 1640

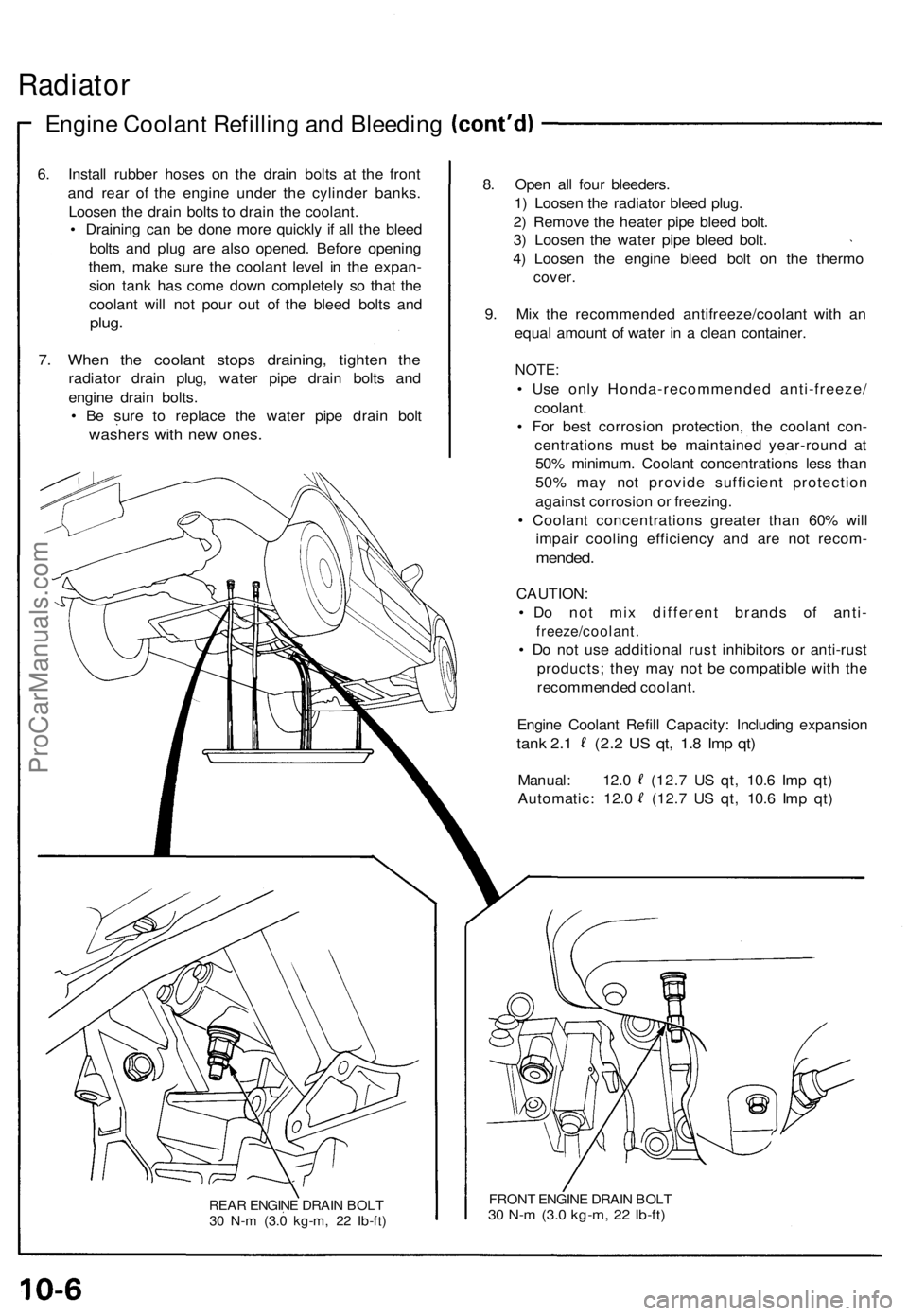

Radiator

Engine Coolan t Refillin g an d Bleedin g

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r of the engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

3 0 N- m (3. 0 kg-m , 2 2 Ib-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover.

9. Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Us e onl y Honda-recommende d anti-freeze /

coolant.

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended.

CAUTION :

• D o no t mi x differen t brand s o f anti -

freeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t Refil l Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T30 N- m (3. 0 kg-m , 2 2 Ib-ft )

ProCarManuals.com

Page 167 of 1640

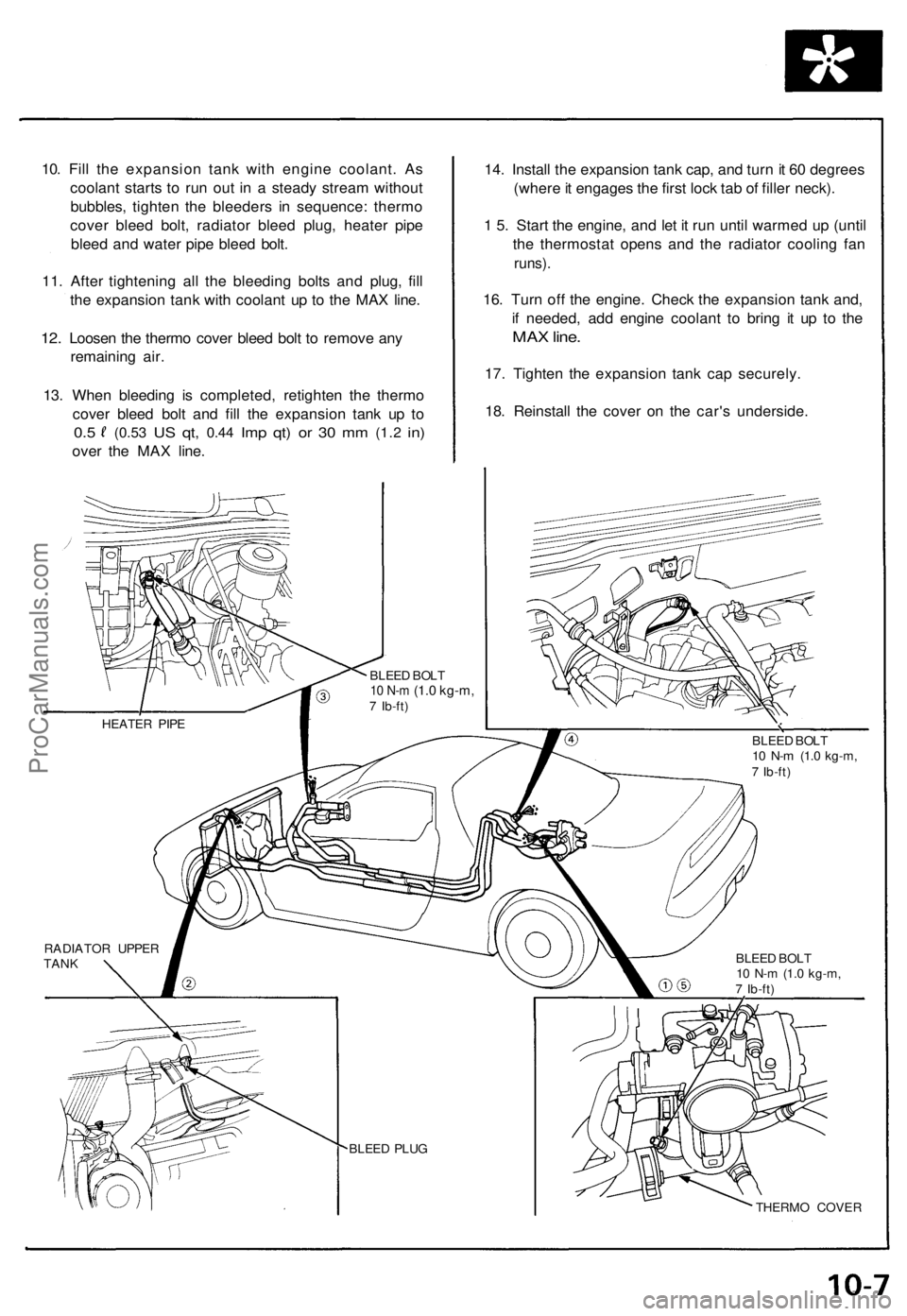

10. Fil l th e expansio n tan k wit h engin e coolant . A s

coolan t start s t o ru n ou t i n a stead y strea m withou t

bubbles , tighte n th e bleeder s i n sequence : therm o

cove r blee d bolt , radiato r blee d plug , heate r pip e

blee d an d wate r pip e blee d bolt .

11 . Afte r tightenin g al l th e bleedin g bolt s an d plug , fil l

th e expansio n tan k wit h coolan t u p t o th e MA X line .

12. Loose n th e therm o cove r blee d bol t t o remov e an y

remainin g air .

13 . Whe n bleedin g i s completed , retighte n th e therm o

cove r blee d bol t an d fill the expansio n tan k u p t o

0. 5 (0.5 3 US qt , 0.4 4 Imp qt ) o r 3 0 m m (1. 2 in)

ove r th e MA X line . 14

. Instal l th e expansio n tan k cap , an d tur n it 6 0 degree s

(wher e it engage s th e firs t loc k ta b o f fille r neck) .

1 5 . Star t th e engine , an d le t i t ru n unti l warme d u p (unti l

th e thermosta t open s an d th e radiato r coolin g fa n

runs) .

16. Tur n of f th e engine . Chec k th e expansio n tan k and ,

i f needed , ad d engin e coolan t t o brin g i t u p t o th e

MA X line .

17. Tighte n th e expansio n tan k ca p securely .

18 . Reinstal l th e cove r o n th e car' s underside .

THERMO COVE R

BLEE

D PLU G

RADIATO

R UPPE R

TAN K HEATE

R PIP E

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

BLEE

D BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 171 of 1640

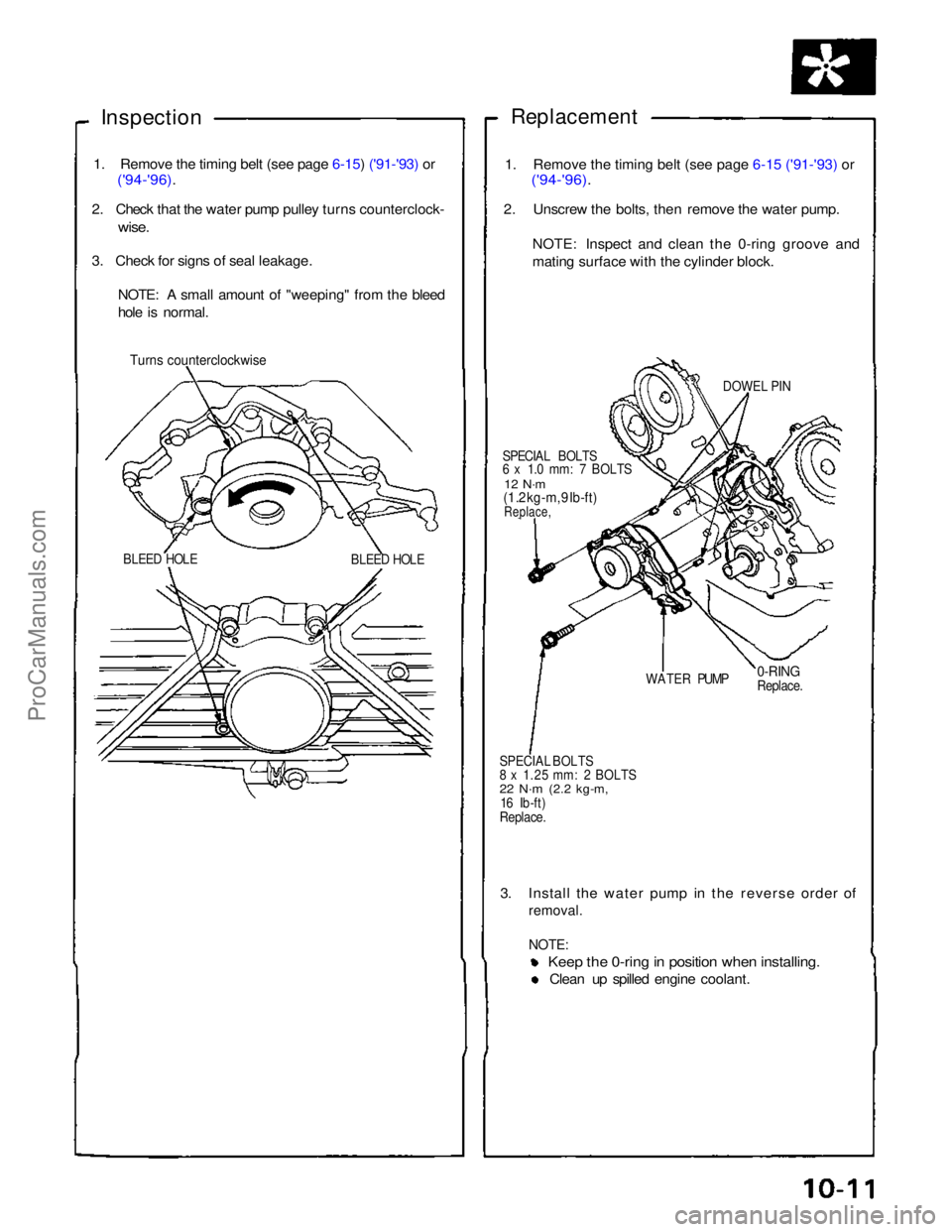

Inspection

Replacement

1. Remove the timing belt (see page 6-15) ('91-'93) or

('94-'96).

2. Check that the water pump pulley turns counterclock-

wise.

3. Check for signs of seal leakage.

NOTE: A small amount of "weeping" from the bleed

hole is normal.

Turns

counterclockwise

BLEED HOLE

BLEED HOLE

1. Remove the timing belt (see page 6-15 ('91-'93) or

('94-'96).

2. Unscrew the bolts, then remove the water pump.

NOTE: Inspect and clean the 0-ring groove and

mating surface with the cylinder block.

DOWEL PIN

SPECIAL BOLTS

6 x 1.0 mm: 7 BOLTS

12 N·m

(1 .2 kg-m, 9 Ib-ft)

Replace,

WATER PUMP

0-RING

Replace.

SPECIAL BOLTS

8 x 1.25 mm: 2 BOLTS

22 N·m

(2.2 kg-m,

16 Ib-ft)

Replace.

3. Install the water pump in the reverse order of

removal.

NOTE:

Keep the 0-ring in position when installing.

Clean up spilled engine coolant.ProCarManuals.com