jump cable ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 304 of 1640

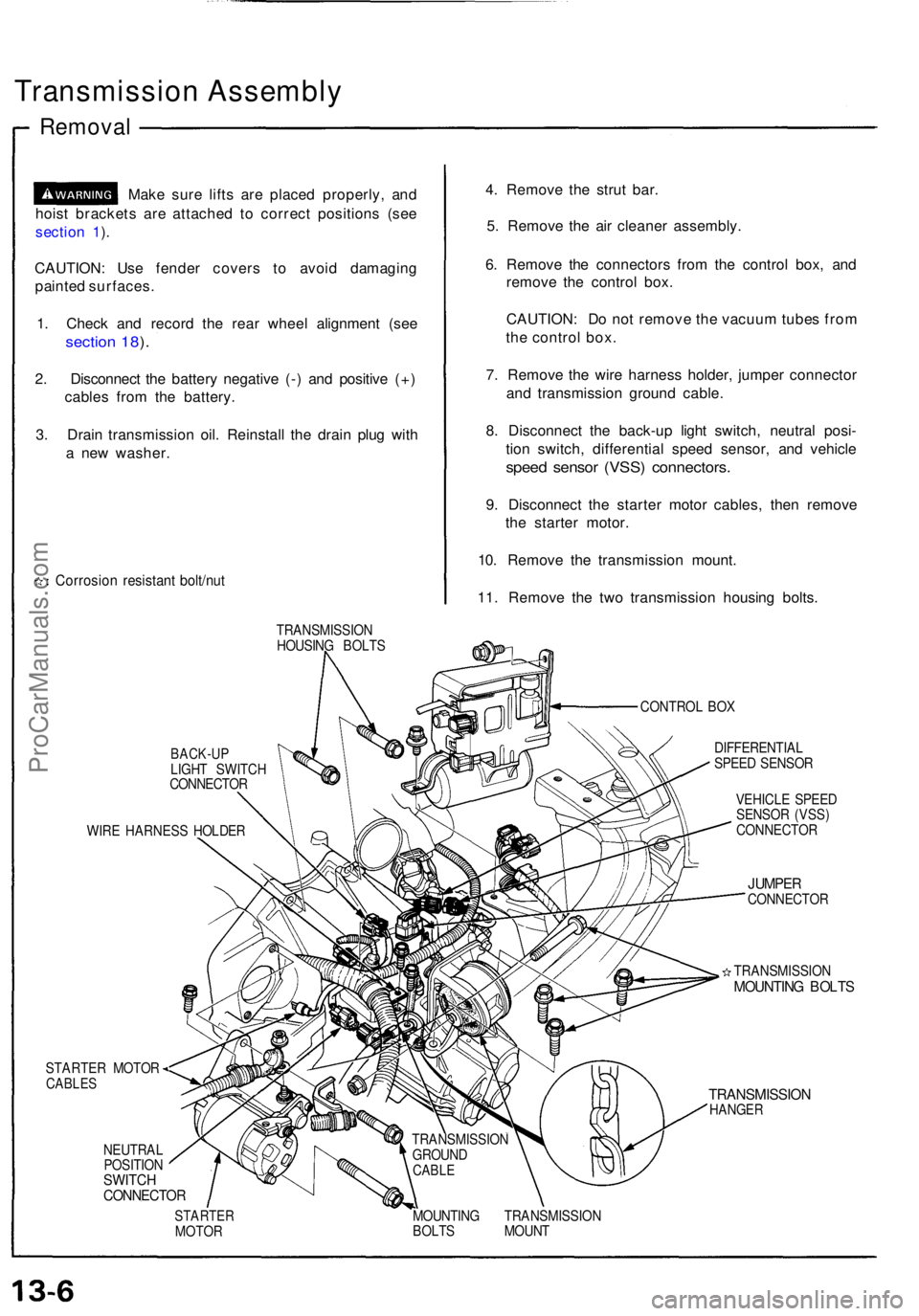

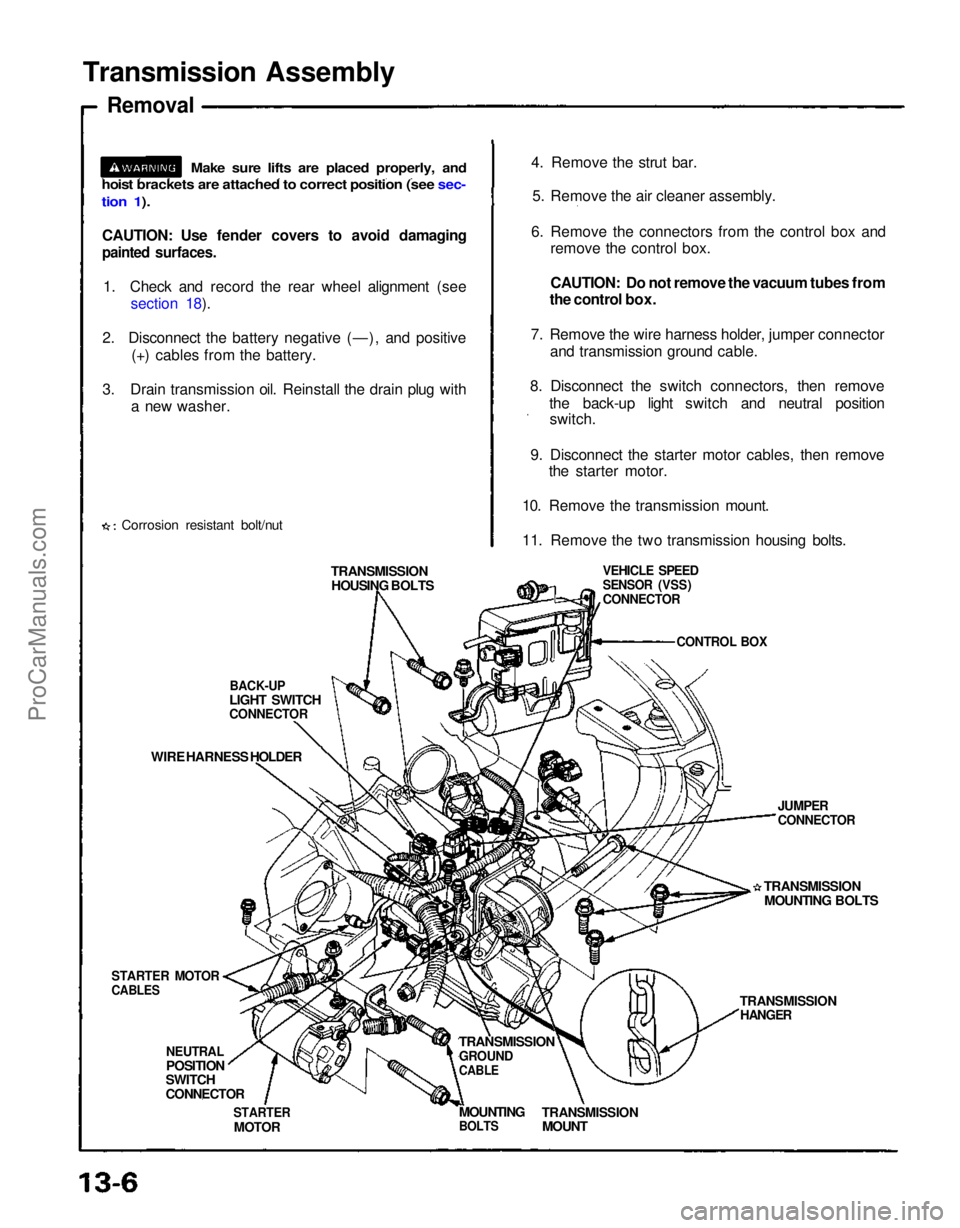

Transmission Assembl y

Removal

Make sur e lift s ar e place d properly , an d

hois t bracket s ar e attache d t o correc t position s (se e

sectio n 1 ).

CAUTION : Us e fende r cover s t o avoi d damagin g

painte d surfaces .

1 . Chec k an d recor d th e rea r whee l alignmen t (se e

sectio n 18 ).

2 . Disconnec t th e batter y negativ e (- ) an d positiv e (+ )

cable s fro m th e battery .

3 . Drai n transmissio n oil . Reinstal l th e drai n plu g wit h

a ne w washer .

Corrosio n resistan t bolt/nu t

4. Remov e th e stru t bar .

5 . Remov e th e ai r cleane r assembly .

6 . Remov e th e connector s fro m th e contro l box , an d

remov e th e contro l box .

CAUTION : D o no t remov e th e vacuu m tube s fro m

th e contro l box .

7 . Remov e th e wir e harnes s holder , jumpe r connecto r

an d transmissio n ground cable.

8 . Disconnec t th e back-u p ligh t switch , neutra l posi -

tio n switch , differentia l spee d sensor , an d vehicl e

speed senso r (VSS ) connectors .

9. Disconnec t th e starte r moto r cables , the n remov e

th e starte r motor .

10 . Remov e th e transmissio n mount .

11 . Remov e th e tw o transmissio n housin g bolts .

TRANSMISSIO N

HOUSIN G BOLT S

CONTROL BO X

BACK-U PLIGHT SWITC H

CONNECTO R

WIR E HARNES S HOLDE R

STARTER MOTOR

CABLES

NEUTRA L

POSITIO N

SWITCHCONNECTO R

DIFFERENTIA L

SPEE D SENSO R

VEHICL E SPEE D

SENSO R (VSS )

CONNECTO R

JUMPERCONNECTO R

TRANSMISSIO N

MOUNTING BOLT S

TRANSMISSIO NHANGER

STARTE RMOTOR MOUNTIN

G TRANSMISSIO N

BOLT S MOUN T

TRANSMISSIO

N

GROUN D

CABLE

ProCarManuals.com

Page 355 of 1640

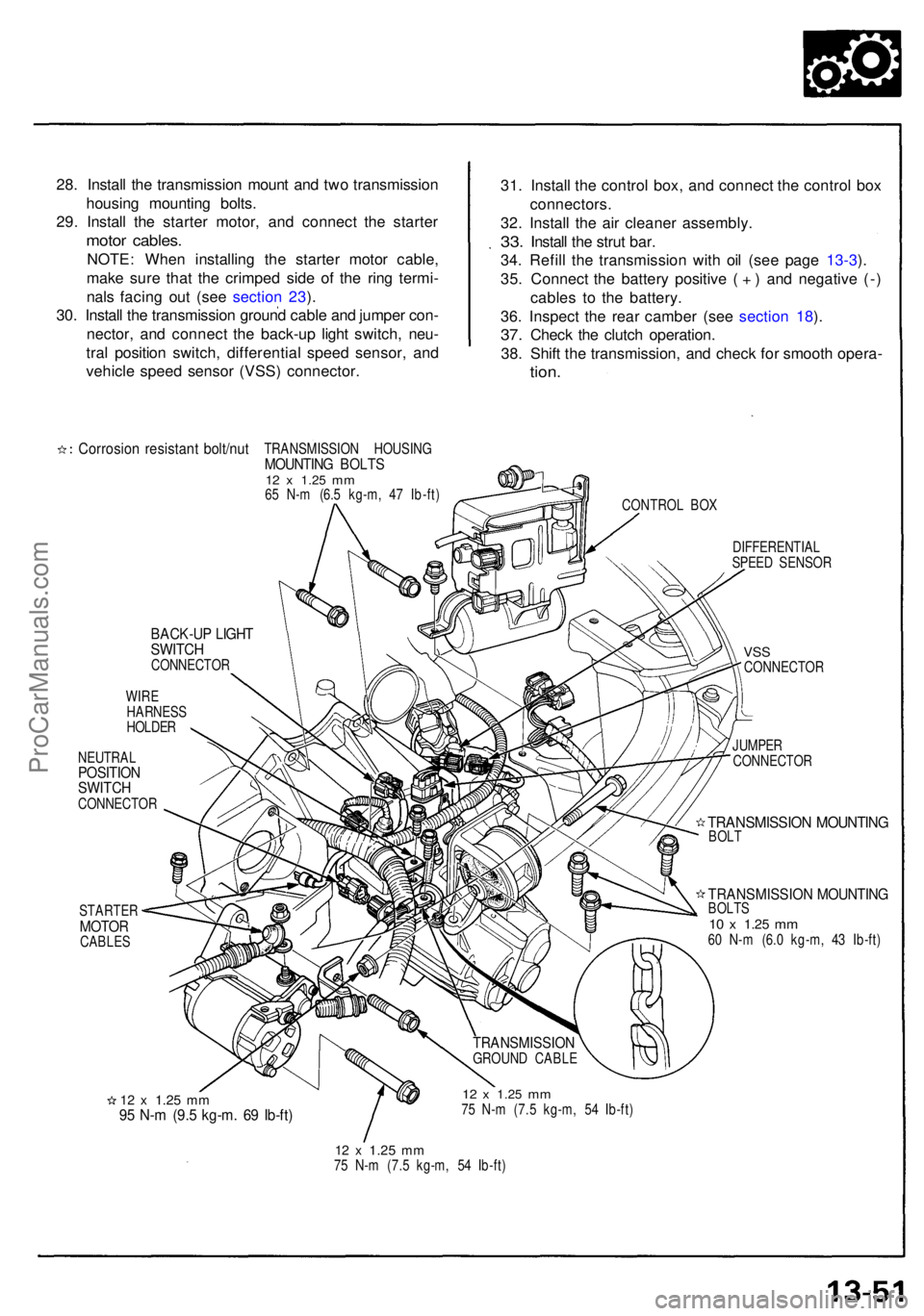

28. Instal l th e transmissio n moun t an d tw o transmissio n

housin g mountin g bolts .

29 . Instal l th e starte r motor , an d connec t th e starte r

motor cables .

NOTE: Whe n installin g th e starte r moto r cable ,

mak e sur e tha t th e crimpe d sid e o f th e rin g termi -

nal s facin g ou t (se e sectio n 23 ).

30 . Instal l th e transmissio n groun d cabl e an d jumpe r con -

nector , an d connec t th e back-u p ligh t switch , neu -

tra l positio n switch , differentia l spee d sensor , an d

vehicl e spee d senso r (VSS ) connector . 31

. Instal l th e contro l box , an d connec t th e contro l bo x

connectors .

32. Instal l th e ai r cleane r assembly .

33. Instal l th e stru t bar .

34 . Refil l th e transmissio n wit h oi l (se e pag e 13-3 ).

35 . Connec t th e batter y positiv e ( + ) an d negativ e (- )

cable s t o th e battery .

36 . Inspec t th e rea r cambe r (se e sectio n 18 ).

37 . Chec k th e clutc h operation .

38 . Shif t th e transmission , an d chec k fo r smoot h opera -

tion.

Corrosio n resistan t bolt/nu tTRANSMISSIO N HOUSIN GMOUNTING BOLT S12 x 1.2 5 mm65 N- m (6. 5 kg-m , 4 7 Ib-ft )

CONTROL BO X

BACK-U P LIGH TSWITC HCONNECTO R

WIR E

HARNES S

HOLDE R

NEUTRA L

POSITIONSWITCHCONNECTO R

STARTE R

MOTORCABLE S DIFFERENTIA

L

SPEE D SENSO R

VSSCONNECTO R

JUMPE R

CONNECTO R

TRANSMISSIO N MOUNTIN GBOLT

TRANSMISSIO N MOUNTIN GBOLTS10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

12 x 1.2 5 mm95 N- m (9. 5 kg-m . 6 9 Ib-ft )

12 x 1.2 5 mm75 N- m (7. 5 kg-m , 5 4 Ib-ft )

12 x 1.2 5 mm75 N- m (7. 5 kg-m , 5 4 Ib-ft )

TRANSMISSIO NGROUND CABL E

ProCarManuals.com

Page 531 of 1640

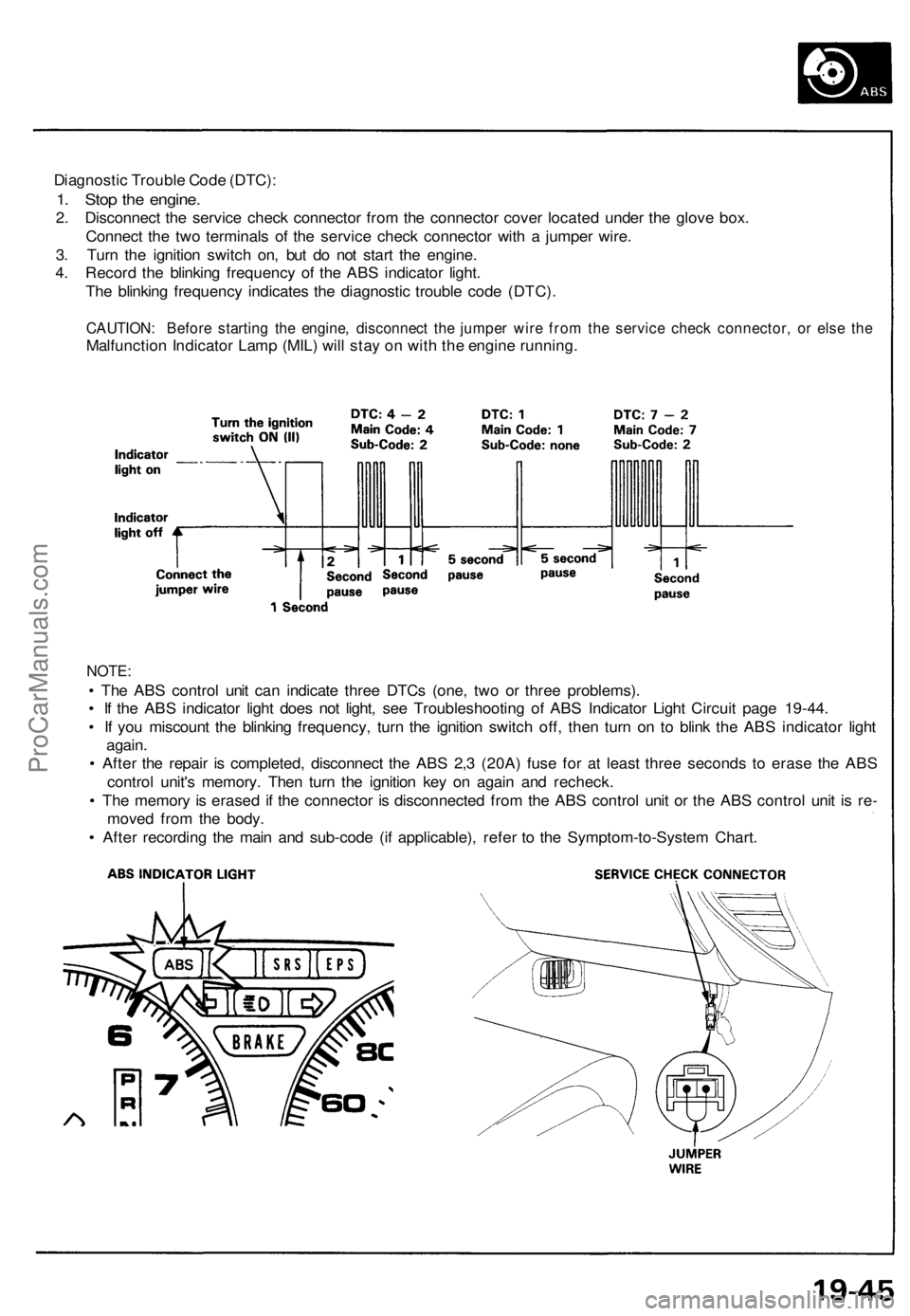

Diagnostic Trouble Code (DTC):

1. Stop the engine.

2. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

3. Turn the ignition switch on, but do not start the engine.

4. Record the blinking frequency of the ABS indicator light.

The blinking frequency indicates the diagnostic trouble code (DTC).

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Malfunction Indicator Lamp (MIL) will stay on with the engine running.

NOTE:

• The ABS control unit can indicate three DTCs (one, two or three problems).

• If the ABS indicator light does not light, see Troubleshooting of ABS Indicator Light Circuit page 19-44.

• If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the ABS indicator light

again.

• After the repair is completed, disconnect the ABS 2,3 (20A) fuse for at least three seconds to erase the ABS

control unit's memory. Then turn the ignition key on again and recheck.

• The memory is erased if the connector is disconnected from the ABS control unit or the ABS control unit is re-

moved from the body.

• After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.ProCarManuals.com

Page 748 of 1640

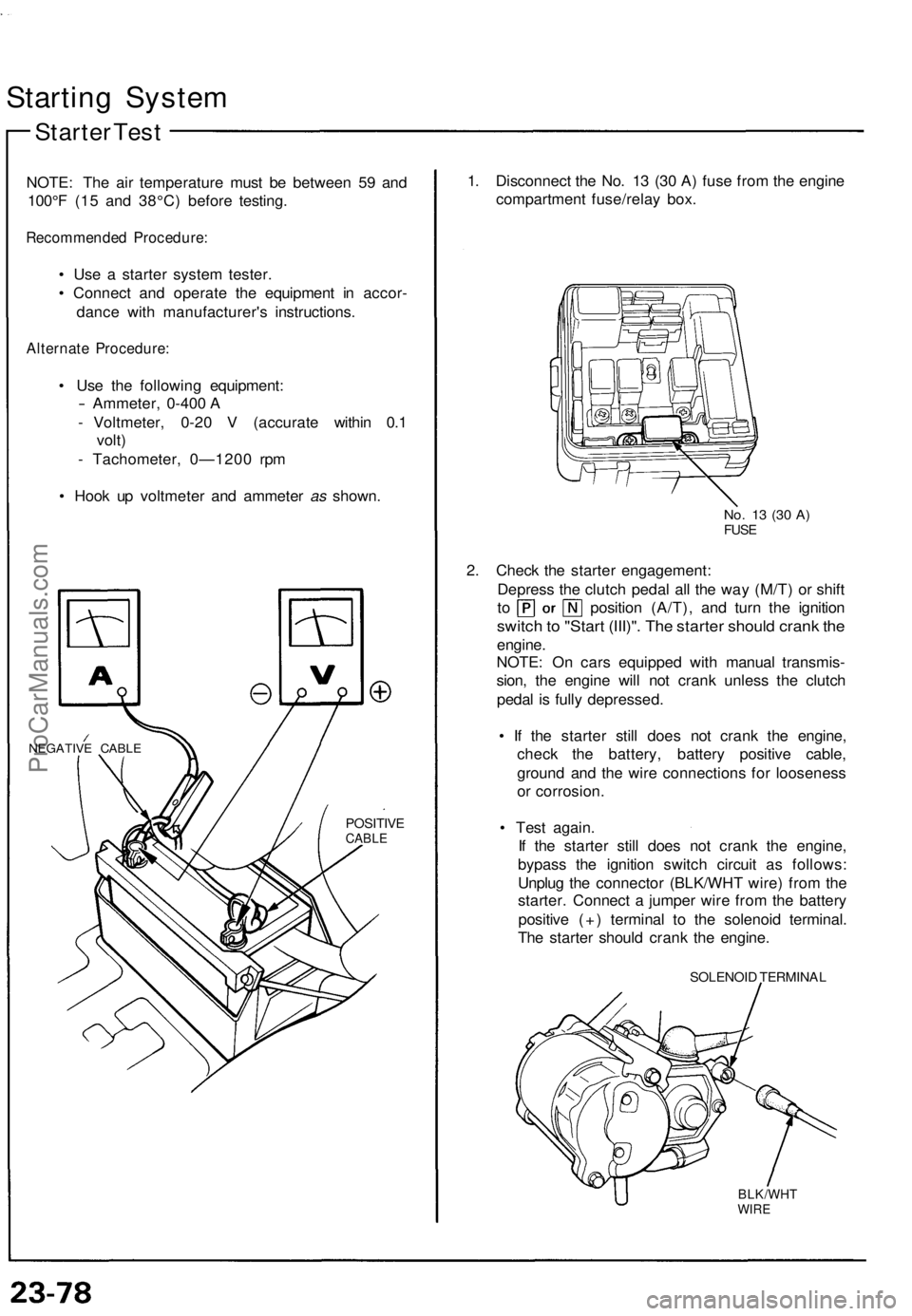

Starting Syste m

Starter Tes t

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

• Us e a starte r syste m tester .

• Connec t an d operat e th e equipmen t i n accor -

danc e wit h manufacturer' s instructions .

Alternate Procedure :

• Us e th e followin g equipment :

- Ammeter, 0-400 A

- Voltmeter , 0-2 0 V (accurat e withi n 0. 1

volt )

- Tachometer , 0—120 0 rp m

• Hoo k u p voltmete r an d ammete r as shown .

NEGATIV E CABL E

POSITIV ECABLE

1. Disconnec t th e No . 1 3 (3 0 A ) fus e fro m th e engin e

compartmen t fuse/rela y box .

No. 1 3 (3 0 A )FUS E

2. Chec k th e starte r engagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , an d tur n th e ignitio n

switch to "Star t (III)" . Th e starte r shoul d cran k th e

engine .

NOTE : O n car s equippe d wit h manua l transmis -

sion , th e engin e wil l no t cran k unles s th e clutc h

peda l i s full y depressed .

• I f th e starte r stil l doe s no t cran k th e engine ,

chec k th e battery , batter y positiv e cable ,

groun d an d th e wir e connection s fo r loosenes s

o r corrosion .

• Tes t again .

I f th e starte r stil l doe s no t cran k th e engine ,

bypas s th e ignitio n switc h circui t a s follows :

Unplu g th e connecto r (BLK/WH T wire ) fro m th e

starter . Connec t a jumpe r wir e fro m th e batter y

positiv e (+ ) termina l t o th e solenoi d terminal .

Th e starte r shoul d cran k th e engine .

SOLENOI D TERMINA L

BLK/WHTWIRE

ProCarManuals.com

Page 769 of 1640

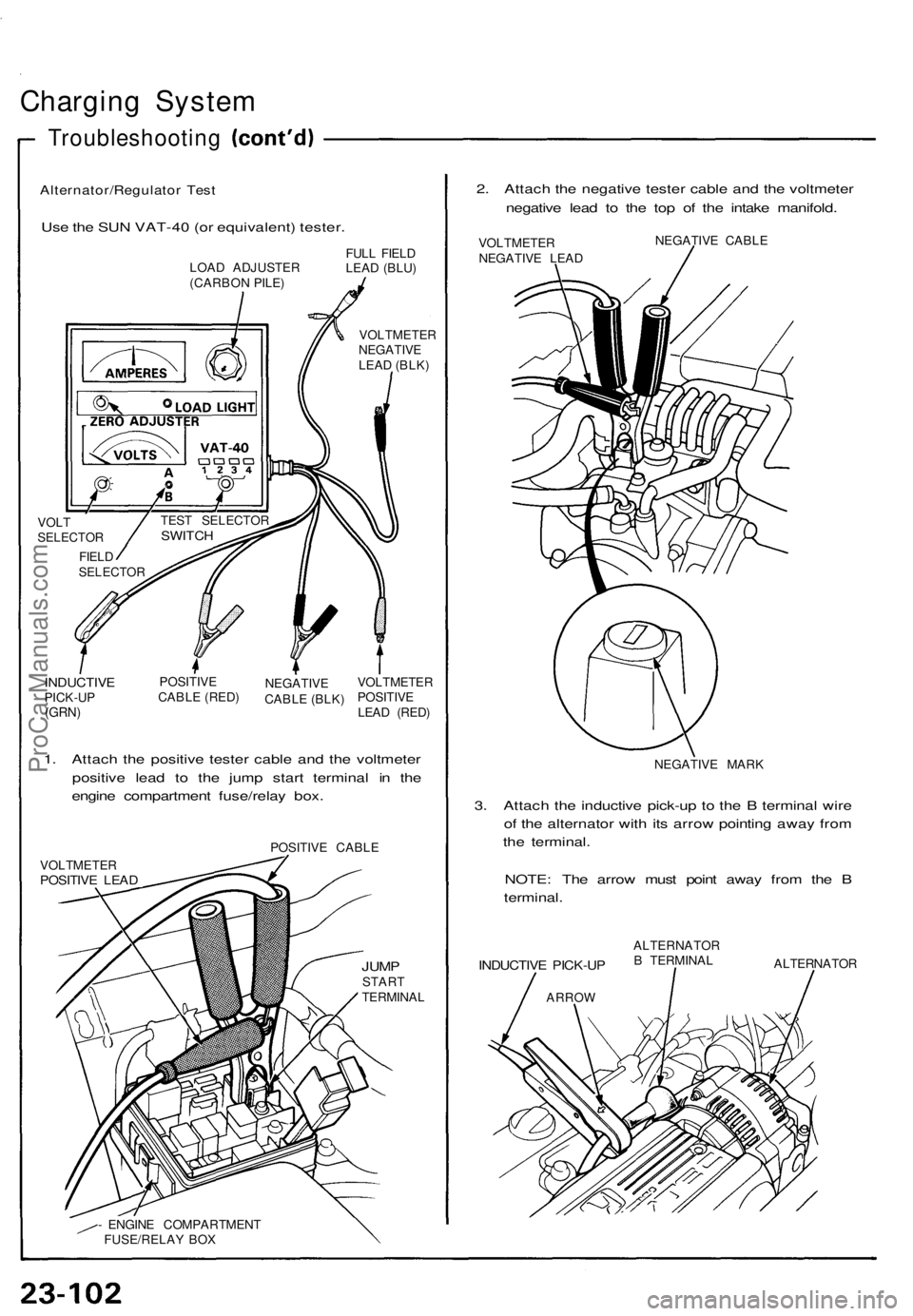

Charging System

Troubleshooting

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

VOLT

SELECTOR

FIELD

SELECTOR

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

- ENGINE COMPARTMENT

FUSE/RELAY BOX

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATOR

TEST SELECTOR

SWITCHProCarManuals.com

Page 1148 of 1640

Transmission Assembly

Removal

CAUTION: Use fender covers to avoid damaging

painted surfaces.

1. Check and record the rear wheel alignment (see section 18).

2. Disconnect the battery negative (—), and positive (+) cables from the battery.

3. Drain transmission oil. Reinstall the drain plug with a new washer.

Corrosion resistant bolt/nut 4. Remove the strut bar.

5. Remove the air cleaner assembly.

6. Remove the connectors from the control box and remove the control box.

CAUTION: Do not remove the vacuum tubes from

the control box.

7. Remove the wire harness holder, jumper connector and transmission ground cable.

8. Disconnect the switch connectors, then remove the back-up light switch and neutral positionswitch.

9. Disconnect the starter motor cables, then remove the starter motor.

10. Remove the transmission mount.

11. Remove the two transmission housing bolts.

TRANSMISSION HOUSING BOLTS

BACK-UP

LIGHT SWITCH

CONNECTOR

WIRE HARNESS HOLDER

STARTER MOTOR

CABLES

NEUTRAL

POSITION

SWITCH

CONNECTOR

STARTER

MOTOR

TRANSMISSION

GROUND

CABLE

TRANSMISSION

MOUNT

MOUNTING

BOLTS

TRANSMISSION

HANGER

TRANSMISSION

MOUNTING BOLTS

JUMPER

CONNECTOR

VEHICLE SPEED

SENSOR (VSS)

CONNECTOR

CONTROL BOX

Make sure lifts are placed properly, and

hoist brackets are attached to correct position (see sec-

tion 1).ProCarManuals.com

Page 1163 of 1640

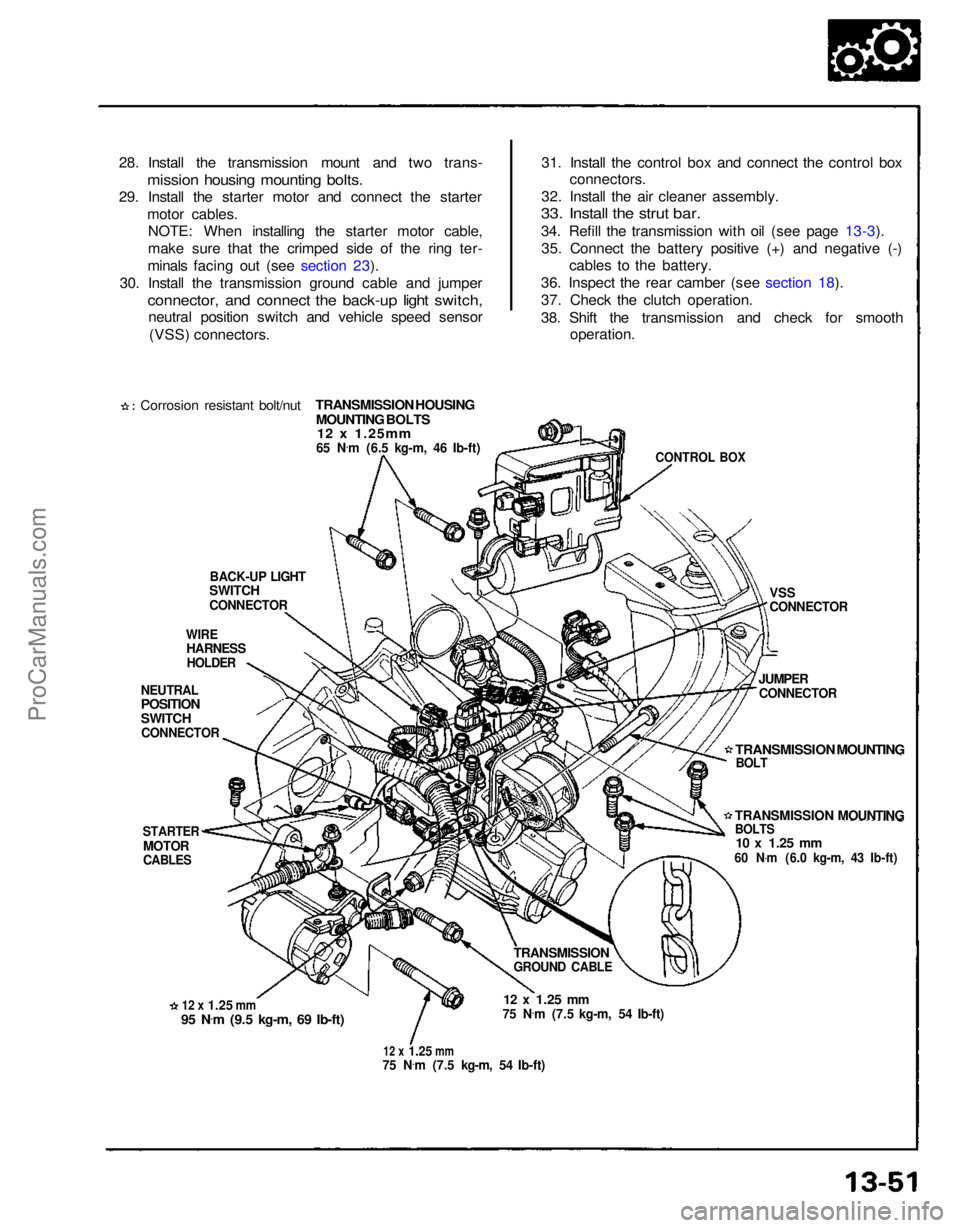

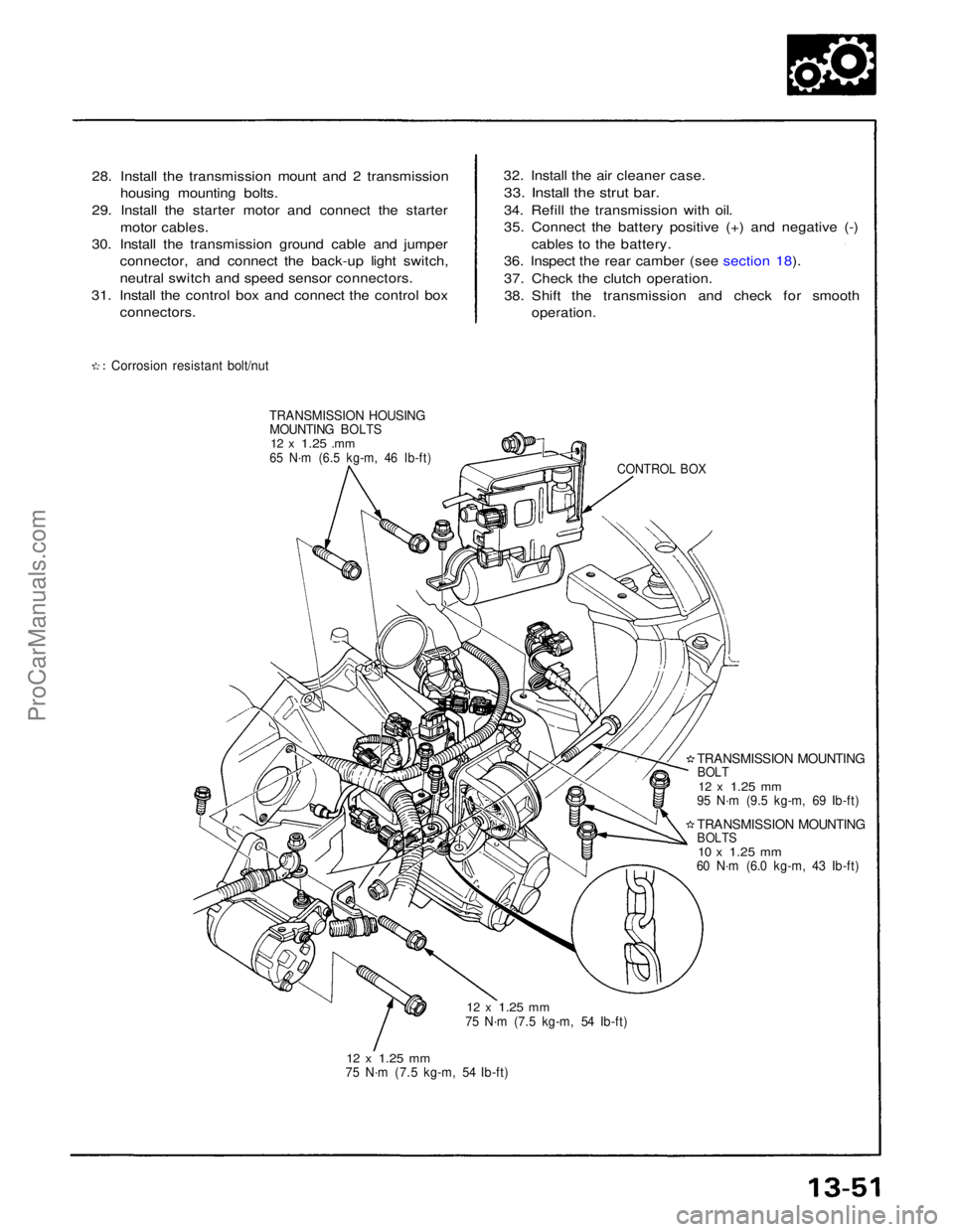

28. Install the transmission mount and two trans-

mission housing mounting bolts.

29. Install the starter motor and connect the starter

motor cables.NOTE: When installing the starter motor cable,

make sure that the crimped side of the ring ter-

minals facing out (see section 23).

30. Install the transmission ground cable and jumper

connector, and connect the back-up light switch,

neutral position switch and vehicle speed sensor

(VSS) connectors.

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS12 x 1.25mm

65 N

.

m (6.5 kg-m, 46 Ib-ft)

BACK-UP LIGHT

SWITCH

CONNECTOR

WIRE

HARNESS

HOLDER

NEUTRAL

POSITION

SWITCH

CONNECTOR

STARTER

MOTOR

CABLES

12 x

1.25

mm

95 N

.

m (9.5 kg-m, 69 Ib-ft)

12 x

1.25

mm

75 N

.

m (7.5 kg-m, 54 Ib-ft)

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

TRANSMISSION

GROUND CABLE

TRANSMISSION MOUNTING

BOLTS

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

JUMPER

CONNECTOR

VSS

CONNECTOR

CONTROL BOX

31. Install the control box and connect the control box

connectors.

32. Install the air cleaner assembly.

33. Install the strut bar.

34. Refill the transmission with oil (see page 13-3).

35. Connect the battery positive (+) and negative (-) cables to the battery.

36. Inspect the rear camber (see section 18).

37. Check the clutch operation.

38. Shift the transmission and check for smooth operation.

TRANSMISSION MOUNTING

BOLTProCarManuals.com

Page 1539 of 1640

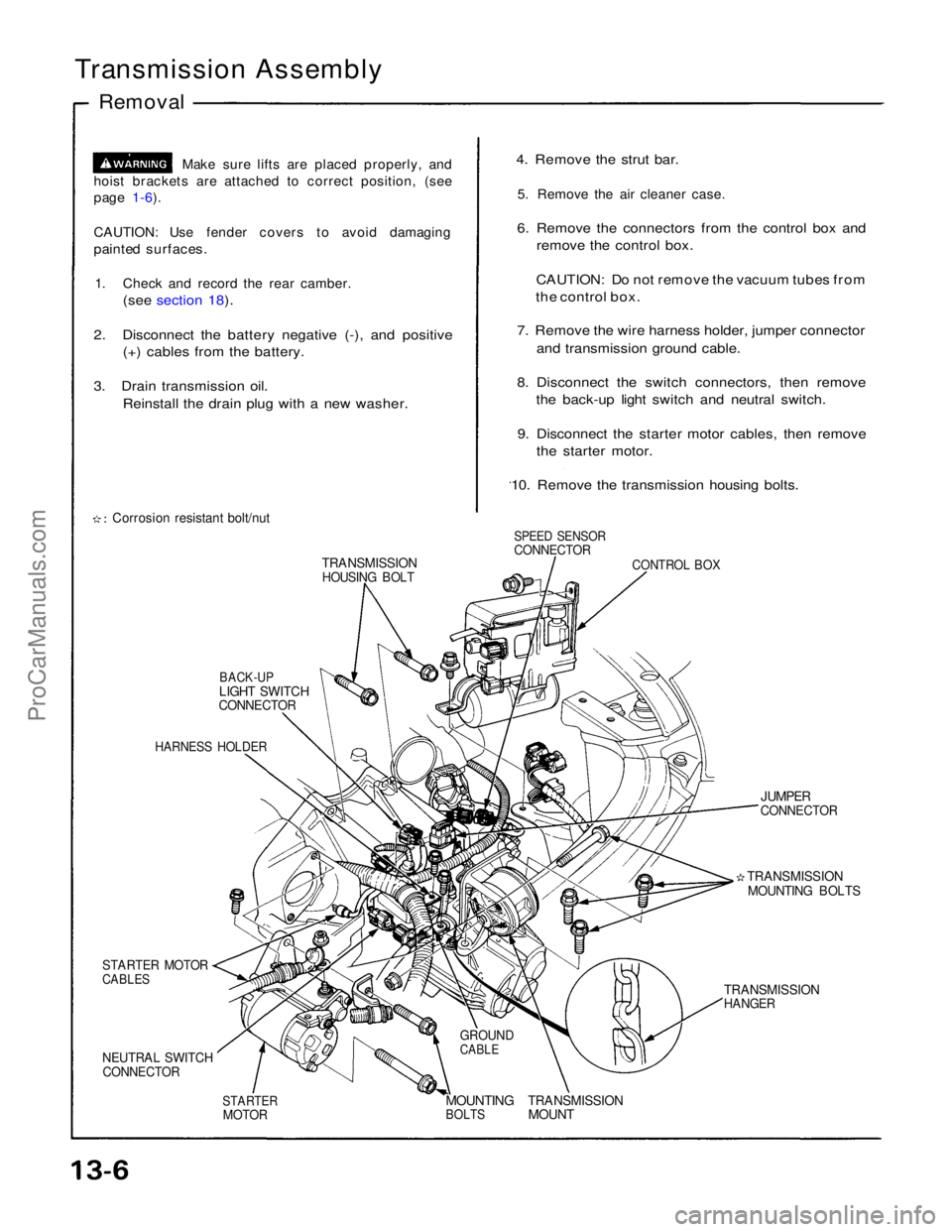

Transmission Assembly

Removal

Make sure lifts are placed properly, and

hoist brackets are attached to correct position, (see

page 1-6).

CAUTION: Use fender covers to avoid damaging

painted surfaces.

1. Check and record the rear camber.

(see section 18).

2. Disconnect the battery negative (-), and positive (+) cables from the battery.

3. Drain transmission oil. Reinstall the drain plug with a new washer.

Corrosion resistant bolt/nut

TRANSMISSION

HOUSING BOLT

BACK-UP

LIGHT SWITCH

CONNECTOR

HARNESS HOLDER

STARTER MOTOR

CABLES

NEUTRAL SWITCH

CONNECTOR

STARTER

MOTOR

MOUNTING

BOLTS

TRANSMISSION

MOUNT

GROUND

CABLE

TRANSMISSION

HANGER

TRANSMISSION

MOUNTING BOLTS

JUMPER

CONNECTOR

CONTROL BOX

SPEED SENSOR

CONNECTOR

4. Remove the strut bar.

5. Remove the air cleaner case.

6. Remove the connectors from the control box and remove the control box.

CAUTION: Do not remove the vacuum tubes from

the control box.

7. Remove the wire harness holder, jumper connector and transmission ground cable.

8. Disconnect the switch connectors, then remove the back-up light switch and neutral switch.

9. Disconnect the starter motor cables, then remove the starter motor.

10. Remove the transmission housing bolts.ProCarManuals.com

Page 1554 of 1640

28. Install the transmission mount and 2 transmission

housing mounting bolts.

29. Install the starter motor and connect the starter motor cables.

30. Install the transmission ground cable and jumper connector, and connect the back-up light switch,

neutral switch and speed sensor connectors.

31. Install the control box and connect the control box

connectors.

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

.mm

65 N·m (6.5 kg-m, 46 Ib-ft)

12 x

1.25

mm

75 N·m (7.5 kg-m, 54 Ib-ft)

12 x

1.25

mm

75 N·m (7.5 kg-m, 54 Ib-ft)

TRANSMISSION MOUNTING

BOLTS

10 x

1.25

mm

60 N·m (6.0 kg-m, 43 Ib-ft)

TRANSMISSION MOUNTING

BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

CONTROL BOX

32. Install the air cleaner case.

33. Install the strut bar.

34. Refill the transmission with oil.

35. Connect the battery positive (+) and negative (-) cables to the battery.

36. Inspect the rear camber (see section 18).

37. Check the clutch operation.

38. Shift the transmission and check for smooth

operation.ProCarManuals.com

Page 1570 of 1640

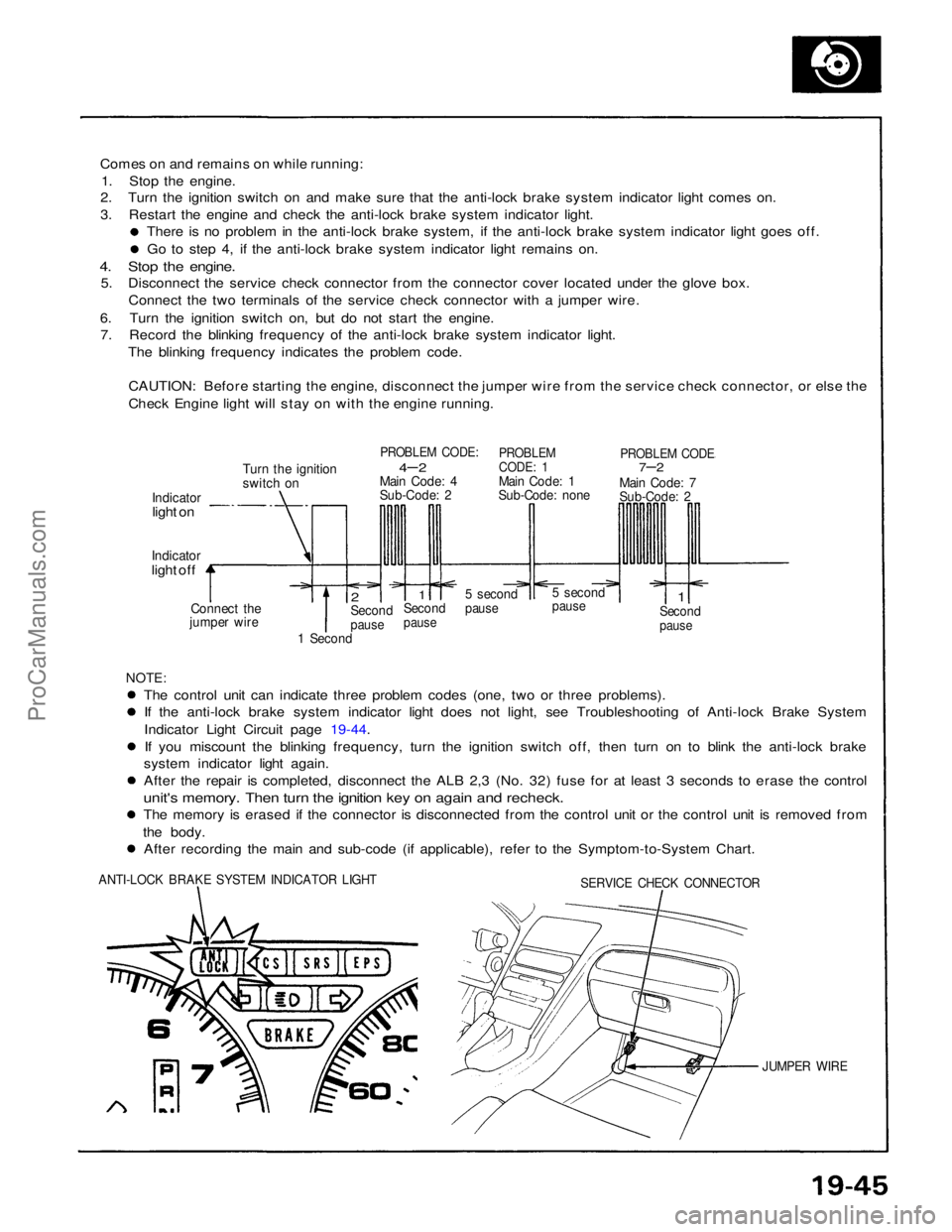

Comes on and remains on while running:

1. Stop the engine.

2. Turn the ignition switch on and make sure that the anti-lock brake system indicator light comes on.

3. Restart the engine and check the anti-lock brake system indicator light.

There is no problem in the anti-lock brake system, if the anti-lock brake system indicator light goes off. Go to step 4, if the anti-lock brake system indicator light remains on.

4. Stop the engine.

5. Disconnect the service check connector from the connector cover located under the glove box.

Connect the two terminals of the service check connector with a jumper wire.

6. Turn the ignition switch on, but do not start the engine. 7. Record the blinking frequency of the anti-lock brake system indicator light.

The blinking frequency indicates the problem code.

CAUTION: Before starting the engine, disconnect the jumper wire from the service check connector, or else the

Check Engine light will stay on with the engine running.

Turn the ignition

switch on

PROBLEM CODE:

4– 2

Main Code: 4

Sub-Code: 2

PROBLEM

CODE: 1

Main Code: 1

Sub-Code: none

PROBLEM CODE

7–2

Main Code: 7

Sub-Code: 2

Indicator

light on

Indicator

light off

Connect the

jumper wire

2

Second

pause

1

Second

pause

5 second

pause

5 second

pause

1

Second

pause

1 Second

NOTE:

The control unit can indicate three problem codes (one, two or three problems). If the anti-lock brake system indicator light does not light, see Troubleshooting of Anti-lock Brake System

Indicator Light Circuit page 19-44.

If you miscount the blinking frequency, turn the ignition switch off, then turn on to blink the anti-lock brake

system indicator light again. After the repair is completed, disconnect the ALB 2,3 (No. 32) fuse for at least 3 seconds to erase the control

unit's memory. Then turn the ignition key on again and recheck.

The memory is erased if the connector is disconnected from the control unit or the control unit is removed from

the body. After recording the main and sub-code (if applicable), refer to the Symptom-to-System Chart.

ANTI-LOCK BRAKE SYSTEM INDICATOR LIGHT

SERVICE CHECK CONNECTOR

JUMPER WIREProCarManuals.com